Features

FEATURES & SPECIFICATIONS

3

• A 250W white LED lamp, 7500K

• 50000 hours life span and low power consumption

• 8/16 bit smooth and precise resolution for PAN/TILT movement

• 540°/630°/ 360°PAN and 270°/180°/90° TILT movement

• Scan position memory, auto reposition after unexpected movement

• 13°Beam angle

• Specific high precision glass optic system

• 1 Rotating gobo wheel with 6 rotatable and interchangeable gobos plus open (3 glass gobos and 3

metal

gobos with speed adjustable, stream effect, dithering effect and rotatable clockwise or anticlockwise

• Gobo indexing available

• Gobo size 22.9mm (external dimensions)/16mm (inner dimensions)

• 1 Static gobo wheel with 8 gobos plus open

• Gobo overlay (gobo morphing)

• 1 Color wheel with 7 colors plus open (available for half color mode)

• Variable direction rainbow effect with speed adjustable

• Gobo time and color time controllable

• 2.5M-15M electric focus

• An effect wheel with 3-facet prism/linear prism/frost filter (hybrid effect for wash)with variable speed

and direction

• 0-100% Smooth linear LED dimmer (2 dimmer modes)

• 25T/sec high speed LED shutter/strobe effect with variable speed

• Preset variable/random strobe and dimming pulse effect

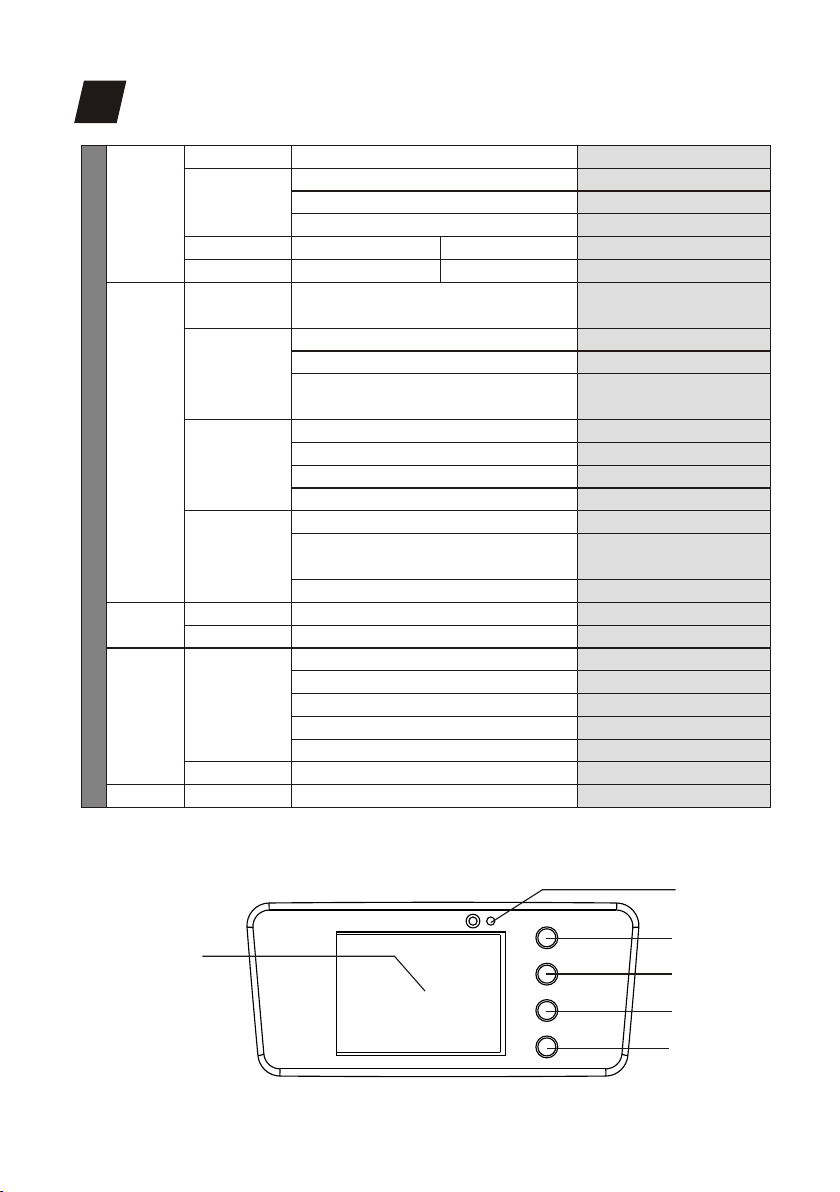

• 13/15/17 DMX channels USITT DMX-512

• DMX512, master-slave, and sound activated controllable or auto operation(7 built-in programs)

• DMX recorder and edit function integrated

• Sound control with sensitivity adjustment

• 2.4" TFT LCD display (320*240pix) with 4 control buttons

• 180°Reversible for LCD display

• LCD display switch-off automatically after 60 seconds

• DMX signal monitoring indicator available

• Lower noise and efficient FAN cooling system

• Efficient low noise self adjusting fan cooling system

• Constant temperature readout and management function

• Over heat protection management

• Powercon IN/ OUT with power switch and fuse

• 3-Pin DMX connectors IN/OUT

• DB rating@1M=54.18dB

• IP20 protection rating

• -35℃ to 45℃ ambient temperature

• 2*1/4 turn fastening Omega Clamps (Adaptable vertically and horizontally)

• 1*Safety attachment point

• CE (EMC/LVD) and RoHS certified

.03.