2. PULL WIRING

IMPORTANT:

1. DECK

FOUNDATION

Drill a fifth hole in the center to accommodate the conduit.

To prevent tampering, it is advisable to tack weld the

lower nuts to the threaded rod.

Drill four holes through the deck or floor for the four

3/4” threaded rods. The holes should be aligned, using

the tem- plate provided in such a way that the phone

faceplate on the unit will face in the desired direction.

Position the second plate working from below the deck.

Have another worker hold the upper plate and rods in place

from above the deck.

1.4.1 Place the second plate gasket and then the second

plate over the threaded rods.

1.4.2 Secure the second plate with nuts and washers pro-

vided. If required, readjust the nuts so that six inches of the

rods are above the top of the upper plate.

A minimum of two feet of wire must be available from the

conduit for electrical and communications wiring.

Position the first plate working from above the deck.

1.3.1 Thread a nut and washer on the end of each rod so

that approximately six inches extends beyond the base of

the washer.

1.3.2 Insert each rod through the top side of the plate, plate

gasket, and down through the four holes in the deck.

Electrical and telephone line conduit is run through the deck

and the center openings (two-inch diameter) of the upper and

lower deck plates. A minimum of four inches and a maximum of

six inches of conduit above the upper plate is required.

Deck Mount Kit Instructions

2.2 Conduit

1.1 Drill Deck Holes

1.2 Drill Conduit Hole

1.5 Secure Lower Nuts

1.3 Position Upper Deck Plate

1.4 Position Lower Deck Plate

2.1 Pull Power and Phone Line up through Conduits

NOTE: The top of the plate is the side with the tapered edge.

Wire gauge must be selected to meet code for voltage/current required for the product to

operate correctly: Minimum 14 AWG. Conduit used must comply to National Electrical Standards as

ob- served locally.

NOTE: Communications wire must be shielded phone line. The phone line must be pulled into the unit using

a separate conduit from the power. Along with a service loop of wire, as noted by the NEC standards.

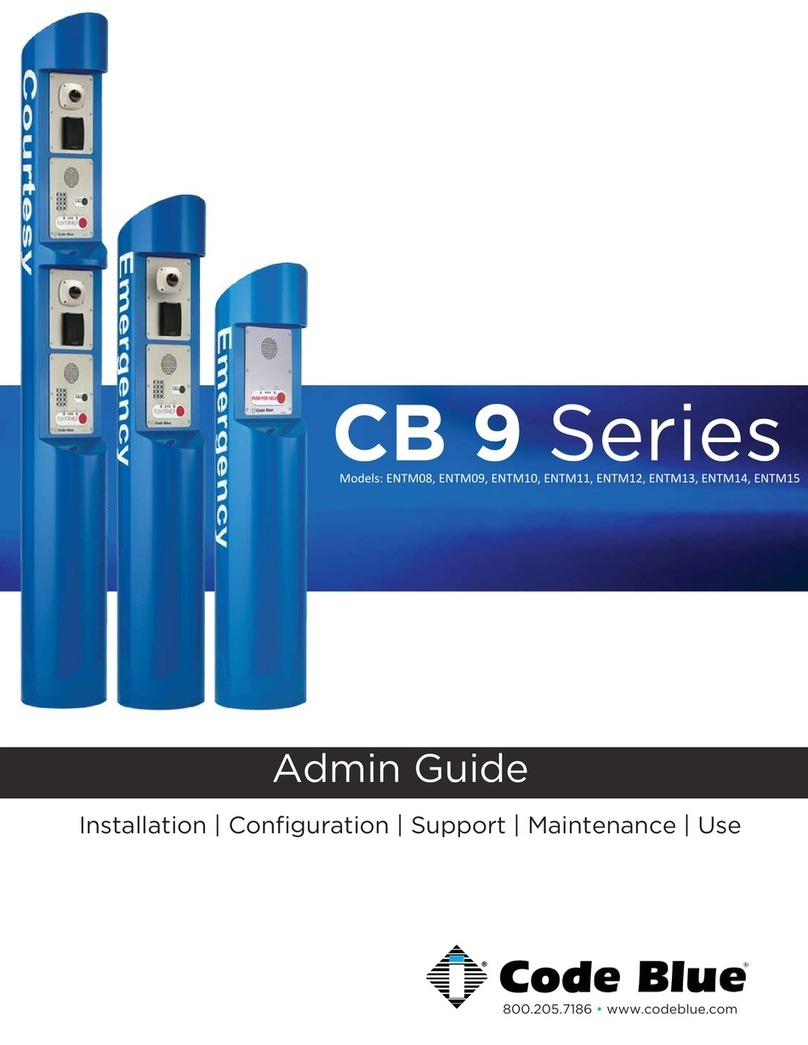

CB 1 Series

Administrator Guide

GU-157-FF

SKIP if installation does not include a Deck Mount Kit

page 10 of 31

Code Blue • 259 Hedcor Street • Holland, MI 49423 USA • 800.205.7186 • www.codeblue.com