Combilift Ltd C2500-C3000CB O&S Manual

i

C2500CB-OM-EN-11

Contents

Section 1:Machine layout and Operator Controls..............1-1

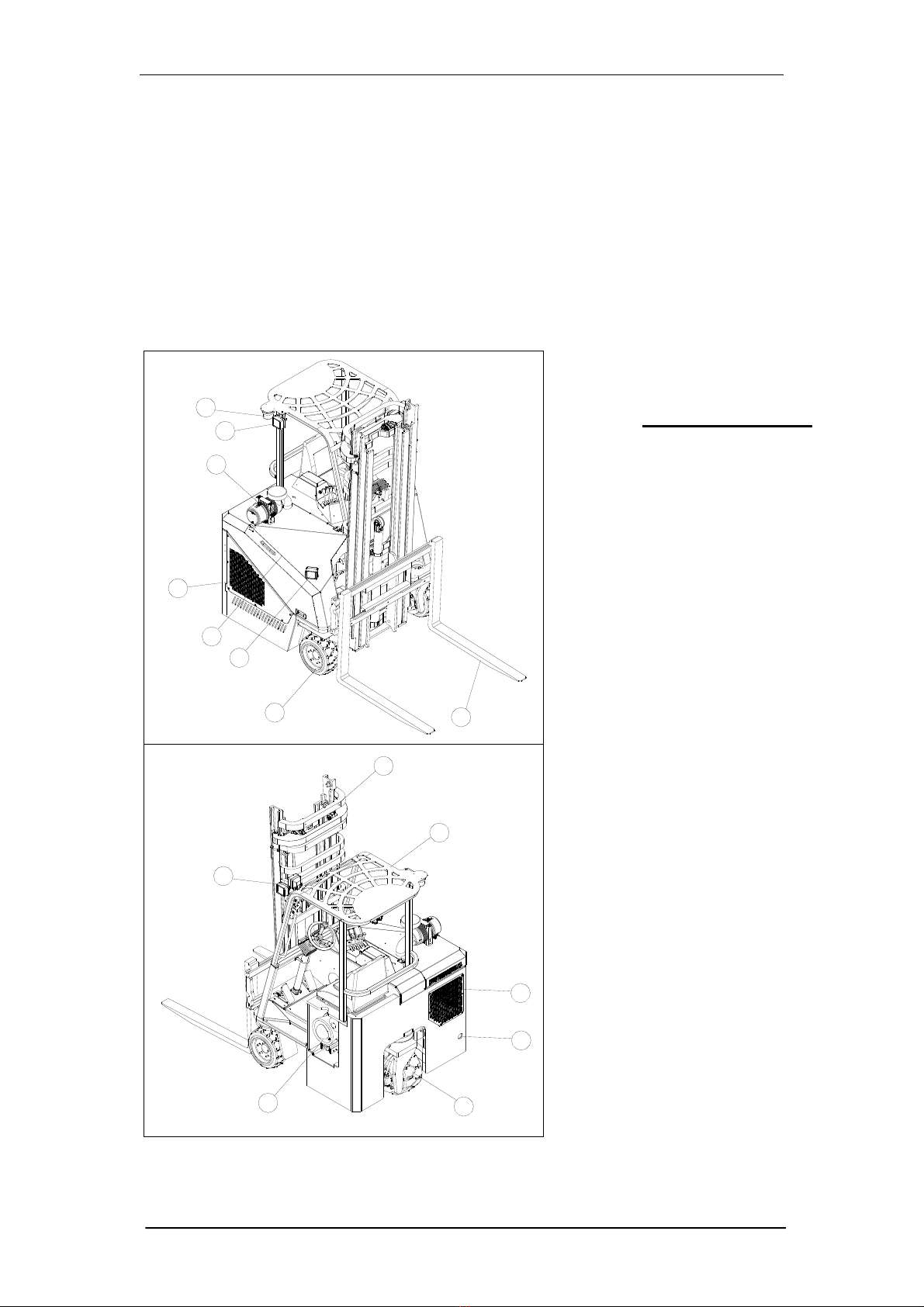

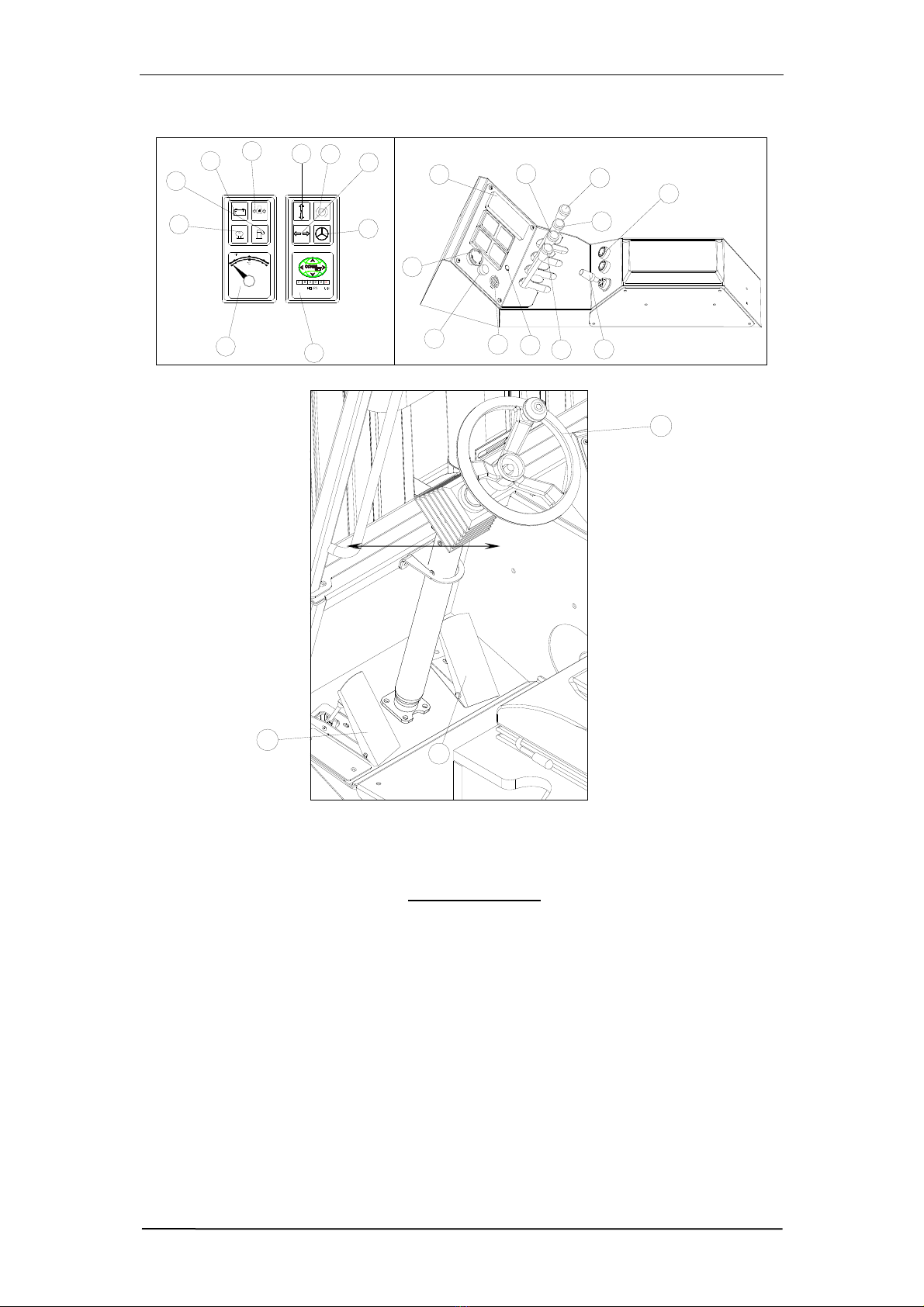

1.1:Machine Overview and Components......................................................... 1-1

Section 2:Operating instructions and Conditions .............2-1

2.1:Understand the Capacity of your Lift-Truck ............................................. 2-1

2.2:Centre of Gravity (CG).............................................................................. 2-1

2.3:Load Chart ................................................................................................. 2-2

2.4:Serial Plate................................................................................................. 2-3

2.5:Operator Qualification............................................................................... 2-3

2.6:Operator Responsibilities........................................................................... 2-3

2.7:Entering and Exiting the Operator Cabin................................................... 2-4

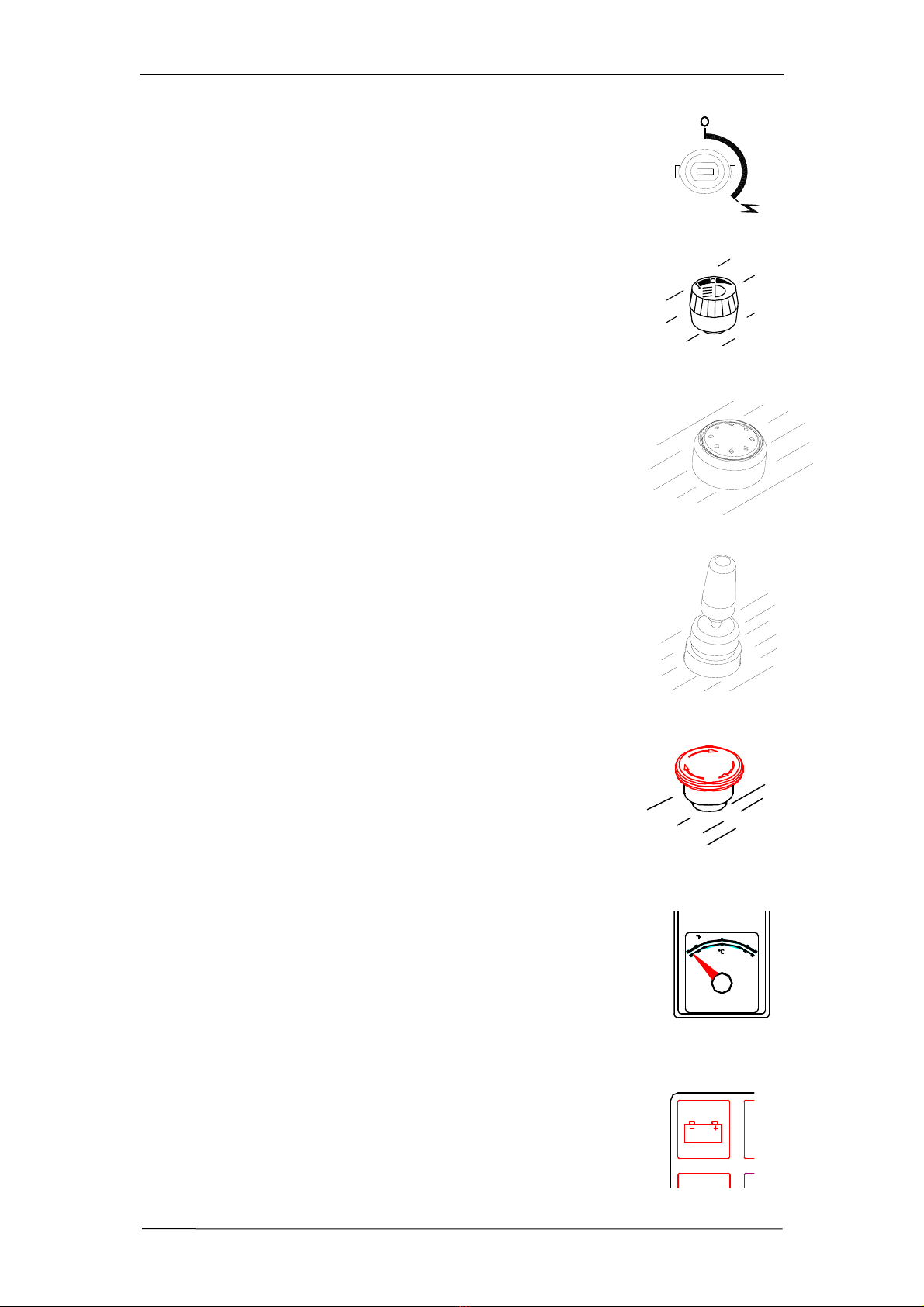

2.8:Starting Procedure...................................................................................... 2-4

2.9:Moving Off ................................................................................................ 2-5

2.10:Changing Direction without Changing Mode............................................ 2-5

2.11:Changing Into Sideward Mode.................................................................. 2-5

2.12:To Change Back to Forward Mode............................................................ 2-5

2.13:Stopping..................................................................................................... 2-6

2.14:Loading...................................................................................................... 2-6

2.15:When Loading in Sideward Mode............................................................. 2-6

2.16:When Loading in Forward Mode............................................................... 2-6

2.17:Placing a Load When In Sideward Mode.................................................. 2-7

2.18:Placing a Load When In Forward Mode.................................................... 2-7

2.19:Double Forking.......................................................................................... 2-7

2.20:Stacking...................................................................................................... 2-8

2.21:De-Stacking................................................................................................ 2-8

2.22:Adjusting Load Forks ................................................................................ 2-8

2.23:Operating Conditions................................................................................. 2-9

Section 3:Safe operation......................................................3-1

3.1:Safe Operation ........................................................................................... 3-1

3.2:Operating in Hazardous Areas................................................................... 3-1

3.3:Safe Driving on Gradients ......................................................................... 3-1

3.4:Driving Position......................................................................................... 3-2

3.5:Parking....................................................................................................... 3-2

3.6:Bridge Plates and Dock Boards ................................................................. 3-2

3.7:Lifting the Machine.................................................................................... 3-2