CNC Solutions DOOR MATE User manual

MANUAL

DOOR MATE

cnc automatic door system

Dear Customer,

Thank you for purchasing your Door Mate CNC automatic door system

from CNC Solutions llc. This manual contains all the important information

regarding safety, installation, usage and care of the Door Mate.

Please review and understand this manual before you get started with cnc

automatic door opener. If you have any questions, please send email

Sincerely,

The team of CNC Solutions LLC

CNC Solutions LLC

260 Grell Lane

Johnson Creek, WI 53038 USA

Phone: 888-392-8970

E-mail [email protected]

Website www.cncsolutionsllc.com

DOOR MATE

cnc automatic door system

INDEX

1

1-1

1-2

1-3

1-4

1-5

2

2-1

2-2

2-3

2-4

2-5

2-6

3

3-1

OVERVIEW

Safetyf rst

Warning

Designed intent

Limited Liability

Overview

Attaching to CNC Machine

Preparation

Mounting

Installing the Door Mate

Adjusting the Door Mate

Door Mate Set up Programming

Troubleshooting

MAINTENANCE

Maintenance overview

DOOR MATE

cnc automatic door system

1 OVERVIEW

1-1 SAFETY FIRST

Below are the safety symbols used in this manual:

1-2 Scope

This symbol is shown to avoid a serious injury or serious damage to

the CNC automatic door system and/or the cnc machine may occur if

the instruction is not followed properly

This symbol is shown to bring extra attention to the explanation, but

that there is no immediate danger for damage or injury

This symbol is shown to avoid a serious injury or serious damage to

the CNC automatic door system and/or the cnc machine may occur if

the instruction is not followed properly

Installation of the cnc automatic door system will change how the

safetyofthedooristted.ThesafetyoftheCNCMachineshouldbe

reevaluated with a safety risk assessment.

DOOR MATE

cnc automatic door system

1-3 DESIGN INTENT

1-4 Limited liability

The cnc automatic door system is an after-market product to an existing CNC machine.

TheautomaticopeningandclosingoftheCNCmachinedoorwaywillallowyoutoll

and remove parts from the CNC machine ergonomically and with Automation using

Robots.

CNC Solutions llc accepts no liability for damage by:

• Failure to comply with these operating instructions.

• Unintended use.

•Maintenancebyunqualiedpersonnel.

•Unauthorizedmodications.

• Technical changes.

• Use of spare parts not recommended by the manufacturer

DOOR MATE

cnc automatic door system

1-5Overview

Complete Door Mate Assembly

Exploded Door Mate Assembly View

DOOR MATE

cnc automatic door system

2 Attaching to CNC machine

2-1 Preparation

Inspect the Door mate upon delivery for any damages.

Tools Needed:

6mm Allen Wrench

9mm Drill bit

Pencil

Parts included in Kit:

Belt

Electrical Enclosure

Cable / Wire

Checkthatthereissucientstabilityaroundthe

CNC machine to enable a safe installation.

The installation of the automatic door opener

shouldbeperformedbyqualiedpersonnelof

the customer or appointed by the customer.

DOOR MATE

cnc automatic door system

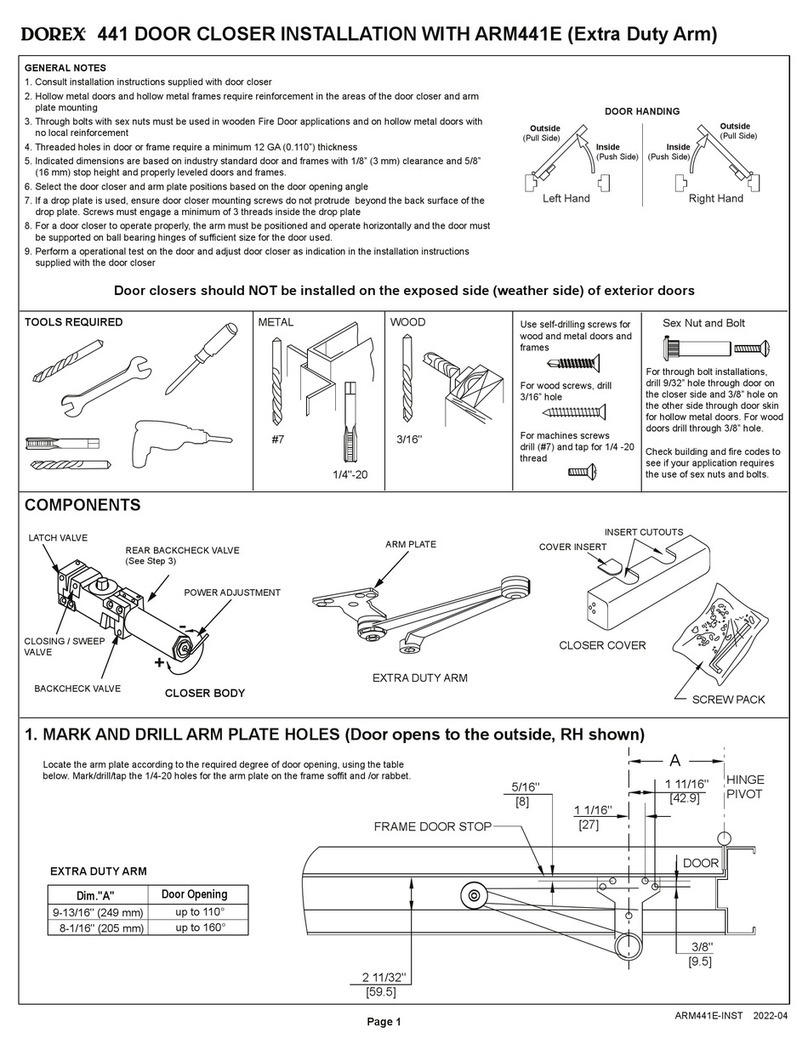

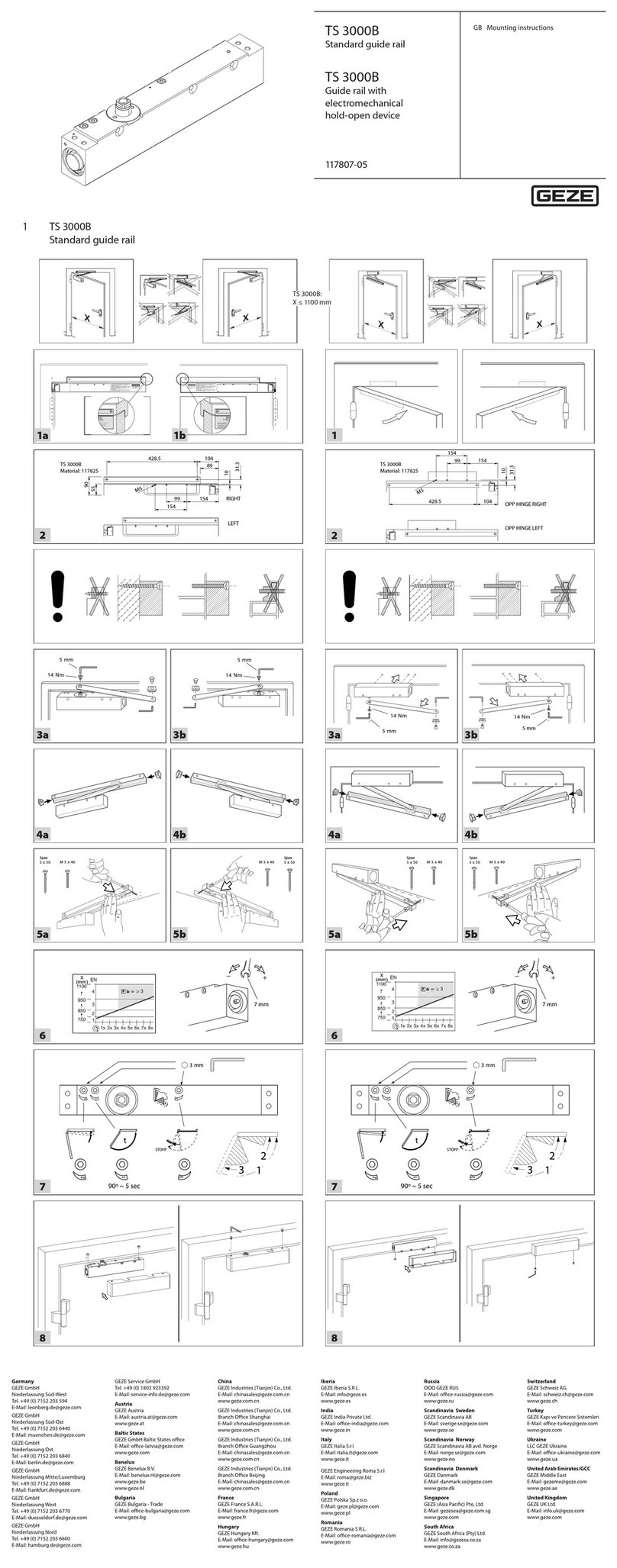

2-2 Mounting on the CNC machine

The top covers need to be removed.

There are (10) 8mm x 1.25 BHCS screws and washers.

A 6mm Allen wrench is also needed to perform this task.

FIG. 2.2-2

FIG. 2.2-1

DOOR MATE

cnc automatic door system

2-3 Installing the Door Mate

Remove machine backing plate with threaded

holes from Door Mate brackets.

Shown in FIG 2.2-3

Place unit on top of machine and mark hole

pattern on the top of the door.

FIG. 2.3-2

FIG. 2.3-1

Remove machine threaded backing plate from

Door Mate brackets.

Shown in FIG 2.3-2

Place unit on top of machine and mark hole

patten on the top of the door to be installed to.

DOOR MATE

cnc automatic door system

Motor connection location

Installing the Electrical Box

Distance from the Electrical box must

not exceed 5 Meters.

Mount using hardware provided

(attached to box)

Place on top of machine or on the

side of the machine within the correct

distance for the legnth of the cable.

2-3 Installing the Door Mate

DOOR MATE

cnc automatic door system

Place unit on top of machine.

Measure stroke distance of the door and center the

Doormate accordingly.

Transfer and Mark hole pattens on the top of

machined.

Drill hole patterns through the top of the machine

and attach the provided threaded backer plates

beneath the sheet metal

2-4 Adjusting the Door Mate

Remove machine backing plate with threaded holes

from Door Mate door bracket.

Align bracket to the edge of the door and transfer

the holes.

Drill out the marks on that door, attach threaded

hole bracket from the bottom the door and tighten

bolts.

FIG. 2.2-6

FIG. 2-4-2

FIG. 2-4-1

DOOR MATE

cnc automatic door system

2-5 Adjustment of the Door Mate

Adjusting the belt tension.

Adjust bolt outwards till belt tension is good

and then tighten locking nut to hold tension.

Adjustability is built in with the slotted brackets

shown here in FIG. 2.2-4 for varying door

heights and parallelism need to run the belt

straight.

Adjust where needed to make belt run parallel.

Loosen the four bolts to adjust up or down.

FIG. 2-5-1

FIG. 2-5-2

DOOR MATE

cnc automatic door system

2-6 Programming Door Mate

Initial Setup - Starting a learn run when the line voltage is applied.

1. Push the door into the CLOSED position.

2. Disconnect the power supply from X3 (DC).

3. Press and hold the learn run button (S401)

4. Connect the power supply to X3 (DC).

5. Inital commissioning or motor adaptation: For the motors M4, MDG400, MDG400

NMS, M5 and MDG700 NMS, the output transmission [mm/rev]

MUST BE CONFIGURED.

For the M4, MDG400 and M5 motors, set default value to 176 mm/rev.

6. Press and hold the learn button (S401)

7. The learn run starts AUTOMATICALLY, and the learn run button can be released.

8. During the learn run, the door is opened about 10 cm, and closed once or twic as

slow start speed. The friction of the door system is then determined by opening and

closing the door once through a range of 25 cm at slow start speed.

The door then opens and closes through its complete range of movement at reduced

speed. After the door thas opened by approximatley 15 cm, it passes through an

additional short acceleration ramp to determine the mass to be moved.

9. The door parameters and the determined door with are saved when the door the

CLOSED postion.

This means that the door width and the mass to be moved are re- adapted and saved.

The default parameters for energy limitation, speed limitation, friction compensation

and all other travel curve parameters are also loaded.

10. Learn run completed.

DOOR MATE

cnc automatic door system

2-6 Programming

Initial Setup - Starting a learn run during operation

1. Push the door into the CLOSED position.

2. Press and hold the learn run button (S401).

3. The learn run starts automatically, and the learn run button can be released.

4. During the learn run, the door is opened about 10cm, and closed once or twice at

slow start speed. The friction of the door system is then deteremined by opening

and closing the door once through a range of 25 cm at slow start speed. The door

then opens and closes through its complete range of mevement at reduced speed.

After the oor has opened by approximately 15 cm, it passes through an additional

short acceeleration ramp to determine the mass to be moved.

5. The door parameters and the determined door width are saved when the door is in

the CLOSED postion.

This means that door width, mass to be moved, enery limiting, speed limiting and

friction compensation are re-adapted adn saved.

6. Learn run completed.

DOOR MATE

cnc automatic door system

2-7 Troubleshooting

2SHUDWLQJVWDWHVDUHLQGLFDWHGRQWKH+VHJPHQWGLVSOD\RUWKH+GLJLWDOGLVSOD\RI

WKHFRQWUROXQLW

7KH6,'225$7':$7':$7':FRQWUROOHUVDGGLWLRQDOO\HQDEOHUHWULHYDORI

VWDWXVLQIRUPDWLRQYLDWKHSDUDPHWHUUVWDWXVFRGH

7KHIROORZLQJRSHUDWLQJVWDWHVDUHVKRZQ

'LVSOD\ 0HDQLQJ

,QIR

/LJKWEDUULHUSUHVVXUHVHQVLWLYHHGJHLQWHUUXSWHG

0RWRUREVWUXFWHGLQWKHFORVLQJGLUHFWLRQ

F 2EVWUXFWLRQZKLOHRSHQLQJ

G 'RRUUHPDLQVVWDWLRQDU\GXULQJLQLWLDOL]DWLRQUXQQR23(1RU&/26(VLJQDOSUHVHQWRUGRRUKDVUHDFKHG

HQGSRVLWLRQ

+ 'HWHUPLQDWLRQRISDUDPHWHUVOHDUQUXQ

R )XQFWLRQ2.

X 'RRUFORVHG

)DXOW

5$0((3520RU&38HUURUV\VWHPHUURU

%UDNLQJFKRSSHUGHIHFWLYH

(UURULQWKHQG6KXWGRZQURXWH

0RWRUSURWHFWLRQPD[LPXPRSHQLQJRUFORVLQJWLPHRIVKDVEHHQH[FHHGHG

0RWRUXQGHILQHGದQROHDUQUXQFDUULHGRXWZLWKWKLVPRWRUW\SH

,IDGLIIHUHQWPRWRUYHUVLRQLVXVHGWKHOHDUQUXQPXVWEHUHSHDWHGDWSRZHURQDVGHVFULEHGLQWKHVH2S

HUDWLQJ,QVWUXFWLRQV6HH7DEOH6WDUWLQJDOHDUQUXQZKHQWKHOLQHYROWDJHLVDSSOLHG3DJH

(UURULQSXOVHJHQHUDWRU

266'(63(W\SHRUSUHVVXUHVHQVLWLYHHGJHದ)XQFWLRQWHVWIDLOHG

0RWRURYHUFXUUHQW

( 0RWRURYHUYROWDJH

) 0RWRUXQGHUYROWDJH

Q 2XWSXWVWDJHGHIHFWLYH

/ &XUUHQWPHDVXUHPHQWHUURU

W %HOWWRUQ

8 0D[PDVVWREHPRYHG

'LVSOD\ 0HDQLQJ

$ODUP

$XWRPDWLFH[WHQVLRQRIWKHKROGRSHQWLPHPRWRUSURWHFWLRQ

1HZPRWRUW\SHGHWHFWHGOHDUQUXQLVUHTXLUHG

3 3DUDPHWHUHUURUHUURUGXULQJOHDUQUXQ

\ 0DVWHUWLPHRXW

B &RQWUROOHUKDVQRSDUDPHWHUVDQGLVZDLWLQJIRUOHDUQUXQ

5HVHUYH

E ದ

K ದ

DOOR MATE

cnc automatic door system

3 Maintenance

Keep debris and dust clear of belts and

motor drive. Do a routine checkup of all

parts.

Make sure all bolts are tight and

brackets are properly aligned

FIG. 3-1-1

FIG. 3-1-2

Table of contents

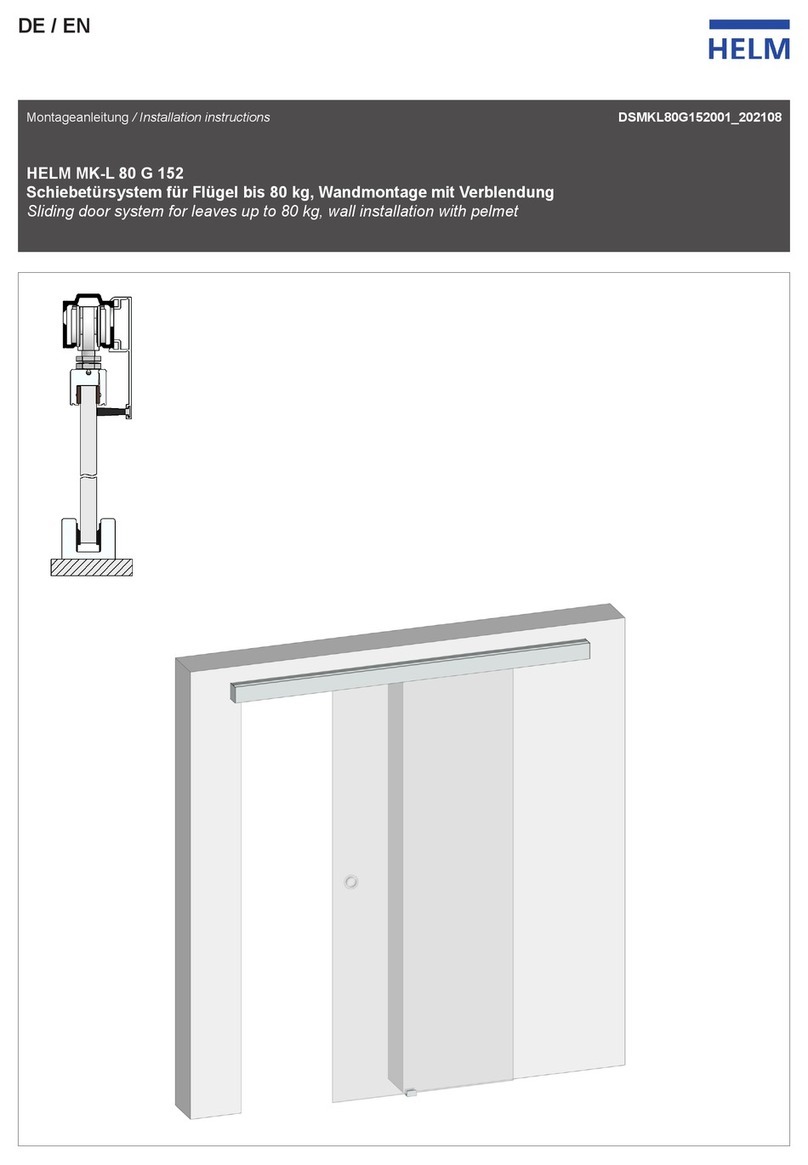

Popular Door Opening System manuals by other brands

Scrigno

Scrigno antamatic OPEN 2.0 installation manual

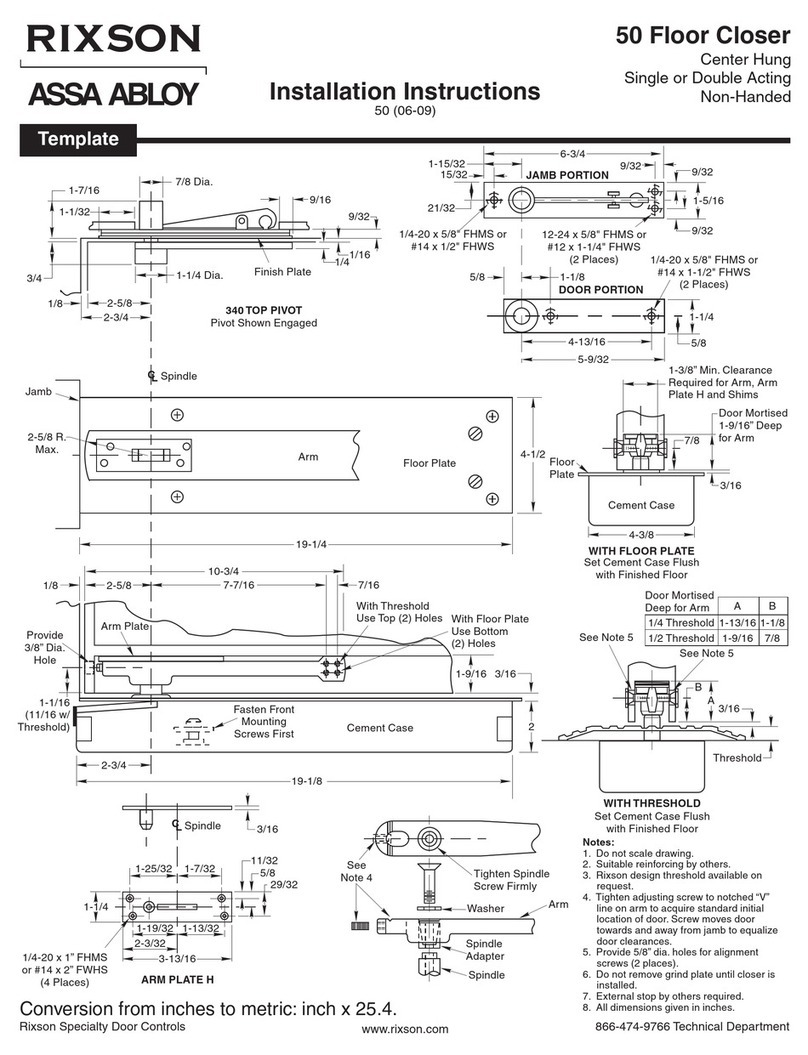

Rixson

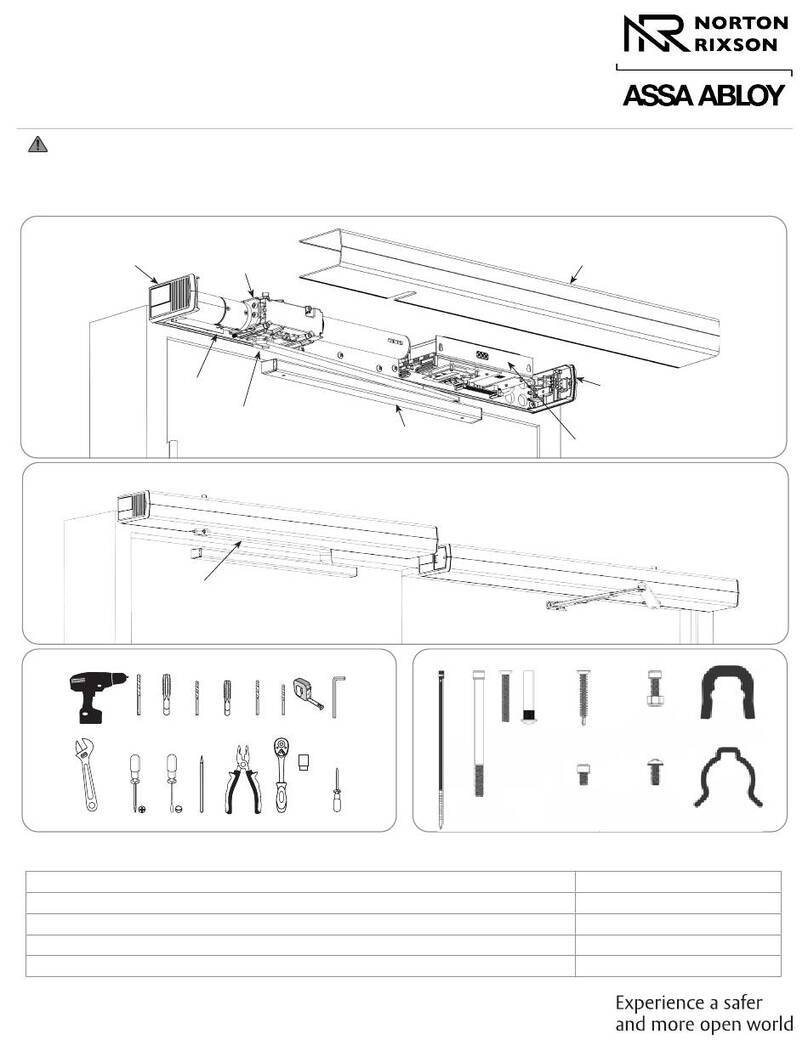

Rixson ASSA ABLOY 50 installation instructions

D+H

D+H ZA 35-BSY+(-HS) manual

CAME

CAME A 5024 installation manual

CornellCookson

CornellCookson AlarmGard FST-EPBD Series Installation instructions and operation manual

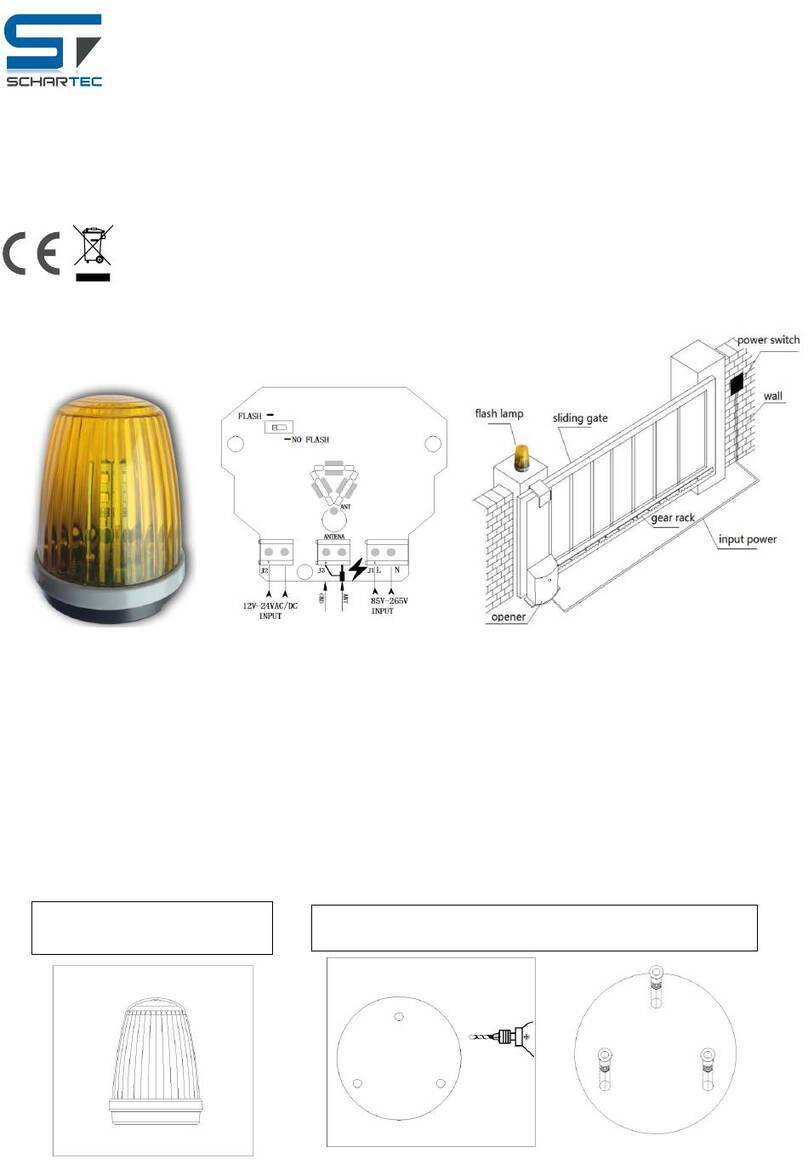

Schartec

Schartec ST201004 user manual

Yale

Yale Power Track Series installation instructions

Assa Abloy

Assa Abloy Besam SW200i US Installation and service manual

Assa Abloy

Assa Abloy NORTON RIXSON 6300 Series installation instructions

ETME

ETME SD series operating instructions

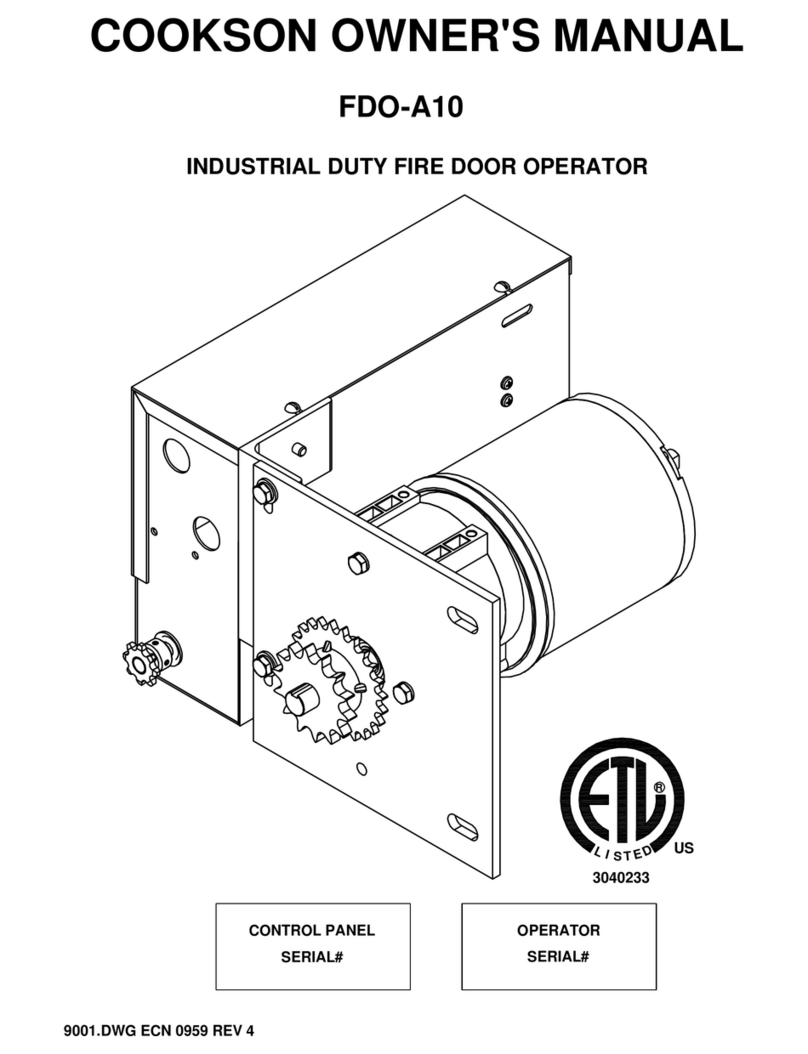

Cookson

Cookson FDO-A10 owner's manual

quiko

quiko Swingy QK-SW80 user manual