IM ORTANT The Anti- anic Mortice Lock has features

which are not found in most other locks and so it is

recommended that you familiarise yourself with them.

The hand of the latchbolt is changed by removing the three

screws holding the faceplate and reversing the latchbolt.

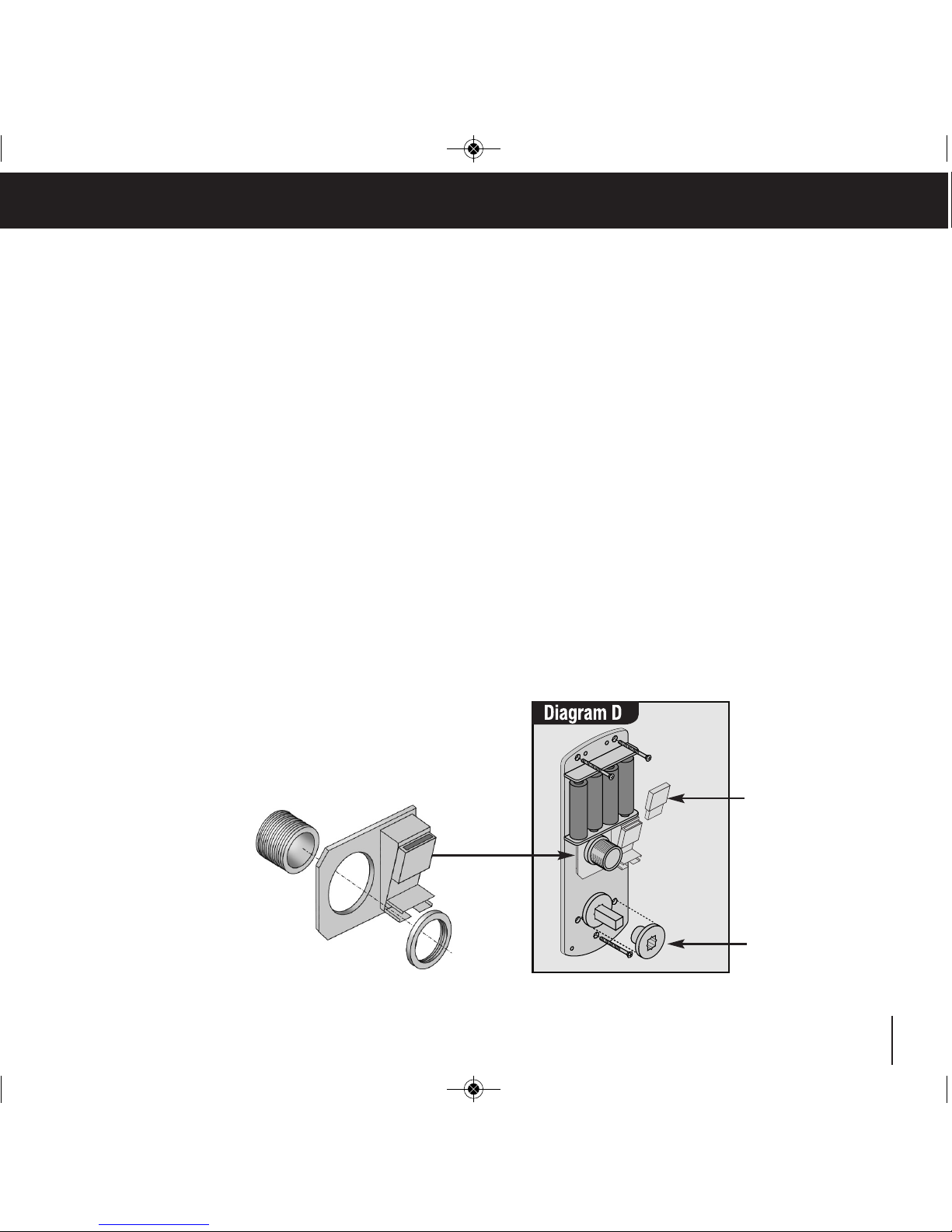

Insert the cylinder centrally in the lockcase and fix in position

with the long bolt through the faceplate.

Using the key it should be possible to double-throw the

deadbolt, retract the deadbolt, and retract the latchbolt.

The latchbolt follower is in 2 parts, with 2 set screws visible

in each part. Determine which side of the lock will be the

outside and remove the set screws from that side. DO NOT

remove the set screws from both sides.

The outside handle will now retract the latchbolt but

NOT the deadbolt.

The inside handle will now simultaneously retract the

latchbolt AND the deadbolt if it is thrown.

This safety feature ensures that it is not possible to

accidentally lock someone in a room by throwing the deadbolt

from outside.

Throwing the deadbolt will deny access to code users when

appropriate.

All door locks should be installed with a degree of precision

to ensure that all components are horizontally and vertically

accurate in relation to each other, and in relation to the door.

Do not install the lock where it will involve cutting into a joint

between the door stile and a mid-rail.

INSTALLING THE ANTI-PANIC ORTICE LOCK FOR

ODELS CL4020 AND CL5020

INSTALLING THE ANTI-PANIC ORTICE LOCK FOR CL5020

1Lightly mark a height line on the

edge and both faces of the door, and

the door jamb, to indicate the top of

the lock when fitted. ark a line

down the centre of the door edge,

extending above the height line and

300mm (1113/16”) below it.

2Hold the mortice lock template

against the edge of the door with the

top in line with the height line, and

with the arrows in line with the

‘Centre of Door Edge’ line. ark the

positions of the fixing screws, and

the holes to be drilled for the

mortice.

3Drill the marked holes 90mm (317/32”)

deep and form the mortice for the

lock.

4Fold the template accurately along

the dotted line and tape it to the door

face with the top in line with the

height line, and the fold on the door

edge. ark the centres of all the

holes to be drilled. Remove the

template and repeat on the other face

of the door.

5Drill the holes from both faces of the

door to improve accuracy. Do not

drill right through the door as this

will damage the door when the drill

breaks through.

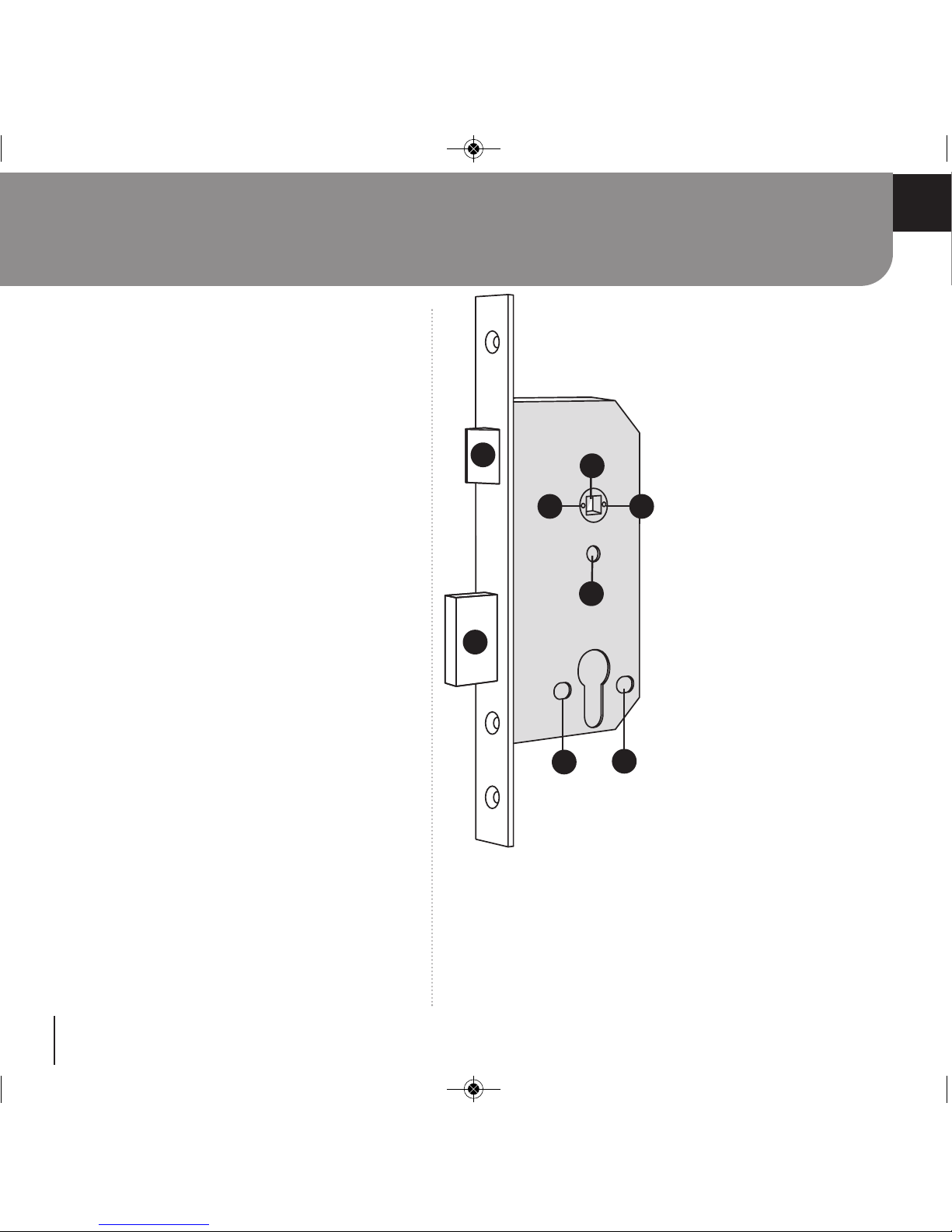

A Reversible latchbolt

B 2 part follower

C Set screws

D Hole for Codelock xing bolt

E Double-throw

22mm (7/8”) deadbolt

F Holes for keyhole-cover xings

A

E

B

C C

D

FF

10