2

INDEX

1 - INTRODUCTION...............................................................................................................................................................3

1.1 - Technical data............................................................................................................................................3

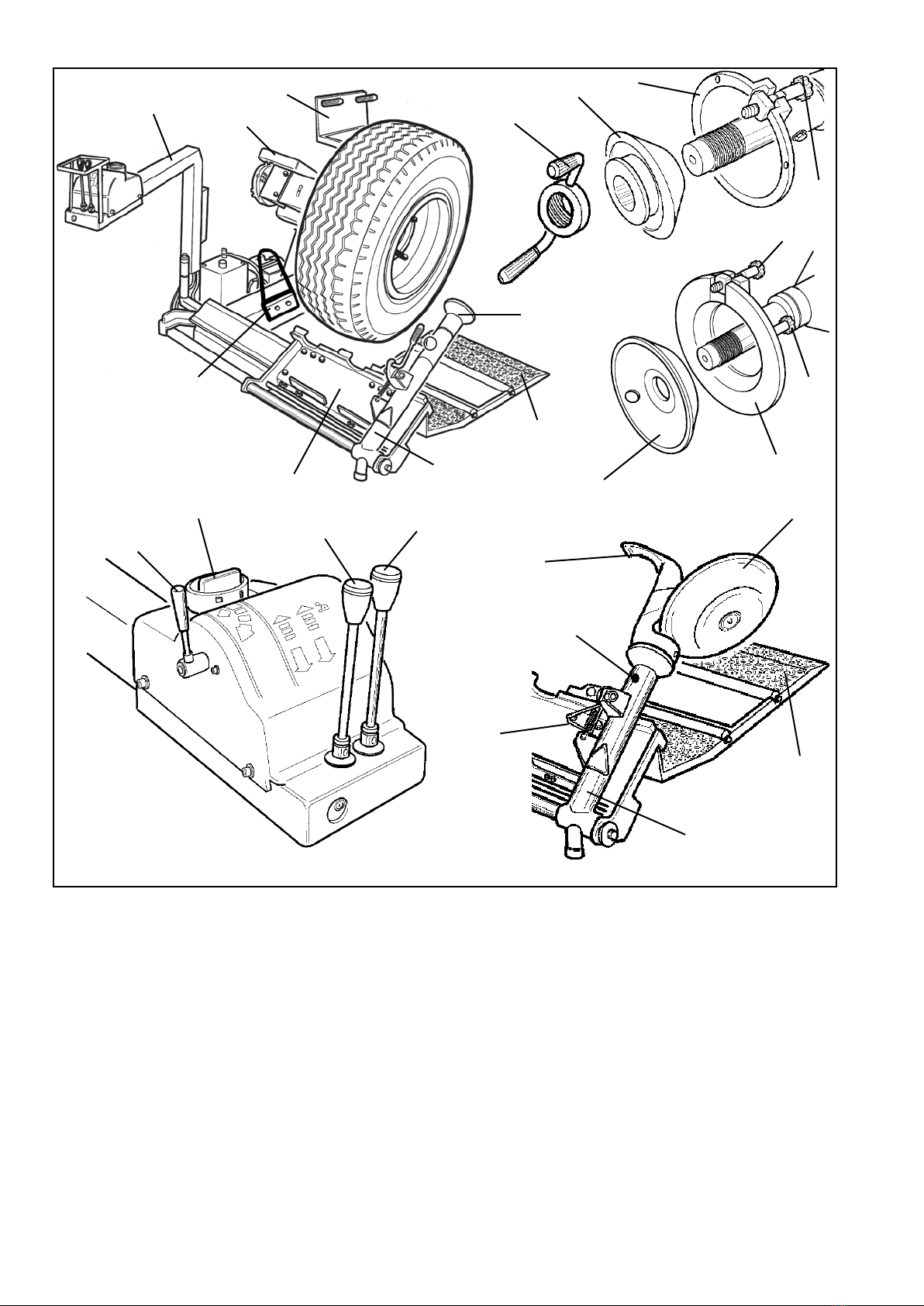

2 - DESCRIPTION OF THE MACHINE....................................................................................................................................4

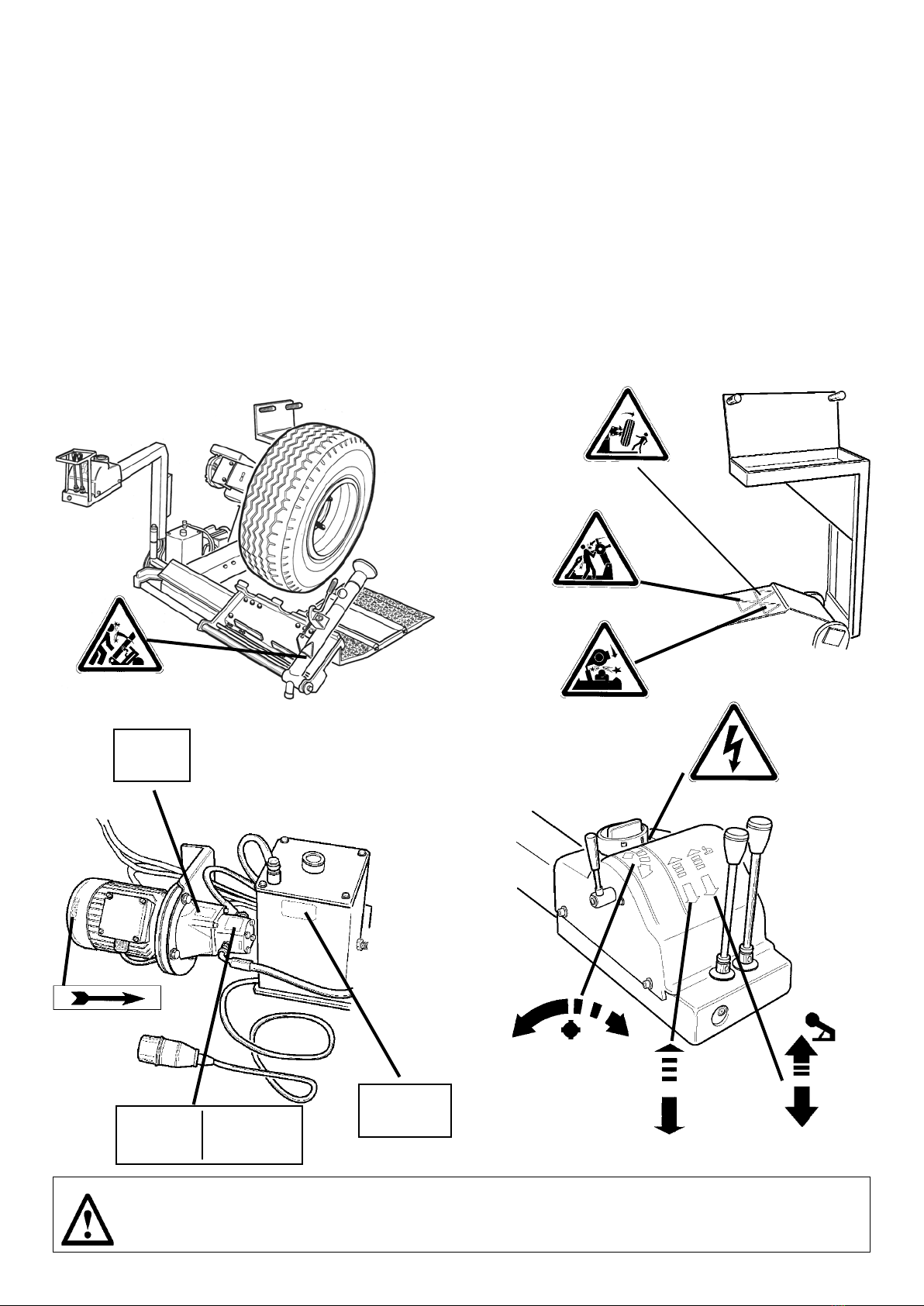

3 - GENERAL ........................................................................................................................................................................5

3.1 - General safety rules...................................................................................................................................5

4 - TRANSPORT.....................................................................................................................................................................6

5 - UNPACKING...................................................................................................................................................................6

6 - INSTALLATION ................................................................................................................................................................7

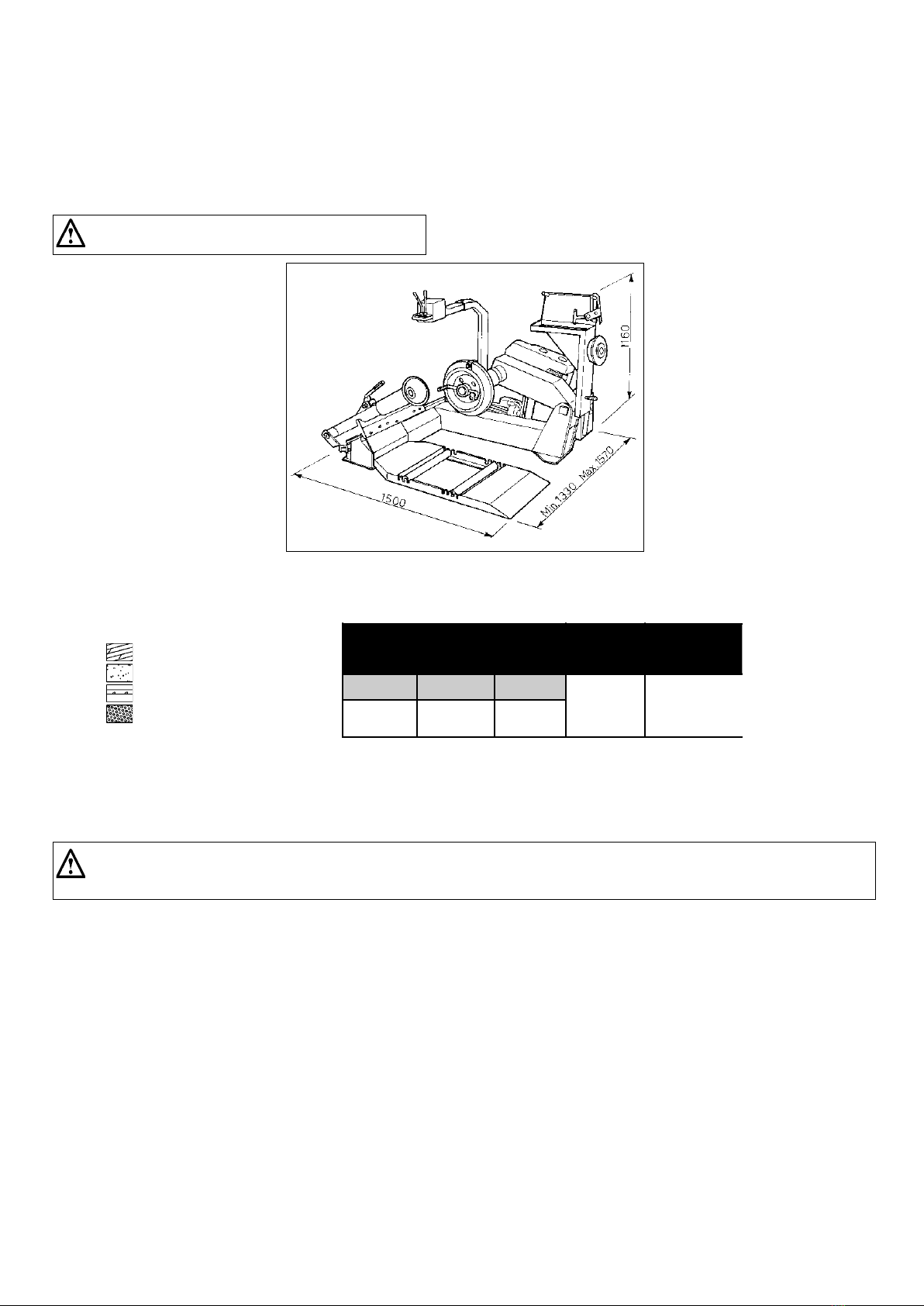

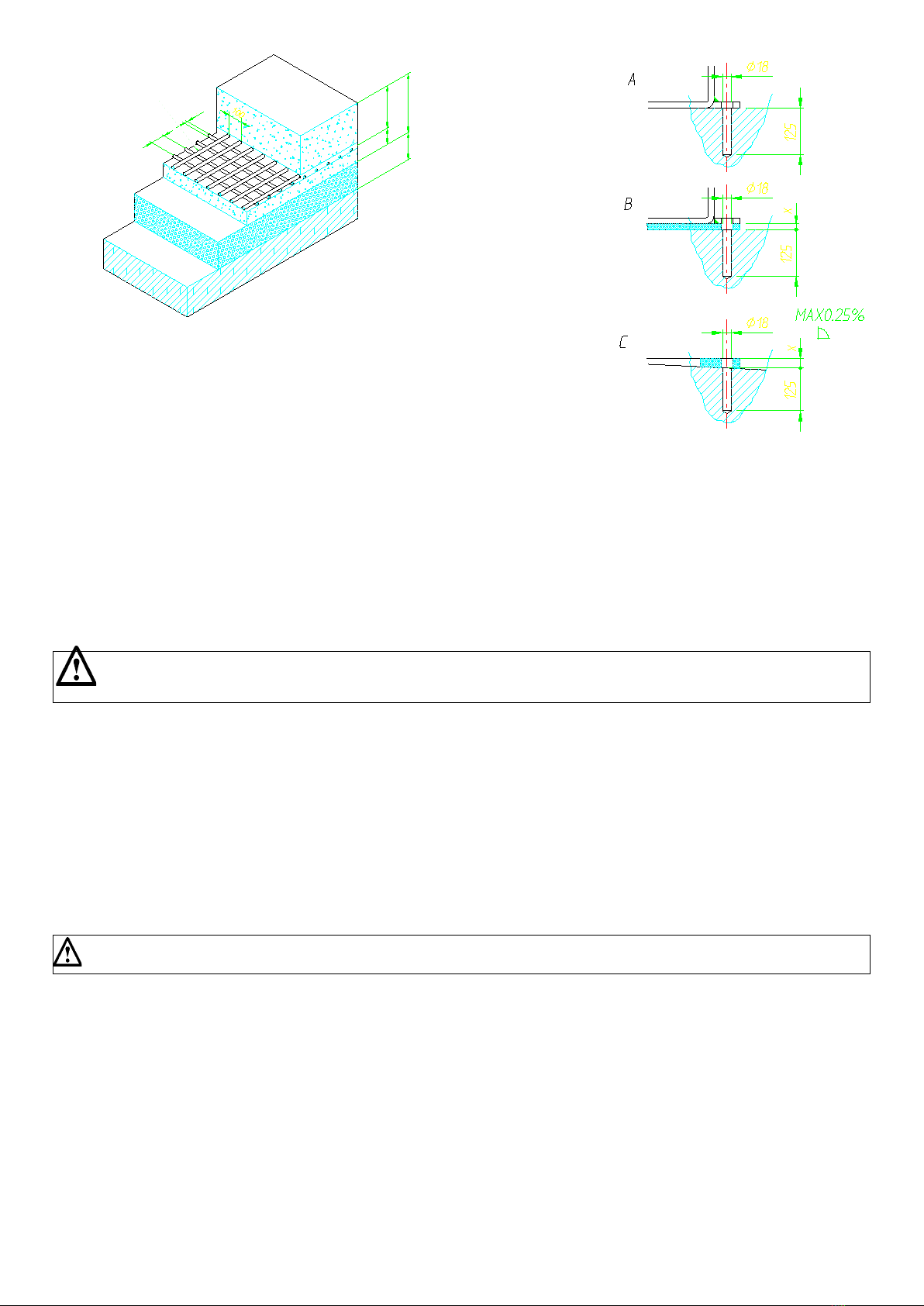

6.1 Installation site....................................................................................................................................................................................7

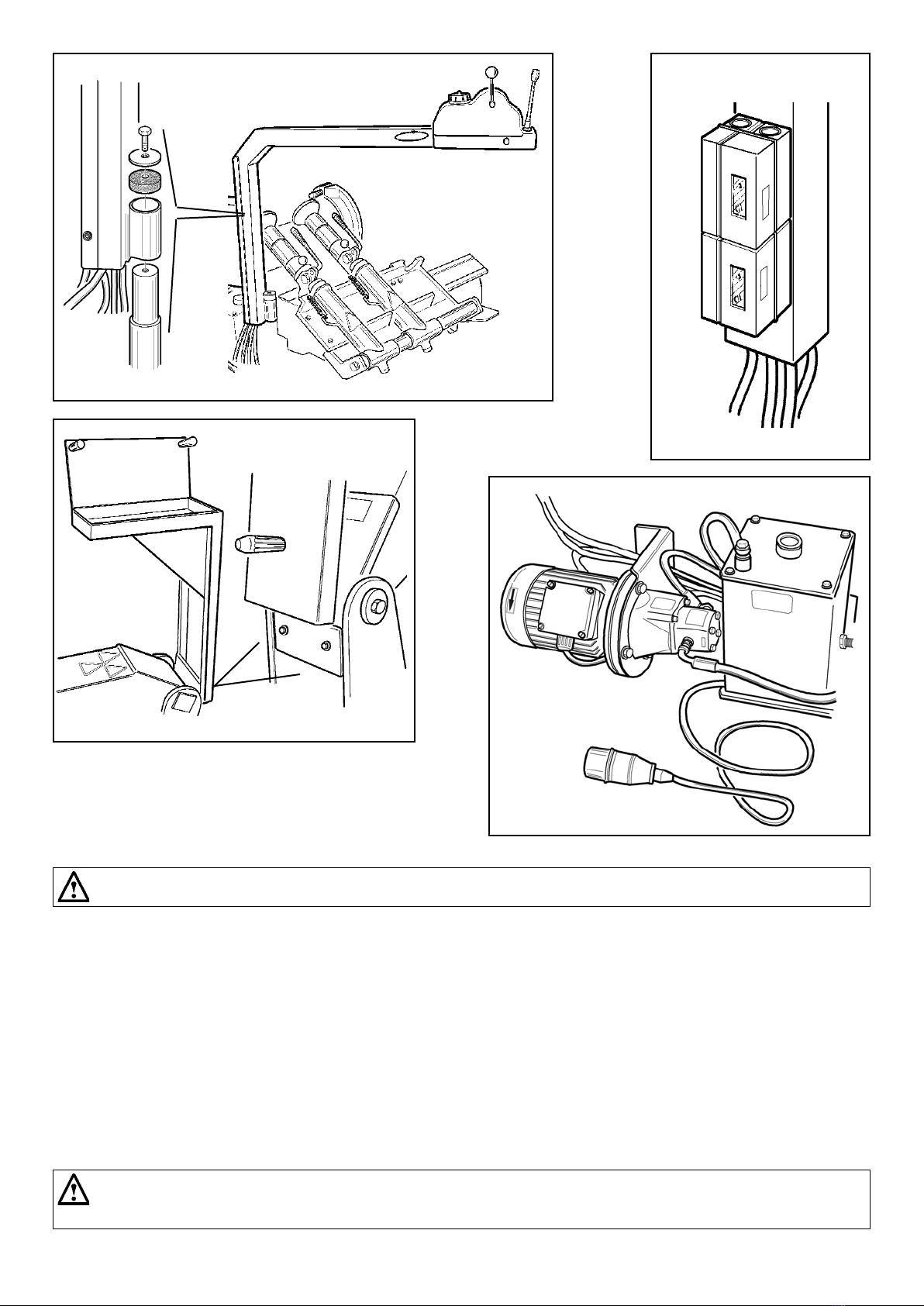

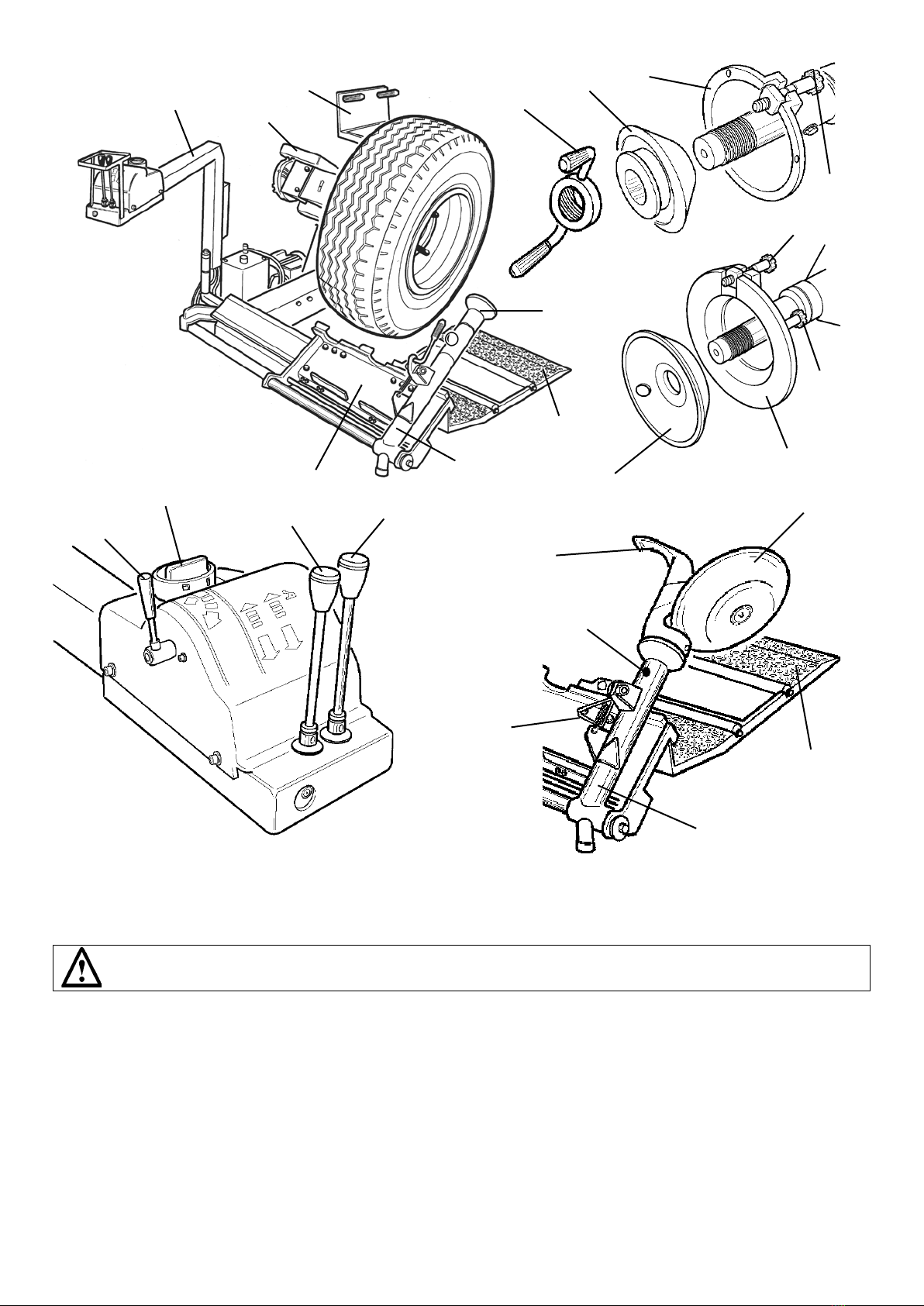

6.2 Parts assembling................................................................................................................................................................................7

6.3 Electrical connection.......................................................................................................................................................................8

6.4 Operation test...................................................................................................................................................................................9

7 - OPERATION.....................................................................................................................................................................10

7.1 Notes for operation...........................................................................................................................................................................10

7.2 Rim clamping.....................................................................................................................................................................................11

7.3 Tubeless tires.......................................................................................................................................................................................12

7.3.1 Bead loosening and demounting with ROLLER TOOL.......................................................................................................12

7.3.2 Bead loosening and demounting with DOUBLE ROLLER TOOL.......................................................................................12

7.3.3 loosening and demounting with DOUBLE TOOL................................................................................................................13

7.3.4Tire mounting with ROLLER TOOL.....................................................................................................................................14

7.3.5 Tire mounting with DOUBLE TOOL.....................................................................................................................................16

7.4 Tube tires............................................................................................................................................................................................18

7.4.1 Bead breaking and tyre removing with DOUBLE TOOL.....................................................................................................18

7.4.2 Tire mounting with DOUBLE TOOL....................................................................................................................................19

7.5 Tire assembly with 3 pieces split ring..................................................................................................................................................21

7.5.1 Bead loosening and demounting with DOUBLE TOOL.......................................................................................................21

7.5.2 Tire mounting with DOUBLE TOOL....................................................................................................................................22

7.6 Tire assembly 5 pieces split ring.........................................................................................................................................................23

7.6.1 Bead breaking and demounting with DOUBLE TOOL........................................................................................................23

7.6.2 Tire mounting with DOUBLE TOOL....................................................................................................................................24

8 - RESITING........................................................................................................................................................................25

9 - STORING........................................................................................................................................................................25

10 - SCRAPPING.................................................................................................................................................................25

11- OIL TREATMENT.............................................................................................................................................................26

12 - FIRE FIGHTING MEANS.................................................................................................................................................26

13 - ORDINARY MAINTENANCE.........................................................................................................................................26

14 - IDENTIFICATION OF THE TIRE CHANGER....................................................................................................................27

15 - ACCESSORIES.............................................................................................................................................................28

ELECTRIC DIAGRAM...........................................................................................................................................................29