GECKO OPERATOR’S MANUAL

3

www.itmtools.com.au

Contents

1. GENERAL INFORMATION ............................................................................................... 3

1.1. Application ................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 4

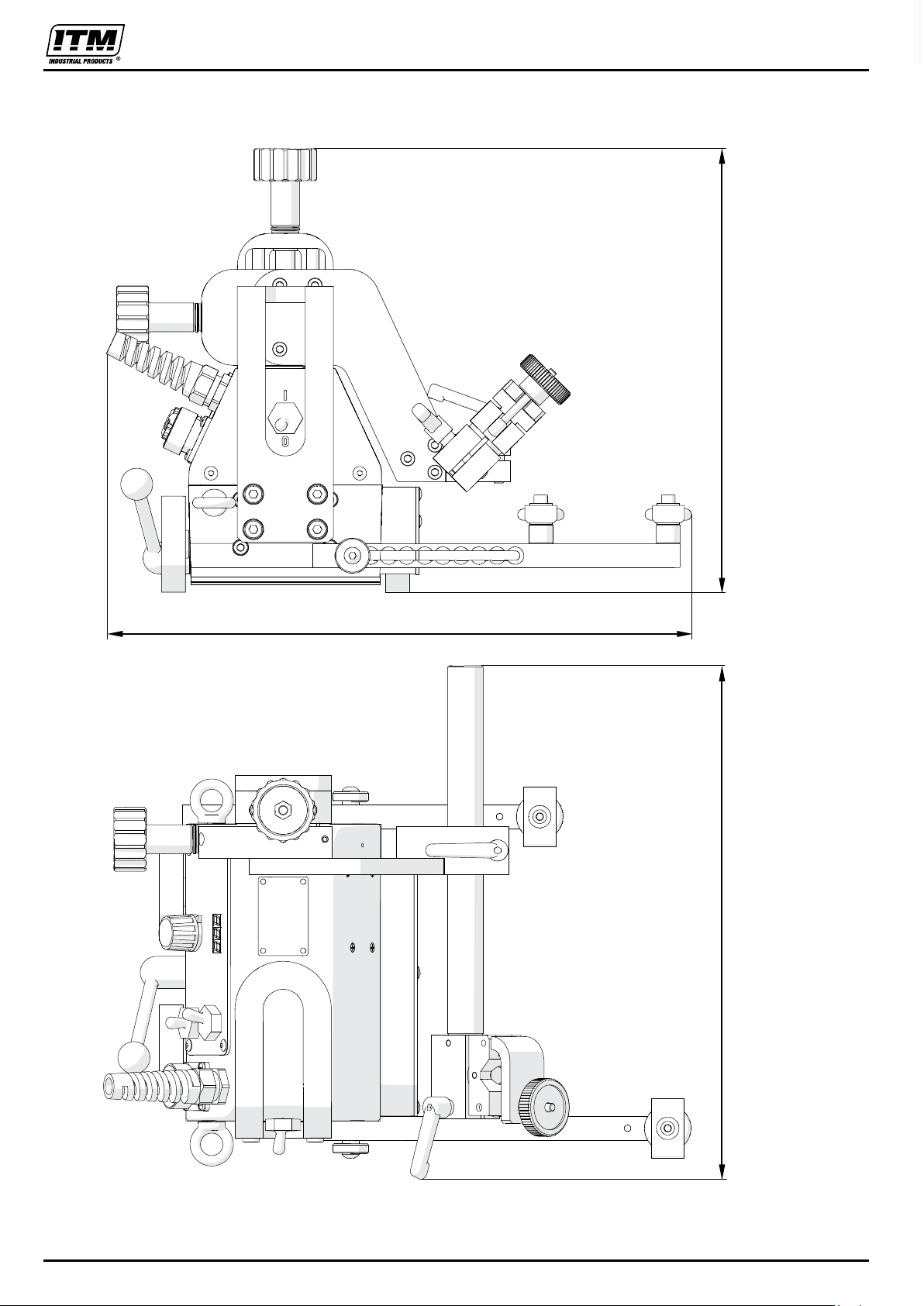

1.4. Dimensions ................................................................................................................ 5

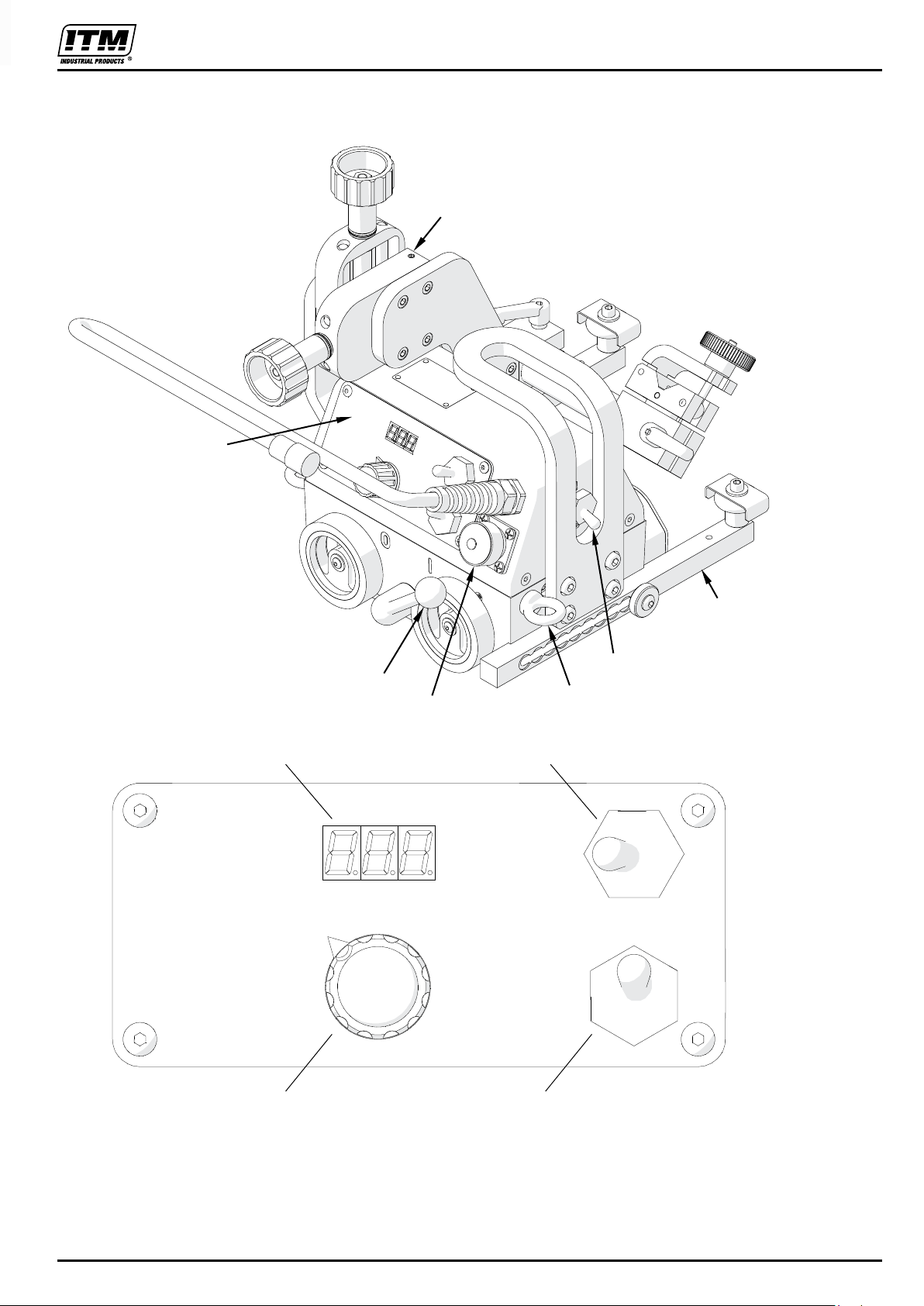

1.5. Design ....................................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION ........................................................................................... 9

3.1. Preparing ................................................................................................................... 9

3.2. Connecting to the welding circuits.............................................................................10

3.3. Positioning at the worksite ........................................................................................11

3.4. Operating ..................................................................................................................12

3.5. Changing the unit of speed .......................................................................................13

3.6. Troubleshooting ........................................................................................................14

4. MAINTENANCE ...............................................................................................................15

5. ACCESSORIES ...............................................................................................................16

5.1. Torch clamps ............................................................................................................16

5.2. Rods .........................................................................................................................17

5.3. Torch holders............................................................................................................18

5.4. Torch extension arm .................................................................................................20

5.5. Guide arms ...............................................................................................................21

5.6. Dual torch mount.......................................................................................................26

5.7. Auxiliary magnet blocks ............................................................................................27

5.8. Flexible guide set ......................................................................................................28

5.9. Guide adjustment tool ...............................................................................................30

5.10. Flexible trackway set...............................................................................................31

5.11. Magnetic units for flexible trackway .........................................................................34

5.12. Support for trackway with magnetic units ................................................................38

5.13. Vacuum unit ............................................................................................................39

5.14. Vacuum track system..............................................................................................40

5.15. Support for trackway with vacuum units ..................................................................41

5.16. 76 mm cross slide ...................................................................................................42

5.17. Cable anchor...........................................................................................................43

5.18. Display protection shield .........................................................................................43

5.19. Fall arrester.............................................................................................................44

5.20. Stainless steel wheels.............................................................................................45

6. 115–230 V WIRING DIAGRAM ........................................................................................46

7. 115–230 V HS WIRING DIAGRAM ..................................................................................47

8. 42 V WIRING DIAGRAM..................................................................................................48

9. 42 V HS WIRING DIAGRAM ............................................................................................49

10. DECLARATION OF CONFORMITY ...............................................................................50

11. WARRANTY CARD........................................................................................................51

1. GENERAL INFORMATION............................................................................................... 4

1.1. Application...................................................................................................................... 4

1.2. Technical data ................................................................................................................ 4

1.3. Equipment included........................................................................................................ 5

1.4. Dimensions..................................................................................................................... 6

1.5. Design ............................................................................................................................ 7

2. SAFETY PRECAUTIONS................................................................................................. 8

3. STARTUP AND OPERATION .......................................................................................... 10

3.1. Preparing........................................................................................................................ 10

3.2. Connecting to the welding circuits.................................................................................. 11

3.3. Positioning at the worksite.............................................................................................. 12

3.4. Operating........................................................................................................................ 13

3.5. Changing the unit of speed............................................................................................. 14

3.6. Troubleshooting.............................................................................................................. 15

4. MAINTENANCE................................................................................................................ 15

5. ACCESSORIES................................................................................................................ 16

5.1. Torch clamps.................................................................................................................. 16

5.2. Rods ............................................................................................................................... 17

5.3. Torch holders.................................................................................................................. 18

5.4. Torch extension arm....................................................................................................... 20

5.5. Guide arms..................................................................................................................... 21

5.6. Dual torch mount ............................................................................................................ 26

5.7. Auxiliary magnet blocks.................................................................................................. 27

5.8. Flexible guide set............................................................................................................ 28

5.9. Guide adjustment tool..................................................................................................... 30

5.10. Flexible trackway set .................................................................................................... 31

5.11. Magnetic units for flexible trackway.............................................................................. 34

5.12. Support for trackway with magnetic units..................................................................... 38

5.13. Vacuum unit.................................................................................................................. 39

5.14. Vacuum track system ................................................................................................... 40

5.15. Support for trackway with vacuum units....................................................................... 40

5.16. 76 mm cross slide......................................................................................................... 41

5.17. Cable anchor ................................................................................................................ 42

5.18. Display protection shield............................................................................................... 42

5.20. Stainless steel wheels .................................................................................................. 43

115–230 V WIRING DIAGRAM............................................................................................. 44

115–230 V HS WIRING DIAGRAM....................................................................................... 45

42 V WIRING DIAGRAM....................................................................................................... 46

42 V HS WIRING DIAGRAM................................................................................................. 47

PARTS LIST.......................................................................................................................... 48

PARTS LIST - ASSEMBLY PANEL....................................................................................... 54

PARTS LIST - TORCH HOLDING ASSEMBLY & LOW TORCH HOLDING ASSEMBLY.... 55