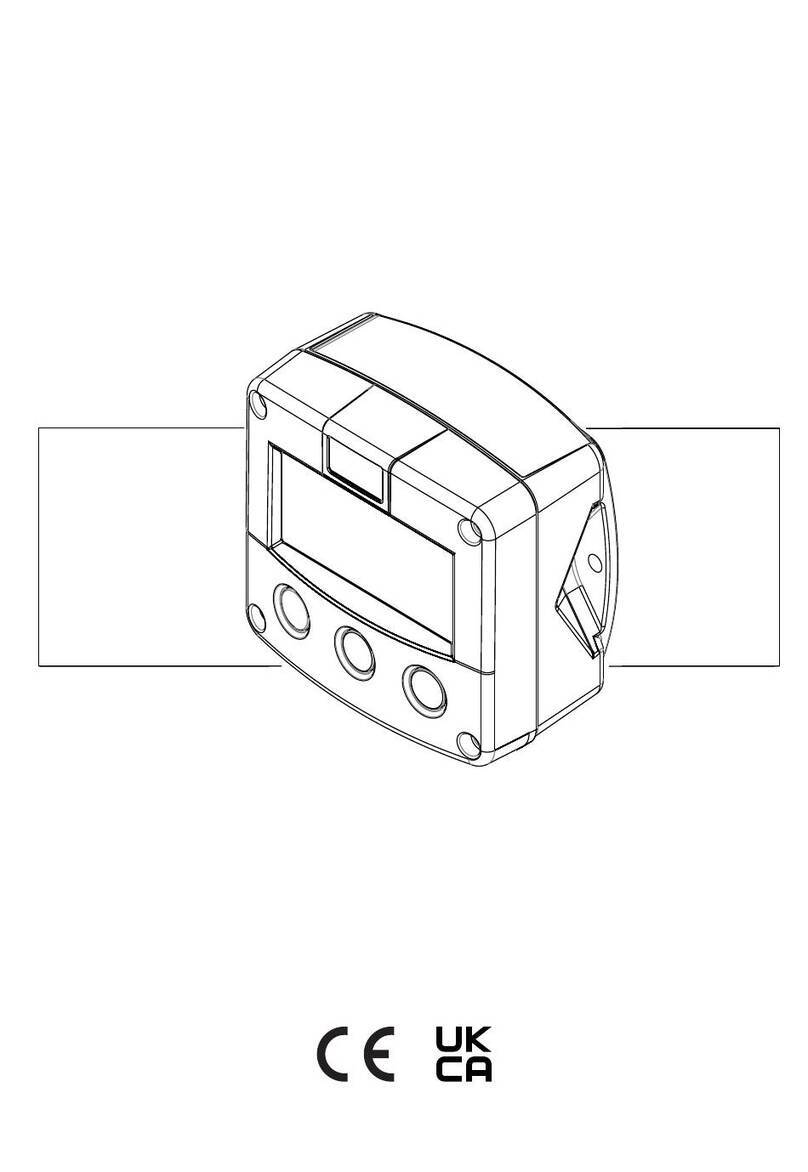

CS Instruments VA 520 User manual

VA 520 Bi directional English V1.21 Page 1 of 45

EN –English

Instruction manual

Consumption counter VA 520

for bi-directional measurements

Stationary

Flow and consumption measurement for compressed air and gases

Foreword

VA 520 EN V1.21 page 2o 45

I. Foreword

Dear customer,

thank you very much for deciding in favour of the VA 520. Please read this

installation and operation manual carefully before mounting and initiating the device

and follow our advice. A riskless operation and a correct functioning of the

VA 520 are only guaranteed in case of careful observation of the described

instructions and notes

Sales Office South / Geschäftsstelle Süd

Zindelsteiner Str. 15

D-78052 VS-Tannheim

Tel.: +49 (0) 7705 978 99 0

Fax: +49 (0) 7705 978 99 20

Web: http://www.cs-instruments.com

Sales Office North / Geschäftsstelle Nord

Gewerbehof 14

D-24955 Harrislee

Tel.: +49 (0) 461 807 150 0

Fax: +49 (0) 461 807 150 15

Web: http://www.cs-instruments.com

Table of Content

VA 520 Bi directional English V1.21 Page 3 of 45

II. Table of Contents

I. Foreword ....................................................................................................................... 2

1Intended use.................................................................................................................. 5

2Instruments description............................................................................................... 5

3Safety instructions........................................................................................................ 6

4Technical data............................................................................................................... 7

5Scaling Analogue output Comprssed Air................................................................... 8

6Installation Description ................................................................................................ 9

6.1 Pipe/tube requirements ......................................................................................................... 9

6.2 Inlet / outlet runs .................................................................................................................... 9

6.3 Installation of VA 520.......................................................................................................... 10

6.4 Displayhead Position........................................................................................................... 10

7Flow measuring ranges...............................................................................................11

7.1 Flow for different gases....................................................................................................... 11

8Dimensions ..................................................................................................................12

8.1 With measurement section and screw-in thread.............................................................. 12

8.2 With measurement section and flange (Material stainless steel 1.4404):...................... 13

9Electrical wiring ...........................................................................................................14

9.1 Modbus RTU, 4…20mA, Pulse or MBus ............................................................................ 14

9.2 Connection diagrams .......................................................................................................... 15

9.2.1 Modbus............................................................................................................................ 15

9.2.2 Analogue output (4-20mA, Pulse).................................................................................... 15

9.2.3 MBus................................................................................................................................ 15

9.2.4 Ethernet (optional PoE) .................................................................................................. 16

Table of Content

VA 520 EN V1.21 page 4o 45

10 Operation...................................................................................................................17

10.1 Initialization .......................................................................................................................... 18

10.2 Main menu ............................................................................................................................ 18

10.3 Settings................................................................................................................................. 20

10.3.1 Sensor Setup................................................................................................................... 21

10.3.1.1 Input / change tube diameter.................................................................................... 21

10.3.1.2 Input / change consumption counter ........................................................................ 22

10.3.1.3 Definition of the units for flow, velocity, temperature and pressure ......................... 23

10.3.1.4 Advanced settings .................................................................................................... 24

10.3.1.4.1 Definition of the reference conditions................................................................... 24

10.3.1.4.2 Time setting for filtering ........................................................................................ 26

10.3.1.5 Setting of Zeropoint and Low-flow cut off................................................................. 27

10.3.2 Modbus settings............................................................................................................... 28

10.3.2.1 Modbus RTU Setup.................................................................................................. 28

10.3.2.2 Modbus TCP (Optional)............................................................................................ 29

10.3.2.2.1 Network Setup DHCP........................................................................................... 29

10.3.2.2.2 Network Settings static IP..................................................................................... 30

10.3.2.2.3 Modbus TCP Settings........................................................................................... 31

10.3.2.3 Modbus Settings register (2001…2005)................................................................. 32

10.3.2.4 Modbus Values Register (1001 …1500) .................................................................. 33

10.3.3 Pulse /Alarm..................................................................................................................... 35

10.3.3.1 Pulse output.............................................................................................................. 35

10.3.4 User Setup....................................................................................................................... 36

10.3.4.1 Password.................................................................................................................. 36

10.3.4.2 Language.................................................................................................................. 36

10.3.4.3 Display / Touch......................................................................................................... 37

10.3.5 Advanced......................................................................................................................... 37

10.3.6 4 -20mA ........................................................................................................................... 38

10.3.7 VA 520 Info...................................................................................................................... 40

10.4 MBus...................................................................................................................................... 41

10.4.1 Default Settings communication...................................................................................... 41

10.4.2 Default values transmitted ............................................................................................... 41

11 Status / Error messages...........................................................................................42

11.1 Status messages.................................................................................................................. 42

11.2 Error messages.................................................................................................................... 43

12 Maintenance..............................................................................................................44

13 Cleaning of the sensor head....................................................................................44

14 Re-Calibration...........................................................................................................44

15 Spare parts and repair..............................................................................................44

16 Calibration.................................................................................................................44

17 Warranty....................................................................................................................44

Intended Use

VA 520 Bi directional English V1.21 Page 5 of 45

1 Intended use

The VA 520 consumption sensor for bi-directional measurements is used for continuous flow

measurement in both directions.

The VA 520 consumption sensor for bi-directional measurements is designed and constructed

exclusively for the intended purpose described here and may only be used accordingly.

The user must check whether the instrument is suitable for the selected application. It must be

ensured that the medium is compatible with the wetted parts. The technical data listed in the data

sheet are binding.

Improper handling or operation outside the technical specifications is not permitted. Claims of any kind

based on improper use are excluded.

Operating principle:

The VA 520 consumption probe operates according to the calorimetric measuring method.

The basis of this measuring method is the electrical heating of the mechanically protected built-in

sensor. The mass flow, the volume flow and the flow velocity can be measured and determined by the

resulting heat flow to the passing medium (gas).

With the calorimetric measurement method (based on the measurement principle), the operating

temperature and pressure of the medium have no influence on the measurement result, only the

material data of the gas component are decisive.

The integrated flow direction recognition allows the bi-directional flow measurement with display of the

flow values. The flow direction is indicated by arrows in blue and green.

A meter reading is available for each flow direction, displayed in the colours blue and green according

to flow direction.

2Instruments description

The VA 520 is a compact consumption counter for compressed air and gases.

Special features:

•Optimum accuracy due to compact design

•Intgrated Display showing Flow, consuption, velocity and temperature for two

directions

•Input inner tube diameter via display keys

•Units free selectable. m³/h, m³/min, l/min, l/s, kg/h, kg/min, kg/s, cfm

•Modbus RTU (RS485) Interface, Ethernet( also PoE) and MBus optional

•2x Analogoutput 4..20mA

•2x Pulse output galv. isolated.

CS Instruments Service Software

•Analogaoutput 4...20 mA scaleabler

•Selection of gas type (Air, Nitrogen, Argon, Nitrous oxide, CO2, Oxygen, Natural gas)

•Read out Service data

•Sensordiagnoses

Safety instructions

VA 520 Bi directional English V1.21 Page 6 of 45

3 Safety instructions

Read this manual carefully before installing the VA 520. If the instructions

given in this manual, in particular the safety instructions, are not observed,

this may result in hazards for people, equipment and plants

Please read carefully before starting the device!

Warning: Do not exceed the pressure range of 16 bar!

Observe the measuring range of the sensor!

The screwed fixture must be pressure tight.

It is absolutely necessary to avoid condensation on the sensor element or water drops in the

measuring air as they may cause faulty measuring results.

The manufacturer cannot be held liable for any damage which occurs as a result of non-

observance or non-compliance with these instructions. Should the device be tampered with

in any manner other than a procedure which is described and specified in the manual, the

warranty is cancelled and the manufacturer is exempt from liability.

The device is destined exclusively for the described application.

We offer no guarantee for the suitability for any other purpose and are not liable for errors

which may have slipped into this operation manual. We are also not liable for consequential

damage resulting from the delivery, capability or use of this device.

We offer you to take back the instruments of the instruments family VA 520 which you would

like to dispose of.

Qualified employees from the measurement and control technology branch should only carry

out adjustments and calibrations.

Flammable gases

If this consumption sensor is used for measurement of flammable gases (e. g. natural gas

and so on) we expressly would like to point out that the sensor has no DVGW admission,

however, it can be used for measurements in natural gas. A DVGW admission is not

mandatory.

The consumption sensor corresponds with the current state of technology and basically it can be used

in any flammable and non-flammable gases.

If the sensor is used e.g. in the medium natural gas, the sensor will be adjusted for natural

gas. The calibration protocol (inspection certificate) will be included in the scope of delivery.

The area outside the pipeline (ambient area of the sensor) must not be an explosive area.

The installation has to be carried out by authorized professionals.

!

Technical data

VA 520 Bi directional English V1.21 Page 7 of 45

4Technical data

Measurement: Flow and consumption

Reference Standard: Standard settings ex works:

DIN 1945, ISO 1217 at 20°C and 1000 mbar

Selectable Units m³/h (Standard settings ex works)

m³/min, l/min, l/s, ft/min, cfm, m/s, kg/h, kg/min, kg/s, °C, °F

Measuring principle: calorimetric measurement

Sensor: Pt45, Pt1000

Measuring medium: Air, gases

Operating temperature: -30 ... 80°C probe tube

-20 ... 70°C housing

Operating pressure: up to 16 bar, special version PN 40 (40 bar)

Power supply: 18 to 36 VDC

Power consumption: max. 5W

Digital output: RS 485 (Modbus RTU)

Optional Ethernet (also PoE) and MBus

Analog output: 4...20 mA (see chapter 4), max. burden < 500 Ohm

Pulse output: pulse outputs potential free (dry contact)

passive: max. 48Vdc, 150mA

1 pulse pro m³ resp. pro l,

Valency adjustable with the display keys

Accuracy: ± 1,5 % m.v., ± 0,3 % f. s.*

Display: TFT 1.8 Resolution 220 x 176

Mounting thread: R 1/4", R1/2", R3/4", R1", R 1 1/4" R1 1/2", R 2” DIN EN

10226 (ISO 7-1)

Material: Stainless steel 1.4301 / 1.4404

Version with flange DIN EN 1092-1: Stainless steel 1.4404

Protection calss: IP65

* m.v. = measured values

f.s. = full scale

Scaling Analogue output

VA 520 Bi directional English V1.21 Page 8 of 45

5Scaling Analogue output Comprssed Air

Reference DIN1945/ ISO 1217: 20°C, 1000 mbar (Reference during calibration)

Description

Version

Analogue output

VA 520 with integrated 1/4" meas. section

Low Speed

4… 20 mA =

0...25 l/min

Standard

0...50 l/min

Max

0...105 l/min

High Speed

0...130 l/min

VA 520 with integrated 1/2" meas. section

Low Speed

4… 20 mA =

0...20 m³/h

Standard

0...45 m³/h

Max

0...90 m³/h

High Speed

0...110 m³/h

VA 520 with integrated 3/4" meas. section

Low Speed

4… 20 mA =

0...45 m³/h

Standard

0...85 m³/h

Max

0...175 m³/h

High Speed

0...215 m³/h

VA 520 with integrated 1" meas. section

Low Speed

4… 20 mA =

0...75 m³/h

Standard

0...145 m³/h

Max

0...290 m³/h

High Speed

0...355 m³/h

VA 520 with integrated 1 1/4" meas.

section

Low Speed

4… 20 mA =

0...140 m³/h

Standard

0...265 m³/h

Max

0...530 m³/h

High Speed

0...640 m³/h

VA 520 with integrated 1 1/2" meas.

section

Low Speed

4… 20 mA =

0...195 m³/h

Standard

0...365 m³/h

Max

0...730 m³/h

High Speed

0...885 m³/h

VA 520 with integrated 2" meas. section

Low Speed

4… 20 mA =

0...320 m³/h

Standard

0...600 m³/h

Max

0…1195m³/h

High Speed

0...1450 m³/h

VA 520 with integrated 2 1/2" meas.

section

Low Speed

4… 20 mA =

0...550 m³/h

Standard

0...1025 m³/h

Max

0…2050m³/h

High Speed

0...2480 m³/h

VA 520 with integrated 3" meas. section

Low Speed

4… 20 mA =

0...765 m³/h

Standard

0...1420 m³/h

Max

0…2840m³/h

High Speed

0...3440 m³/h

Installation

VA 520 Bi directional English V1.21 Page 9 of 45

6Installation Description

6.1 Pipe/tube requirements

•Correctly sized gaskets

•Correct aligned flanges and gaskets

•Diameter mismatch at the pipe junctions should be avoided but must be less than 1mm. For

further information see ISO 14511

•Ensure clean pipes after installation

6.2 Inlet / outlet runs

The principle of thermal Mass flow measurement is very sensitive against disturbances. Therefore, it is

necessary to ensure the recommended inlet and outlet runs.

Table of additionally required inlet sections

Flow obstruction in front of the

measuring section

Minimum length inlet

section (L1)

Minimum length

outlet section (L2)

Slight curve

(bend < 90°)

12 x D

5 x D

Reduction

(pipe narrows towards the meas. section)

15 x D

5 x D

Expansion

(pipe expands towards the meas. section)

15 x D

5 x D

90° bend

or T-piece

15 x D

5 x D

2 bends á 90°

on one level

20 x D

5 x D

2 bends á 90°

3-dimensional change of direction

35 x D

5 x D

Shut-off valve

45 x D

5 x D

15 x D 5 x D

15 x D 5 x D15 x D

15 x D 5 x D

20 x D 5 x D

35 x D 5 x D

5 x D45 x D

The respective minimum values required are indicated here. If it is not possible to observe the

stipulated equalising sections, considerable deviations in the measuring results must be expected.

Attention:

The dimensions of the VA 520 consumption counter measuring sections do not fullfill the required

minimum lengths of the input and outlet runs.

Please ensure recommended in - and outlet distances, dimensions for measuring sections see page

12 and 13.

Installation

VA 520 EN V1.21 page 10 o 45

6.3 Installation of VA 520

The sensor VA 520 is pre-supplied with the measuring section.

An installation at customer site is only allowed in the unpressurized state of the

system

The connecting nut is tightened to a torque of 25 -30 Nm.

Tightness of the connection must be checked and ensured.

6.4 Displayhead Position

Fastening screws

The Position of the Displayhead is twistable by 180 e.g. in

case of reverse flow direction.

For this purpose the 6 fastening screws are to be released

and the displayhead rotated 180°.

Caution:

It must be ensured that the connection plugs are still plugged

and the gasket is installed correctly.

Measuring ranges

VA 520 Bi directional English V1.21 Page 11 of 45

7Flow measuring ranges

7.1 Flow for different gases

1/4"

1/2"

3/4"

1"

1 ¼"

1 ½"

2"

2 ½"

3"

Analog

output

20mA

Analog

output

20mA

Analog

output

20mA

Analog

output

20mA

Analog

output

20mA

Analog

output

20mA

Analog

output

20mA

Analog

output

20mA

Analog

output

20mA

l/min

[m³/h]

[m³/h]

[m³/h]

[m³/h]

[m³/h]

[m³/h]

[m³/h]

[m³/h]

Reference DIN1945/ ISO 1217: 20°C, 1000 mbar (Reference during calibration)

Air

Low Speed

25

20

45

75

140

195

320

550

765

Standard

50

45

85

145

265

365

600

1025

1420

Max

105

90

175

290

530

730

1195

2050

2840

High Speed

130

110

215

355

640

885

1450

2480

3440

Adjustment to DIN 1343: 0°C, 1013,25 mbar

Air

Low Speed

25

20

40

70

130

180

295

505

705

Standard

50

40

80

135

240

335

550

945

1305

Max

100

80

160

270

485

670

1100

1885

2610

High Speed

120

100

195

325

590

815

1330

2280

3165

Argon

(Ar)

Low Speed

45

35

75

120

220

305

505

865

1200

Standard

85

70

135

230

415

570

935

1605

2225

Max

170

140

275

460

830

1140

1870

3205

4440

High Speed

205

170

335

555

1005

1385

2265

3880

5380

Carbon dioxide

(CO2)

Low Speed

25

20

45

75

140

195

320

545

760

Standard

50

45

85

145

260

360

590

1015

1405

Max

105

90

175

290

525

720

1185

2030

2810

High Speed

130

105

210

350

635

875

1430

2455

3405

Nitrogen

(N2)

Low Speed

25

20

40

70

130

180

295

505

705

Standard

50

40

80

135

240

335

550

945

1305

Max

100

80

160

270

485

670

1100

1885

2610

High Speed

120

100

195

325

590

815

1330

2280

3165

Oxygen f

(O2)

Low Speed

25

20

45

75

135

185

305

525

730

Standard

50

40

80

140

250

345

570

980

1355

Max

100

85

165

280

505

695

1140

1955

2710

High Speed

125

105

205

340

610

845

1380

2365

3280

Nitrous oxide

(N2O)

Low Speed

25

20

45

75

140

190

315

540

750

Standard

50

40

85

140

260

355

585

1005

1395

Max

105

85

170

285

520

715

1170

2010

2785

High Speed

125

105

210

345

630

865

1420

2435

3375

Natural gas

(NG)

Low Speed

15

15

25

45

85

115

190

325

450

Standard

30

25

50

85

155

215

355

605

840

Max

60

50

105

170

310

430

705

1210

1680

High Speed

75

65

125

210

380

520

855

1465

2035

Other gases on request

Please note:

The consumption sensor corresponds with the current state of technology and basically it can be used

in any flammable and non-flammable gases.

If this consumption sensor is used for measurement of flammable gases (e.g. natural gas and so on)

we expressly would like to point out that the sensor has no DVGW admission, however, it can be used

for measurements in natural gas. A DVGW admission is not mandatory.

The area outside the pipeline (ambient area of the sensor) must not be an explosive area.

Dimensions

VA 520 Bi directional English V1.21 Page 12 of 45

8Dimensions

8.1 With measurement section and screw-in thread

A

A

L1 L

ØAD

ØID

H1

H

76,5 75,0

Pipe size

AD / ID

(mm)

L

(mm)

L1

(mm)

H

(mm)

H1

(mm)

R

A

(mm)

VA 520 1/4"

DN 8

13,7 / 8,5

194

137

176,6

166,3

R 1/4"

15

VA 520 1/2“

DN 15

21,3 / 16,1

300

210

177,0

166,3

R 1/2“

20

VA 520 3/4“

DN 20

26,9 / 21,7

475

275

179,8

166,3

R 3/4“

20

VA 520 1“

DN 25

33,7 / 27,3

475

275

183,2

166,3

R 1“

25

VA 520 1 1/4"

DN 32

42,4 / 36,0

475

275

187,5

166,3

R 1 1/4"

25

VA 520 1 1/2“

DN 40

48,3 / 41,9

475

275

190,5

166,3

R 1 1/2“

25

VA 520 2“

DN 50

60,3 / 53,1

475

275

196,5

166,3

R 2“

30

Dimensions

VA 520 EN V1.21 page 13 o 45

8.2 With measurement section and flange (Material stainless steel 1.4404):

Flange DIN EN 1092-1

Pipe size

AD/ID

(mm)

L

(mm)

L1

(mm)

H

(mm)

H1

(mm)

Ø D

in mm

Ø K

in mm

nxØL

in mm

VA 520 1/2“

DN 15

21,3 / 16,1

300

210

213,8

166,3

95

65

4 x 14

VA 520 3/4“

DN 20

26,9 / 21,7

475

275

218,8

166,3

105

75

4 x 14

VA 520 1“

DN 25

33,7 / 27,3

475

275

223,8

166,3

115

85

4 x 14

VA 520 1 1/4"

DN 32

42,4 / 36,0

475

275

263,3

166,3

140

100

4 x 18

VA 520 1 1/2“

DN 40

48,3 / 41,9

475

275

2 40,7

166,3

150

110

4 x 18

VA 520 2“

DN 50

60,3 / 53,1

475

275

248,2

166,3

165

125

4 x 18

VA 520 2 1/2“

DN 65

76,1 / 68,9

475

275

268,2

175,7

185

145

8 x 18

VA 520 3“

DN 80

88,9 / 80,9

475

275

275,7

175,7

200

160

8 x 18

Electrical wiring

VA 520 Bi directional English V1.21 Page 14 of 45

9Electrical wiring

9.1 Modbus RTU, 4…20mA, Pulse or MBus

Attention: Not required connections NC must not be connected to a voltage and/or to protection

earth. Cut and insulate cables.

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Connector plug A

+VB

RS 485 (A)

RS 485 (+)

-VB

RS 485 (B)

RS 485 (-)

I+ (Ch1)

4..20 mA

Connector plug B

Pulse output (standard)

I+ (Ch2)

4..20 mA

Pulse (Ch2)

galv. isolated

Pulse (Ch2)

gavl. isolated

Pulse (Ch1)

galv. isolated

Pulse (Ch1)

gavl. isolated

Connector plug B

Option MBus

NC

GND

DIR

MBus

MBus

Colours pulse cables

0553 0106 (5 m)

0553.0107 (10 m)

brown

white

blue

black

grey

Legend:

-VB

Negative supply voltage 0 V

Pulse

Pulse for consumption

+VB

Positive supply voltage 18...36 VDC smoothed

NC

Must not be connected to a voltage

and/or to protection earth. Please cut

and isolate cables.

I +

Current signal 4...20 mA –selected measured

signal

RS 485 (A)

RS 485 (B)

Modbus RTU A / Modbus RTU (+)

Modbus RTU B / Modbus RTU (-)

MBus

MBus (reverse polarity protected)

If no connection cable/ pulse

cable is ordered the sensor will

be supplied with a M12

connector plug. The user can

connect the supply and signal

cables as indicated in the

connection diagram.

.

M12 Connector plug

View from back side

(terminal side)

- Connector plug A

- Connector plug B

Dimensions

VA 520 EN V1.21 page 15 o 45

9.2 Connection diagrams

9.2.1 Modbus

Connector plug A (M12 - A-coding)

3

4

5

1

2

+ VB

- VB

Blau / Blue

Weiss / White

Schwarz / Black

Modbus (B)

Modbus (A)

Braun / Brown

Remark: If the sensor is placed at the end of the Modbus system a termination is required. The sensors have an

internal switchable termination, therefore the 6 fastening screws from the lid are to be released and set

the internal DIP Switch to “On”. It must be ensured that the connection plugs are still plugged and the

gasket is installed correctly.

Alternatively, a 120R resistor can be installed in the plug between pin 2 and pin 4.

9.2.2 Analogue output (4-20mA, Pulse)

Connector plug A (M12 A-coding) Connector plug B (M12 A-coding)

3

4

5

1

2

+ VB

- VB

4 … 20mA

+ -

Grau / Grey

Blau / Blue

Braun / Brown

4 … 20mA

+

-

3

4

5

1

2

Grau / Grey

Blau / Blue

Weiss / White

Schwarz / Black

Braun / Brown

Pulse CH1

Pulse CH2

Channel 2

Channel 1

9.2.3 MBus

Connector plug A (M12 A-coding) Connector plug B (M12 A-coding)

3

4

5

1

2

Blau / Blue

Grau / Grey

Schwarz / Black MBus

MBus

3

4

5

1

2

+ VB

- VB

Blau / Blue

Braun / Brown

Dimensions

VA 520 EN V1.21 page 16 o 45

9.2.4 Ethernet (optional PoE)

Connector plug B Connection cable

M12 x-coded 8 pole M12 x-coded to RJ45

Data LINES: 1,2 und 3,4

PoE LINES: 5,6 und 7,8

2

81

3

5 4

6

7

M12 x 1

Connection cable: Cat 6.

*PoE: Power over Ethernet

- Connector plug A

- Connector plug B (M12 X-coded 8 pole)

Operation

VA 520 Bi directional English V1.21 Page 17 of 45

10 Operation

“Up“ ( ) “OK“ ( )

The operation of the VA 520 is done by the two capacitive key buttons Up () and Enter ()

Operation

VA 520 EN V1.21 page 18 o 45

10.1 Initialization

10.2 Main menu

HW Version Modbus Id Page No

SW Version

Gas /

Status Info

0.000

Switching to pages 2-5 or back by pressing key „“

After switching on the VA 520, the initialized

screen is displayed followed by the main

menu.

0.0

Counter Direction green

Counter direction blue

Total counter

Actual flow

Operation

VA 520 EN V1.21 page 19 o 45

AV-Time ( Period for average value calculation) could be changed under Sensor Setup.-Advanced–AV-Time

Flow direction blue ( Average, max. Value)

Flow direction green( Average, max. Value)

Total counter

Velocity. Direction blue (Average, max. Value)

Velocity. Direction green (Average, max. Value)

Temperature Medium (actual and min. vaslue)

Temperature Medium (Average and max. value)

8177

Operation

VA 520 EN V1.21 page 20 o 45

10.3 Settings

The settings menu could accessed by pressing the key „OK“.

But the access to the settings menu is password protected.

Selection of a menu item or to change a value

is done with the key „“,a final move to the

chosen menu item or takeover of the value

change needs the confirmation by pressing the

key „OK“

Factory settings for password at the time of

delivery: 0000 (4 times zero).

If required the password could be changed at

Setup–User setup-Password.

.

Other manuals for VA 520

2

Table of contents

Other CS Instruments Measuring Instrument manuals

CS Instruments

CS Instruments LD 510 User manual

CS Instruments

CS Instruments 0554 0504 User manual

CS Instruments

CS Instruments DP 400 mobil User manual

CS Instruments

CS Instruments DS400 User manual

CS Instruments

CS Instruments VA 452 Operator's manual

CS Instruments

CS Instruments VA 550 Ex User manual

CS Instruments

CS Instruments LD 500 User manual

CS Instruments

CS Instruments DS 500 User manual

CS Instruments

CS Instruments DS 300-P User manual

CS Instruments

CS Instruments FA 400 User manual