3

Contents

LEGAL NOTICES 3

SAFETY INFORMATION 4

MANUAL SYMBOLS 4

PRECAUTIONS 4

MARKING SYMBOLS ON THE EQUIPMENT 4

SAFETY WARNINGS 5

EQUIPMENT SPECIFICATIONS 7

SYSTEM COMPONENTS 7

TECHNICAL SPECIFICATIONS 7

SITE PREPARATION AND INSTALLATION 8

SYSTEM SITE PREPARATION 8

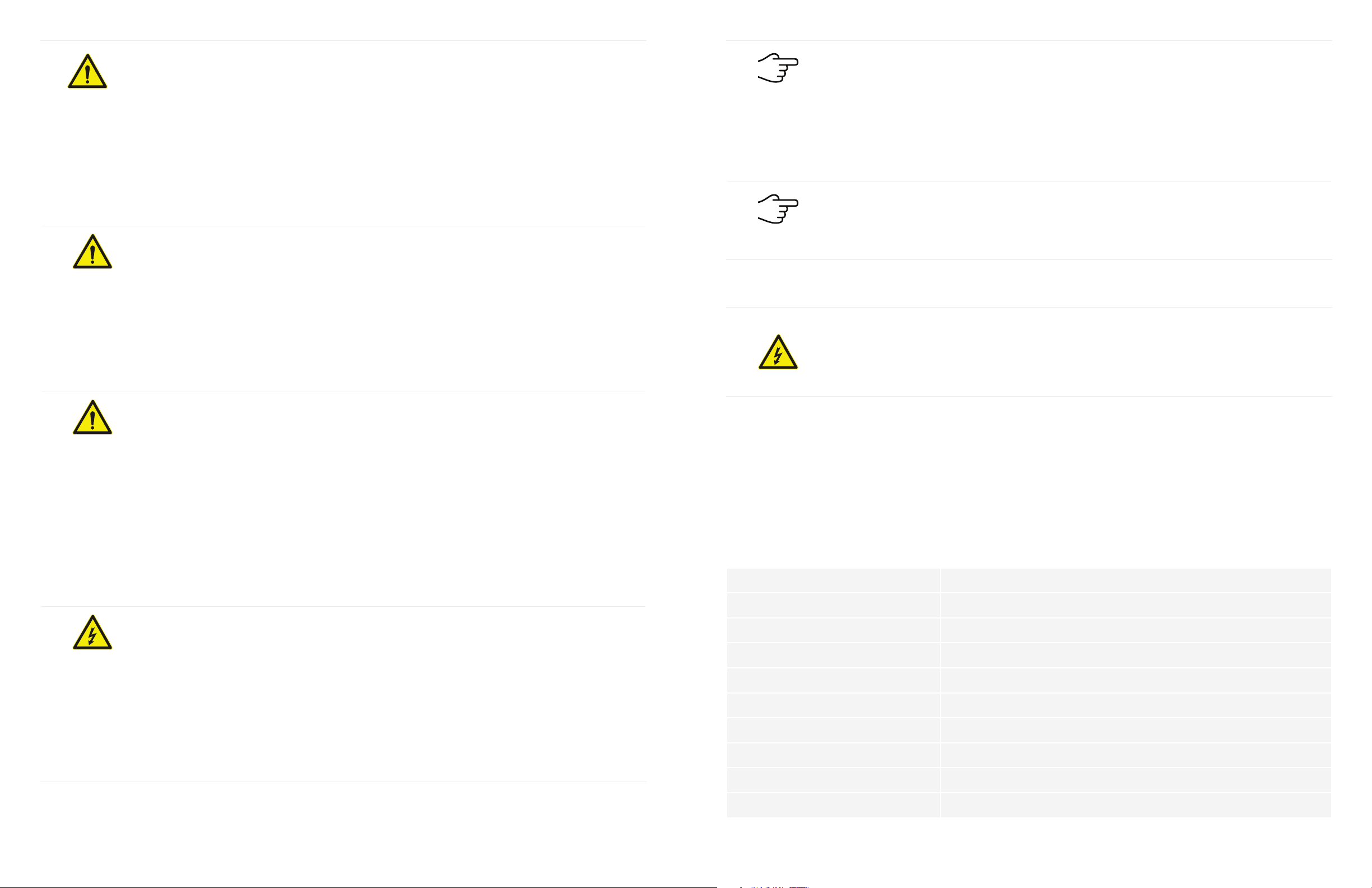

GETTING TO KNOW THE BIOXP™ SYSTEM 8

HARDWARE OVERVIEW 8

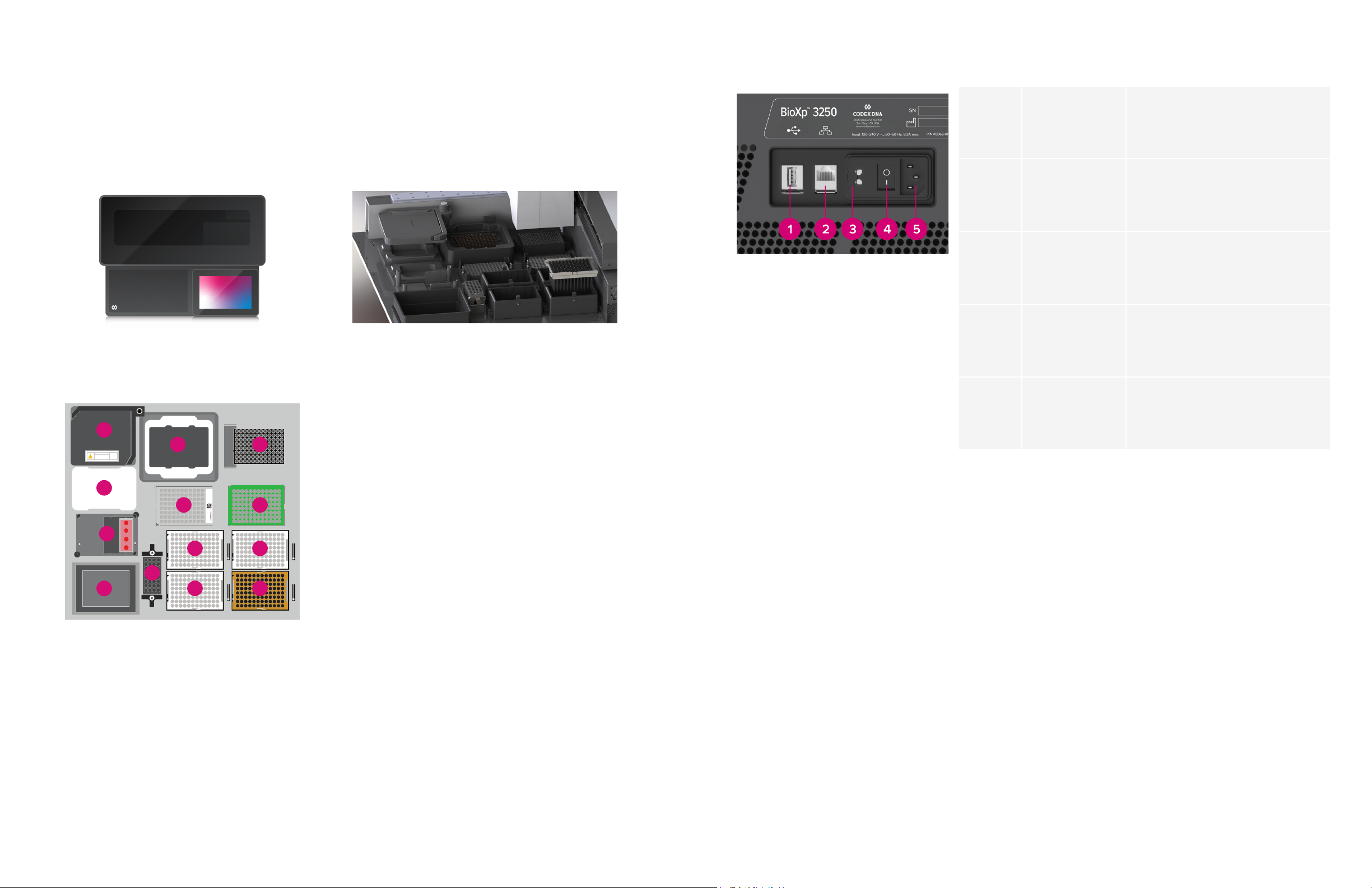

INSTRUMENT PORTS AND POWER SWITCH 9

BIOXP™ APPLICATIONS 9

PLACING AN ORDER 9

SETTING UP THE BIOXP™ SYSTEM 10

LEAVE THE BIOXP™ SYSTEM POWERED ON 10

ETHERNET SETUP 10

START THE BIOXP™ SYSTEM 10

CONFIGURE THE BIOXP™ SYSTEM 11

TEST THE NETWORK CONNECTION 11

CHANGE THE CLOCK OPTIONAL 12

RUNNING THE BIOXP™ SYSTEM 12

RECEIVING A BIOXP™ APPLICATION PROJECT 12

PREPARING THE BIOXP™ SYSTEM FOR A RUN 13

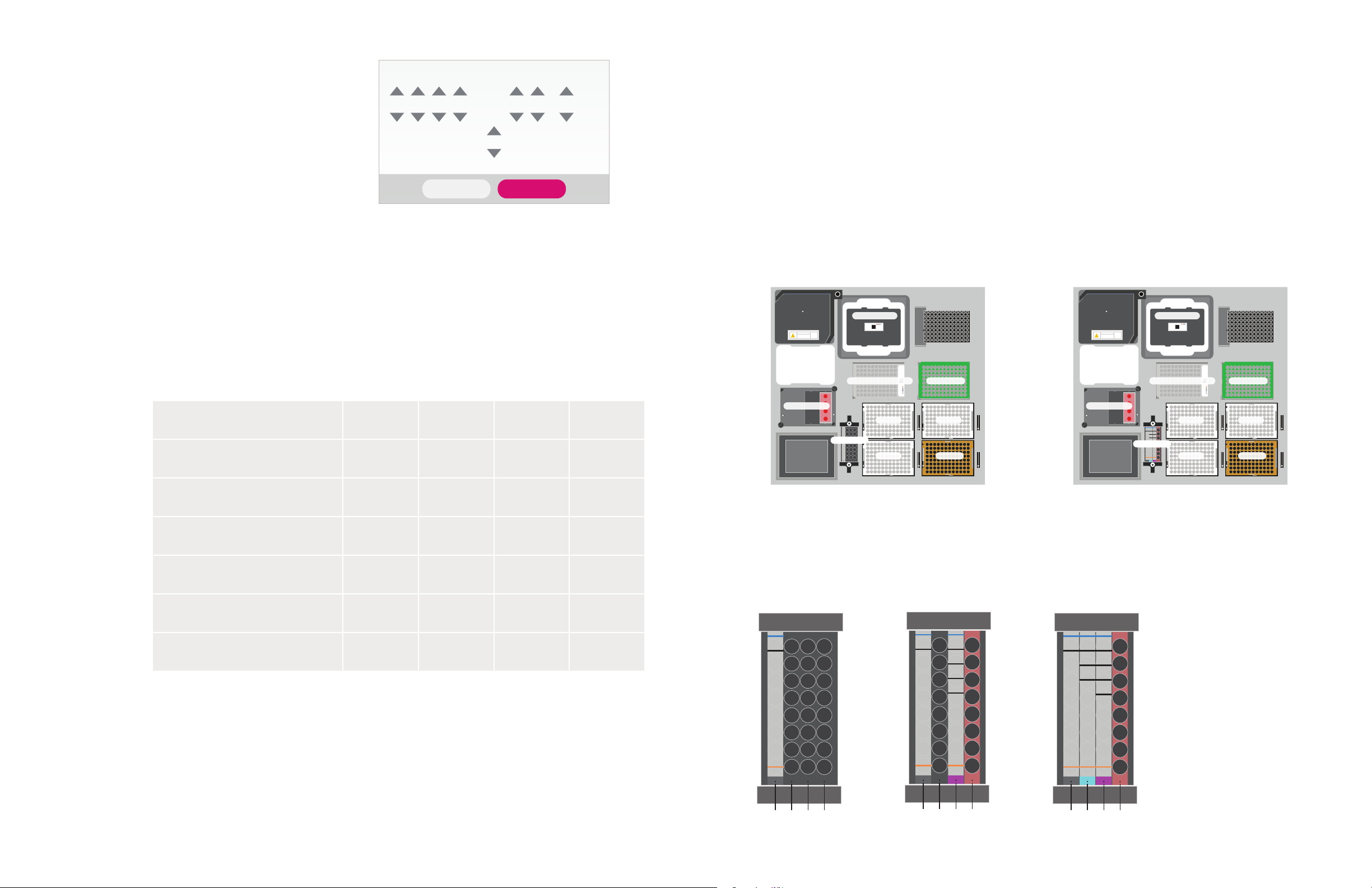

LOADING THE BIOXP™ DECK 13

INITIATING A BIOXP™ RUN 14

CANCELLING A JOB DURING A RUN 14

BIOXP™ RUN COMPLETION 15

TROUBLESHOOTING 16

BIOXP™ DECK INSPECTION ERROR 16

GENERAL TROUBLESHOOTING 17

CLEANING AND MAINTENANCE 17

CLEANING INSTRUCTIONS 17

CALIBRATION 18

PREVENTATIVE MAINTENANCE 18

REPAIR 18

EQUIPMENT DISPOSAL 18

WEEE COMPLIANCE 18

REGULATORY STATEMENTS 18

FCC COMPLIANCE STATEMENT 18

KOREAN EMC COMPLIANCE STATEMENT 19

Legal notices

Limited use label license Except as otherwise agreed in writing by our authorized representative, this product is for INTERNAL

RESEARCH USE ONLY AND NOT FOR HUMAN, ANIMAL, THERAPEUTIC OR DIAGNOSTIC USE. For

additional information about your rights under this research license, visit codexdna.com.

Limited warranty a) Codex DNA, Inc.’s entire liability and your exclusive remedy if the Product fails to conform to the

following warranty (a “Nonconforming Product”) shall be, at Codex DNA, Inc.’s sole option, either repair or

replacement of such Nonconforming Product, or, if neither is practicable, a refund of the fees paid for the

Product. The warranty for the repaired or replaced Product is limited to the scope and remaining duration

of the original warranty for the Nonconforming product or, if longer, for 30 days after the date of shipment

to you of the repaired or replaced Product. The warranty is contingent upon proper use of the Product in

accordance with the user guide and does not apply to any Product that is subjected to unusual physical

or electrical stress, misuse, neglect, improper testing or storage, modification or unauthorized repair or

upgrade. b) Codex DNA, Inc. warrants that the product, as delivered, will be free from defects in material

and workmanship for a period of one year from the date it is delivered to you (“the Warranty Period”).

c) This warranty gives you specific legal rights and you may have other legal rights which vary from

state to state. This warranty is non-transferable. d) OTHER THAN AS EXPRESSLY SET FORTH ABOVE,

Codex DNA, Inc. MAKES NO WARRANTIES, EXPRESS, STATUTORY, IMPLIED, OR OTHERWISE. NO

DISTRIBUTOR, AGENT OR EMPLOYEE IS AUTHORIZED TO MAKE ANY MODIFICATIONS, EXTENSIONS

OR ADDITIONS TO THIS WARRANTY. e) You shall indemnify, defend and hold harmless Codex DNA, Inc.

from any costs, expenses, damages, or other losses arising out of i) any warranty of greater scope or

duration than that set forth in this Codex DNA, Inc. Limited Warranty; and ii) failure to disclaim implied

warranties and limit remedies and liabilities, by and on behalf of Codex DNA, Inc.

Trademark information Gibson Assembly® is a registered trademark and BioXp™ and Oligo Vault™ are trademarks of

Codex DNA, Inc.

Patents Gibson Assembly® US patent numbers 7,776,532, 8,435,736, and 8,968,999.

Regulatory statement For research use only.

Statement of

proprietary information

Copyright in this work is vested in Codex DNA, Inc. and the document is issued in confidence for the

purpose only for which it is supplied. It must not be reproduced in whole or in part except under an

agreement or with the consent in writing of Codex DNA, Inc. and then only on the condition that this

notice is included in any such reproduction. No information as to the contents or subject matter of this

document or any part thereof arising directly or indirectly there from shall be given orally or in writing or

communicated in any manner whatsoever to any third party being an individual firm or company or any

employee thereof without the prior consent in writing of Codex DNA, Inc.

Terms and conditions IMPORTANT — This agreement (the “Agreement”) is a legal agreement between you and

Codex DNA, Inc. By installing or otherwise using the BioXp™ 3250 system (referred in this agreement as

the “Product”), you agree to be bound by the terms of this Agreement. If you do not wish to be bound by

the terms of this Agreement, do not use the Product and promptly return the unused, unopened Product

to the place of purchase for a full refund. The user is prohibited from reverse engineering the software or

output files generated from the BioXp™ 3250 system.

Limitation of liability CODEX DNA, INC.’S LIABILITY ARISING OUT OF OR RELATING TO A PRODUCT SHALL NOT EXCEED

THE AGGREGATE AMOUNTS YOU PAID TO CODEX DNA, INC. FOR THE PRODUCT. IN NO EVENT

WILL CODEX DNA, INC. BE LIABLE FOR LOST USE, PROFITS, REVENUE, COST OF PROCUREMENT

OF SUBSTITUTE GOODS, OR ANY OTHER SPECIAL, INDIRECT, RELIANCE, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, HOWEVER CAUSED AND UNDER ANY THEORY OF LIABILITY. THE

FOREGOING LIMITATIONS SHALL APPLY REGARDLESS OF WHETHER CODEX DNA, INC. HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES AND NOT WITHSTANDING THE FAILURE OF

ESSENTIAL PURPOSE OF ANY LIMITED REMEDY.

Disclaimer The material in this manual is for informational purposes only and is subject to change without prior

notice at any time. Codex DNA, Inc. and/or its aliates assume no responsibility for any errors that may

appear in this document.

Indications for use The BioXp™ 3250 system is a device which is intended for the processing of DNA materials.

The system is not approved for use other than that stated above.

Technical services For technical assistance, contact help@codexdna.com or call 858.228.4115.