6

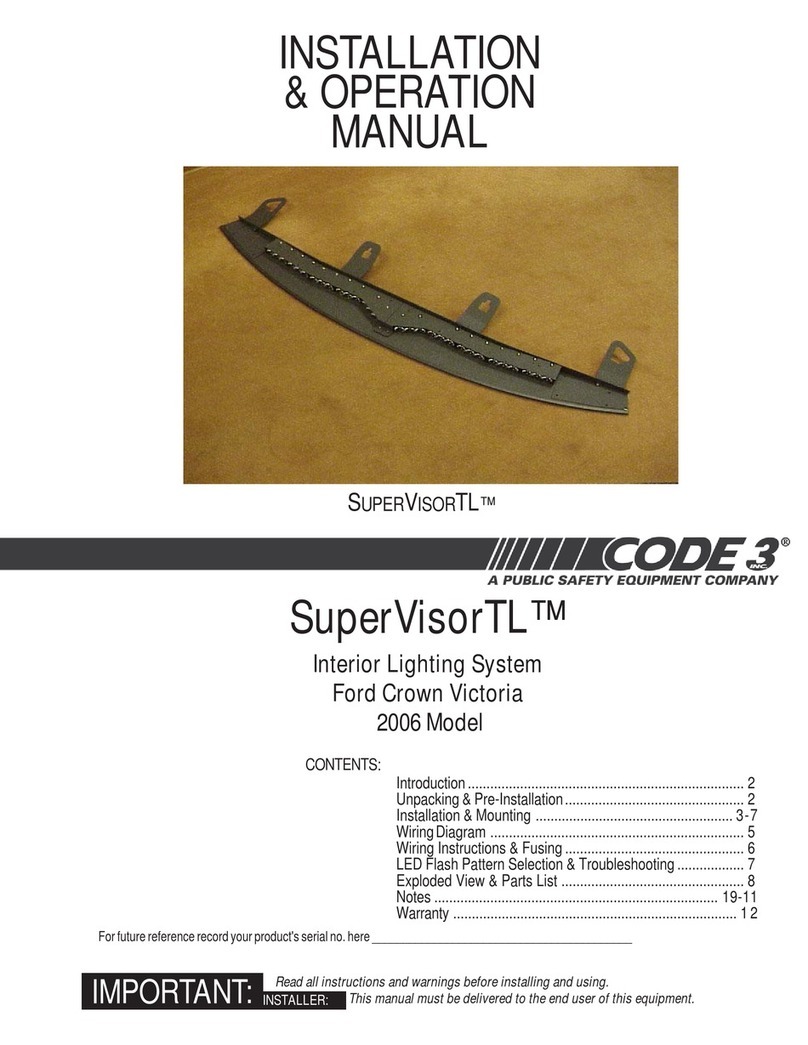

FIGURE 4

Oncethelightbarislevelandcentered,marktheholesthroughthemountingtabsandremovethelightbarfromthevehicle.

Makesurethatthedrillwillnotdamageanythingwhenpenetratingtheroof. Drillthe mountingholesandremoveanyburrs.

Attachmentcanbemadeusing1/4"capscrews,togglebolts,orotherfastenersasmaybeconvenient. Usesealantas

necessarytopreventwaterleakageintothevehicle.

Wiring Instructions

Largerwiresandtightconnectionswillprovidelongerservicelifeforcomponents. Forhighcurrentwiresitis

highlyrecommendedthatterminalblocksorsolderedconnectionsbeusedwithshrinktubingtoprotectthe

connections. Donotuseinsulationdisplacement connectors(e.g.3M®Scotchlocktypeconnectors). Route

wiringusinggrommetsandsealantwhenpassingthroughcompartmentwalls. Minimizethenumberofsplicesto

reducevoltagedrop. Highambienttemperatures(e.g.underhood)willsignificantlyreduce thecurrentcarrying

capacityofwires,fuses,andcircuitbreakers. Use"SXL"typewireinenginecompartment. Allwiringshould

conformtotheminimumwiresizeandotherrecommendationsofthemanufacturerandbeprotectedfrommoving

partsandhot surfaces. Looms,grommets,cableties,andsimilarinstallationhardwareshouldbeusedto

anchorandprotectallwiring. Fusesorcircuitbreakersshouldbelocatedasclosetothepowertakeoffpointsas

possibleandproperlysizedtoprotectthewiringanddevices. Particularattentionshouldbepaidtothelocation

andmethodofmakingelectricalconnectionsandsplicestoprotectthesepointsfromcorrosionandlossof

conductivity. Groundterminationsshouldonlybemadetosubstantialchassiscomponents,preferablydirectlyto

thevehiclebattery. Theusershouldinstallafusesizedtoapproximately125%ofthemaximumAmpcapacityin

thesupplylinetoprotectagainstshortcircuits. Forexample,a30Ampfuseshouldcarryamaximumof24

Amps. DONOTUSE1/4"DIAMETERGLASSFUSESASTHEYARENOTSUITABLEFORCONTINUOUS

DUTYINSIZESABOVE15AMPS. Circuitbreakersareverysensitivetohightemperaturesandwill"falsetrip"

whenmountedinhot environmentsoroperatedclosetotheircapacity.

WARNING!

!

Before attempting to connect wiring refer to wire tag attached to the lightbar's main cable. Each wire in the cable controls

a separate lightbar function as described in the wire tag.

The only significant difference between the CODE360® with optional ArrowStik® and a conventional CODE360, is the

additional, thinner cable exiting the bottom of the lightbar. The larger cable is the lightbar power cable. Route the wiring

cable into the engine or passenger compartment, taking care to use grommets and to apply sealant around openings to

keep water out. It is advisable to leave an extra loop of cable when installing the light bar to allow for future changes

or reinstallations. Connect the black lead to a solid frame ground(earth), preferably, the(-) or ground(earth) side of the

battery and bring the other wires to the control head or switches. Connect the wires as directed by the wiring

instructions on the cable.

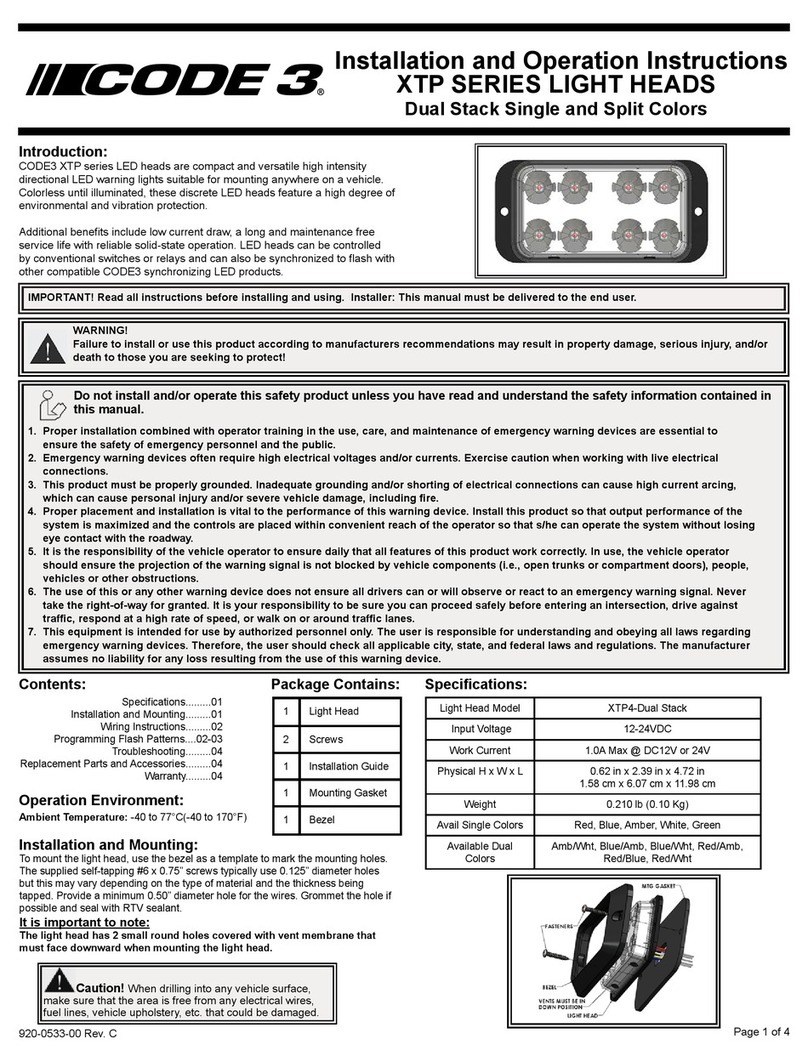

CurvedRoof

FlatRoof

PlaceFeeton

CurvedPortion