1

2

®

COMBISAFE

0208-012

95 0

1

2

2

1

1

!

Max

1020 kg

Max

60°

© Combisafe International AB 0208 100128

2

Max 50 pcs

®

COMBISAFE

Always read the instruction manual before use

Combisafe accepts no liability for items that has

been altered

Use

- Only use the Barrier box for its intented purpose

only, dont stack or load anyting other than

Combisafe Steel mesh barriers No. 3200

- Load box with maximum 50 barriers

- Secure nets in box from sliding or overturning.

Use strap around box and barriers

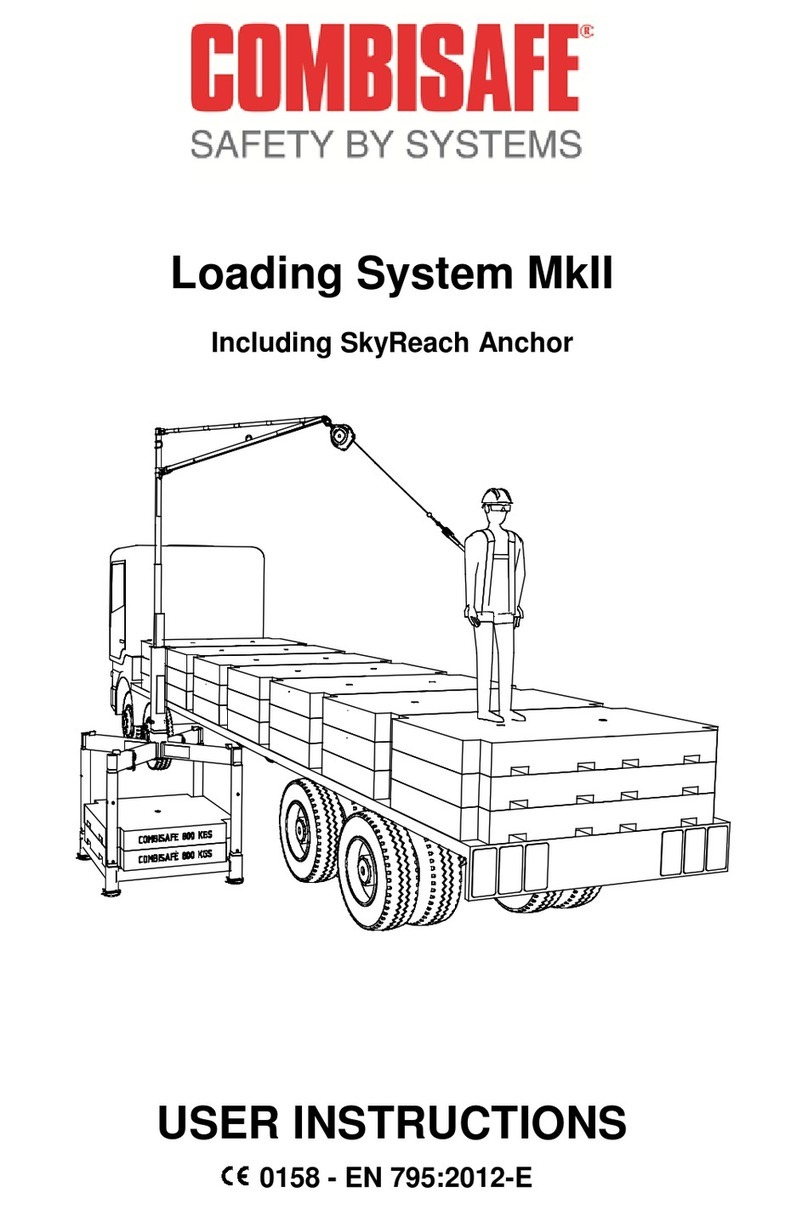

Lifting by crane

- Use a suitable 4-legged lifting chain with

permissable loadability (SWL) above 1020 kg.

- Max chain spread angle 60°

Lifting with forks

- The box can be lifted from all sides with forks.

When lifting from short side, make sure that

the barriers inst in the way.

- Place forks centered on box and make sure

that forks is pushed in enough so the box

supports on both sides.

Max 50 pcs

Max

1020 kg

Max

60°

!

®

COMBISAFE

Stacking nets in the box

Its importent to stack the nets correctly in the box.

Otherwise the nets will become too high and

unstable.

Place every second net in opposite direction, i.e

every second net with the toebord upwards.

Make sure that the nets are placed centrally in the

box to avoid overturning.

Dont stack nets above the beam

The nets weigh 19,5 kg and can be handled by one

person, but it is recommended for frequent loading

and unloading to be carried out by two persons or

use lifting equipment. Dont move or lift the box by

hand

Refer to current Health and safety regulations

applicable to contry of use to ensure compliance.

Safety precaution

Before every use

Always check the Barrier boxes for any signs of

damage or visible deformation.

Dont use boxes that dont pass checks according

to the following checklist:

Checklist

- Crack free and notch-free welds

- Deformation

- Corrosion

- Damage

- Wearing

- Visible Combisafe label and ID number

- Deformed or damaged lifting eyes

- No sharp edges

If in doubt consult Combisafe!

Annual Inspection

It is recommended that the box is inspected at least

once a year by a trained competent person unless

stated otherwise in a community country of use.

ID number

0208-012

Year Month Serial Number

Batch

800 mm 1130 mm

1142 mm

Dont stack

beyond this

point

© Combisafe International AB 0208

Subject to technical changes

2

1

1

2