11 12

80-89, Pattern 1 shake effect, from slow to fast.

90-99, Pattern 2 shake effect, from slow to fast.

100-109, Pattern 3 shake effect, from slow to fast.

110-119, Pattern 4 shake effect, from slow to fast.

120-129, Pattern 5 shake effect, from slow to fast.

130-139, Pattern 6 shake effect, from slow to fast.

140-149, Pattern 7 shake effect, from slow to fast.

150-200, Linear pattern effect speed adjustment, from fast to slow.

201-255, Speed adjustment of reverse linear pattern effect, from slow to fast.

08. Gobo. R

Please use this function when selecting a rotating pattern.

0-127, 0-400° rotation effect.

128-190, Rotation pattern rotation(no rotation limit), speed from fast to slow.

191-192, Stop. 193-255, Reverse rotation pattern rotation (no rotation limit), speed from slow to fast.

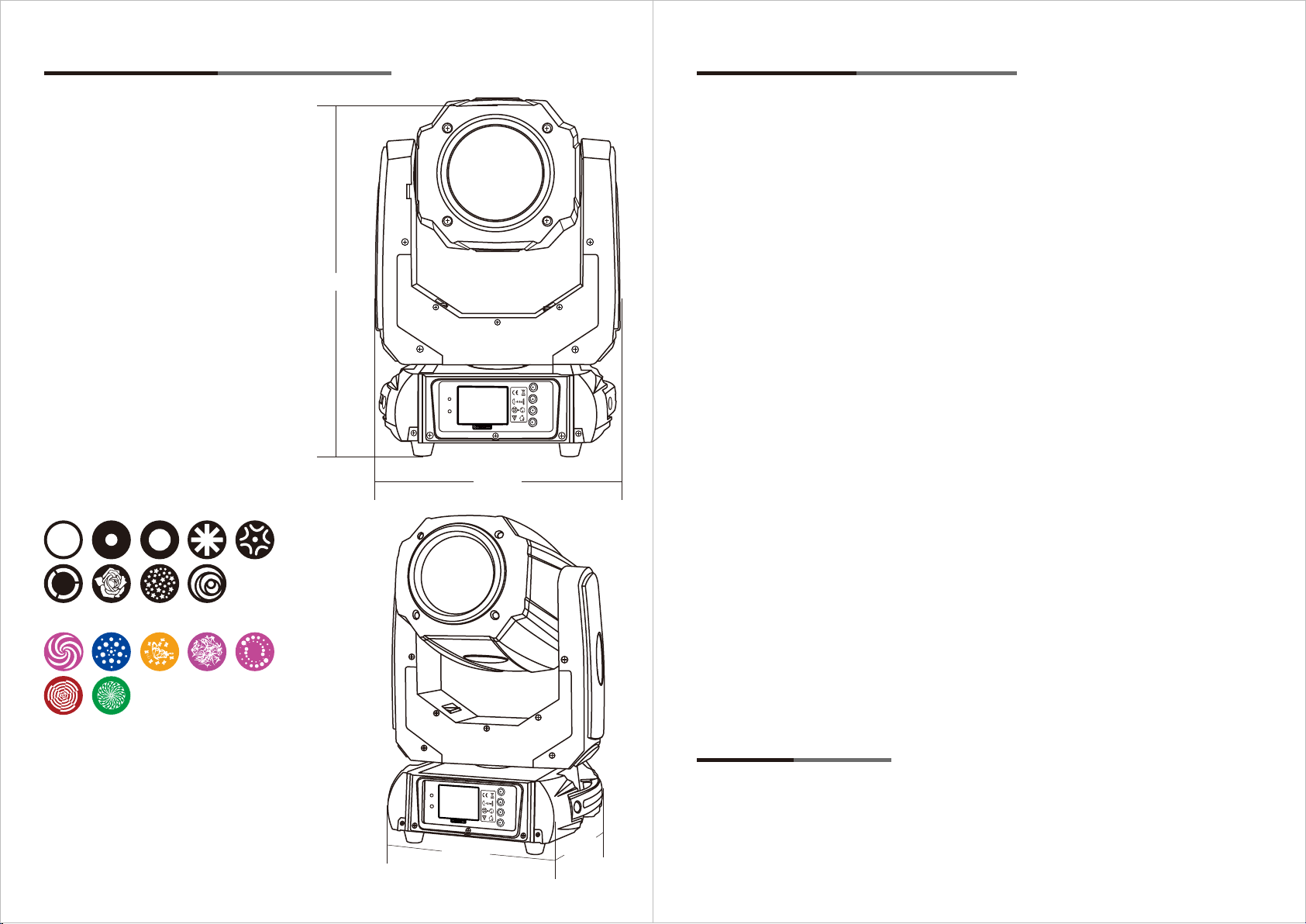

09. Gobo

Blank pattern

0-9

Pattern 1 Pattern 2 Pattern 3 Pattern 4 Pattern 5 Pattern 6 Pattern 7 Pattern 8 Pattern 9

10-19 20-29 30-39 40-49 50-59 60-69 70-79 80-89 90-99

100-109, Pattern 1 shake effect, from slow to fast.

110-119, Pattern 2 shake effect, from slow to fast.

120-129, Pattern 3 shake effect, from slow to fast.

130-139, Pattern 4 shake effect, from slow to fast.

140-149, Pattern 5 shake effect, from slow to fast.

150-159, Pattern 6 shake effect, from slow to fast.

160-169, Pattern 7 shake effect, from slow to fast.

170-179, Pattern 8 shake effect, from slow to fast.

180-189, Pattern 9 shake effect, from slow to fast.

150-200, Linear pattern effect speed adjustment, from fast to slow.

201-255, Speed adjustment of reverse linear pattern effect, from slow to fast.

10. Col Fine

Test function 06, linear colors fine-tuning, this fine-tuning functio n makes the half-color effect

more perfect

11. Prism

0-31 No function. 32-255 Turn on the prism effect.

12. Prism. R

Use this function when the prism function is ture on.

0-127, 0-400° rotation effect.

128-190, Prism rotation(no rotation limit), speed from fast to slow.

191-192, Stop.

193-255, reverse rotation pattern rotation (no rotation limit), speed from slow to fast.

13. Focus

0-255, Focusing size from far to near.

14. Zoom

0-255, Zoom function changes from small to large.

15. Frost

0-127 No function. 127-255 Turn on the frost effect.

16. Pan Fine

0-255, X direction fine-tuning, fine-tuning within 1°.

17. Tilt Fine

0-255, Y direction fine-tuning, fine-tuning within 1°.

18. Reset

0-239, Reset. Before enabling this function, ensure that the optocoupler calibration has been

started. If not, start the optocoupler calibration. Wait 10 seconds after starting the reset and the

unit will enter the reset waiting screen.

* Please complete the data adjustment, save the current data, press to save.

◆ Advanced → Advanced setting mode

Address

WorkMode

Display

TestMode

Advanced

Status

Escape

Pan Invert

Tilt Invert

P/T Rectify

Pan Offset

Tilt Offset

Lamp when

Data hold

Factory Setting

ON

ON

ON

010

010

Power ON

OFF

Pan Invert:

Pan initial position and end position are reversed, and steering is set;

OFF→Motor rotates reversed.

ON → Motor rotates forward.

Tilt Invert:

Tilt initial position and end position are reversed, and steering is set;

OFF→Motor rotates reversed.

ON → Motor rotates forward.