Yale Power Track Series User manual

Other Yale Door Opening System manuals

Yale

Yale 7110 User manual

Yale

Yale UNI Series User manual

Yale

Yale YM Series User manual

Yale

Yale YDC201 User manual

Yale

Yale 3000 Series User manual

Yale

Yale 7000 Series User manual

Yale

Yale PR3301 User manual

Yale

Yale UNOplus 3000 User manual

Yale

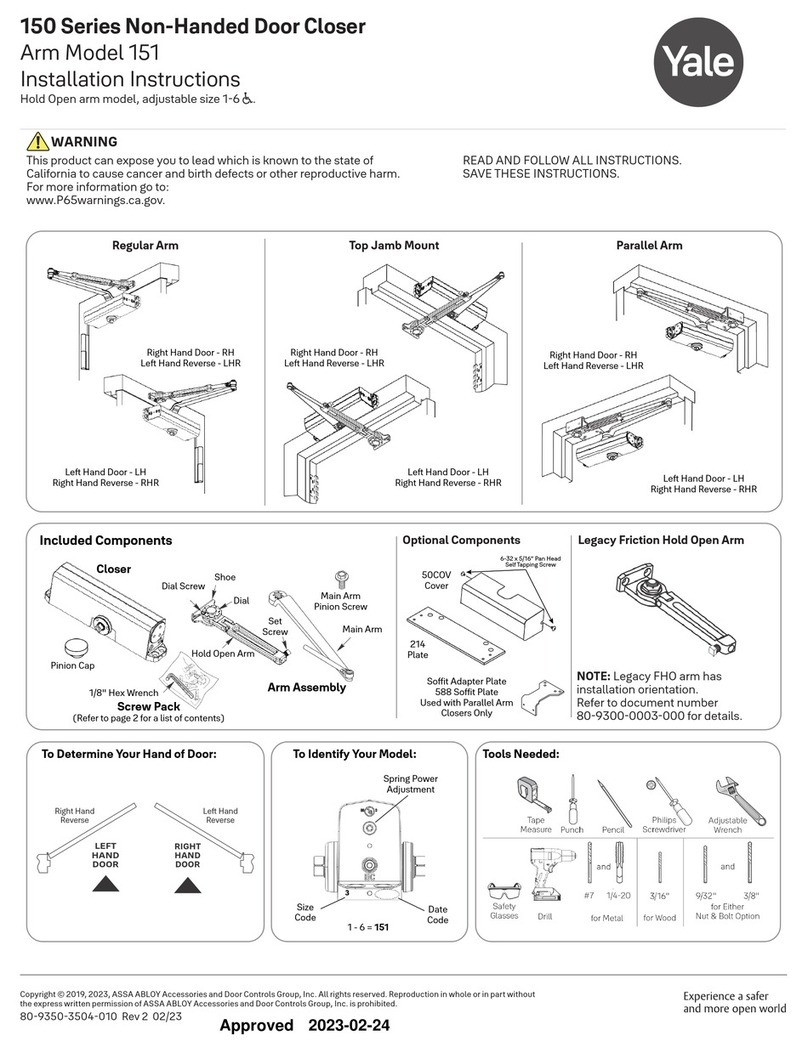

Yale 150 Series User manual

Yale

Yale Tri-Pack 51 User manual

Yale

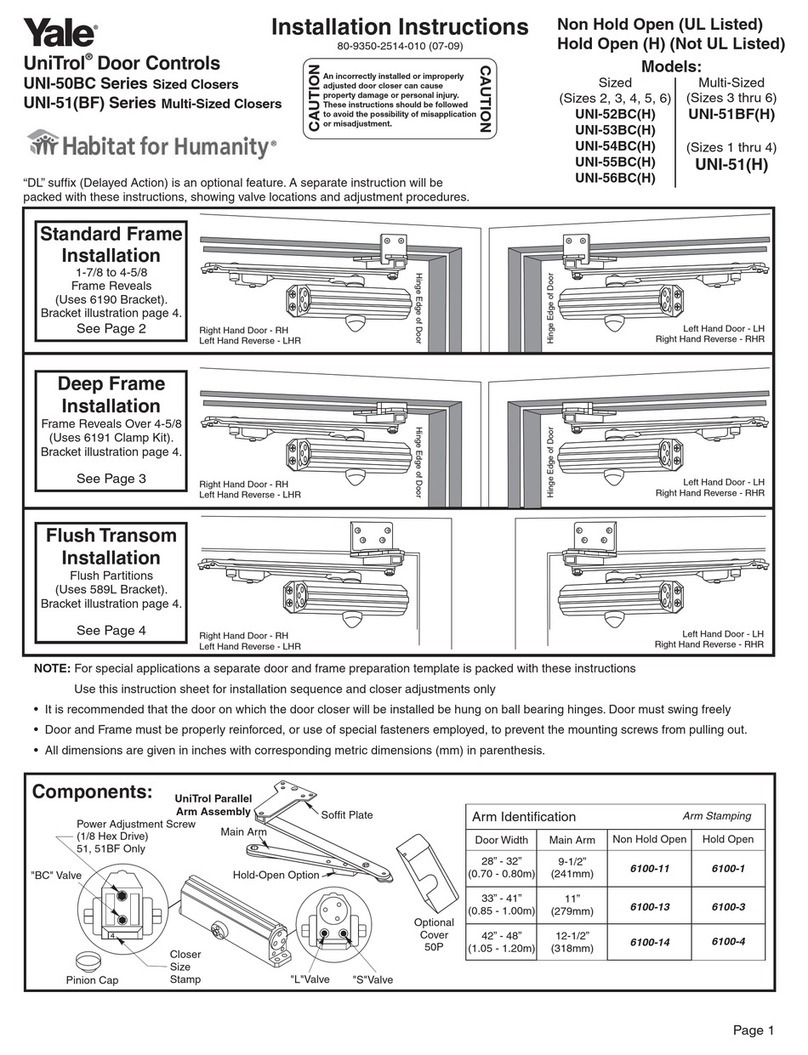

Yale UniTrol UNI-50BC Series User manual

Yale

Yale Tri-Pack 50 Series User manual

Yale

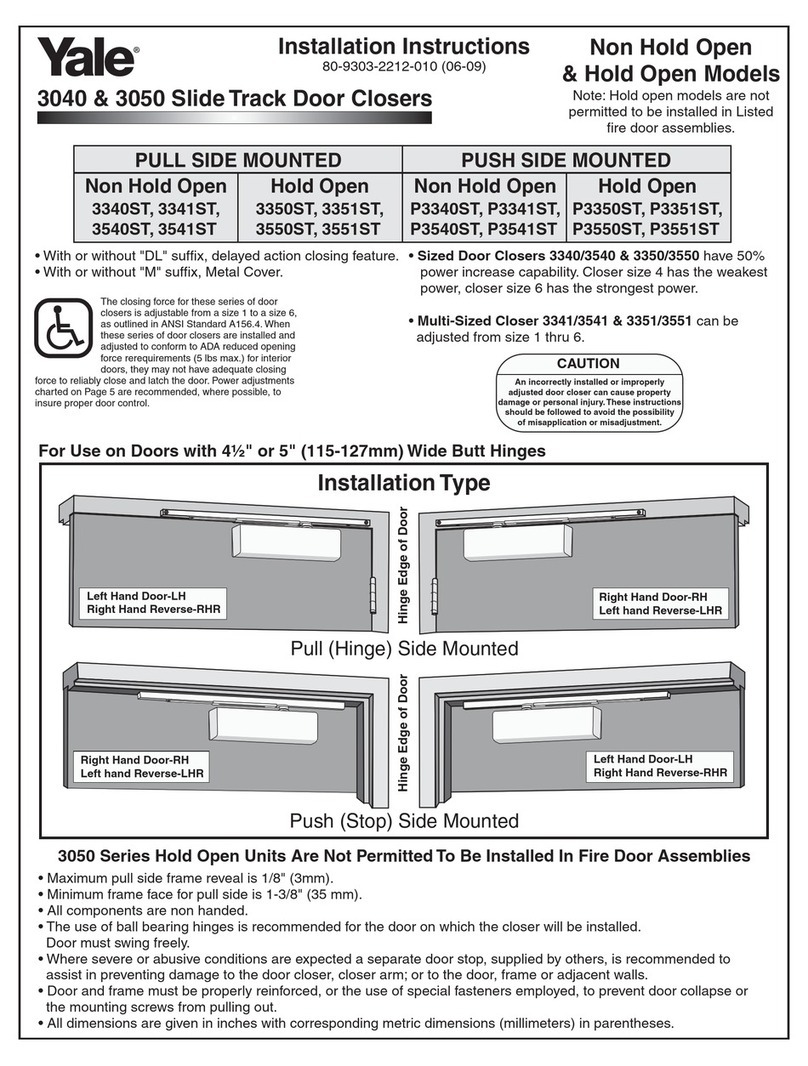

Yale 3040 User manual

Yale

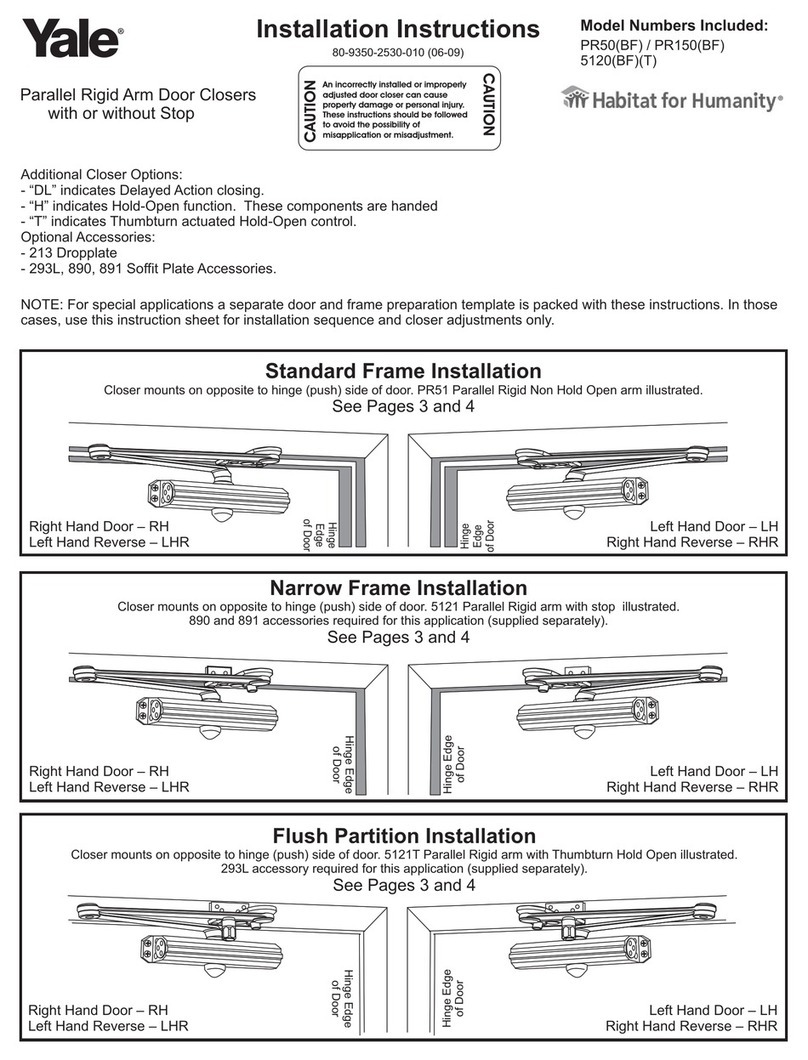

Yale PR50 User manual

Yale

Yale Delayed Egress 7100 Series User manual

Yale

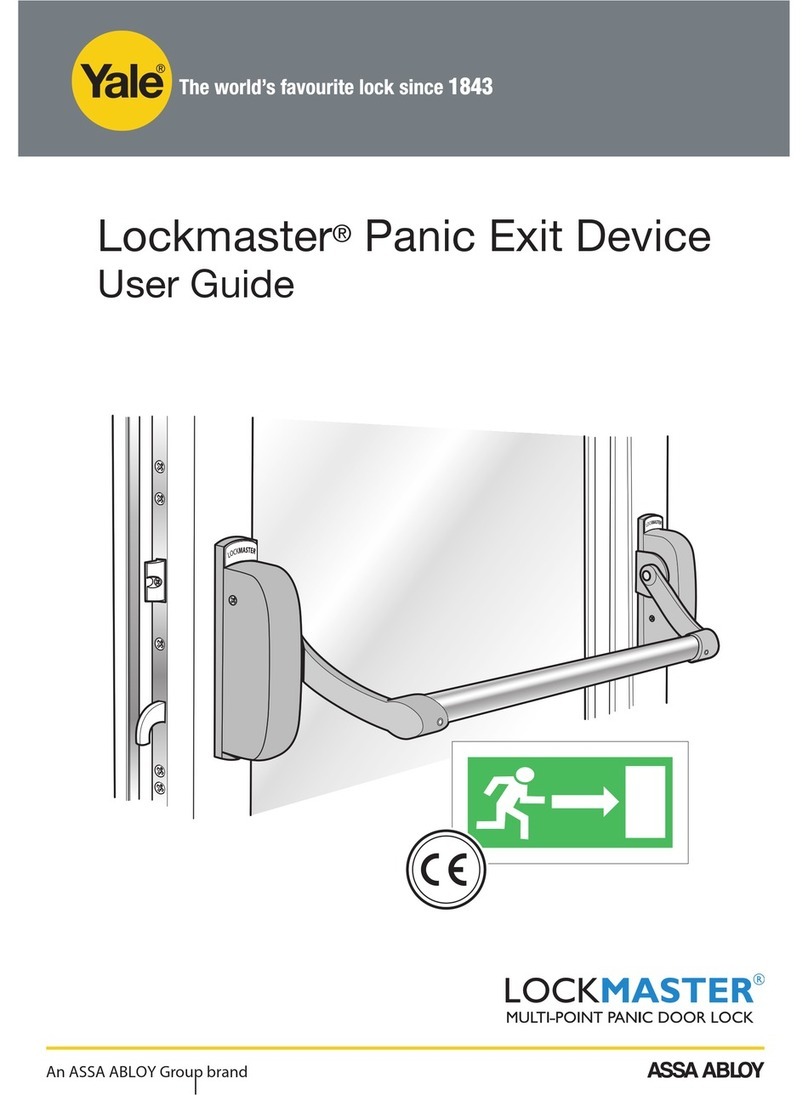

Yale Lockmaster PED1000 User manual

Yale

Yale YM Series User manual

Yale

Yale 2100 Series User manual

Yale

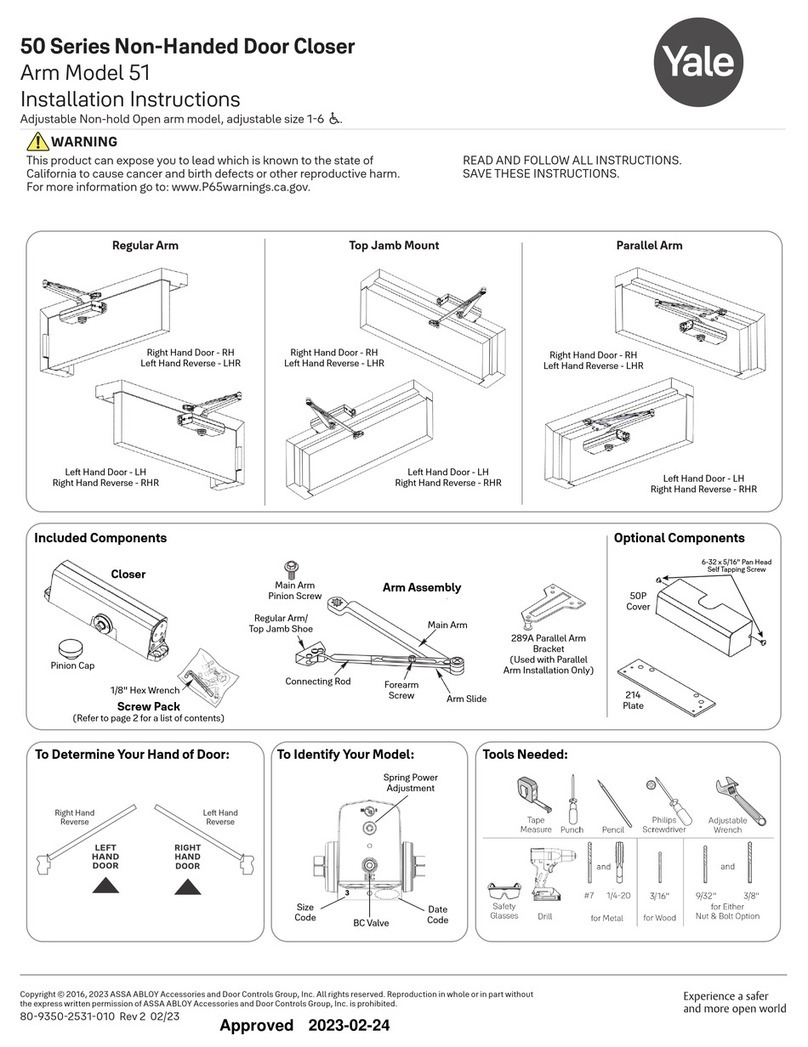

Yale 50 Series User manual

Yale

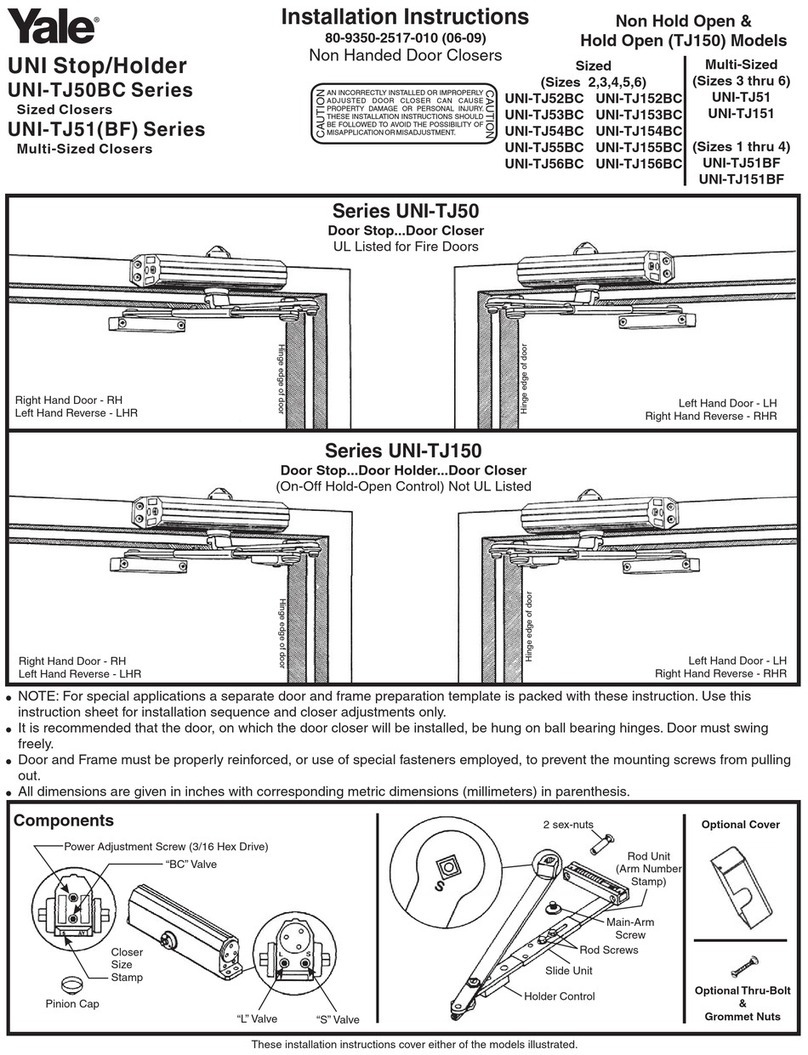

Yale UNI-TJ50BC Series User manual

Popular Door Opening System manuals by other brands

AGS

AGS D-PL Instructions for fitting, operating and maintenance

Stanley

Stanley MA900ñ Installation and owner's manual

WITTUR

WITTUR Hydra Plus UD300 Instruction handbook

Alutech

Alutech TR-3019-230E-ICU Assembly and operation manual

MPC

MPC ATD ACTUATOR 50 ATD-313186 Operating and OPERATING AND INSTALLATION Manual

GEZE

GEZE ECturn user manual