TABLE OF CONTENTS

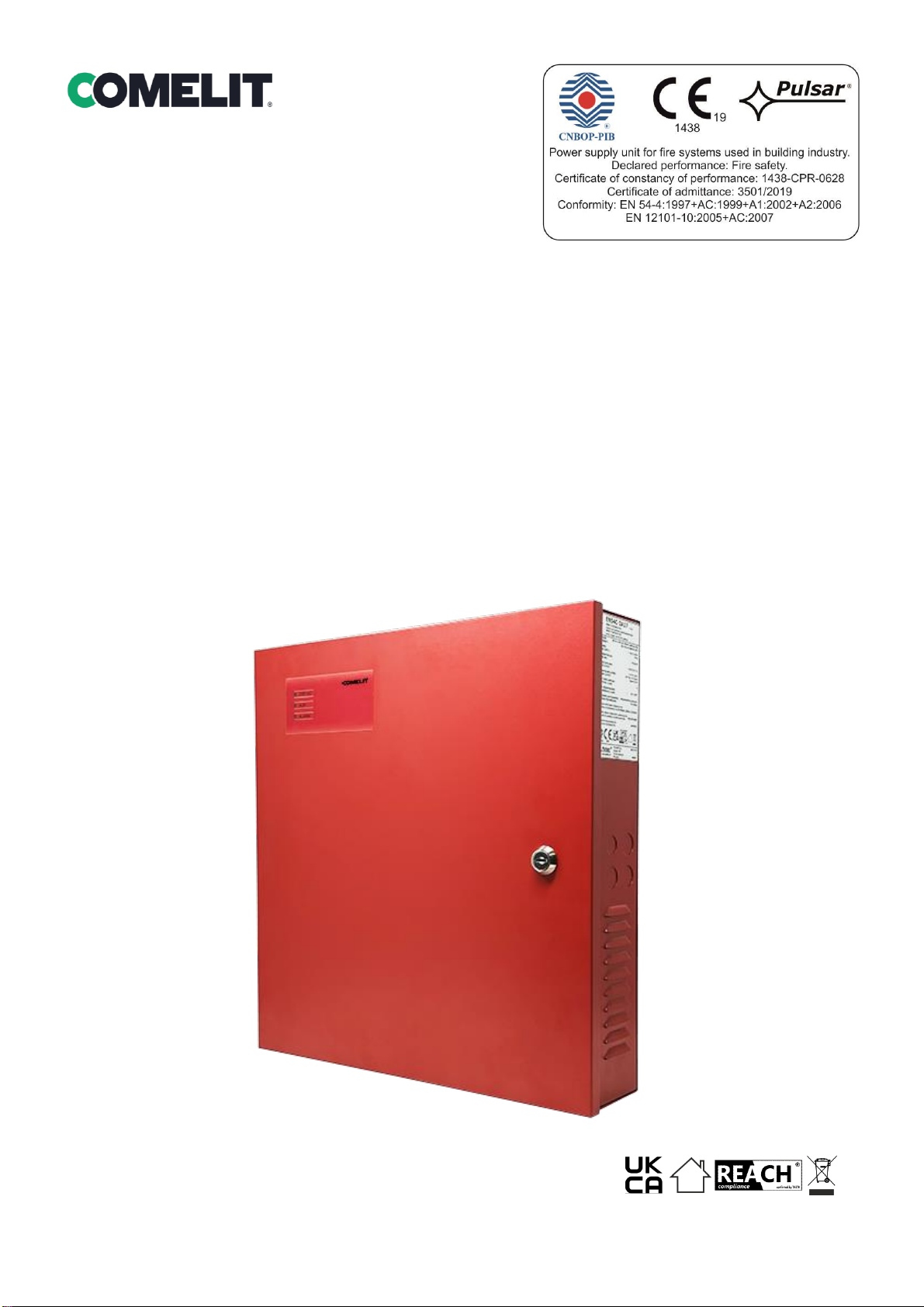

1. PSU FEATURES.....................................................................................................................................4

2. FUNCTIONAL REQUIREMENTS OF THE PSU.............................................................................4

3. TECHNICAL DESCRIPTION..............................................................................................................5

3.1. GENERAL DESCRIPTION........................................................................................................................................................5

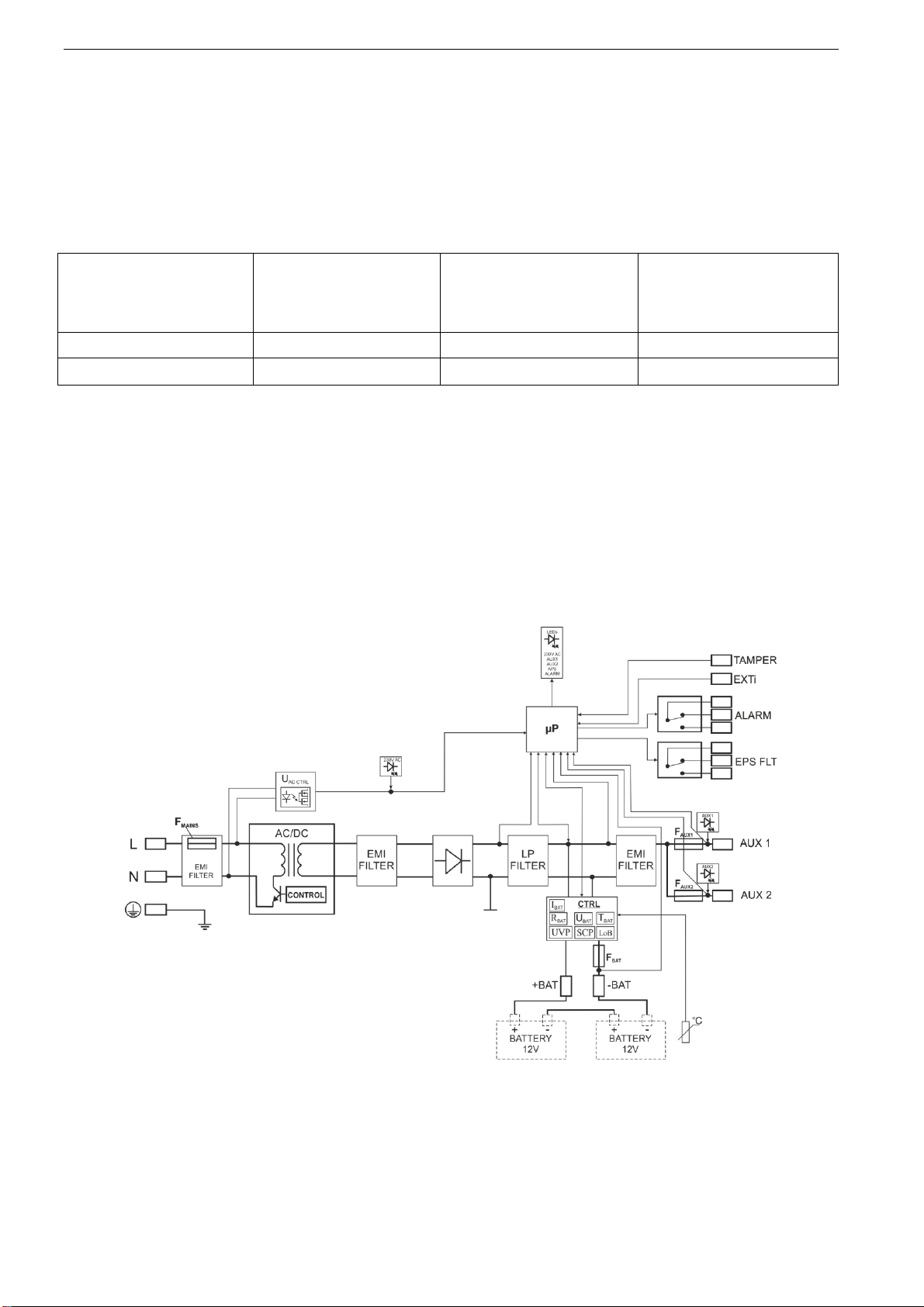

3.2. BLOCK DIAGRAM.................................................................................................................................................................5

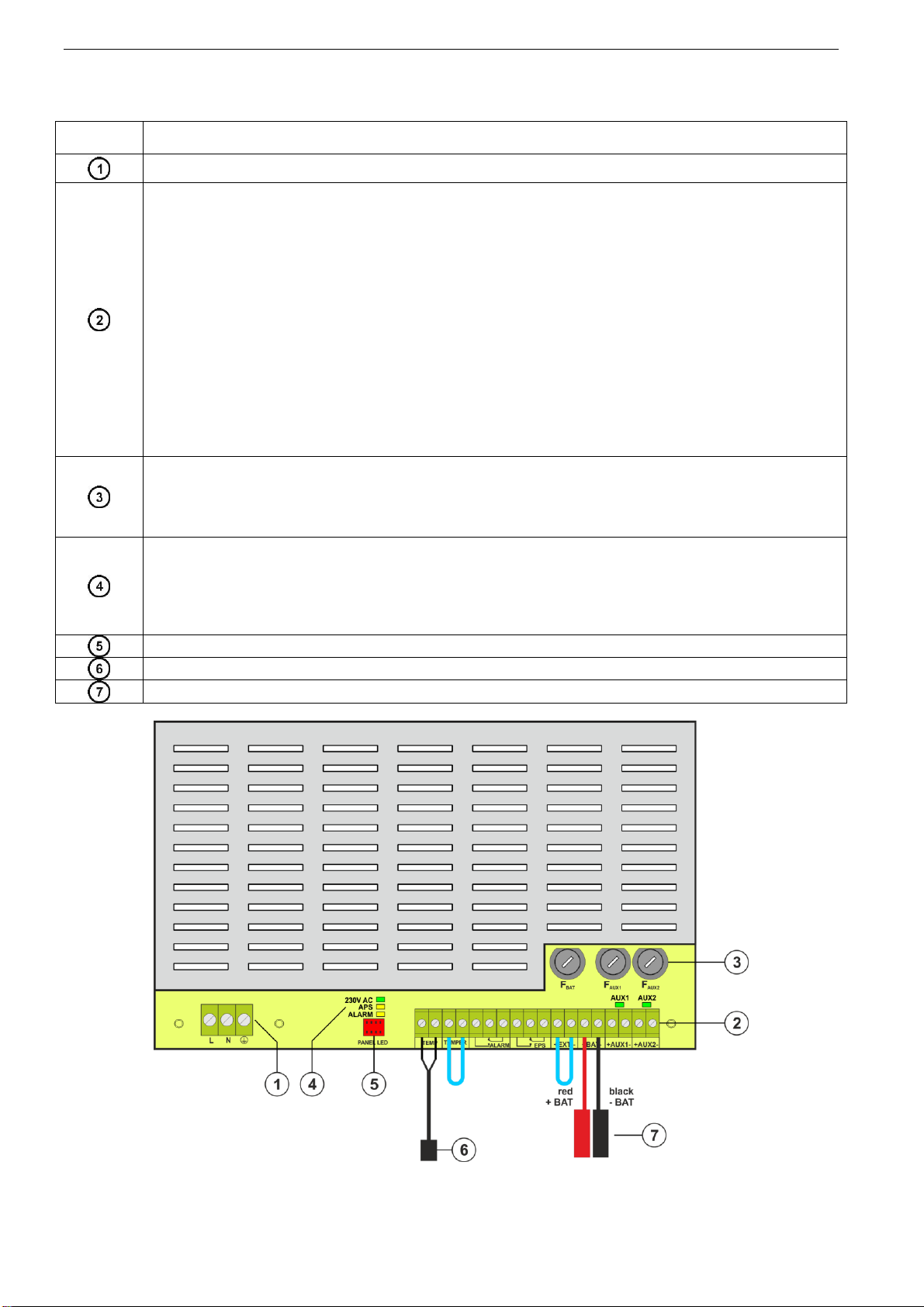

3.3. DESCRIPTION OF COMPONENTS AND POWER SUPPLY TERMINALS.........................................................................................6

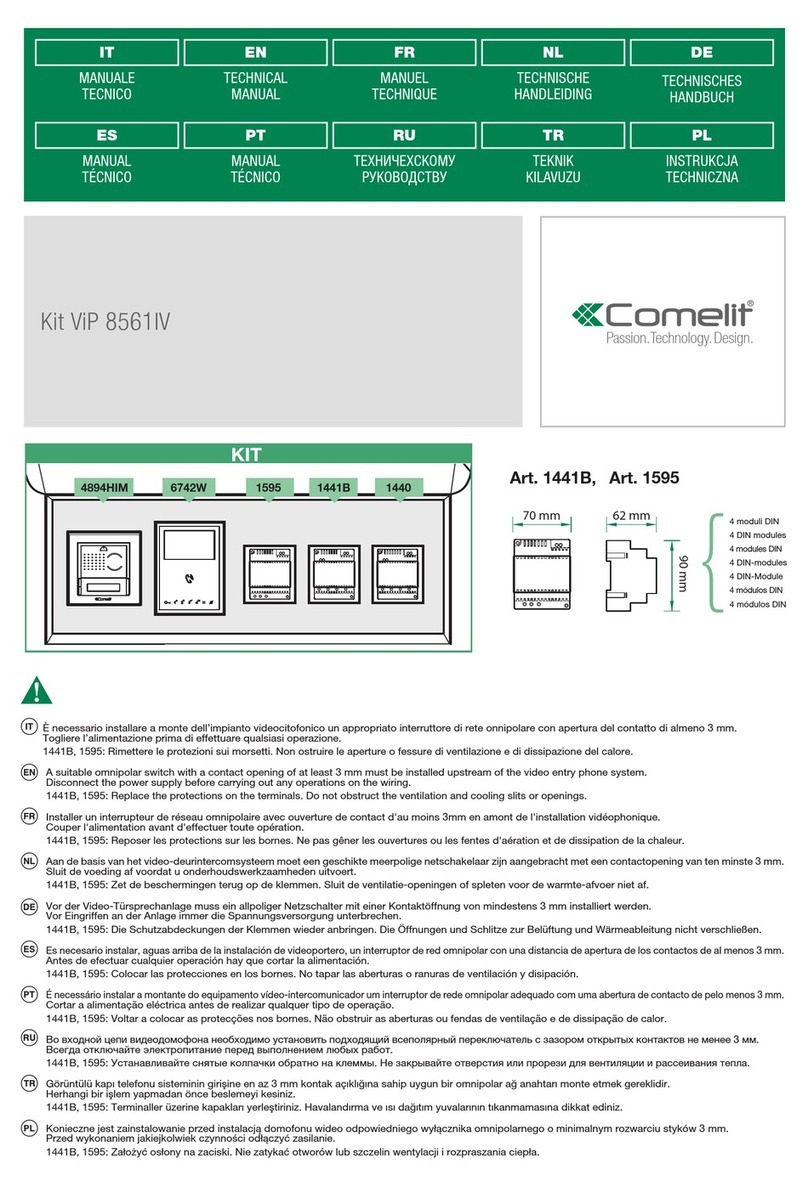

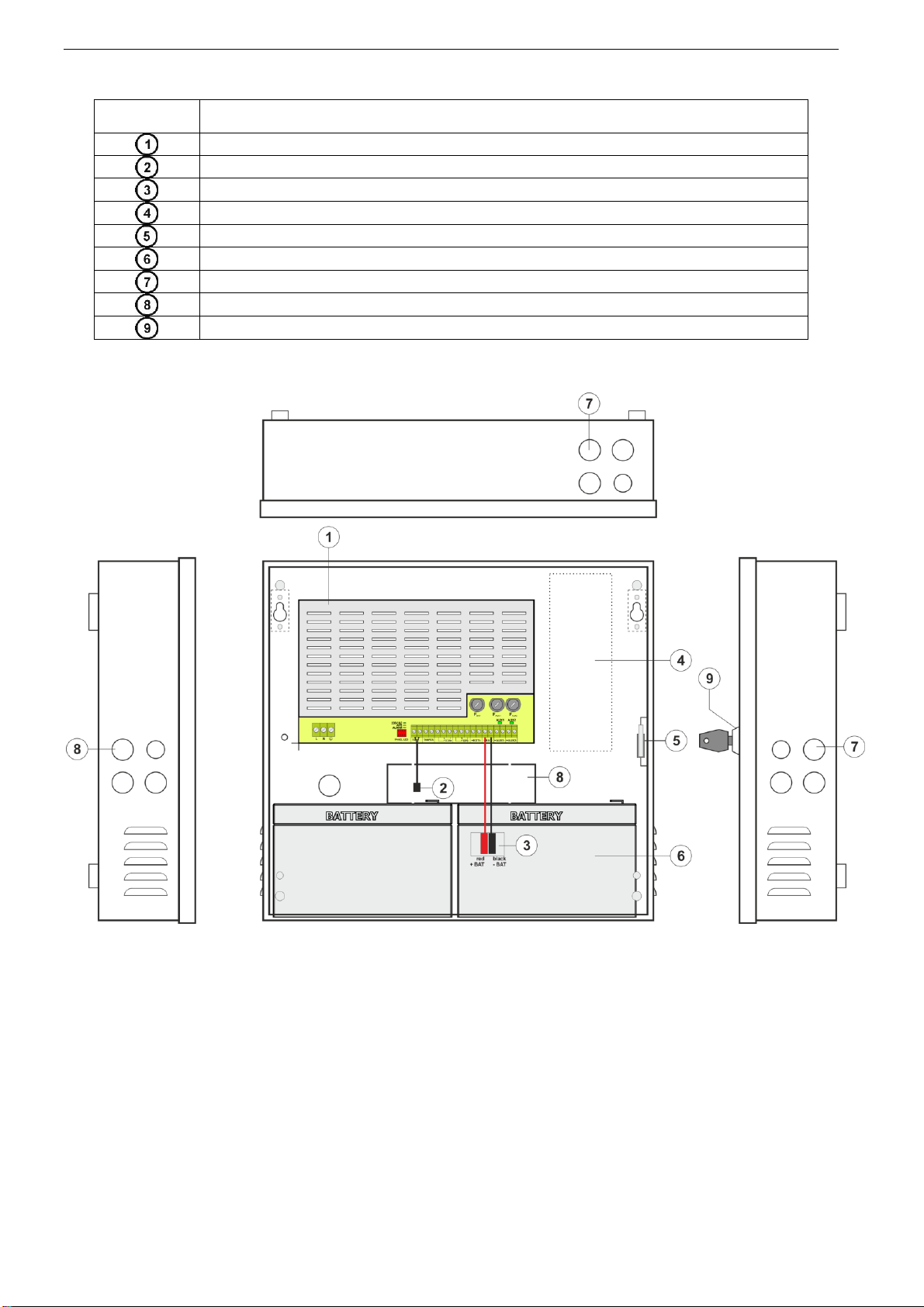

4. INSTALLATION....................................................................................................................................8

4.1. REQUIREMENTS...................................................................................................................................................................8

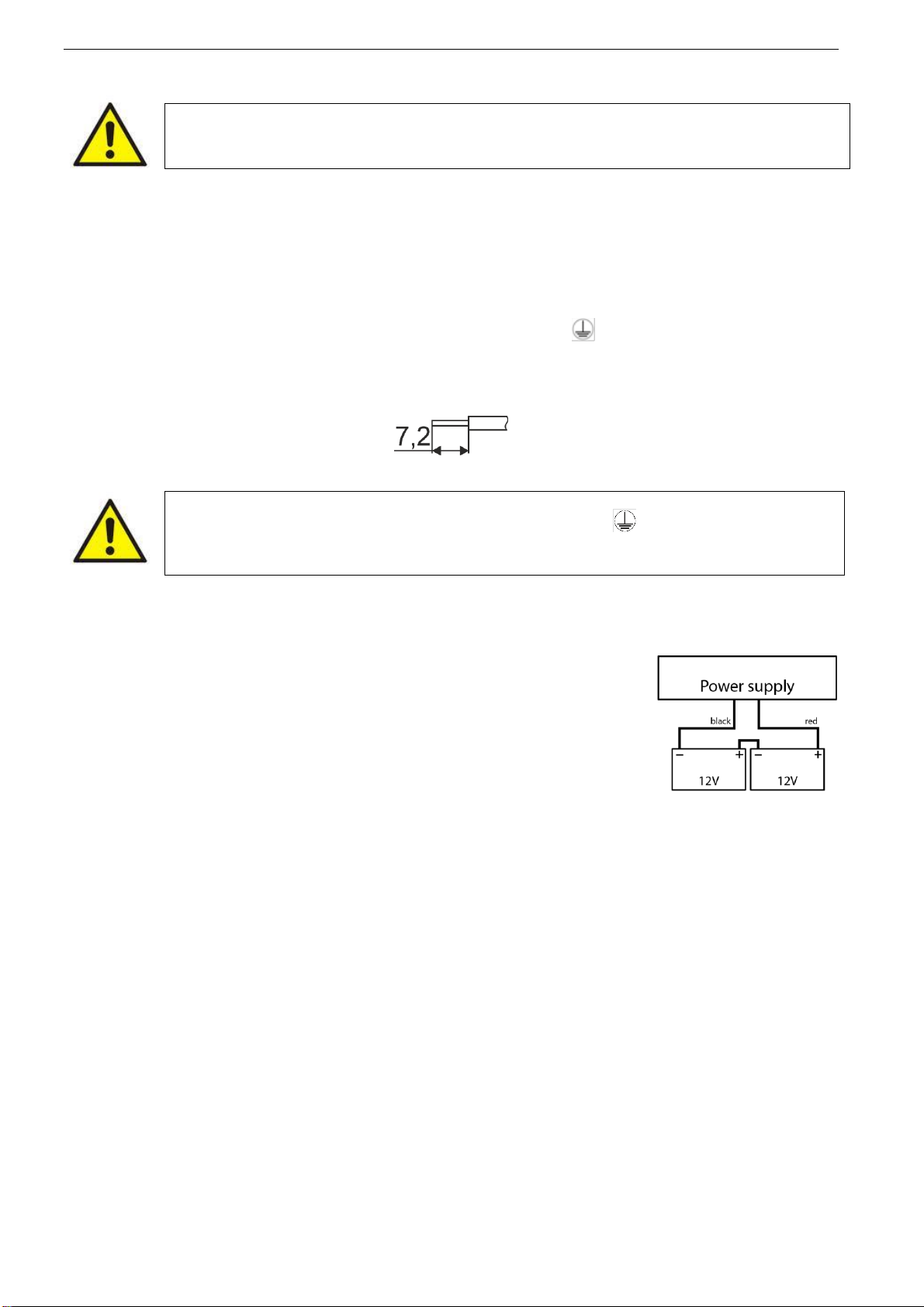

4.2. INSTALLATION PROCEDURE. ................................................................................................................................................9

4.3. PROCEDURE FOR CHECKING THE POWER SUPPLY AT THE PLACE OF INSTALLATION............................................................10

5. FUNCTIONS.........................................................................................................................................11

5.1. CONTROL PANEL................................................................................................................................................................11

5.2. TECHNICAL OUTPUTS.........................................................................................................................................................12

5.3. INPUT OF COLLECTIVE FAILURE:EXTI...............................................................................................................................13

5.4. INDICATION OF THE ENCLOSURE OPENING -TAMPER. .....................................................................................................13

5.5. PSU OVERLOAD.................................................................................................................................................................13

5.6. SHORT-CIRCUIT OF THE PSU OUTPUT. ...............................................................................................................................13

6. RESERVE POWER SUPPLY CIRCUIT...........................................................................................14

6.1. BATTERY DETECTION. .......................................................................................................................................................14

6.2. PROTECTION AGAINST SHORT-CIRCUIT OF THE BATTERY TERMINALS................................................................................14

6.3. PROTECTION AGAINST REVERSE BATTERY CONNECTION....................................................................................................14

6.4. DEEP DISCHARGE BATTERY PROTECTION UVP. .................................................................................................................14

6.5. BATTERY TEST...................................................................................................................................................................14

6.6. MEASUREMENT OF THE RESISTANCE OF THE BATTERY CIRCUIT.........................................................................................14

6.7. BATTERY TEMPERATURE MEASUREMENT. .........................................................................................................................14

6.8. STANDBY TIME. .................................................................................................................................................................15

7. TECHNICAL PARAMETERS. ..........................................................................................................16

Table 5. Electrical parameters.............................................................................................................................................16

Table 6. Mechanical parameters..........................................................................................................................................18

Table 7. Safety of use............................................................................................................................................................18

Table 8. Operation parameters. ...........................................................................................................................................18

Table 9. Recommended types and sections of installation cables. .......................................................................................18

8. TECHNICAL INSPECTIONS AND MAINTENANCE...................................................................19