CNB TYC-NHD25 User manual

MANUAL

TYC-NHD25

20

22

Contact our after sales department for any questions or concerns

www.cnbmachinery.com [email protected] (02) 8824-6391 /6386

THE HOME OF REBAR HANDLING MACHINES

TABLE OF CONTENTS

Basic Guidelines to Follow -----------------------------04

Machine Specifications ---------------------------------03

Proper Rebar Cutting Guidelines --------------------08

Electric Handy Cutter

Diameter of

Rebar

25mm

22mm

19mm

16mm

13mm

10mm

No. of Rebars

1 rebar

1 rebar

1 rebar

1 rebar

2 rebars

3 rebars

Number of rebars the machine can cut at once

Machine Specification

Cutting Capacity

10-25mm rebar (0.375-1.00 inches)

Motor

2.1kW (2HP)

Power Requirements

Single phase, 220V-230V 60HZ (factory set up)

Weight

23kg / 51lb

Dimension

(L) 500mm (W) 157mm (H) 250mm

TYC-NHD25

Power Cable Requirements

Power Supply / Power

Standard Sizes / Length

Excess Length

220-230V, single phase, 2HP, 2.2KW

#12 AWG / 3.5mm wires, Max length

from Main Circuit Breaker 20 Amps is

30 meters

When the wire exceeds 30 meters,

replace the wires to a bigger size

depending on the length

requirements to avoid power

fluctuation or voltage drop.

CNB Machinery and Steel Corporation

www.cnbmachinery.com [email protected]

The Home of Rebar Handling Machines

Page 3

Activate the machine by pressing the deco switch. When cutting rebars gently press

CNB Machinery and Steel Corporation

www.cnbmachinery.com [email protected]

The Home of Rebar Handling Machines

Page 4

Power Supply Guidelines

the deco switch in short intervals. Once the blade is near the rebar, fully press the

How to activate the TYC-NHD25

Make sure to check that the power supply is stable between 220-230V.

The machine's power supply can be supplied by plugging it in to a socket or you may

choose to tap directly from the main circuit breaker.

We recommend that you would use a thicker power cable to avoid power fluctuation.

Press the Deco Switch

deco switch until the rebar has been cut.

CNB Machinery and Steel Corporation

www.cnbmachinery.com [email protected]

The Home of Rebar Handling Machines

Page 5

Carbon Brush Inspection

When the machine is in use, the carbon brush located in the side of the machine

will slowly be worn out. In order order to inspect the carbon brush, use the screw

When is it time to change your carbon brush?

driver included in the tool box and check the carbon brush.

The carbon brush on the left is a brand new carbon brush. If you look closely, you can

see the number "27" inscribed in the carbon brush. That will be the indicator of a carbon

brush that is usable. The carbon brush on the right is a worn out carbon brush. And as

Step 1 Step 2

NOTE: Many times, a worn out carbon brush is the cause of an inoperable machine.

This is why it is important to check the carbon brush from time to time.

seen in the picture, the carbon brush is no longer usable if it reaches the inscribed "27".

Page 6

CNB Machinery and Steel Corporation

www.cnbmachinery.com [email protected]

The Home of Rebar Handling Machines

Change Oil for maintenance and smooth cutting

Adjusting of Bar Stopper for accurate cutting of rebars

The TYC-NHD25 is an hydraulic machine. The oil of the machine has to be refilled and

changed from time to time for the machine to properly operate. Use the Allen Wrench

to remove the cap of the oil and change the oil of the machine to operate the machine

The TYC-NHD25 is a 25mm cap electric rebar handy cutter. Its maximum capacity

is 25mm Grade 60 rebars. Adjust the bar stopper located beside the cutter blade

by using the wrench included in the tool box to accurately cut the rebars

to its original capability and performance.

Page 7

CNB Machinery and Steel Corporation

www.cnbmachinery.com [email protected]

The Home of Rebar Handling Machines

Proper way of placing rebars when cutting

Before cutting the rebars, make sure that the rebars enter in the side where the bar

stopper is located. Holding on the rebar in the opposite side of the bar stopper can lead

to serious injuries as the operator can lose his grip due to the vibration of the machine.

All 4 sides of our cutter blades can be used for cutting. As mentioned above, make

sure that when cutting, the rebars will come in contact only with one side of the blade

so that you can use all 4 sides of the cutter blade to its maximum capacity.

Maximizing the Cutter Blades (4 usable sides)

NOTE: The TYC-NHD25 is a powerful machine. Please be mindful of the safety precautions

emphasized for the safety of the machine operators.

Page 8

CNB Machinery and Steel Corporation

www.cnbmachinery.com [email protected]

The Home of Rebar Handling Machines

Proper Rebar Cutting Guidelines

Make sure to follow the proper number of rebars to cut at once. Refer to page 3

for the highest number of rebars you may choose to cut at once. Not following the

instructions will lead to shorter lifespan of your bar cutter blades.

When cutting rebars, make sure to firmly grip on the handle of the machine so

that you will not lose hold of the machine while engaging in cutting. As mentioned

in page 7, make sure that your other hand is holding onto the rebars in the side of

the bar stopper. DO NOT hold rebars on the opposite side as it may cause serious

injuries to the operator.

NOTE: For every 3-4 hours of consecutive usage, make sure to rest the machine for

15-30 minutes. Failure to do so may cause leaks from the seal and gasket.

Page 9

CNB Machinery and Steel Corporation

www.cnbmachinery.com [email protected]

The Home of Rebar Handling Machines

After Sales Service

Make sure to follow the proper number of rebars to cut at once. Refer to page 3

for the highest number of rebars you may choose to cut at once. Not following the

instructions will lead to shorter lifespan of your bar cutter blades.

When cutting rebars, make sure to firmly grip on the handle of the machine so

that you will not lose hold of the machine while engaging in cutting. As mentioned

in page 7, make sure that your other hand is holding onto the rebars in the side of

the bar stopper. DO NOT hold rebars on the opposite side as it may cause serious

injuries to the operator.

NOTE: For every 3-4 hours of consecutive usage, make sure to rest the machine for

15-30 minutes. Failure to do so may cause leaks from the seal and gasket.

Unit #13 Geoland Industrial Compound 7760

Narra Road Barangay San Antonio San Pedro Laguna

TEL: (02) 8824-6386/8824-6389/8824-6346/8824-6391

FAX: (02) 8857-2346

E-mail: [email protected]

Website: www.cnbmachinery.com

THANK YOU, AND WE LOOK FORWARD TO BE

PARTNERS WITH YOU

The Home of Rebar Handling Machines

CNB MACHINERY

AND STEEL CORPORATION

Route from Evia Lifestyle Center

Route from San Pedro Exit South

GEOLAND INDUSTRIAL COMPOUND ENTRANCE

Unit 13

Entrance of the Industrial Compound

SKETCH OF COMPOUND

Table of contents

Popular Cutter manuals by other brands

Parkside

Parkside PUS 4 A1 Operating instructions and safety instructions

Anytron

Anytron Any-cut1 user manual

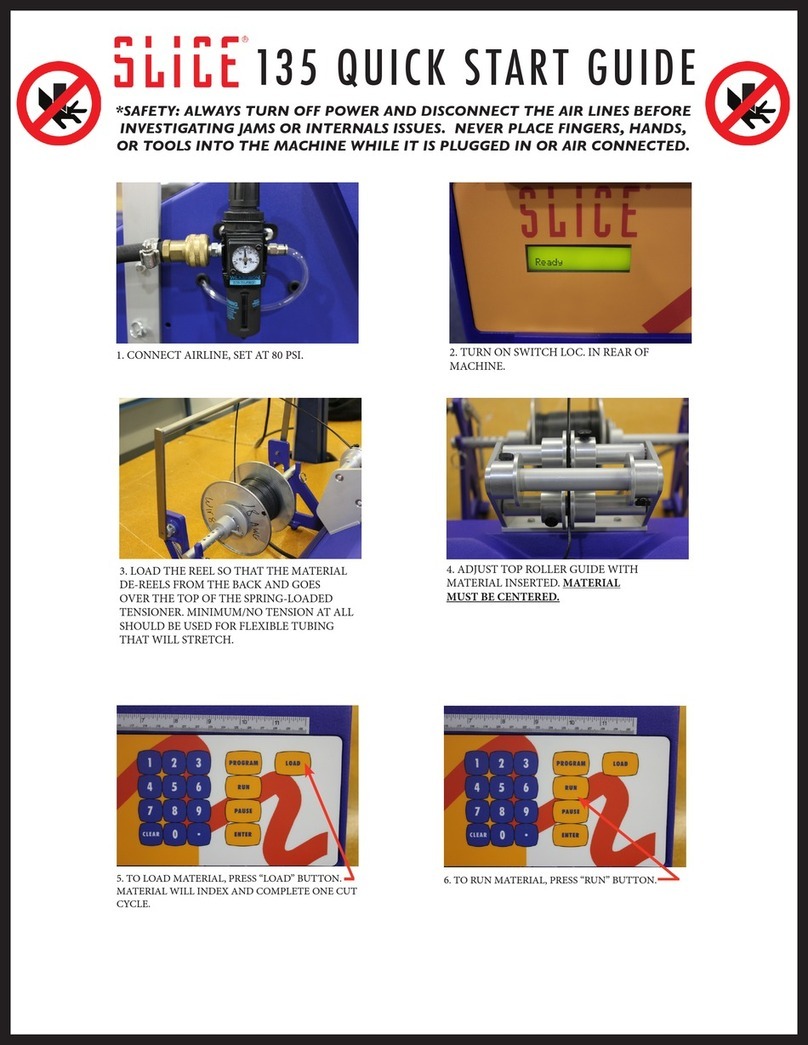

AMTI Products

AMTI Products SLICE 135 quick start guide

Panasonic

Panasonic EY3552 - 18V METAL SAW operating instructions

Keyline

Keyline GYMKANA 994 quick start guide

DeWalt

DeWalt DC550 instruction manual