CNC4PC C25XP User manual

___________________________________________________________________________

User’s Manual Page i

USER’S

MANUAL

VER.1.5

C25XP- MULTIFUNCTION CNC BOARD

Rev. 1.1

AUGUST 2020

___________________________________________________________________________

User’s Manual Page ii

USER'S MANUAL TABLE OF CONTENTS

Contents Page #

1.0 FEATURES.....................................................................................................................1

2.0 I/O SPECIFICATIONS.....................................................................................................2

3.0 BOARD DESCRIPTION..................................................................................................3

4.0 POWER TERMINALS AND CONFIGURATION..............................................................4

4.1 Power terminal...........................................................................................................4

4.2 Source Output 5VDC.................................................................................................4

4.3 Source Output 10-30VDC..........................................................................................5

5.0 PORT_3 ESS..................................................................................................................5

6.0 E-STOP TERMINAL........................................................................................................6

7.0 CONFIGURATION JUMPERS........................................................................................6

7.1 Selecting the SCHP operation mode........................................................................6

7.2 Configuration jumper mode US or INT.....................................................................7

7.3 Configuration jumper pin 16 or 17............................................................................7

8.0 OUTPUT TERMINAL FOR GENERAL PURPOSE .........................................................8

9.0 INDICATORS LEDs........................................................................................................8

10.0 WIRING SAMPLE INPUT PORT_1 AND PORT_2..........................................................9

11.0 WIRING SAMPLE AXI ..................................................................................................10

12.0 WIRING SAMPLE VFD.................................................................................................11

13.0 DIMENSIONS................................................................................................................12

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 1

1.0 FEATURES

•Connects directly to the motion controller or parallel ports

•Built-in PWM-Based Speed Control and Two Built-in Electromechanical

Relays with NO and NC positions for spindle control.

•The system monitors:

-E-Stop

-Safety Charge Pump.

•Electromechanical Relay with NO and NC positions for general purpose

(Port_2 16 or 17, jumper-selectable).

•Microcontroller based SCHP.

•Optoisolated inputs working at 5-24VDC.

•Can be powered with a voltage between +10 and +30VDC.

•Status LEDs on all input and Output connections.

•DIN Rail mountable.

•Open Collector Outputs pins 1, 14, 16, 17.

•Screw-On connections for all terminals.

•Status LEDs for enable.

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 2

2.0 I/O SPECIFICATIONS

PINS

PORT1

PORT2

PORT3

TOTAL

INPUT

5

13

13

31

OUTPUT

12

4

4

20

TOTAL

17

17

17

51

OPTOISOLATED DIGITAL INPUT TTL SPECIFICATIONS

On-state voltage range

5 to 24VDC

Maximum off-state voltage

0.8V

Typical signal delay

2.8uS

DIGITAL OUTPUT TTL SPECIFICATIONS

Maximum output voltage

5VDC

Maximum output current

50mA

Maximum off-state voltage

0.44 V

Maximum supported frequency

400KHz

Typical signal delay

10nS

Time of transition to high impedance state

12 s*

OPEN COLLECTOR OUTPUT SPECIFICATIONS

Maximum output voltage

60VDC

Maximum output current

2A

Typical signal delay

0.5 µS

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 3

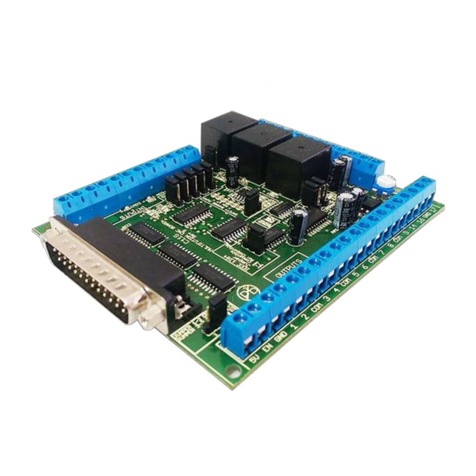

3.0 BOARD DESCRIPTION

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 4

4.0 POWER TERMINALS AND CONFIGURATION

4.1 Power terminal

Regulated +10VDC or +30VDC is required to power this board.

WARNING

Check the polarity and voltage of the external power source and connect the 10VDC to 30VDC

and GND. Overvoltage or reverse-polarity power applied to these terminals can cause damage

to the board, and/or the power source

4.2 Source Output 5VDC

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 5

4.3 Source Output 10-30VDC

10-30VDC can be sourced to sensors or other cards requiring it.

5.0 PORT_3 ESS

PORT_3 ESS

Pin

Function

P_1

OUTPUT

P_2

IN/OUT

P_3

IN/OUT

P_4

IN/OUT

P_5

IN/OUT

P_6

IN/OUT

P_7

IN/OUT

P_8

IN/OUT

P_9

IN/OUT

P_10

INPUT

P_11

INPUT

P_12

INPUT

P_13

INPUT

P_14

OUTPUT

P_15

INPUT

P_16

OUTPUT

P_17

OUTPUT

P_18/25

GND

P_26

5V

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 6

6.0 E-STOP TERMINAL

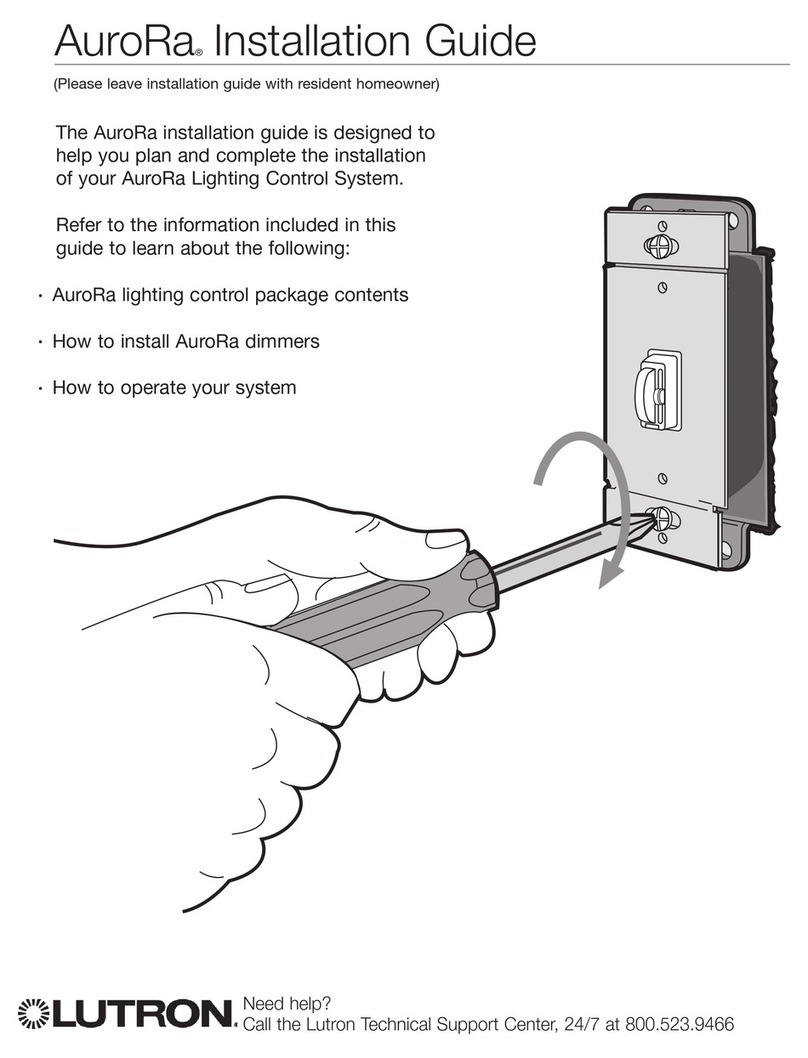

Connect an E-STOP push button as is shown in the below images.

Pin 10 port 1 is used for E-Stop. Since this board controls the enable line, and the

enable line is the one responsible for notifying the controller of the e-stop condition, the

user does not have a direct access to the pin itself, just to the e-stop terminal on the

board. The E-Stop terminal is tied to the enable line and will trigger the e-stop. A fault

or E-Stop triggers a low for 5 seconds to notify the controller of the fault condition, then

resets to high again

7.0 CONFIGURATION JUMPERS

7.1 Selecting the SCHP operation mode

The Safety Charge Pump can be activated or deactivated depending on the jumper position

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 7

7.2 Configuration jumper mode US or INT

7.3 Configuration jumper pin 16 or 17

For the Variable speed control go to

http://cnc4pc.com/Tech_Docs/VARIABLE_SPEED_CONTROL.pdf

For Configure the control software go to

http://cnc4pc.com/Tech_Docs/CONFIGURATION_OF_CONTROL_SOFWARE.pdf

For Replacing Potentiometer go to

http://cnc4pc.com/Tech_Docs/Replacing%20a%20Potentiometer.pdf

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 8

8.0 OUTPUT TERMINAL FOR GENERAL PURPOSE

Theses output are Open Collector

In this terminal can be connected relay, led or lamps, alarm, etc.

9.0 INDICATORS LEDs

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 9

10.0 WIRING SAMPLE INPUT PORT_1 AND PORT_2

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 10

11.0 WIRING SAMPLE AXI

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 11

12.0 WIRING SAMPLE VFD

____________________________________________________________________________

___________________________________________________________________________

User’s Manual Page 12

13.0 DIMENSIONS

All dimensions are in Millimeters.

Disclaimer:

Use caution. CNC machines can be dangerous machines. Neither DUNCAN USA, LLC

nor Arturo Duncan are liable for any accidents resulting from the improper use of these

devices. This product is not a fail-safe device and it should not be used in life support

systems or in other devices where its failure or possible erratic operation could cause

property damage, bodily injury or loss of life.

Other manuals for C25XP

1

This manual suits for next models

1

Table of contents

Other CNC4PC Control System manuals