Cloos Arc Flash 4 evo Guide

Operating

instructions

and

spare parts list

Welding accessories

CLOOS Arc Flash 4 evo Air

Rev.0

Original instructions

2

Important:

This manual must be read and fully understood before using the CLOOS ArcFlash4air unit.

The manual must be retained for future reference.

Compulsory Information for the use of a powered respirator with Hood type head unit

Please read these instructions carefully before unpacking your product. Failure to comply with the instructions in

this leaflet may void your warranty and adversely affect your health. If you have any questions regarding the suita-

bility of this product to your task, please contact an occupational hygienist or call the manufacturers technical

help line.

Address and telephone number information is printed at the back off this leaflet.

CLOOS ArcFlash4air has been designed and manufactured to comply with EN12941: 1998 as a TH2P R SL device.

8S4275 (Guide to implementing an effective respiratory protective device program), which the user is advised to

read, defines an EN12941 TH2P R SL device as offering an Assigned Protection Factor of 20.

CLOOS ArcFlash4air can only provide this level of protection when used with filters provided by the manufacturer

marked "CLOOS ArcFlash4" and "EN12941:1998 TH2P R SL".

The CR-2B01/2013 is certified with the PL-2B01/2013 and GT-2B01/2013 helmets which are certified to EN 175 B.

CLOOS ArcFlash4air is manufactured under ISO 9001:2000 Quality System.

Certification EN 12941:1998+A1:2003+A2:2008 Certified by: DEKRA-EXAM GmbH

3

Inhalt

1. General information.................................................................................4

1.1 Operating instructions..........................................................................................4

1.2 Explanation of symbols.........................................................................................4

1.3 Limitation of liability..............................................................................................5

1.4 Copyright .....................................................................................................................5

2. Safety ...........................................................................................................6

2.1 Proper use....................................................................................................................6

2.2 Reasonably foreseeable misuse.........................................................................6

2.3 Personnel requirements........................................................................................6

2.4 Hazards.........................................................................................................................6

2.5 Warranty clause........................................................................................................7

2.6 Warranty ......................................................................................................................8

3. Technical Data............................................................................................9

3.1 Storage and Transportation ................................................................................9

4. Unpacking / Assembly............................................................................10

4.1 Unpacking ................................................................................................................10

4.2 Assembly...................................................................................................................10

4.2.1 Waist-Belt Adjustment...................................................................................10

4.2.2 Particulate Filter ................................................................................................10

4.2.3 Removing the Filter..........................................................................................11

4.2.4 Fitting a new Filter ...........................................................................................11

4.2.5 Changing the Pre-Filter..................................................................................11

4.2.6 Attaching the Hose to the Blower Unit...................................................11

4.2.7 Donning the Welding Helmet .....................................................................11

5. Before use .................................................................................................12

5.1 Inspection before use..........................................................................................12

5.2 Air Flow Test.............................................................................................................12

5.3 Batteries ....................................................................................................................12

5.3.1 Battery charging................................................................................................13

5.3.2 Battery changing...............................................................................................13

6. Usage .........................................................................................................14

7. Maintenance / Cleaning ........................................................................15

8. Fault finding.............................................................................................16

9. List of parts...............................................................................................17

4

1. General information

1.1 Operating instructions

These operating instructions contain important information for the safe,

efficient handling of the device. Compliance with all of the safety instruc-

tions and operating instructions contained herein is a pre-condition for

safe working with the device.

Illustrations in these instructions are intended to provide a basic under-

standing, and may differ from the actual design of the device. Claims

cannot be derived therefrom.

Information manual for the welder protective helmet complying with Para-

graph 1.4 of Appendix ll of the EC regulations. The welding helmet is a high

quality product that contribute to the comfort and safety of the welder.

The welding helmet may be used only in connection with arc welding.

1.2 Explanation of symbols

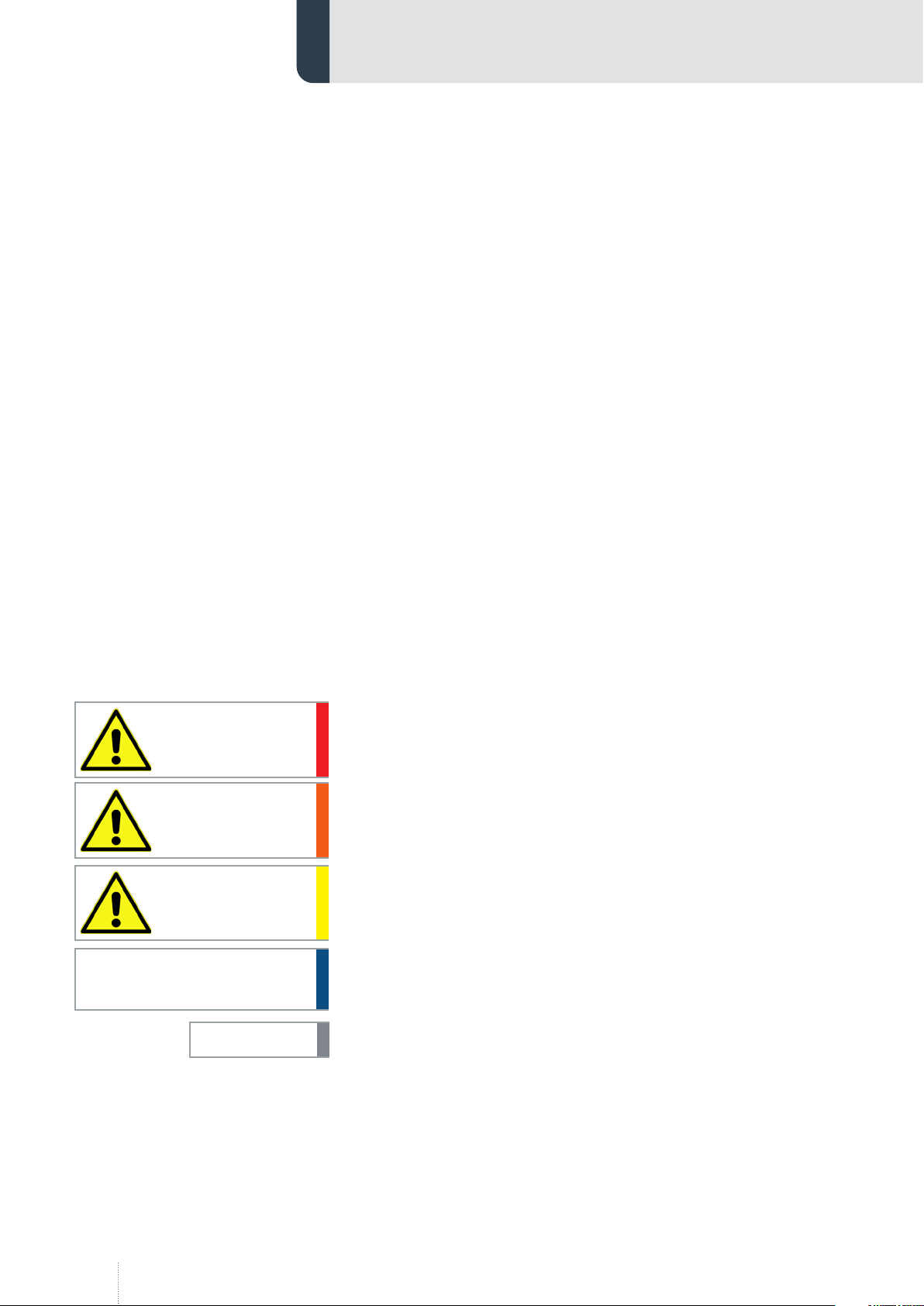

Warning and safety instructions in the manual are identified by means of

pictograms and highlighted in a colour-coded block.

Warning and safety instructions which draw your attention to basic haz-

ards are additionally marked with signal words which express the level of

damage. These are categorised as follows:

The signal word indicates a hazard with a high level of risk, which, if not

avoided, leads to fatal or severe injury.

The signal word indicates a hazard with a moderate level of risk, which, if

not avoided, can lead to fatal or severe injury.

The signal word indicates a hazard with a low level of risk, which, if not

avoided, leads to minor or moderate injury.

The signal word indicates a hazard without risk of a physical impairment,

which, if not avoided, can lead to property damage.

Tips and recommendations as well as information for efficient and

smooth operation.

DANGER!

WARNING!

CAUTION!

ATTENTION!

NOTICE

5

1.3 Limitation of liability

All information and notes in this manual were compiled taking into con-

sideration the applicable standards and regulations and the state of the

art, as well as our many years of knowledge and experience .

The manufacturer assumes no liability for damages caused by:

• Non-observanceofthemanual

• Improperuse

• Useofuntrainedandnon-instructedpersonnel

• Unauthorisedalterations

• Technicalchanges

• Useofunauthorisedspareparts

1.4 Copyright

This document is protected by copyright.

The unauthorised transfer of these instructions to third parties, reproduc-

tion of any kind and in any form, even in excerpts, as well as the recovery

and/or notification of the content is prohibited without the written per-

mission of the publisher.

Infringements of this trademark will be subject to compensation for dam-

ages. All rights to further claims reserved.

6

2. Safety

2.1 Proper use

The device is only to be used for the following purpose:

The device affords reliable protection against particulates and aerosols

Risk from improper use!

Any use of the device other than the intended purpose can lead to hazard-

ous situations.

• Thedeviceshouldnormallyonlybeusedinaccordancewiththeinfor-

mationinthisdocument,inparticularwithrespecttocompliancewith

theapplicationlimitvaluesgiveninthetechnicalspecifications.

• Refrainfromanyuseofthedevicewhichdiffersorextendsbeyond

theselimits.

• Donotconvert,retrofitorotherwisealterthestructureorindividual

fittedcomponentswiththeaimofalteringthescopeofapplicationor

usabilityofthedevice.

Claims of any kind for damages caused by improper use are excluded.

2.2 Reasonably foreseeable misuse

The unit must not be used in an atmosphere that is immediately hazar-

dous to user hygiene or health and or has oxygen content of less than 17 %

or contains unknown substances.

• in confined spaces or unventilated areas such as tanks, pipes, canals etc.,

• near to flames and or sparks,

• in areas with danger of explosion,

• in an area where there are high winds

2.3 Personnel requirements

Work may only be performed by a trained specialist. All personnel involved

must be instructed with regard to the safety requirements, safety regula-

tions and operational instructions which must be applied in their work.

2.4 Hazards

The warning and safety notices listed here and in the operations chapters

of these instructions must be observed in order to prevent potential harm

to health and hazardous situations.

Hazard by lack of oxygen (<17 %)

When the blower unit is switched off a rapid buildup of carbon dioxide and

depletion of oxygen within the head unit may occur

• Itisessentialnottousetheblowerunitwhenitisswitchedoff.

WARNING!

WARNING!

7

Choking hazard

The user is advised to leave the contaminated area immediately if:

• TheManufacturer‘sMinimumDesignFlow(MMDF)warningAlarm

sounds.

• breathingbecomesdifficult,

• dizzinessordistressoccurs,

• anypartofthesystembecomesdamaged,

• airflowintotheHead-Unitdecreasesorstops,

• contaminantcanbesmeltortastedinsidetheHead-Unit,

• Materialsthatmaycomeintocontactwiththeusersskinarenot

knowntocauseallergiereactionstothemajorityofindividualsbutin

theunlikelyeventofareaction,theusershouldimmediatelyleavethe

contaminatedarea,removetheunitandseekmedicaladvice.

2.5 Warranty clause

If any of these conditions are not kept or followed, the warranty is automa-

tically invalid.

Nothing is allowed to touch the moving parts.

There is no attempt to modify or alter the unit or filter in any way. No wa-

ter or other Iiquids enter the unit in any way - in particular the motor and

fan, the filter or the battery.

Make sure that the headpiece fits the user‘s face perfectly. Only then the

efficiency of the system is sufficient. The protective factor of the complete

system is reduced if the seal of the headpiece is not fitted properly, for e.g.

due to beards or long hair intervening into the seal line.

There is a possibility that the hose to the head unit may become caught up

in use. The blower unit should be positioned on the person in such a way

as to reduce this possibility.

Filters cannot be fitted directly to the head units and should not be adap-

ted to do so. Correct respiratory protection will not be provided if any parts

of the equipment are modified. At very high work rates the pressure in the

device may become negative at peak inhalation flow. Blower unit systems

are for use only by competent, trained personnel.

Filters should not be modified to fit different blower units.

WARNING!

8

2.6 Warranty

The blower unit is guaranteed for a period of 12 months from date of

purchase against mechanical or electrical defects.

The battery is guaranteed for a period of 6 months from the date of

purchase.

This guarantee is subject to:

• The blower unit has been used solely for the purpose for which it is

intended.

• The blower unit has not been subject to misuse, accident, modification

or repair.

In the event of a claim, contact the retailer from which the blower unit

was purchased. This guarantee does not cover normal wear and tear. This

guarantee does not affect your legal rights.

9

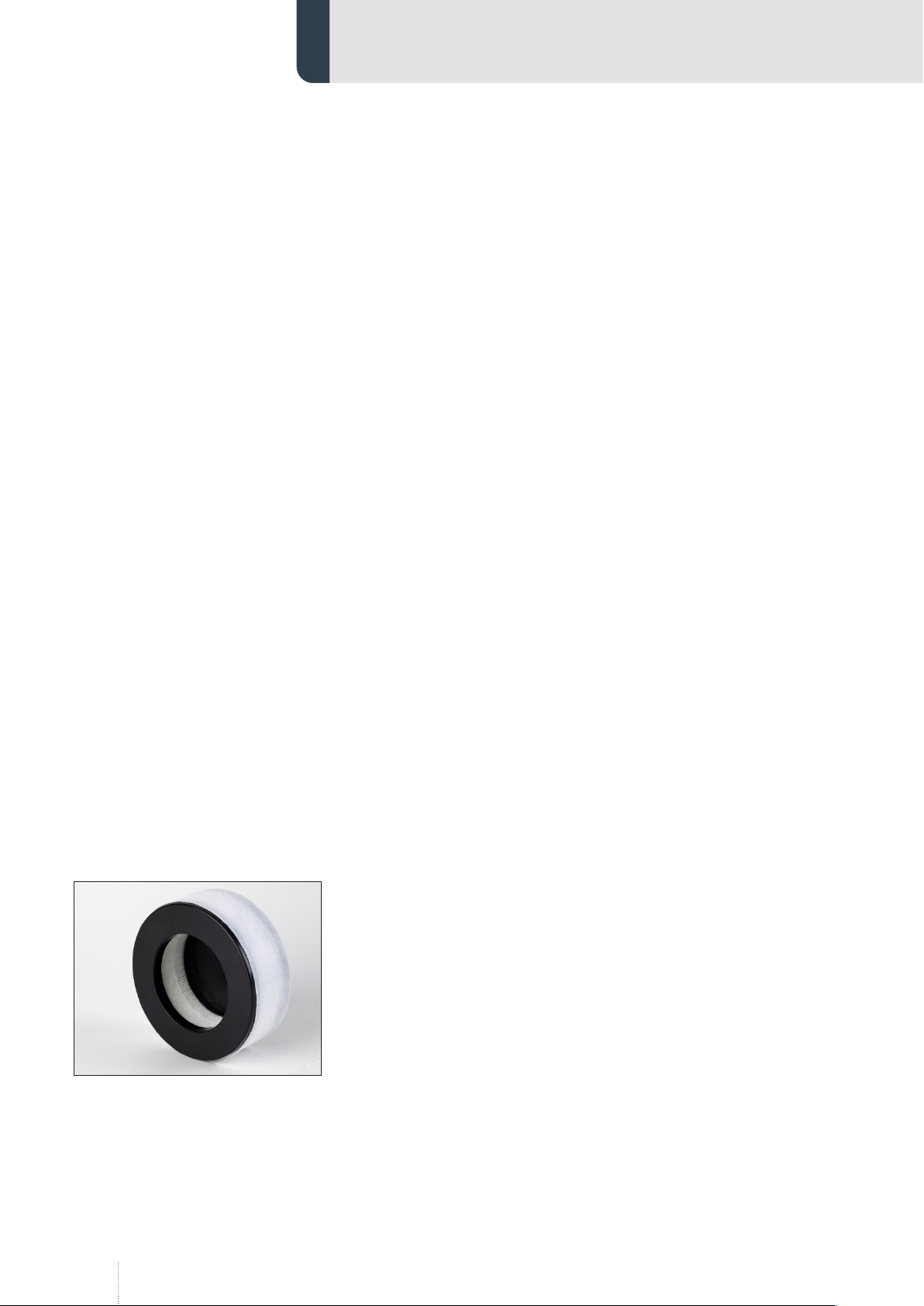

3. Technical Data

Air flow 180…220 Litres/min

Minimum 170 Litres/min

Weight with filter 920 g

Head size 535…600 mm

Type of filter P R S L

Type of battery Replaceable and rechargeable Li-Ion 7.4 V/5200 mAh

Charging cycles >350

Visual, audible alarm for low battery voltage

Visual, audible alarms for insufficient flow rate (below 170Umin)

Actual Protection Factor (APF) 20

Noise level 65 dBA

Operating time On minimum flow rate with a new filter and fully

charged battery in a clean environment:

• greater than 8 hours

• 5 hours on maximum flow rate

Operatingtimecanbeshortenedincaseofclogged

filterunderchargedbattery.

Filter Symbols:

R = means the filter is reusable for more than one shift.

S = means the filter protects against solid particles.

L =means the filter proteet against Iiquid particies.

3.1 Storage and Transportation

When not in use or during transportation the blower and head units

should be stored in the container in which they were provided, or other

similar container, such that it is out of direct sunlight, not in contact with

solvents and cannot be damaged by physical contact with hard suriaces/

items.

Do not store:

• outside the temperature range of +O°C to +40°C or

• humidity above 75%RH

10

4. Unpacking / Assembly

4.1 Unpacking

Check that the package is complete and that no part is damaged due to

the transport or for other reasons.

A package with the complete system including accessories contains:

1. Blower unit incl. Battery and P R SL Filter and Pre Filter

2. Belt

3. Air hose

4. Air flow indicator

5. Battery charger

6. User Instructions

4.2 Assembly

Attach the respiratory unit onto the belt: Pass the inner strap through

the back of the blower loops. The pass through the 2 belt loops and then

through the buckle. Fit the battery to the Blower unit.

4.2.1 Waist-Belt Adjustment

Put the belt around your waist with the blower unit to the back and fasten

the two ends together. If the belt is too loose, slide the male adjuster down

the belt, towards the female half. If the belt is too tight, slide the male ad-

juster away from the female half.

Repeat the above processes until a comfortable and secure fit is achieved.

Once the belt fits correctly, secure any excess belt material using the velcro

sections.

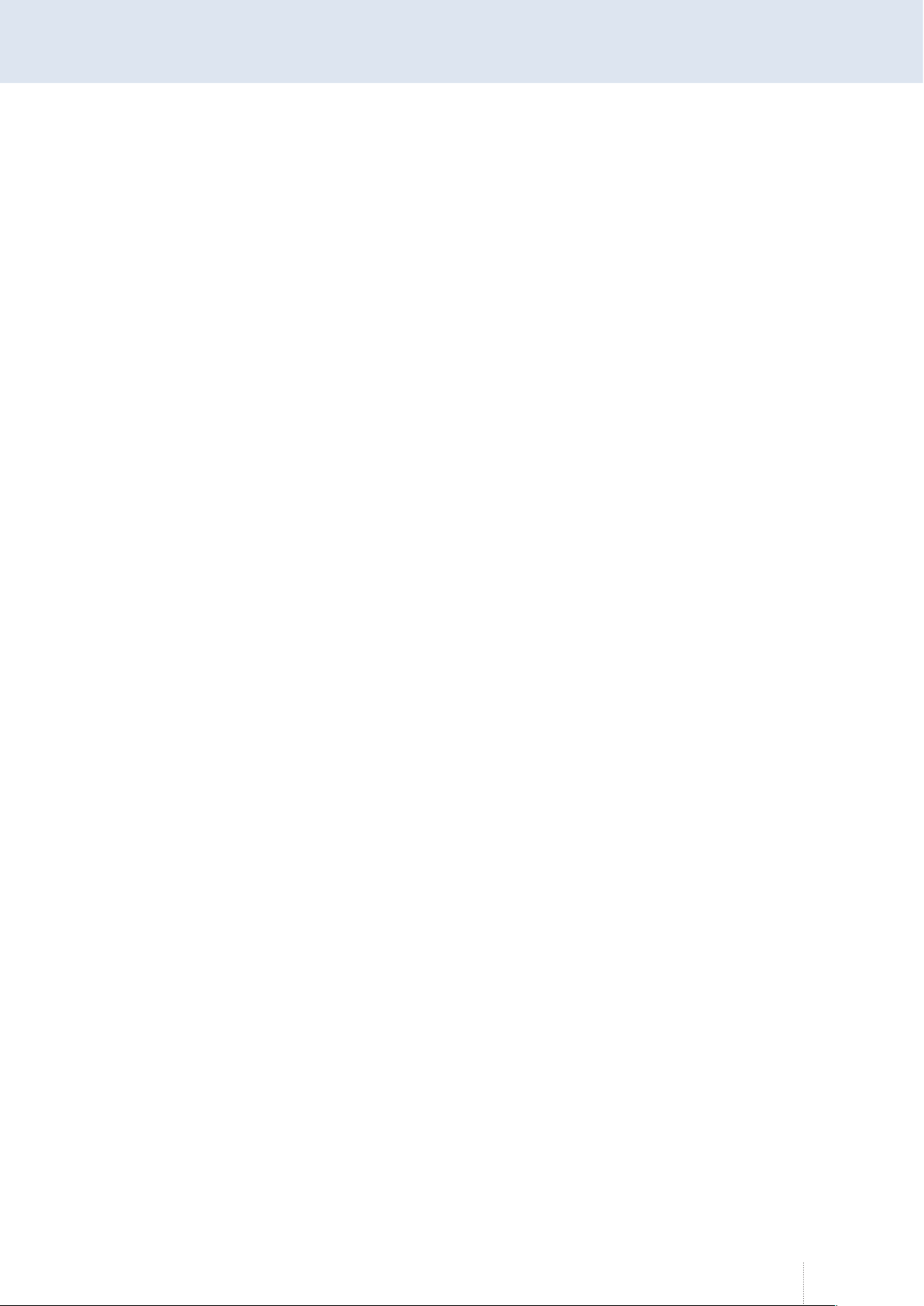

4.2.2 Particulate Filter

Use only filters and Pre-Filters as supplied by CLOOS. It should first be

ascertained by consulting an occupational hygienist or by calling the ma-

nufacturers technical help line as to whether or not the CLOOS Filter will

offer suitable protection from the hazard.

The respiratory power unit is equipped with a high efficiency particle

filter class PRSL and a Pre-Filter. As soon as the warning alarm sounds, the

Pre-FiIter should be exchanged or checked. In very dusty areas this can be

necessary on a frequent basis.

The filters must be regularly checked (see „Air Flow Test“) and replaced.

Make sure that the new filters are within their expiry date, unused and

not evidently damaged . From the hygienic point of view the maximum

working time of a main filter is 180 hours and should not be exceeded. It is

prohibited to clean the filters by any procedure!

11

4.2.3 Removing the Filter

Opening the filter cover:

Grip the blower and pull up the cover from the right side to the blower.

ATTENTION ! lt is strictly forbidden to use any tools to open the filter cover.

To remove the filter, pull it off the filter seal while rotating it. Clean the unit

from dust.

4.2.4 Fitting a new Filter

Inserting a new filter:

Put the filter back into position using the same rotating motion and gently

push until it fits well on the body of the unit.

Closing the filter Cover:

Simply snap the cover into place. Pay special attention to snap the cover

properly into the blower. Do not attempt to use the blower unit without

the cover fitted correctly.

4.2.5 Changing the Pre-Filter

The Pre-Filter is a sleeve which is fitted over the main filter. To remove / re-

place simply pull off the old filter and stretch the new one into position. It‘s

important to ensure that the filter media of the main filter is completely

covered by the Pre-Filter.

4.2.6 Attaching the Hose to the Blower Unit

Align the pins of the Hose Bayonet connector with the slots in the air

outlet of the blower. Push the bayonet connector into the blower until it

reaches the bottom of the hole and then twist in a clockwise direction until

the locating pins clips into place.

Fitting the hose to the hoods is the same procedure.

4.2.7 Donning the Welding Helmet

First set the Welding helmets rake and adjust the welding filter to suit

personal comfort (See the helmet‘s user instructions). Lift the helmet to it‘s

upper position. Place over the head and adjust the headgear ratchet wheel

by pushing it in and twisting until a satisfactory tightness is achieved.

Pull the elasticated chin guard downwards and at the same time pull the

helmet down. Ensure the elasticated chin guard fits comfortably under the

chin. The Welding helmet is now ready for use.

12

5. Before use

5.1 Inspection before use

Each time before starting work check that:

• All components are in good condition with no visible damage (Iike holes,

tears etc.). Replace any damaged or worn parts. Carefully examine the

air hose, seals and the face piece.

• There is a good connection between the air hose and the headpiece as

well as the blower unit.

• There is sufficient air flow (see 5.2).

• The air is supplied through the whole respiratory system from the blo-

wer to the hood.

• Check the battery before the first use (see 5.3).

5.2 Air Flow Test

1. Disconnect the air hose fram the Blower unit.

2. Insert the Airflow indicator into the air hose connector and keep the

hose in vertical position at about the eye level.

3. Switch the power unit on. The airflow is sufficient only if the ball indi-

cator reaches the minimum flow rate level. If the indicator is below the

minimum flow rate level, it is necessary to charge the battery or change

the filter. If the problem still persists, see chapter 8 for additional sugge-

stions.

5.3 Batteries

The removable rechargeable battery used is a Lithium Ion cell. When

supplied the battery may hoId a small charge, the unit should be run flat

and then charged for sixteen hours before the first use.

NOTE! Batteries are delivered only partially charged. All batteries must be

charged before they are used for the first time. The battery can be charged

separately or on the blower unit.

The charger must not be used for any other purpose than that for which

it was manufactured. Do not charge the battery in a potentially explosive

atmosphere. The battery charger is intended for indoor use. It must be

protected against damp. The charger controls the charging automatically.

After the battery has been charged, the charger switches to the trickle

charging regime and keeps the battery fully charged. The charging time is

6 to 8 hours.

13

5.3.1 Battery charging

1. Check that the voltage of the electrical power supply is correct.

2. Plug the charger into the socket.

3. Connect the battery to the charger. The socket of the battery is positio-

ned on the back side.

4. The charging state is indicated by a red LED diode light.

5. After charging has been completed, the trickle charging regime is ac-

tivated: -red LED Diode goes out, the green LED diode comes on at the

moment of trickle charging.

5.3.2 Battery changing

Removing the battery:

1. Locate the battery catch.

2. Pull back the battery catch and at the same time the battery can be

removed by lifting upwards.

Fitting the battery:

Make sure the battery is the correct way up and then slide into the blower

until the battery catch engages.

It is essential that the battery catch is fully locked.

14

Usage

6. Usage

Switch on the unit by pressing the ON/OFF button on the control panel.

The airflow can be adjusted by two arrow-buttons from 180 I/min up to

220 I/min.

The unit ensures a constant supply of air. The microprocessor inside the

unit automatically regulates the motor speed to compensate the filter

clogging and the battery state. If the microprocessor cannot keep the ad-

justed airflow, the unit will sound a ‚beeping‘ alarm (an acoustic signal can

be heard). At which point the user must check the blower unit. If possible,

the microprocessor automatically reduces the airflow to the next lower

level, if it fails to meet the lower level, the alarm will still sound. When the

airflow falls below the minimum safe operating level, a second audible

alarm joins the first and the unit will vibrate. At this point, the user must

stop working at once, leave the working environment and reach an area

nominated to be safe and change the filter or recharge/change the battery.

To check the battery:

When first starting the unit, the battery LED must show red - this shows a

fully charged battery. It is recommended that only a fully charged battery

should be used when starting a work shift.

With a fully charged battery in place, the unit should function normally,

but if the audible alarm still sounds, the user must change the filter. If the

problem still persists, see chapter 8 for additional suggestions.

15

7. Maintenance / Cleaning

The Blower unit, filter housing and head units must all be regularly clea-

ned to keep them in good working order.

For single users, the units can all be cleaned with a cloth moistened with

lukewarm water and soap.

For multiple users, the units should be disinfected when passed from one

user to another.

The Manufacturer recommends that ‚Incidur‘ from Ecolab GmbH & Co.

OHG is used for disinfecting.

Liquids must not be allowed to enter the workings of the blower unit or

get on to the element of the filter.

Parts should be allowed to air dry. Under no circumstances should any

solvents or abrasive cleaning agents be used. The unit must not be dried

using hot air or radiant heat.

The unit should continue to provide protection to the designed specificati-

on for 2 to 3 years, when maintained in accordance with these instructions.

Prior to each use the user should check that the unit is free from defects,

such as cracks, split filters and hoses, cracked visors and helmet compo-

nents as appropriate

16

Fault finding

8. Fault finding

If there is a sudden change in air supply while using the blower unit, it is

necessary to check the following:

• that all parts of the air-supply system are assembled properly,

• the battery and its connector,

• whether the charger is not faulty or malfunctioning (if so, diodes do not

work),

• Filters and their clogging,

• That there is not a hole in the air hose,

• whether the hood seal is not damaged,

• whether the working time after a full recharging of the battery has not

decreased (if so, it is necessary to replace the battery).

17

9. List of parts

Welding Helmet Arc Flash 4 air 0875006250

Arc Flash 4 air helmet only 0875006251

Arc Flash 4 air Headgear cpl. 0875006252

Arc Flash 4 air face seal 0875006253

Arc Flash 4 air filter complete 0875006254

Arc Flash 4 air hose cover 0875006255

Arc Flash 4 air hose 0875006256

Arc Flash 4 air particle filter 0875006257

Arc Flash 4 air prefilter (10 pc) 0875006258

Arc Flash 4 air Li-Ion battery standard 0875006259

Arc Flash 4 air Li-Ion battery HD 0875006260

Arc Flash 4 air charger EU/AUS/UK/US 0875006261

18

List of parts

Arc Flash 4 air belt with lumbar support 0875006262

Arc Flash 4 air ventilation grill 0875006263

Arc Flash 4 air storage bag 0875006264

19

www.qineo.de

Carl Cloos Schweißtechnik GmbH

Industriestraße

D-35708 Haiger

Germany

Telefon +49 (0)2773 85-0

Telefax +49 (0)2773 85-275

E-Mail [email protected]

www.cloos.de

Other manuals for Arc Flash 4 evo

1

Table of contents

Other Cloos Welding Accessories manuals

Popular Welding Accessories manuals by other brands

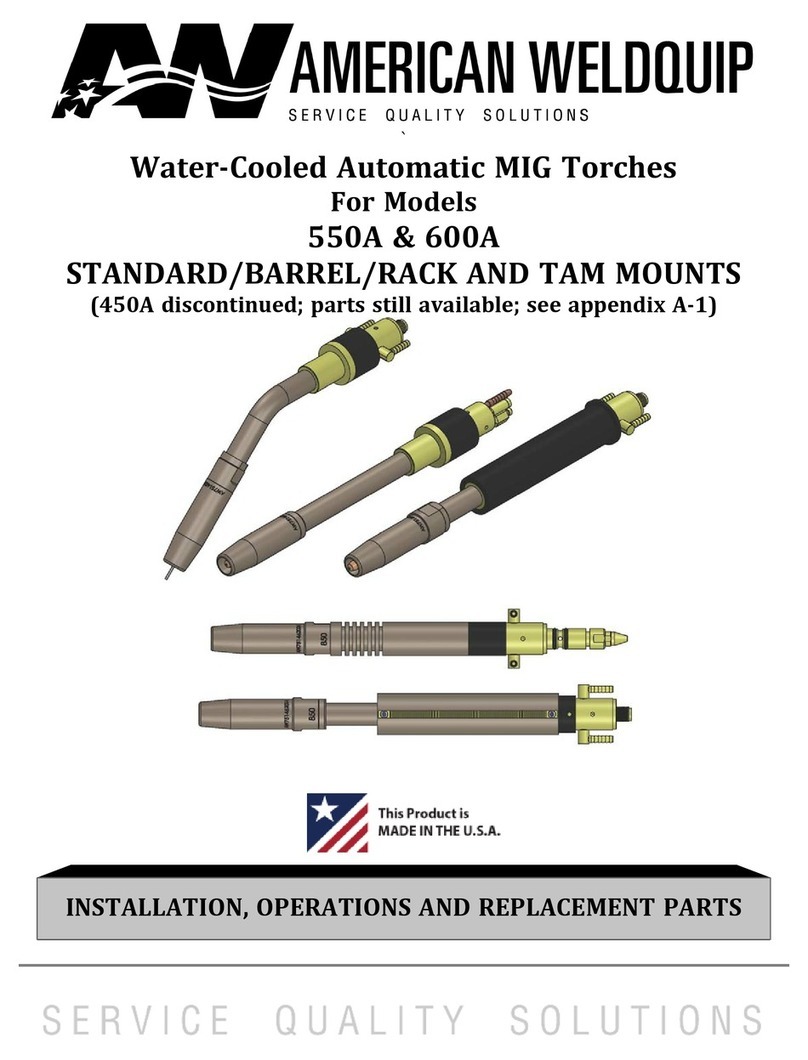

AMERICAN WELDQUIP

AMERICAN WELDQUIP 550A manual

Kemper

Kemper MaxiFil Clean operating instructions

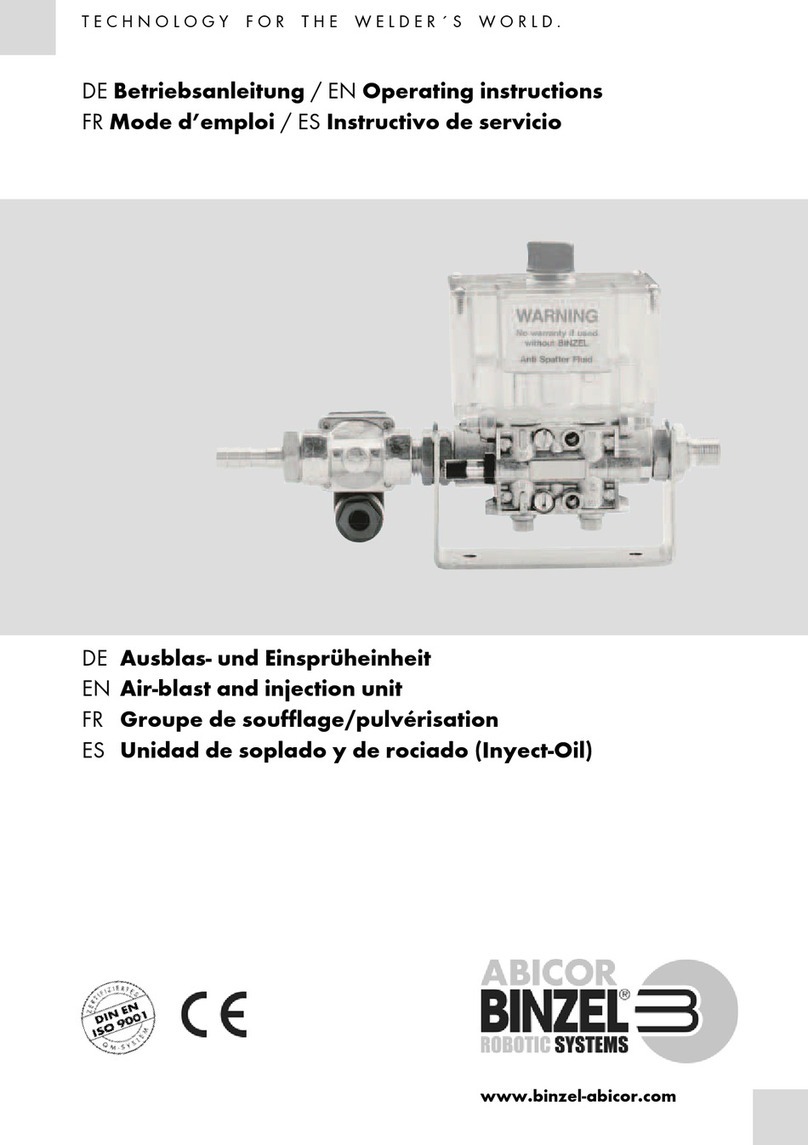

Abicor Binzel

Abicor Binzel Air-blast and injection unit operating instructions

Scheppach

Scheppach AWH-500FL Translation of original instruction manual

ESAB

ESAB A6 VEC instruction manual

Itm

Itm GECKO Operator's manual

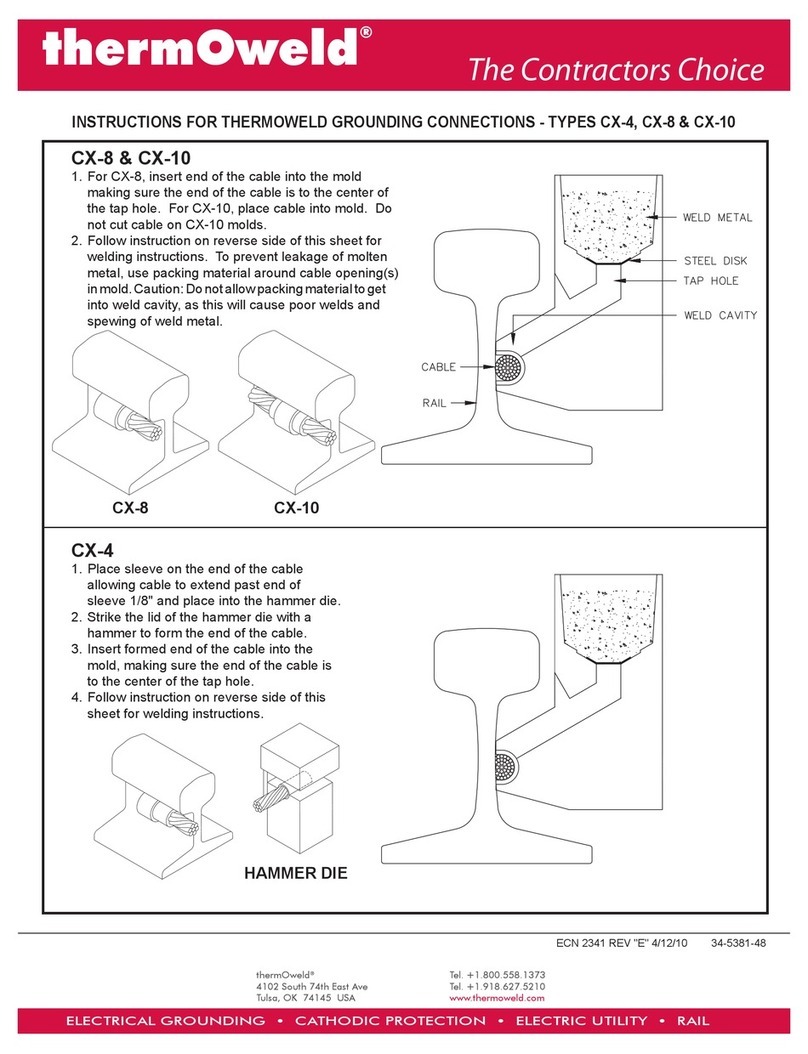

ThermOweld

ThermOweld CX-4 instructions

SHINE

SHINE 5000 instruction manual

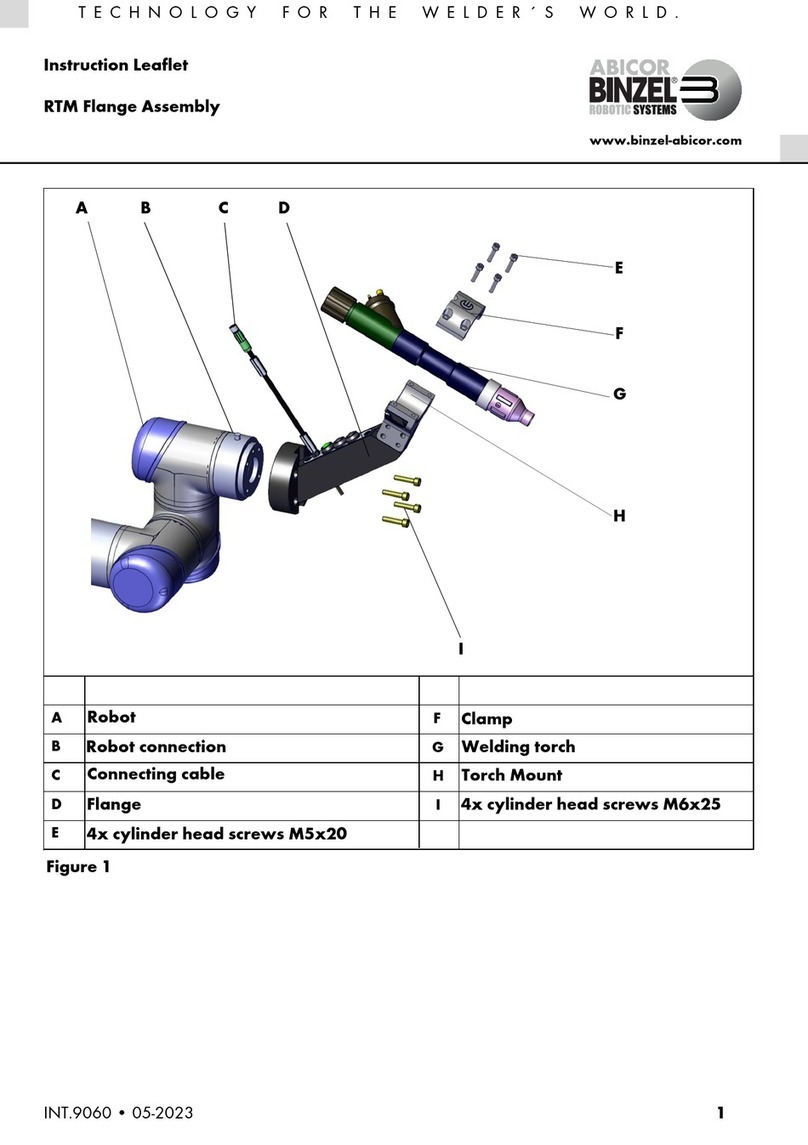

Abicor Binzel

Abicor Binzel xFUME ABIROB AF500 Instruction leaflet

Abicor Binzel

Abicor Binzel MF Control operating instructions

iBell

iBell IBL 550S Operator's manual

Professional Tool Products

Professional Tool Products PWH4000 quick start guide