Clinx XinPRO User manual

XinPRO

Mini Vertical Electrophoresis Cell

User Manual

Content

01 Brief introduction------------------------------------------------------------ 1

02 Component--------------------------------------------------------------------1

03 Technical specification------------------------------------------------------4

04 Safety Information----------------------------------------------------------- 5

05 Installation and basic operation-------------------------------------------- 6

06 Trouble shooting------------------------------------------------------------- 16

07 Quality guarantee------------------------------------------------------------ 20

08 Technical Support------------------------------------------------------------20

1 2

01 Brief introduction

XinPRO Vertical Electrophoresis Cell is used to run pre-casting gel and

hand-casting gel, at most 4 pieces of gels are available simultaneously. It is

compatible with 1-D and 2-D electrophoresis application. The gel-making

frame and glass plate with fastening side strip make the activity of hand-casting

gel simple and avoid the leakage.

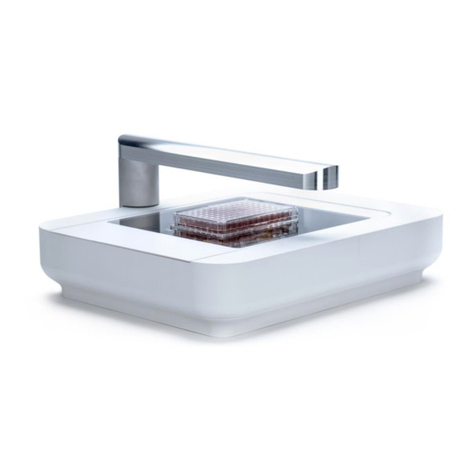

02 Component

In order to achieve best performance, please read the instruction manual

carefully and operate the instrument strictly according to the instruction

manual.

①Glass plate with fastening side stripe: It is the relatively high glass plate with

fastening side stripe. There are 3 kinds of glass plate with the thickness of

0.75mm, 1.0mm, 1.5mm respectively.

②Short glass plate: It is the relatively short glass plate and combined with

glass plate to form the gel sandwich clamp.

③Gel-casting frame: It is put on the desk and align the short glass plate and

glass plate with fastening side strip, and make sure to form the gel sandwich

clamp.

④Components of gel clamp: 1 piece of gel casting frame, a piece of glass

plate with fastening side stripe and a piece of short glass plate.

⑤Gel base: Pressure leverage seal the components of gel to the gel casing pad

to avoid the leakage of gel.

⑥Gel sandwich: It consists of short glass plate and glass plate with side strip

as well as polymer gel.

⑦Replacement plate for single gel: Transparent mound pressing baffle, it is

used to make 1 piece of gel or 3 pieces of gels.

⑧Electrophoresis core: It is used to hold the gel sandwich and supply the

U-sealing strip and upper and lower electrode as well as connecting plug.

Anode is marked by red while the cathode is marked by black.

⑨Buffer tank and upper lid: The buffer tank and the upper lid are closed to

make sure the electrophoresis is conducted smoothly. The power is off when

the upper lid is opened. The tank and upper lid are compatible with other

electrophoresis module, such as the electrophoresis transfer, 2-D single

direction electrophoresis and electrophoresis elution etc.

⑩Comb: The comb with side teeth and inner-built ridge are isolated from air

to avoid the polymerization reaction of inhibition glue.

⑪Glass plate support

⑫multi-functional gel scraper

⑬the gray gel gasket

⑩⑪ ⑫ ⑬

Figure 1:Accessories

①

⑤

③

②

3 4

Figure 2: XinPRO electrophoresis installation

03 Technical specification

Model

XinPRO-4

XinPRO-2

Gel quantity

1-4 pieces

1-2 pieces

Gel thickness

1.0mm(standard) 、0.75mm、1.5mm

Glass plate

100×83mm

Gel area

83×73mm

Comb

specifications

1.0mm 10 wells,15 wells,(standard),

0.75mm 10 wells,15 wells.

1.5mm 10 wells ,15 wells.

Precast gel

Compatible with BIO-RAD,PIERCE,INVITROGEN

Dimension

180×130×160mm

Maximum volume of sample

Hole quantity

Width of hole

0.75 mm

1.0 mm

1.5 mm

5

12.7 mm

70 μl

105 μl

160 μl

9

5.08 mm

33 μl

44 μl

66 μl

10

5.08 mm

33 μl

44 μl

66 μl

15

3.35 mm

20 μl

26 μl

40 μl

IPG

6.2 mm

----

420 μl

730 μl

Prep/2-D

Reference well

3.1 mm

13 μl

17 μl

30 μl

Sample well

71.7 mm

310 μl

400 μl

680 μl

⑥Gel sandwich

⑨upper lid

⑨Buffer tank

⑧Electrophoresis core

U-sealing strip

Electrode plug

⑦Replacement plate

5 6

04 Safety Information

The power is off when the upper lid is opened, never try to operate the

electrophoresis when there is no upper lid.

Note: The safety standard is applied to the Clinx product from design stage to

production stage, and it would be safe in case of proper and right operation.

Please do not improve or mend it by any means.

Compatibility of chemical reagent:

All the components of XinPRO electrophoresis cell should be kept clear of

acetone and ethyl alcohol. The damage caused by using the organic reagent is

not covered by the guarantee policy.

The comb of XinPRO electrophoresis cell should be kept clear of 100%

TEMED, whose structure will be damaged by long time friction of TEMED.

05 Installation and basic operation

1.Preparing gel plate

Hand casting gel

Note to installation of glass plate clamp and gel casting frame

a. Put the gel casting frame vertically on the horizontal desk and let the door of

gel casting frame open.

b. Choose the glass plate with side strip according to the thickness of gel and

put the shore glass plate above (Please refer to the figure 3a).

c. Keep the marked tip of glass plate with side strip up, slide 2 pieces of glass

plates into the gel casting frame, make the face of shore glass forward (Please

refer to the figure 3b).

Note: Keep the 2 pieces of glass plates on the same level and right direction of

marker. The leakage occurs in case of wrong direction of glass plate and

non-aligning.

d. Close the hinge of gel casting frame if the glass plate is in the right position,

clamp the glass plate tightly in gel casting frame (Please refer to figure 3c).

Check the bottom of glass plate is level.

e. Keep the hinge of gel casting frame outward and put the gel casting frame

on the gray gel gasket of gel base, the put the spring leverage on the glass plate

with side strip (Please refer to figure 3d).

f. Repeat step a-e to make another gel plate.

7 8

Figure 3: Installation of gel casting frame and gel base.

Gel casting

a. Non continued polyacrylamide gel

1) Put the comb into the gel clamp completely and mark the part 1 cm blow

the lower end of tooth. The mark indicates the height of separated gel.

2) Blend all the reagent except APS and TEMED to make gel single solution

(Please refer to gel list of chapter 4), vacuum degassing for more than 15

minutes.

3) Put APS and TEMED in single solution after being vacuum degassed, and

use the pipette or sample adding pipette to inject the solution between

glass plate until reach the marker. Keep stable injection in order to avoid

the blend with air.

4) Cover the surface of solution by water or tert-amyl alcohol (2- methyl, 2-

butanol). Note: Please inject the water slowly and stably in order to avoid

blend with air.

5) Leave the gel from 45 minutes to 60 minutes until it is of polymerization.

Cleanse the surface of gel completely by double distilled water. Do not let

the matters of alcohol kind stay on the gel more than 1 hour in order to

avoid the dehydration of upper part of gel.

Note: Such separated gel can be store in room temperature overnight. Add 5 ml

of 1.5MTri-HCl with ratio of 1 to 4 and buffer with pH8.8 (Laemmli system) to

the separated gel to be dried. In case of other buffer, please add 5 ml of 1 fold

diluted solution.

6) Prepare spacer gel single solution, blend all the reagents except APS and

TEMED, vacuum degassing for more than 15 minutes.

7) Use the filter paper to dry the surface of separated gel before injecting

spacer gel.

8) Add APS and TEMED in the degassed spacer gel single solution and

inject the solution until it reaches the level the glass plate.

9) Insert comb and make sure that the back of comb and the glass plate are

on the same level.

10) Leave the gel from 45 minutes to 60 minutes until it is of polymerization.

9 10

11) Take out the comb slightly and cleanse the surface of gel by distilled water

and buffer.

12) Cleanse the used gel clamp frame and gel casting frame by distilled water

and ion-removing water.

b. Continued polyacrylamide gel

1). Blend all the reagent except APS and TEMED to make gel single solution

(Please refer to gel list of chapter 4), vacuum degassing for more than 15

minutes.

2). Put APS and TEMED in single solution after being vacuum degassed, and

inject the solution until it reaches the level the glass plate.

3). Insert comb and make sure that the back of comb and the glass plate are on

the same level.

4). Leave the gel from 45 minutes to 60 minutes until it is of polymerization.

5). Take out the comb slightly and cleanse the surface of gel by distilled water

and buffer.

And cleanse the used gel clamp frame and gel casting frame by distilled water

and ion-removing water.

2 Installation of electrophoresis module and adding sample

Clean and dry XinPRO electrophoresis buffer tank.

Electrophoresis module (Electrophoresis core can only be used for 1 piece gel

or 2 pieces of gels, the shared module should be used in case of 3 pieces of gels

or 4 pieces of gels.

1) Installation

Note: If only run 2 pieces of gels, please use electrode head electrophoresis

core. If only run 4 pieces of gels, please use the electrode head electrophoresis

core and mushroom head electrophoresis core, each module for 2 pieces of

gels.

a. Put the opened gel-casting frame on the clean and horizontal surface of desk

(Please refer to the figure 4a).

b. Adjust the short glass plate inwardly, put the first gel sandwich on the gel

supporter, put the module of gel supporter on both two sides of bottom of

module, each side with two, in case of which, there is a 30 degrees angle

between the middle side of gel plate. Be careful to put the first gel and keep

balance, then put the second gel on the other side of gel supporter. There are

totally 2 pieces of gel slant from the center (Please refer to the figure 4b).

11 12

c. Note: Be sure to adjust the short glass plate inwardly and then put the gel on

the two sides of gel clamping frame. The gel clamping frame requires 2 pieces

of gels to form the functional module. In case of running odd number of gel (1

piece of gel or 3 pieces of gels), please use single gel plate (Please refer to

figure 4b).

d. Push 2 pieces of gel plates slightly to the center and close to gel band, to

make sure that the short glass plate is under the concaved tank of gel gasket.

e. Compress the gel plate tightly by one hand, while close the gel clamp frame

by another hand and make it in the best position. Or hold the whole unit and

stabilize the gel plate and close gel clamp frame on both two sides in order to

make it be locked in the right position (Please refer to the figure 4c). The gel

clamp frame pushes the gel plate and make the concaved tank of short glass

plate and concaved tank of gel gasket matched together tightly in order to avoid

the leakage of liquid (Be sure the the short glass plate is under the bottom of

concaved tank of gel gasket). Thus, use the buffer to cleanse the sample and

start to add the sample (Please refer to the figure 4b).

Important note: Never try to close the gel clamp frame when the gel plate

is not under the bottom of concaved tank of gel gasket. In order to avoid the

movement of gel plate in the process of being locked, please use single hand

to compress the gel plate on the two sides of gel clamp frame stably and

evenly.

Note: Please do not put mushroom head electrophoresis core in the

electrophoresis cell, otherwise the surplus heat is generated which affects the

result of electrophoresis separation.

Figure 4: Installation of XinPRO electrophoresis module.

2) Sample adding

a. Inject the buffer into the tank, from the outside of outer tank and follow

lower part of glass plate, just flood the short glass plate slightly.

b. Add the sample before or after the electrophoresis core is put in the

electrophoresis cell, both of two methods are available to obtain the satisfied

13 14

result.

c. Add the sample into the hole by syringe and sample adding pipette.

Note: Make the sample fall onto the bottom of hole slowly and evenly. Be sure

not to puncture the bottom.

Note: Anode and cathode should be flooded by the buffer and on the same

level.

3) Put the electrophoresis module in the buffer tank.

Note: The volume requires, 2 pieces of gels with 700ml, 4 pieces of gels with

1000ml.

There are two places of buffer tank for two module: Electrophoresis core is

second and the mushroom head electrophoresis core is first.

a. Put the XinPRO buffer on the smooth desk, make the front side (The side

indicating the words of 2 gels and 4 gels) forward. If the direction is correct,

the red mark of edge of tank should be on the right side and the black left.

b. If running 2 pieces of gels, please use the electrophoresis core with plug. Put

it on the back and make the red (+) corresponding to the red mark on the right

side of tank.

c. If running 4 pieces of gels, please us not only the electrophoresis core with

plug but also the mushroom head electrophoresis core that should put in the

front. Make the red (+) of the two corresponding to the red mark on the right

side of tank. Note: The wrong direction and position will make the upper lid

impossible to be closed.

d. Put the buffer into the tank until reach the marker.

4) XinPRO installation of buffer tank

Put the upper lid on the buffer tank, and make sure the plug and socket match

to obtain the right location, the protruded part of upper lid can help avoid the

error. Note: The two protruded parts of buffer tank should go through the slot

of upper lid in order to make it open and close smoothly. At this time, please

compress the upper lid continuously with thumb until is is done.

5) Power condition

a. Insert the plug into the socket correctly.

b. Power on the XinPRO, the constant voltage is 200V is recommended to

SDS-PAGE and most of native PAGE. 200V voltage can be used to run 2

pieces of gels and 4 pieces of gels. The customer choose the voltage according

to the real situation. SDS-PAGE needs around 35 minutes under the voltage of

200V.

6) Extract gel

a. Power off and take out the plug when the electrophoresis is done.

b. Open the upper lid, take out the electrophoresis core carefully, and remove

the buffer. Please pour out the buffer before open the clamp.

15 16

c. Take out the gel plate.

d. Separate the two glass plates carefully and take out the gel.

e. Put the gel downward and immerse the gel and glass plate in the buffer and

make them separated.

f. Cleanse the XinPRO electrophoresis core and buffer tank by the

ion-removing distilled water.

06 Trouble shooting

Problem

Cause

Solution

Smile effect –

band pattern

curves upward

at both sides

of the gel

Center of the gel

running hotter

than either end

Power conditions

excessive

Buffer not mixed well or

buffer in upper chamber too

concentrated. Remake

buffer, ensuring thorough

mixing, especially when

diluting 5x or 10x stock.

Decrease the power setting

from 200 V to 150 V or fill

lower chamber to within 1

cm of top of short plate.

Vertical

streaking of

protein

Sample

overloaded

Sample

precipitation

Dilute sample, selectively

remove predominant protein

in sample, or reduce the

voltage about 25% to

minimize streaking.

Centrifuge sample before

addition of SDS sample

buffer, or decrease %T of the

gel*

The ratio of SDS to protein

should be enough to coat

each protein molecule with

SDS, generally 1.4:1.

It may require more SDS for

some membrane protein

samples.

Lateral band

spreading

Diffusion of the

wells prior to

turning on the

current.

Ionic strength of

the sample lower

than that of the

gel.

Minimize the time between

sample application and

turning on the power

start-up.

Use same buffer in sample

as in the gel or the stacking

gel.

17 18

Problem

Cause

Solution

Skewed or

distorted band

Poor

polymerization

around wells

Salts in sample

Uneven gel

interface

Degas stacking gel

solution completely prior

to casting; +C2:C5

increase ammonium

persulfate and TEMED

concentrations by 25%,

for stacking gel or

low %T, leave APS the

same and double the

TEMED concentration.

Remove the salts by

dialysis, desalting,

column, etc.

Decrease the

polymerization rate.

Overlay gels very

carefully.

Lanes

constricted at the

bottom of the gel

Ionic strength of

sample higher than

the surrounding

gel

Desalt sample and

neighboring samples.

Run taking

unusually long

Running buffer too

concentrated

Excessive salt in

sample

Check buffer protocol,

dilute if necessary

Desalt sample

Run too fast

Running or

reservoir buffer too

dilute

Voltage too high

Check buffer protocol,

dilute if necessary

Decrease voltage by

25–58%

Problem

Cause

Solution

Doublets

observed where

single protein

species is

expected

(SDS-PAGE)

A portion of the

protein may have

been re-oxidized

during the run or

may not have been

fully reduced prior

to the run

Prepare fresh sample

buffer solution if over 30

days old

Increase concentration in

the

sample buffer

Substitute DTT for

BME

Fewer bands

than expected

and one heavy

band at the dry

front

Protein(s)

migrating at the

dye front

Protein

degradation

Increase the %T of the

resolving gel

Use protease inhibitors,

e.g., PMSF, etc

Fewer bands

than expected

and one heavy

band at the dry

front

Protein(s)

migrating at the

dye front

Protein

degradation

Increase the %T of the

resolving gel*

Use protease inhibitors,

e.g., PMSF, etc.

Upper buffer

chamber leaks

Upper buffer

chamber overfilled

Improper assembly

Keep buffer level below

the top of the spacer plate

Be sure U-shaped

electrode core gasket is

clean, free of cuts, and

lubricated with buffer

Be sure short plate is

under the notch on the

gasket, not on top of it

19 20

Problem

Cause

Solution

Leaking during

hand casting

Chipped glass

plates

Spacer plate and

short plate not

level

Casting stand

gasket is dirty,

flawed, or

worn out.

Ensure glass plates are

free of flaws

Ensure plates are aligned

correctly

Wash the gasket if it is

dirty, replace casting

stand gaskets if flawed or

worn out

Poor end well

formation

Incorrect catalyst

formation

Monomer solution

not degassed

Oxygen inhibits

polymerization

Prepare fresh catalyst

solution, or increase the

catalyst concentration of

the stacking

gel to 0.06% APS and

0.12% TEMED

Degas monomer solution

immediately prior to

casting the

stacking gel

Webbing/excess

acrylamide

behind the comb

Incorrect catalyst

concentration

Prepare fresh catalyst

solution,

or increase the catalyst

concentration of the

stacking gel to 0.06%

APS and 0.12%

TEMED

The pressure

cams on the

casting frame

are difficult to

close or make

noise when

closed

Powder residue

has built up at the

pivot

of the pressure

cams

Rinse or wipe off the

powder residue before

each use

07 Quality Guarantee

1. The warranty is 1 years since the date of sales.

2. The warranty excludes the following situations otherwise it is charged/

a. No presentation of warranty card and invoice.

b. The invoice is revised.

c. Improper operation or accident factors.

d. The damage is caused by the user’s repair.

e. Out of the warranty, the instrument is still in usage after repair.

08 Technical Support

If you have any questions about the use or operation of the products, please

contact us.

Clinx Science Instruments Co., Ltd.

Address: 5C-102, 258 West SongXing Road, Baoshan District, Shanghai,

200940, China

Email: info@clinxsci.com

Website: www.clinxsci.com

This manual suits for next models

2

Table of contents

Other Clinx Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Scilogex

Scilogex MX-T6-Pro user manual

Ocean Optics

Ocean Optics SpectroClip-R Installation and operation manual

Mecmesin

Mecmesin MultiTest-i Series Assembly and installation

PHI

PHI VersaProbe Operations

NuAire

NuAire LabGard NU-581-400 Operation and maintenance manual

Metrohm

Metrohm 883 Basic IC plus manual