4SAFETY GUIDELINES - INSTALLATION & USE www.comfortcompany.com

COMFORT-TEK™ fabric cover is uid-resistant, easily cleaned at any time

and soft to the touch. Comfort-Tek™fabric has stretch which helps alleviate

pressure and conforms to both support pad and user.

STRETCH-AIR™fabric cover is 2-Ply designed to be breathable on the

surface for comfort while the bottom layer is uid-resistant for cleanliness.

The multi-directional stretch allows for optimal conforming to the user and

support pad shape.

GLIDEWEAR®fabric cover is intended for maximum hair and skin protec-

tion by reducing shear. Recommended most for those with abnormal tone

causing involuntary movements, difcult postures and frequent repositioning

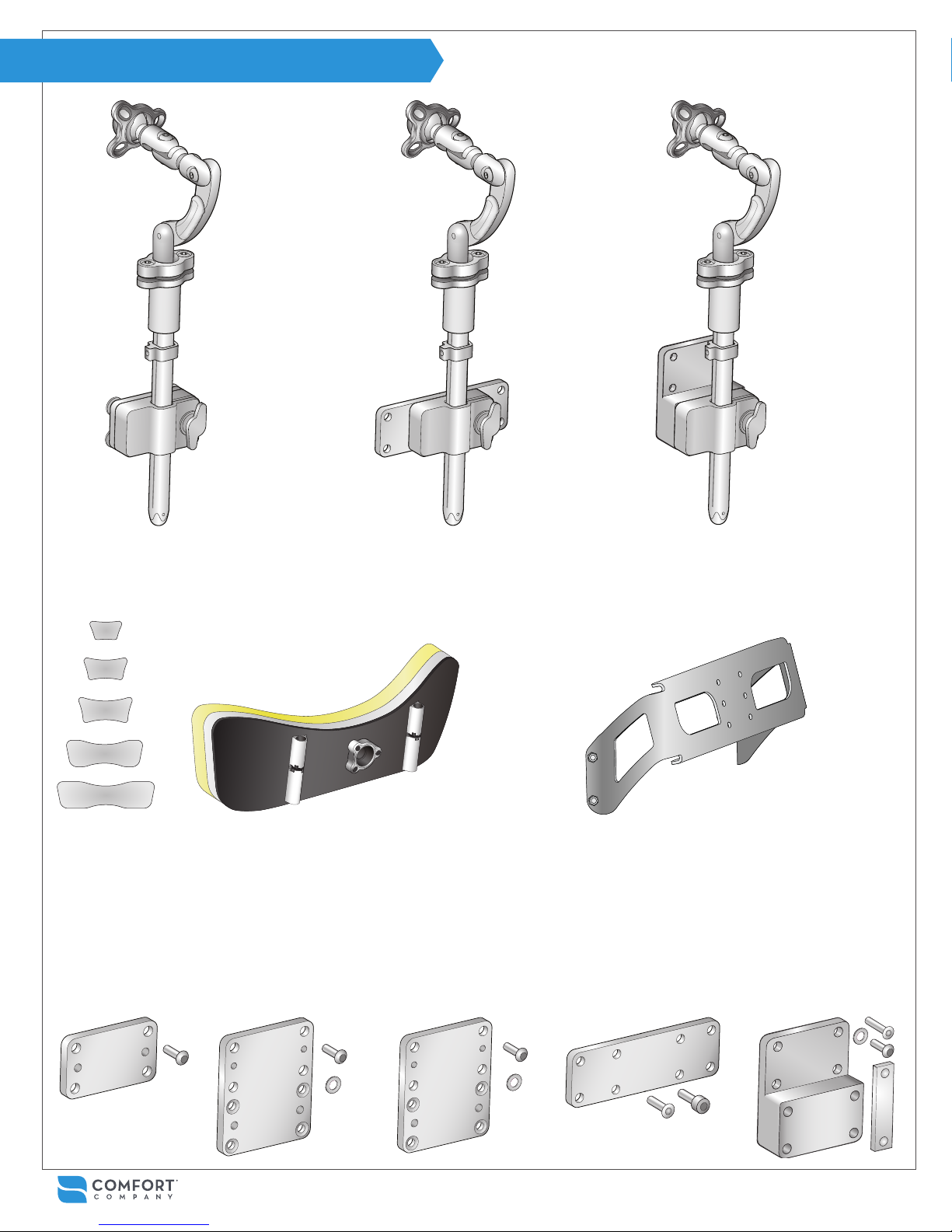

BodiLink™ head support is intended for those with positioning and support needs as deemed necessary by a qualied healthcare professional.

BodiLink™head support offers a wide variety of available positions to accommodate user rehabilitation needs and goals while allowing for function and

comfort. The sizes available and range of adjustability t pediatric to full grown users and should be matched by the healthcare provider to suit the user

needs. Adjustments or replacement components may be necessary as changes in condition occur or to accommodate developments such as growth.

All fabrics used in BodiLink™Head Support covers are latex-free.

Comfort-Tek™fabric is used on all head support pad covers along

the outer edge.

BodiLink™ Head Support pads come in 2 levels of rmness (soft and

extra soft). Both use a layer of Viscool®extra soft foam over a high

resiliency foam base layer. This combination allows for immersion and

conforming to the user for optimal surface contact, comfort and pres-

sure redistribution.

This product passed crash testing. However, when

possible, do not use head support during transport.

Repeated or excessive force (braking or crash) could

potentially change adjustment or cause extra wear

shortening the life of the product. Use after a crash is

not recommended.

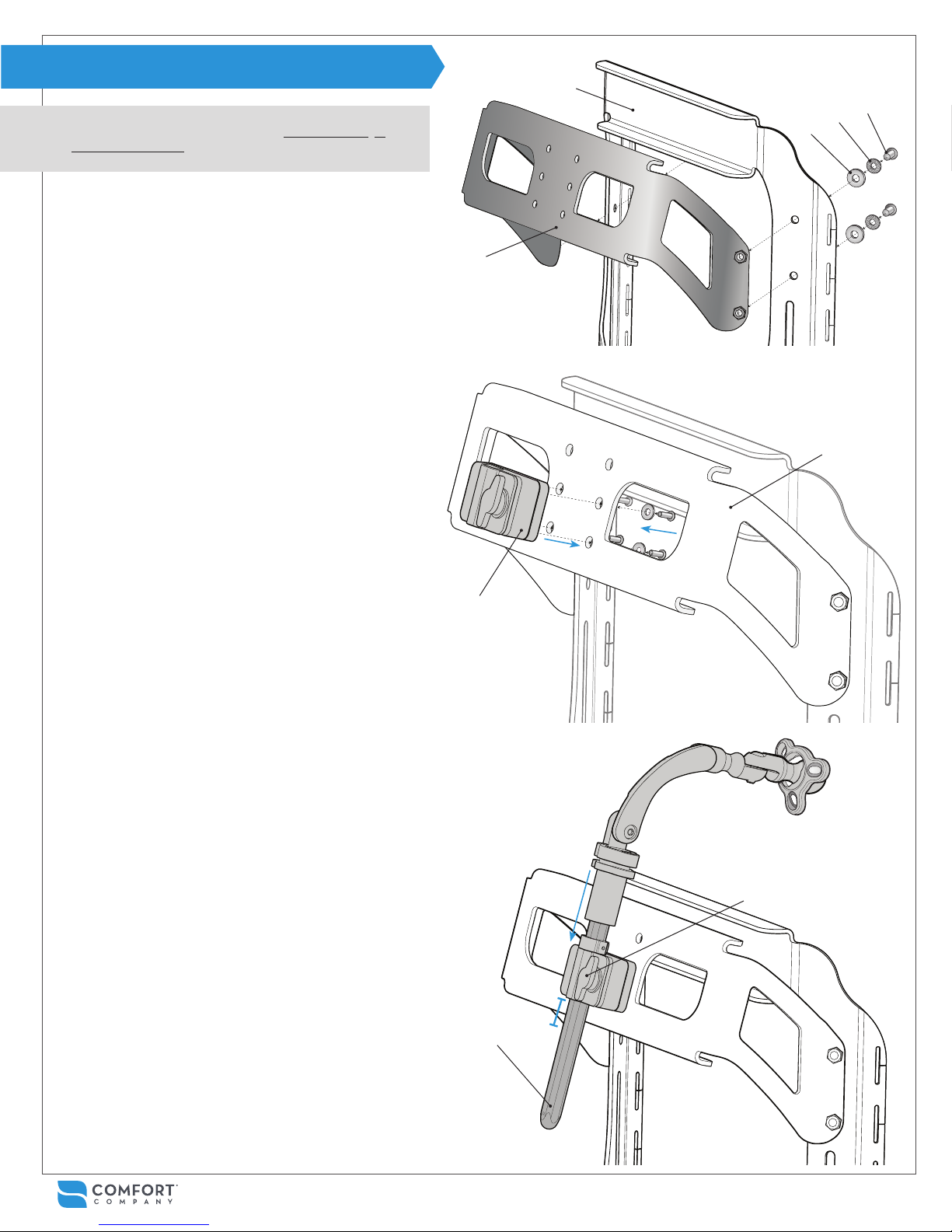

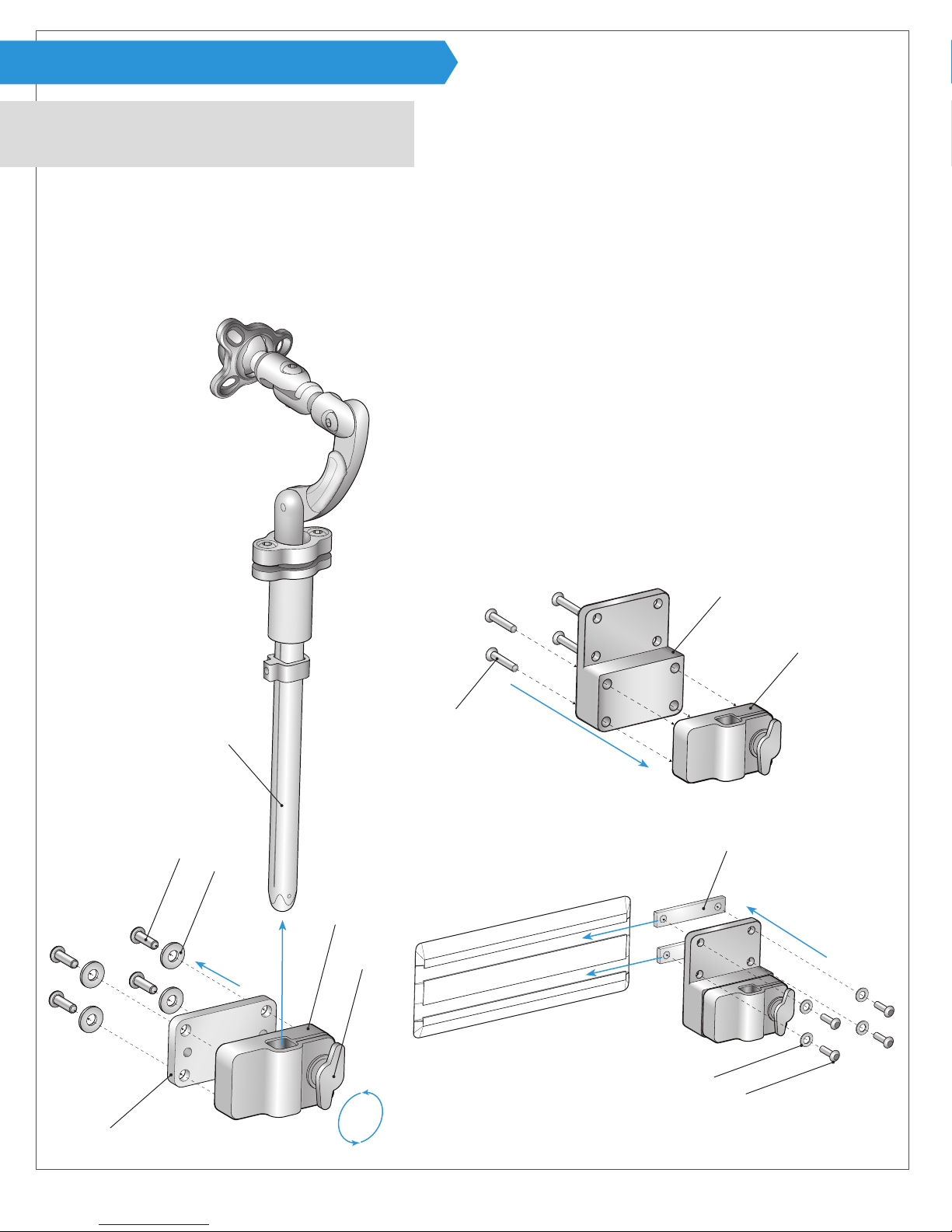

ATTENTION! Always check that the gear teeth in each joint

are aligned for full tooth engagement before nal tighten-

ing. Failing to do so could cause wear on the teeth leading

to parts slipping out of adjustment or hardware failure.

ATTENTION! Unless otherwise specied, fasteners

should be tightened to 10.5 Nm (93 lb-in).

ATTENTION! Make sure that the head support is securely

mounted to the back support system and it is adjusted

properly each time it is in use.

This product is designed for the intended user and use

only. Be aware that any modications could potentially

endanger the user, cause discomfort or damage.

WARNING! It is necessary to fully articulate power recline

features to ensure there is no possible equipment interfer-

ence after installation. Do so slowly while watching closely.

Caregivers: It is necessary to learn from a healthcare provider

how to properly adjust the equipment for the user’s specic

positioning needs and goals.

WARNING! Ensure that the product does not interfere with

any other chair components. Interference could jeopardize

effectiveness and user safety as well as cause damage.

PROHIBITED! Never use the equipment to maneuver a

chair or anything that it is attached to. It is never to be

used as a handle, lift, guide or support for anything other

than what it was intended. (ex. support during transfers.)

PROHIBITED! Never use the equipment unless all compo-

nents are fully functional. Any issues should be addressed

by contacting your dealer or customer service. Do not at-

tempt to make your own modications or repairs.

SAFETY GUIDELINES

INTENDED USE - MATERIALS

BODILINK™ HEAD SUPPORT SAFETY DETAILS

INTENDED USER

CAUTION! Please consider that adding additional

links to the hardware may reduce the overall strength.