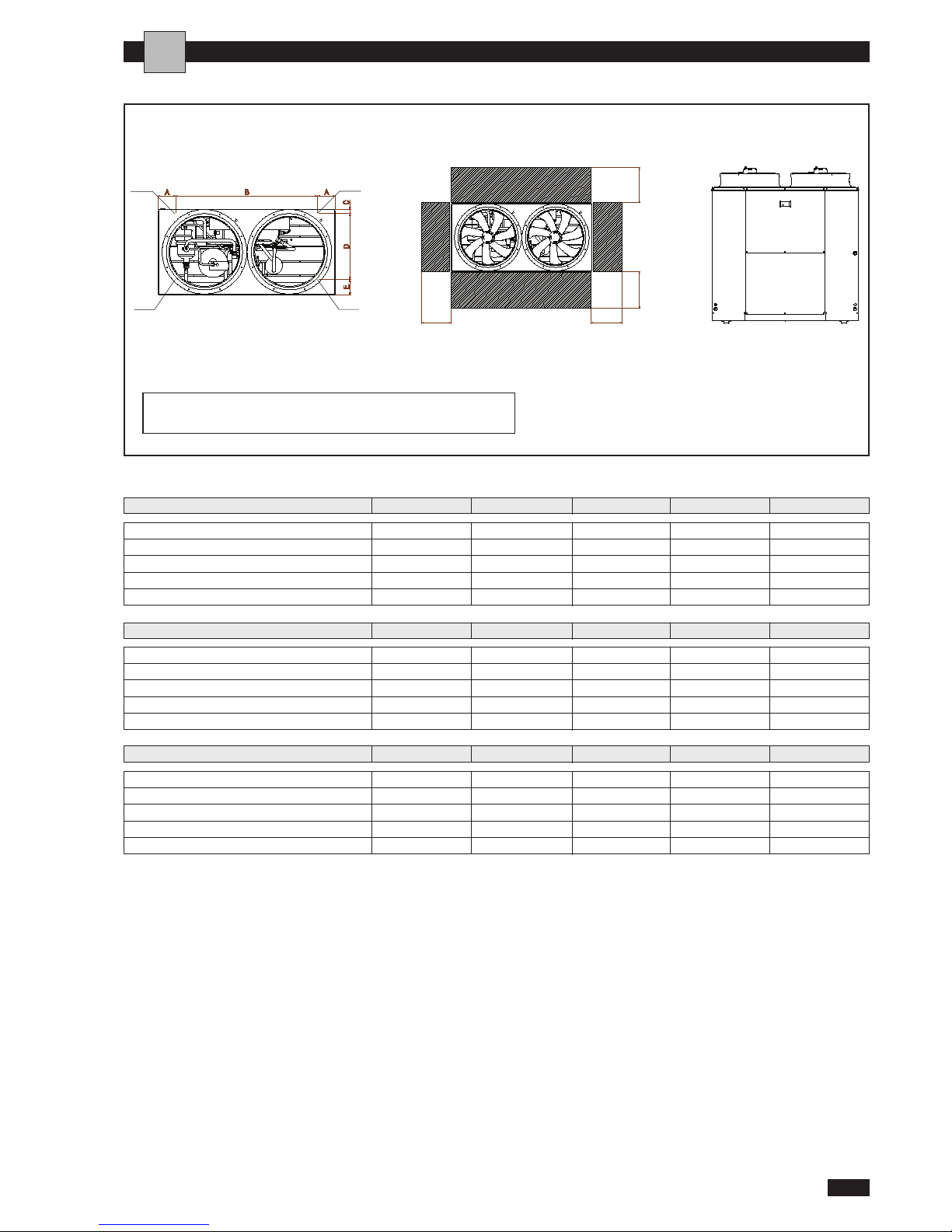

elettrica F.L.I. F.L.A. L.R.A. F.L.I. F.L.A. F.L.I. F.L.A. F.L.I. F.L.A. F.L.I. F.L.A. FU1 FU4 FU5 FU6

(V-Ph-Hz) (kW) (A) (A) (kW) (A) (kW) (A) (kW) (A) (kW) (A)

0072

400-3 N ~ 50

5,9 11,2 48 0,6 2,8 0,7 4,8 7,2 18,8 9,9 23,6 1A 1A 0,5A 3,15

0092

400-3 N ~ 50

8,7 16,3 64 0,6 2,8 0,7 4,8 10,0 23,9 12 27,6 1A 1A 0,5A 3,15

0122

400-3 N ~ 50

9,5 16,6 74 1,2 5,6 0,7 4,8 11,4 27 19 40,4 1A 1A 0,5A 3,15

0152

400-3 N ~ 50

12,2 22,6 95 1,2 5,6 1,3 9,0 14,7 37,2 19,8 46,6 1A 1A 0,5A 3,15

0182

400-3 N ~ 50

14,3 25,9 111 1,2 5,6 0,9 5,4 16,4 36,9 25,1 53,0 1A 1A 0,5A 3,15

ELECTRICAL CONNECTIONS

ICS / ICS-N

8English 07/07

The ICS / ICS-N chillers leave the factory already

wired, and ready for connection to the mains electricity sup-

ply and for the flow switch and remote ON/OFF switch to be

connected. All the above operations must be carried out by

qualified personnel in compliance with the legislation in force.

For all electrical work, refer to the electrical wiring diagrams

in this manual.You are also recommended to check:

- That the characteristics of the mains electricity supply

are adequate for the power input values indicated in the

electrical characteristics table below, also bearing in mind

the possible use of other equipment at the same time.

Power to the unit must be turned on only after

installation work (mechanical, hydraulic and electri-

cal) has been completed.

All electrical connections must be carried out

by qualified personnel in accordance with legislation

in force in the country concerned.

Respect instructions for connecting phase, neu-

tral and earth conductors.The power line should be

fitted upstream with a suitable device to protect

against short-circuits and leakage to earth, isolating

the installation from other equipment.

Voltage must be within a tolerance of ±10% of the rat-

ed power supply voltage for the unit (for three phase

units, the unbalance between the phases must not

exceed 3%). If these parameters are not respected, con-

tact the electricity supply company.

For electrical connections, use double insulation

cable in conformity with current legislation in the

country concerned. Install, if possible near the unit, an

appropriate protection device to isolate the unit from

the mains supply.This should have a delayed character-

istic curve, contacts opening by at least 3 mm and an

adequate interruption and residual current protection

capacity.

If these devices are not visible from the unit,

they should be lockable.

An efficient earth connection is obligatory. Fail-

ure to earth the appliance absolves the manufactur-

er of all liability for damage.

In the case of three phase units, ensure the

phases are connected correctly.

Do not use water pipes to earth the unit.

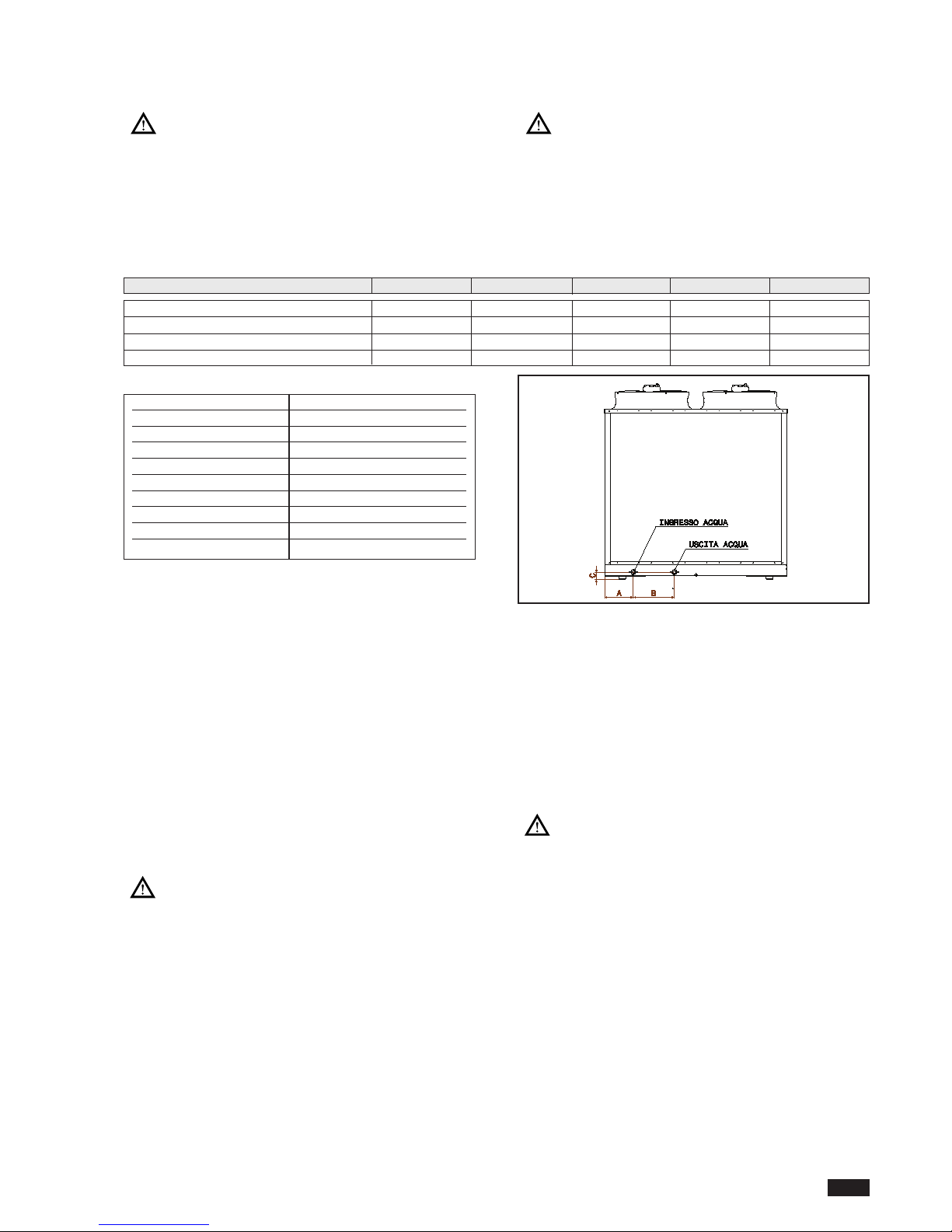

Rated values (1) FUSES

odel Electrical Compressor Fans Pump Total Max. values (3) lass 5x20mm 250V

F.L.I. power input

F.L.A. current input

L.R.A. compressor start-up current

(1) Outside air temperature 35°C - Water temperature at evaporator 12/7°C.

(2) Outside air temperature 7°C - Water temperature at condenser 40/45°C.

(3) These values should be used to dimension protection switches and power

cables.

ICS ELECTRICAL DATA

AI

elettrica F.L.I. F.L.A. L.R.A. F.L.I. F.L.A. F.L.I. F.L.A. F.L.I. F.L.A. F.L.I. F.L.A. FU1 FU2 FU3 FU4

(V-Ph-Hz) (kW) (A) (A) (kW) (A) (kW) (A) (kW) (A) (kW) (A)

Rated values (2) FUSES

odel Electrical Compressor Fans Pump Total Max. values (3) lass 5x20mm 250V

ICS-N ELECTRICAL DATA

0072

400-3 N ~ 50

5,9 11,2 48 0,6 2,8 0,7 4,8 7,2 18,8 9,9 23,6 1A 1A 0,5A 3,15

0092

400-3 N ~ 50

8,0 14,9 64 0,6 2,8 0,7 4,8 9,3 22,5 12 27,6 1A 1A 0,5A 3,15

0122

400-3 N ~ 50

10,0 17,5 74 1,2 5,6 1,1 7,6 12,3 30,7 19,4 43,2 1A 1A 0,5A 3,15

0152

400-3 N ~ 50

12,8 23,7 95 1,2 5,6 0,9 5,4 14,9 34,7 19,4 43,0 1A 1A 0,5A 3,15

0182

400-3 N ~ 50

14,2 25,7 111 1,2 5,6 0,9 5,4 16,3 36,7 25,1 53,0 1A 1A 0,5A 3,15