©COMEVAL VALVE SYSTEMS Technical Dept. Ref. IOM - DUAL PLATE CHECK VALVES, UNIFLOW DC/DP - Ed.20/07

Comeval Valve Systems reserves the right to alter any technical data contained in this manual without prior notice. Regularly updated data on www.comeval.es

Page 2

IOM - DUAL PLATE CHECK VALVES AND DISC

UNIFLOW DC/DP

1. GENERAL INFORMATION ON THE MANUAL

-ThisManualprovidesinformationonsafelyusingtheproduct,beingbindingforpreservation,storage,handling,trans-

port,installation,commissioning,operation,maintenance,repairanddisposal,andmustbethoroughlyobservedatany

step.

-PleasecontactthesupplierorthemanufacturerincaseofissueswhichcannotbesolvedbyreferencetothisManual.

-AnydeviationfromthisManualandsoundengineeringpracticeormodicationontheproductshallbenotiedtoma-

nufacturer for advice or approval.

-Inaddition,regionalsafetyrequirementsmustbealwaysappliedandobservedatanystep.

-All the work related to the product must be carried out, supervised and inspected by specialist personnel. It is the

owner’sresponsibilitytodeneareasofresponsibilityandcompetenceandtoensurethepropermonitoring.

- This Manual is in accordance with Directive 2014/68/EU on Pressure Equipment (PED).

-ForATEXapplications,pleaserefertoATEXSpecicinstructions.

-Themanufacturerreservestherighttomaketechnicalmodicationsatanytime.

2. NOTES ON POSSIBLE DANGERS

2.1Signicanceofsymbols

ATTENTION!

...

Warning of general danger

2.2Explanatorynotesonsafetyinformation

In this Manual dangers, risks and items of safety information are highlighted to attract special attention.

Informationmarkedwiththesymbolabovedescribespractices,whichiffailtocomplywith,canresultinseriousinjuryor

danger of death for users or third parties or in material damage to the system or the environment. It is vital to comply with

these practices and to monitor compliance.

TherestofinformationnotspecicallyemphasizedinthisManual,alongwithDataSheetandproductmarking,mustalso

beobservedandcompliedwithforsafelyusingtheproduct.

3. PRESERVATION, STORAGE AND TRANSPORT

ATTENTION!

- Protect against external force (impacts, vibrations, etc.).

- Allow only skilled personnel; suitable handling and lifting equipment must be used. See Data Sheet for weights or

consult manufacturer.

- Always use suitable protection equipment, and minimize the use of human body force at any step to avoid injuries.

- There is a risk of body member (hand, nger, arm…) crushed against any other solid element (wall, pipe, oor, etc.)

during handling. Take this into account and handle with care.

- There is a crushing hazard between the plates (or discs) and the seat. Ensure the plates are in rest position in case

a hand is introduced inside the valve.

- Check correct position of nameplate and handle with care to avoid personnel cuttings.

- Use proper packing for transportation.

-Keepstorageprotectionbeforeinstallation.

- Keep exposed machined surfaces cleaned and greased when necessary. In order to prevent damage, corrosion or

rust on the surface, avoid extreme temperatures (keep at 5ºC to 50ºC), avoid high environmental humidity or corrosive

environment.Keepthevalvesawayfromdirectsunlight,dust,amesorrain.ProtectrubbersalsoagainstUVlight.Do

notpileupexcessiveweight.Incaseofseverebumpinginspectthematerialforanydamageandreplaceifnecessary.

4. DESCRIPTION

4.1GeneralDescription/Operatingprinciples

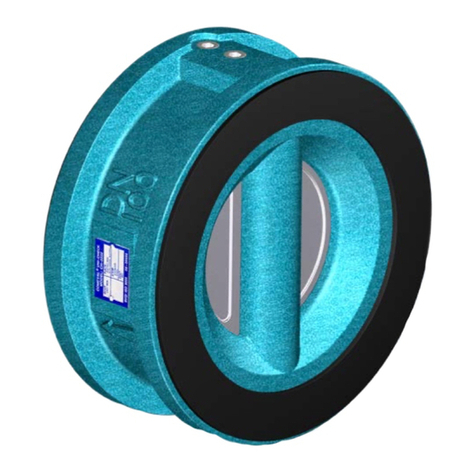

Dual Plate Check Valves use two half-sphere discs or plates and a connecting hinge to create a closure element that

collapseswhenpositiveowexists,andfoldsbacktoafullcirculardiscandcloseagainstapressurereversal.Discsare

preloadedwithspringsthatfavortheclosingofthevalvewhennopositiveow.

ValvediagramwithpartscanbeseenatthelastpageoftheManual.

4.2AreaofApplication

DualPlateCheckValvesarefeaturedasalight,compactandeconomicanti-returndevicetobeusedonindustrialand

wastetreatmentplants.Itswaferorlugdesignsuitabletoinstallationbetweenangesmakesthesevalvesquiteaprime

optionespeciallyonlargesizes.

4.3Technicaldata–remarks

For data such as main features, duties/limits of use, dimensions, weights, etc. refer also to Data Sheet.