ENGLISH

8

Common problems

1. Grainy paint. This happens when thepaint is too thick. Carefully thin thepaint.

Make sure theneedle and adjustment screw are free from dried paint. Also check

theair pressure.

2. Bubbles arise on thepaper. Thepaint is probably too thin. Do not spray too long

over thesame spot. Move theairbrush faster or weaken thestream.

3. Blotches at theend of thesweep. Begin spraying before beginning thesweep and end

thesweep before stopping thespray.

4. Flared ends. Caused by turning thewrist while sweeping. Your entire arm must

sweep horizontally across thepaper.

5. Spidery splashes. You are spraying too much and too close. When you want to

spray fine lines, pull thelever back only slightly.

6. Splashing. This happens when theneedle slides too quickly into thenozzle. Always

operate thenozzle slowly, feeling your way forward. Make sure there is no dried paint

on theneedle or nozzle.

7. Curved line. This happens when making thesweep with your arm too close to thepaper.

Always hold your arm thesame distance from thework surface to avoid this.

8. No stream. Thenozzle may be tightened too much. Loosen 1–2 turns.

9. Bubbles in thepaint reservoir. Thenozzle may be open too much. Tighten it

somewhat. Another cause may be aclogged siphon.

10. Thestream will not shut off. Thenozzle may be clogged. This is evident when

theneedle feels spongy when moving it forward. Clean thenozzle carefully and

flush it with solvent (see Cleaning and care).

11. Theairbrush spits. This is caused by deposits on theneedle or in thepaint

reservoir. Alternatively, thepaint may be too thick.

Remarks from the manufacturer

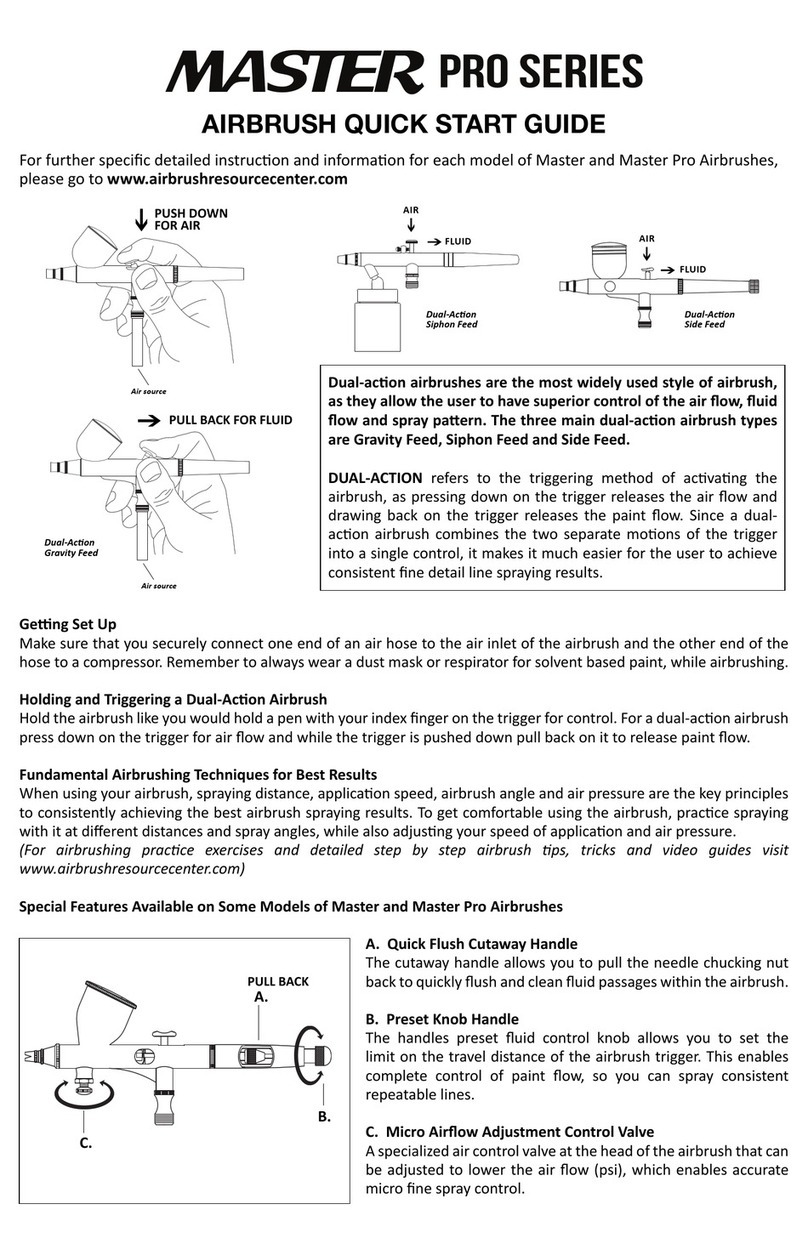

Nozzle Needle

O-ring

AnO-ring on theback of thenozzle eliminates theneed

to wax thethread there. Normal wear, solvents or other

damage may eventually allow air to leak in thus resulting

in apulsating stream. Replace thepacking.

Disposal

Follow local ordinances when disposing of this product.

If you are unsure about how to dispose of this product contact your municipality.