Installation Guide_PV-ezRack_SolarTerraceII-A_AU_V2.0

1/10 Duerdin Street, Clayton VIC 3168 Australia

Tel: +61 3 9239 8088 Fax: +61 3 9239 8024

E-mail: sales@clenergy.com.au www.clenergy.com.au

01page of 21

Introduction

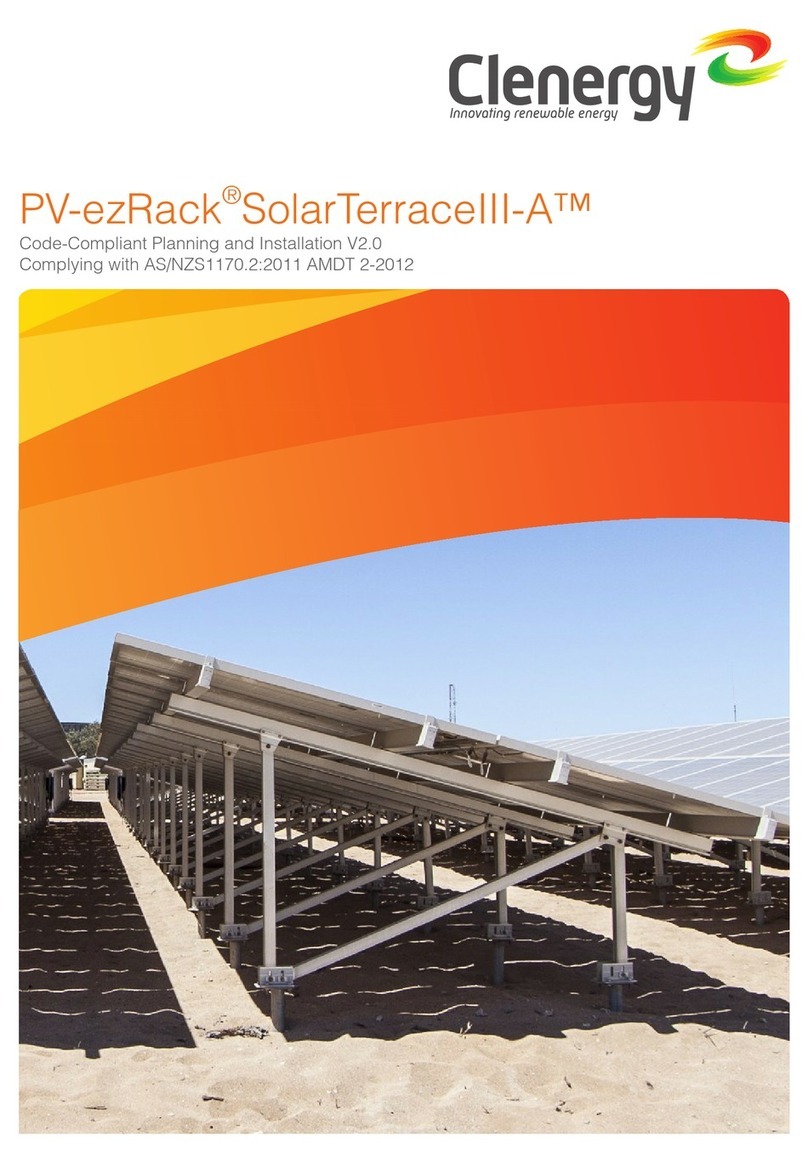

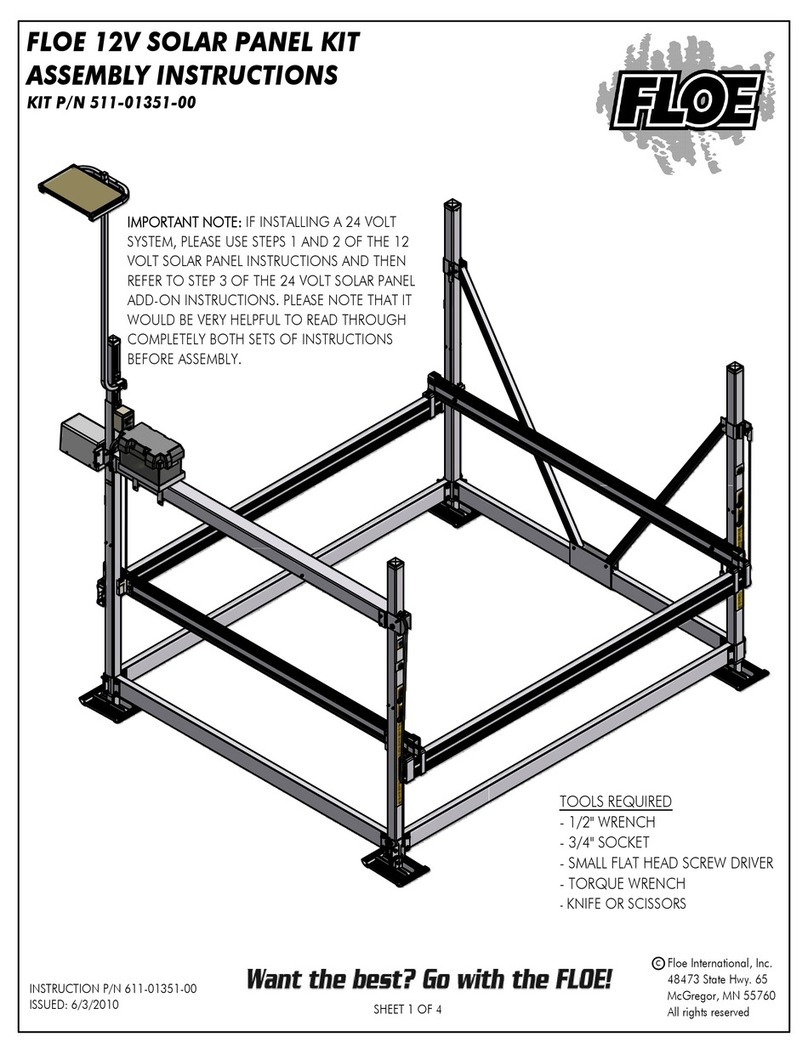

Clenergy PV-ezRack®SolarTerrace II-A™ is a

pre-assembled ground mount system suitable

for large scale commercial and utility scale

installations. PV-ezRackSolarTerrace II-A has

been developed to fit any PV module. The

innovative and patented SolarTerrace II-A

T-Rails simplify and improve the accuracy

of the installation. SolarTerrace II-A uses

high quality engineered components, saving

developers and installers’ time and money

when delivering ground mount projects.

Please review this instruction guide thoroughly

before installing PV-ezRackSolarTerrace II-

A. This manual provides the supporting

documentation for building permit applications

relating to PV-ezRackSolarTerrace II-A

Universal PV Mounting System.

The PV-ezRackSolarTerrace II-A components,

when installed in accordance with this guide,

will be structurally adequate and will meet the

AS/NZS1170.2:2011 Amdt. 3-2012 standard.

During installation and especially when working

on the ground, you will need to comply with

the appropriate occupational health and safety

regulations. Please also check other regulations

relevant to your local region. Make sure that you

are using the latest version of the installation

instruction guide, which you can do by

contacting Clenergy by email on sales@clenergy.

com.au, or contacting your local distributor.

The installer is solely responsible for:

•Complying with all applicable local or national

building codes, including any that may

supersede this manual;

•Ensuring that ezRack and other products are

appropriate for the particular installation and the

installation environment;

•Using only ezRack parts and installer-supplied

parts as specified by ezRack (substitution of

parts may void the warranty and invalidate the

letter of certification);

•Ensuring that the ground condition are suitable;

•How to recycle: according to the local relative

statute.

•How to disassemble: reverse installation

process.

•Ensure that there are no less than two

professionals working on the panel installation.

•Ensure the installation of the electrical

equipment is performed by a professional and

accredited electrician.

•Ensuring safe installation of all electrical aspects

of the PV array including providing adequate

earth bonding of the PV array and PV-ezRack®

SolarTerraceII-A™components as required in AS/

NZS 5033-2014 ADMT 2 2-2018.

Introduction

Planning

Tools & Components

System Overview

Installation Instruction

Warranty

01

02

04

06

08

21

List of Contents

1. Introduction