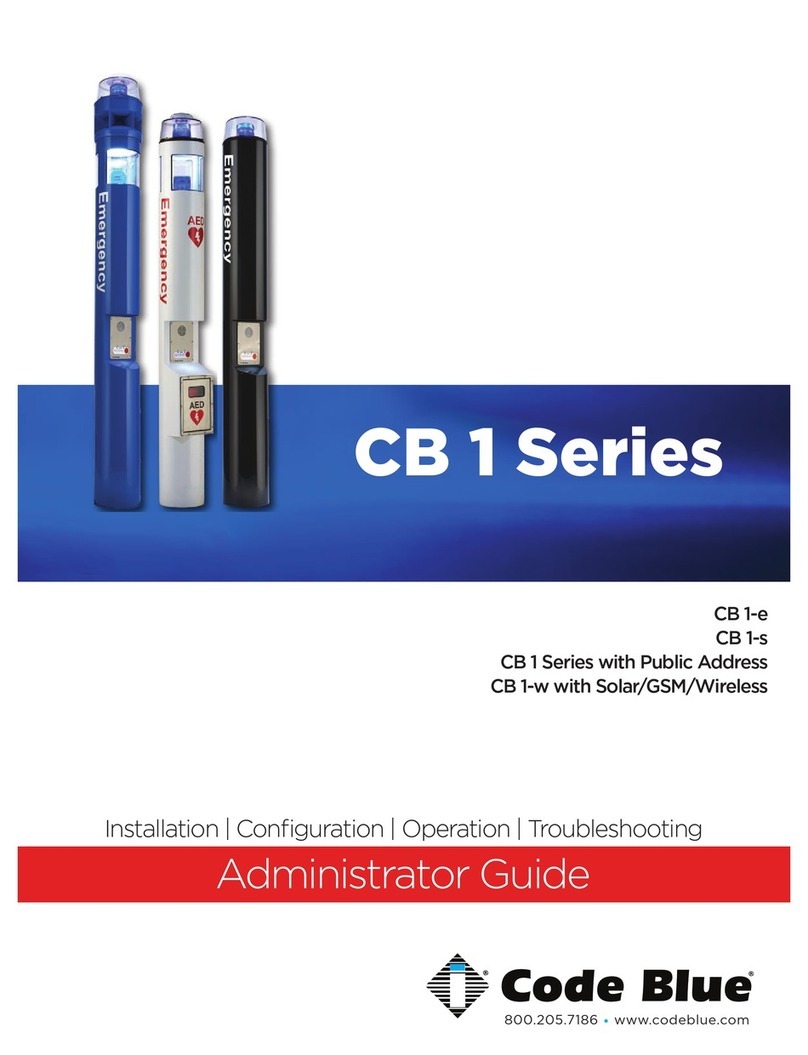

page 10 of 35 GU-158-O

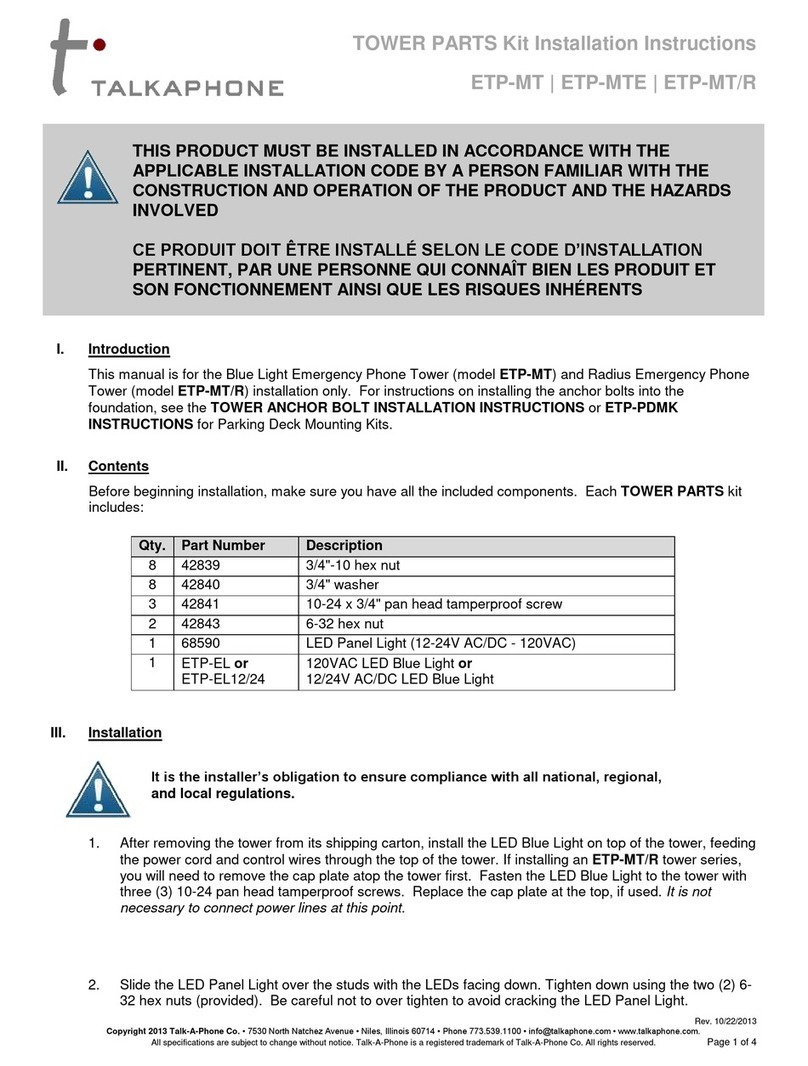

1.0 DECK MOUNT FOUNDATION

2.0 WIRING

2.1 Pull power and phone line through conduits – A minimum of two feet of wire

must be available from the conduit for electrical and communications wiring.

2.2 Conduit – Electrical and telephone line conduit is run through the deck and the

center openings (two inch diameter) of the upper and lower deck plates. A

minimum of four inches and a maximum of six inches of conduit above the upper

plate are required.

1.1 Drill Deck Holes– Drill three holes through the deck or floor for the three 3/4”

threaded rods. The holes should be aligned, using the template provided, so the

phone faceplate on the unit will face in the desired direction (see figure below). Drill

a fourth hole in the center to accommodate the conduit.

1.2 Position Upper Deck Plate – Position the first plate working from above the

deck. Thread a nut and washer on the end of each rod so that approximately six

inches extends beyond the base of the washer. Insert each rod through the top side

of the plate, plate gasket, and down through the three holes in the deck. (NOTE:

The top of the plate is the side with the tapered edge.)

1.3 Position Lower Deck Plate – Position the second plate working from below the

deck. Have another worker hold the upper plate and rods in place from above the

deck. Place the second plate gasket and then the second plate over the threaded

rods. Secure the second plate with nuts and washers provided. If required, readjust

the nuts so that six inches of the rods are above the top of the upper plate. (see

figure below)

1.4 Secure Lower Nuts – To prevent tampering, it is advisable to tack weld the lower

nuts to the threaded rod.

B B

3/4" THREADED ROD OF SUFFICENT

LENGTH TO PASS THROUGH DECK

AND ALLOW A MINIMUM OF 6”

ABOVE THE TOP DECK PLATE.

PHONE

FACEPLATE

DIRECTION

CB V Base

ALLOW

1/2" GAP FOR

VENTING

Ø14.00

DECK PLATE

Ø6.00

BOLT CIRCLE

ELECTRICAL

AND TELEPHONE

LINE CONDUIT

6.00

All wiring must be installed and connected by experienced and certified personnel to meet

local and national electrical codes, and will include a service disconnect.

Code Blue • 259 Hedcor Street • Holland, MI 49423 USA • 800.205.7186 • www.codeblue.com

Administrator Guide

CB 5 Series

Deck Mount Kit Installation Instructions

SKIP if installation does not include a Deck Mount Kit