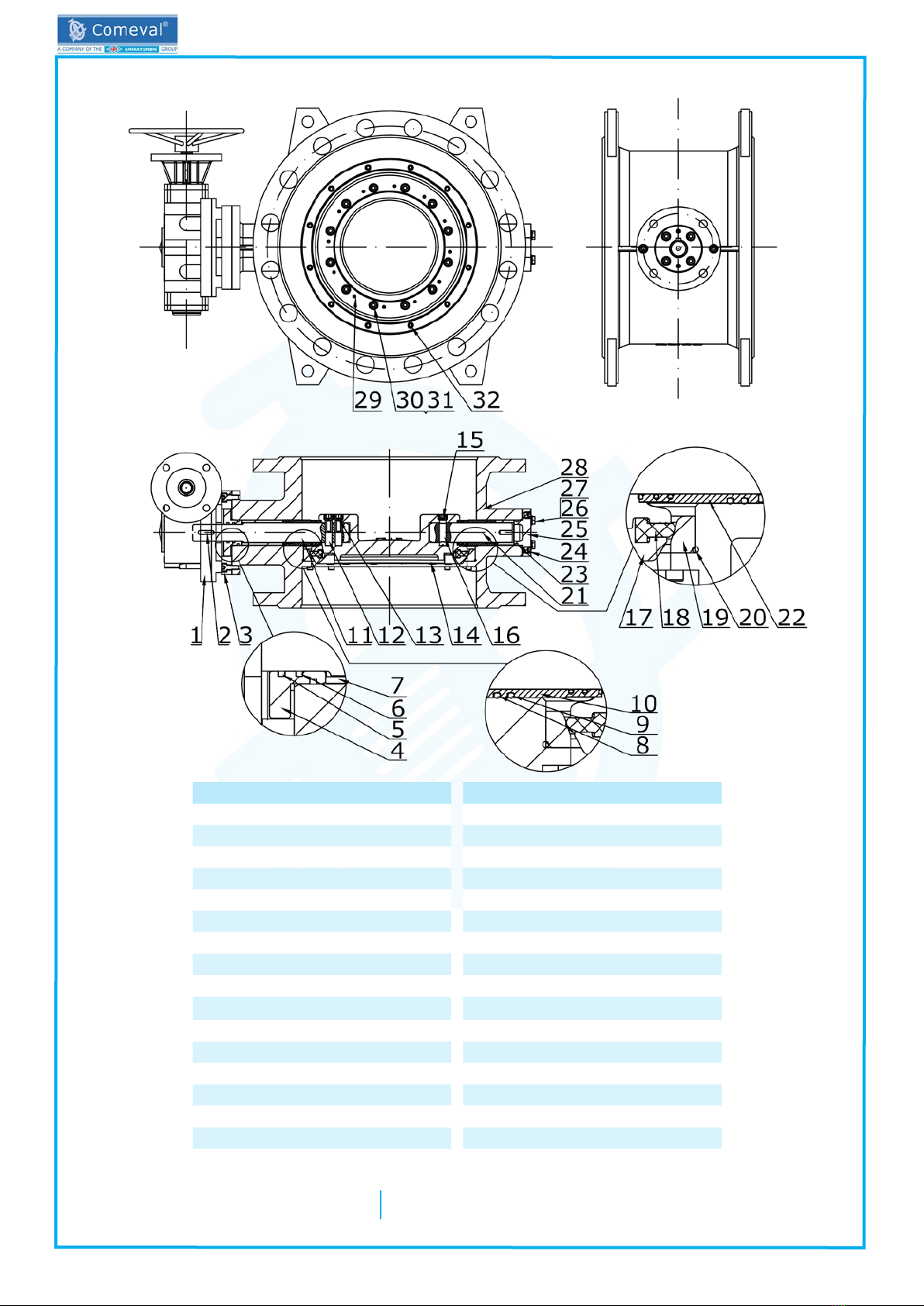

IOM - DOUBLE ECCENTRIC BUTTERFLY VALVES

UNIWAT® VF791

©COMEVAL VALVE SYSTEMS Technical Dept. Ref. IOM - DOUBLE ECCENTRIC BUTTERFLY VALVES, UNIWAT® VF791 - Ed.20/07

Comeval Valve Systems reserves the right to alter any technical data contained in this Manual without prior notice. Regularly updated data on www.comeval.es

5.2 Assembling additional modules

Optional accessories (limit switches, extensions, etc.) that are supplied with valves must be tted as required for their

functions as shown in the system plan.

5.3 Requirements at the place of installation

- Aggressive environmental conditions may reduce the life span of the product. Consider special construction/protective

measures in such a case.

- Consider the interaction between the system and the equipment. Foresee elements to absorb vibrations, pipe dilata-

tions, guides, anchoring and proper support according to the weight of the components. Max. recommended velocities as

follows: PN6: 2,5 m/s; PN10: 3 m/s; PN16: 4 m/s.

- The system and operation protocol should be conceived in such a way to avoid high velocities and cavitation. Prevent

pulsing ow or water hammers, which are very harmful for valves and the rest of the components.

- Flooding of the product is not recommended.

- Allow enough space for valve installation, operation and maintenance.

- It is recommended to install a proper sized mesh strainer upstream the valve in order to protect seating surfaces from

abrasion or erosion that could lead to seat leakage.

- Planners / construction companies or the owner are responsible for positioning and installing products.

6. COMMISSIONING & OPERATION

Page 4

ATTENTION!

- When using the valve as an end seal, the employers’ liability insurance association of the gas and waterworks

species the use of a safety precaution such as a plug-in disc, blind ange, etc. With a medium jet that freely exists,

you must secure the exit area.

- When installing the valve, there is a crushing hazard between valve and pipe system. Mind the hands to avoid it.

- Make sure that counteranges are compatible with the standard of the valve anges. When matching up anges,

avoid gradients, rotation and pipe misalignment that could cause pipe and valve stress and leakage once installed.

Flanges should t smoothly. Select the proper ange face gaskets according to duty and centre them on the ange

face properly. Do not force the counteranges and do not try to tighten the bolts when a gap exists between valve

and pipe or if misalignment is observed. Add anti-seize compound on the threads. Tighten in a crosswise, moderate

and uniform manner. During start-up tighten again if leakage is noticed or replace gasket if necessary.

NOTE: Cap screws will be necessary for the top and bottom alignment tapped holes. The studs should be used in

the through-holes.

- When the valve is operated, there is a crushing hazard between the disc and the body. Ensure the valve is not

under operation in case hands are introduced inside the valve.

- ACTUATORS: If the valve requires pneumatic, electric or hydraulic actuator, separate actuator Manual shall be also

followed. To avoid unnecessary stress and risk of valve break, consider the weight and the relative position of ac-

tuator to evaluate its support. Make sure that the actuator is suitable for service particular requirements, valve adap-

tability, function needed, adequate torque for the valve, adequate speed, need for limit switches, etc. Contact our

Technical Department for advice. In case of actuator mounted, disconnect the energy supply before starting work.

ATTENTION!

- Before commissioning the valve, check the material, pressure, temperature, ow direction and other essential para-

meters. Always use the product within the scope of intended service and operating duties.

- Before commissioning, make sure previous chapters are thoroughly followed.

- Regional safety instructions should be adhered to.

- It is essential to ush the pipe system thoroughly to eliminate all the particles and impurities which could remain in

the pipes and particularly welding residue, chips, tool remains, etc. that could damage the equipment during start-up.

Ensure that during cleaning of the pipe system, any chemicals used and temperature are compatible with the valve

construction.

- Temperatures above 50ºC or below 0ºC may cause personnel injuries if valves are touched.

- Leakage of media through valve stem, between counteranges or at closing (end of pipeline) may also cause scal-

ding, health harm, pollution, re or damage to other parts of the installation depending on the media.

Use suitable protection equipment when approaching the valve, ensure that the corresponding warning signs are

displayed on the valve or surrounding area, and/or isolate the equipment in case of danger.

- Do not pressurize if the valve does not have operating device. Buttery valves are not self-locking.

- Before commissioning a new plant or restarting it after repairs or modication, always ensure that:

- All work has been completed correctly.

- The valve is in the correct position for its function.

- Safety devices/measures have been implemented.

- Valve operation, lling, warming-up and starting-up shall be gradual so as to avoid any inadmissible stress.