A

1 11/16"

[42.9]

1 1/16"

[27]

5/16"

[8]

3/8"

[9.5]

2 11/32"

[59.5]

_

+

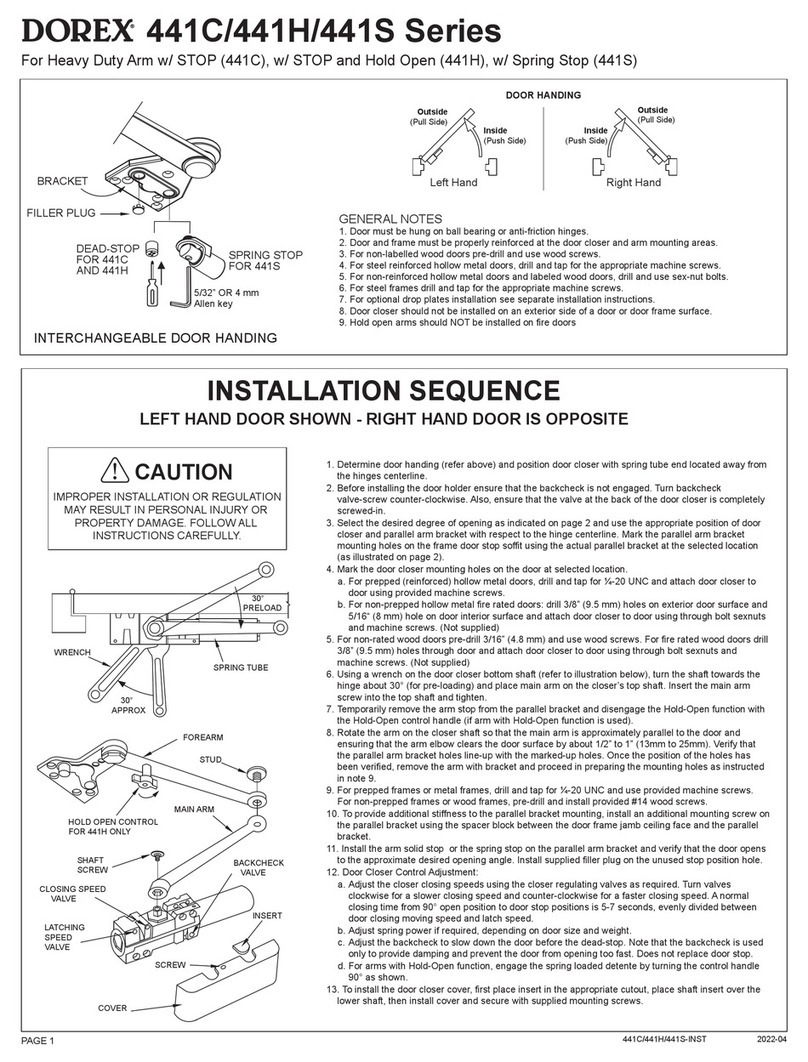

TOOLS REQUIRED METAL WOOD Sex Nut and Bolt

Check building and fire codes to

see if your application requires

the use of sex nuts and bolts.

LATCH VALVE

REAR BACKCHECK VALVE

(See Step 3)

CLOSING / SWEEP

VALVE

BACKCHECK VALVE CLOSER BODY

POWER ADJUSTMENT

EXTRA DUTY ARM

COVER INSERT

INSERT CUTOUTS

CLOSER COVER

SCREW PACK

#7

1/4"-20

3/16"

HINGE

PIVOT

DOOR

FRAME DOOR STOP

EXTRA DUTY ARM

8-1/16" (205 mm)

9-13/16" (249 mm) up to 110°

up to 160°

Door Opening

Dim."A"

Page 1

Door closers should NOT be installed on the exposed side (weather side) of exterior doors

Use self-drilling screws for

wood and metal doors and

frames

For wood screws, drill

3/16” hole

For machines screws

drill (#7) and tap for 1/4 -20

thread

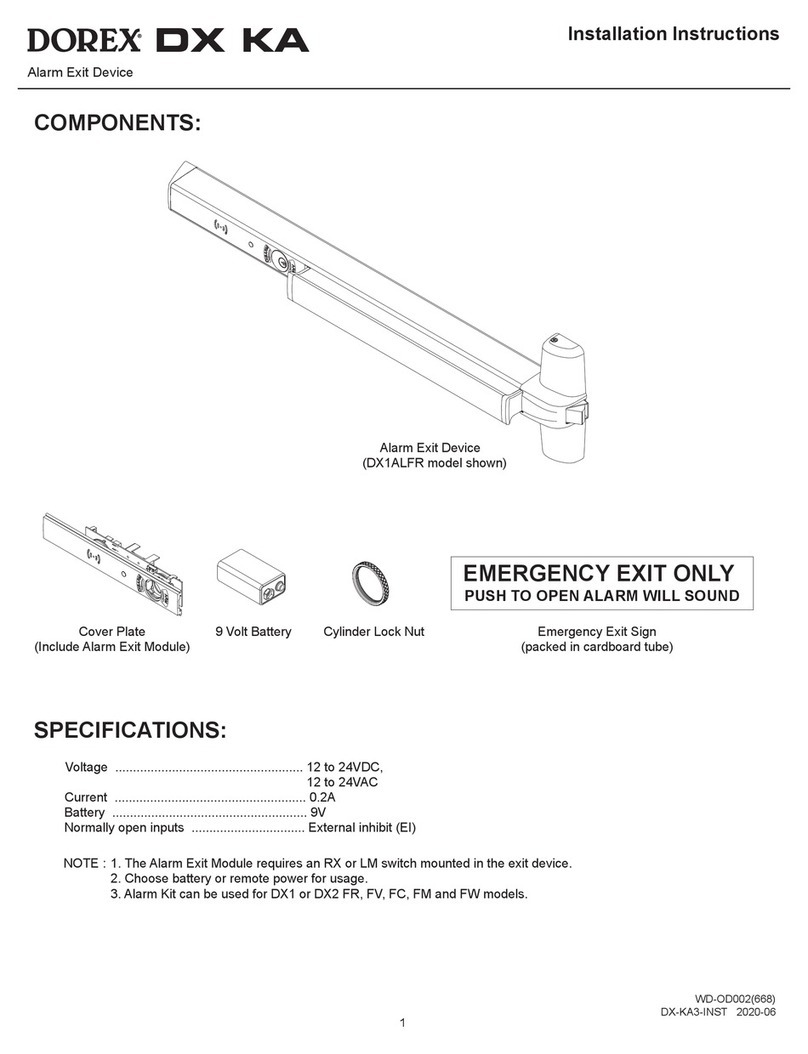

COMPONENTS

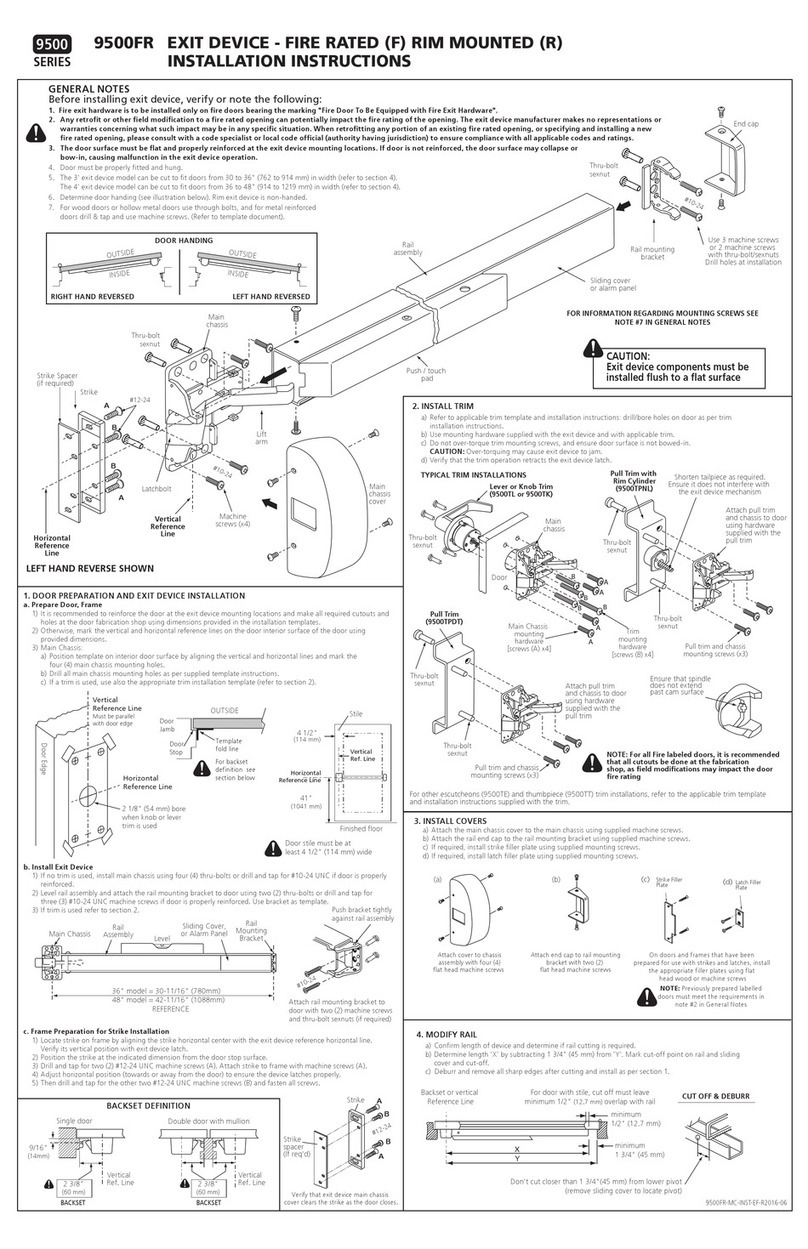

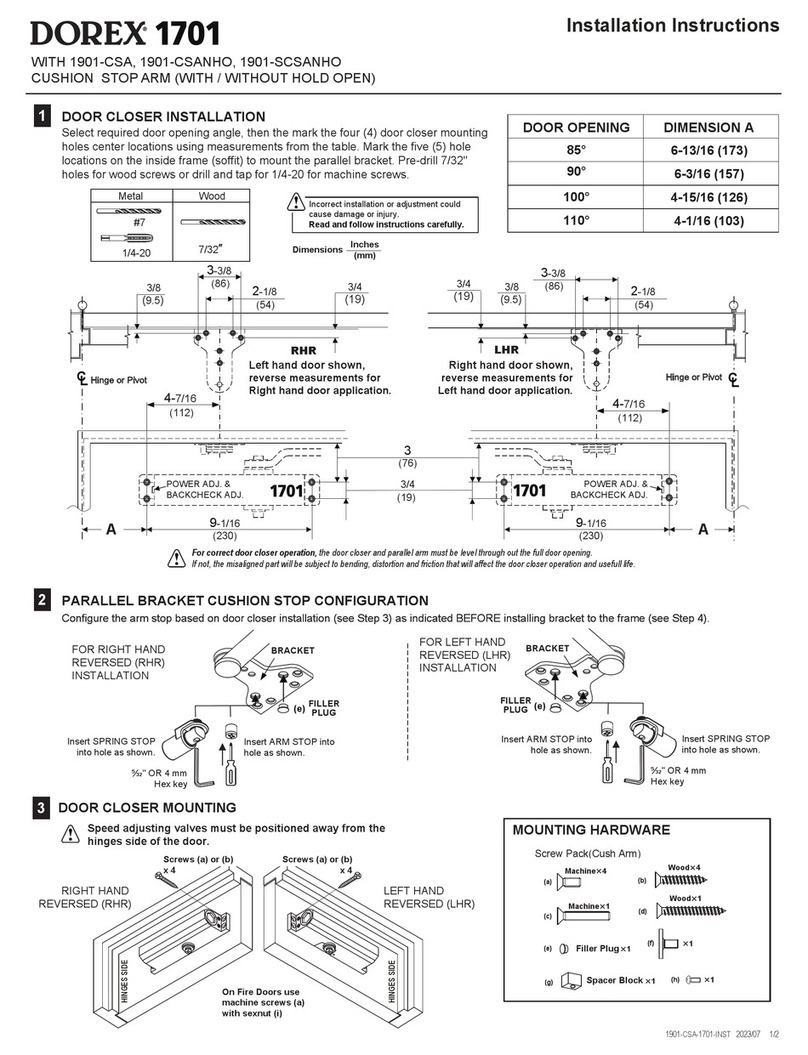

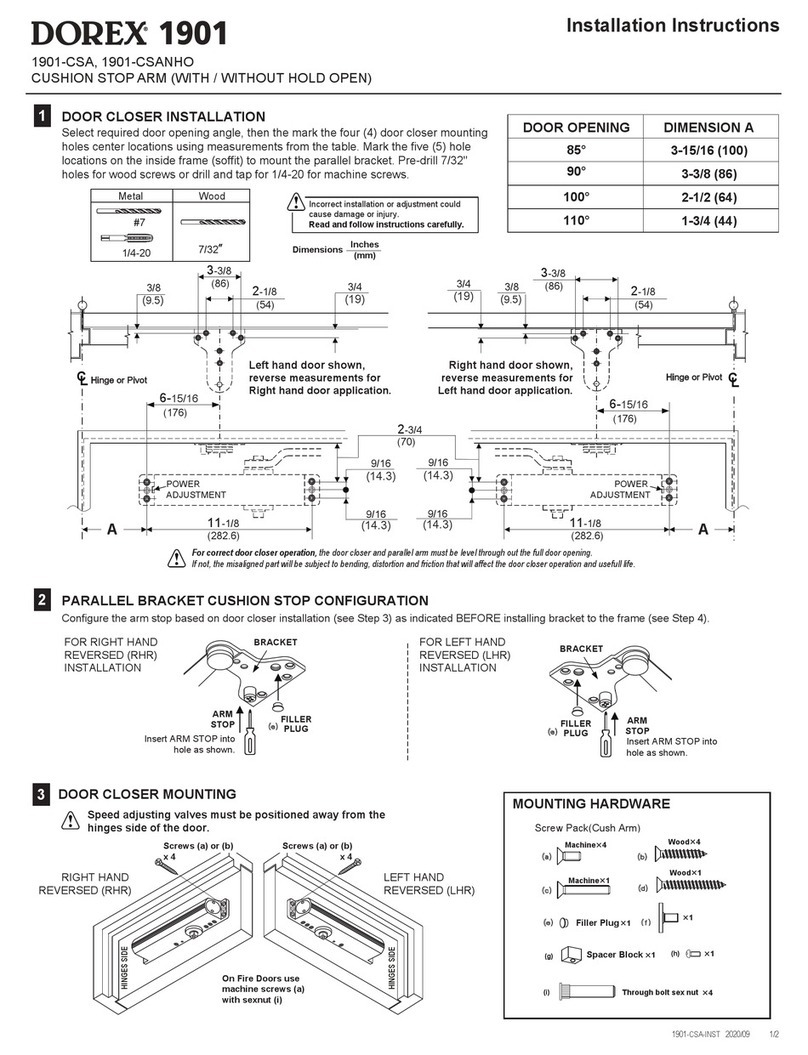

1. MARK AND DRILL ARM PLATE HOLES (Door opens to the outside, RH shown)

441 DOOR CLOSER INSTALLATION WITH ARM441E (Extra Duty Arm)

Locate the arm plate according to the required degree of door opening, using the table

below. Mark/drill/tap the 1/4-20 holes for the arm plate on the frame soffit and /or rabbet.

ARM441E-INST 2022-04

Left Hand Right Hand

DOOR HANDING

Outside

(Pull Side)

Outside

(Pull Side)

Inside

(Push Side)

Inside

(Push Side)

ARM PLATE

GENERAL NOTES

1. Consult installation instructions supplied with door closer

2. Hollow metal doors and hollow metal frames require reinforcement in the areas of the door closer and arm

plate mounting

3. Through bolts with sex nuts must be used in wooden Fire Door applications and on hollow metal doors with

no local reinforcement

4. Threaded holes in door or frame require a minimum 12 GA (0.110”) thickness

5. Indicated dimensions are based on industry standard door and frames with 1/8” (3 mm) clearance and 5/8”

(16 mm) stop height and properly leveled doors and frames.

6. Select the door closer and arm plate positions based on the door opening angle

7. If a drop plate is used, ensure door closer mounting screws do not protrude beyond the back surface of the

drop plate. Screws must engage a minimum of 3 threads inside the drop plate

8. For a door closer to operate properly, the arm must be positioned and operate horizontally and the door must

be supported on ball bearing hinges of sufficient size for the door used.

9. Perform a operational test on the door and adjust door closer as indication in the installation instructions

supplied with the door closer

For through bolt installations,

drill 9/32” hole through door on

the closer side and 3/8” hole on

the other side through door skin

for hollow metal doors. For wood

doors drill through 3/8” hole.