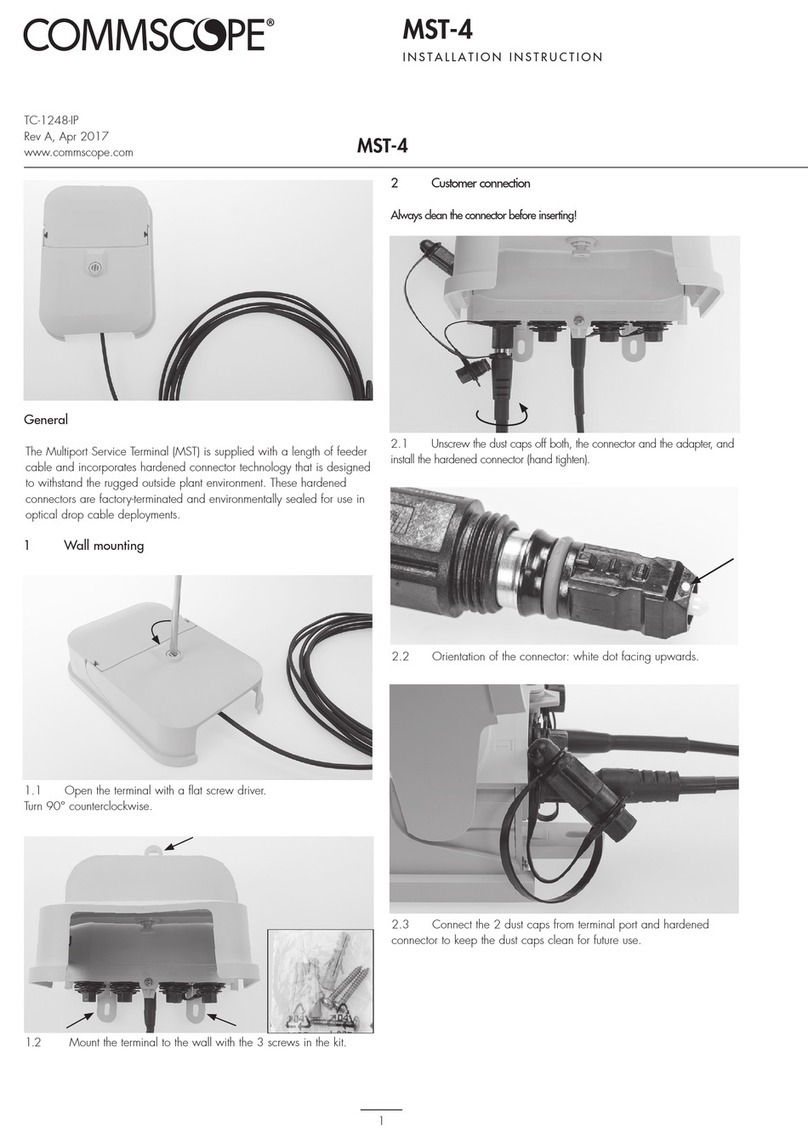

1 General

1.1 General product information

1.2 Cable types

1.3 Symbols in this guide

2 Tools Required

3 Parts List

3.1 Kit content

3.2 Terminal components

3.3 Configuration overview

4 Feeder cable preparation

5 Product Installation

5.1 Take out organizer with pre-connectorized

adapter drops

5.2 Secure feeder cable in the gel seal cable plugs

5.3 Store the loop (buffer tubes) in the basket

5.4 Store stripped/shaved tubes in the basket of

the base tray

5.5 Make fusion splice and store overlength in the

splice tray

5.6 Insert the gel strips

6 Close and lock the terminal closure

6.1 Place the organizer with pre-connectorized

adapter drops in the terminal housing

6.2 Close the terminal housing latches and lock

the terminal housing

6.3 Re-entry recommendations

7 Pedestal mounting

7.1 Installation on universal back plate

7.2 Installation on D-Bar

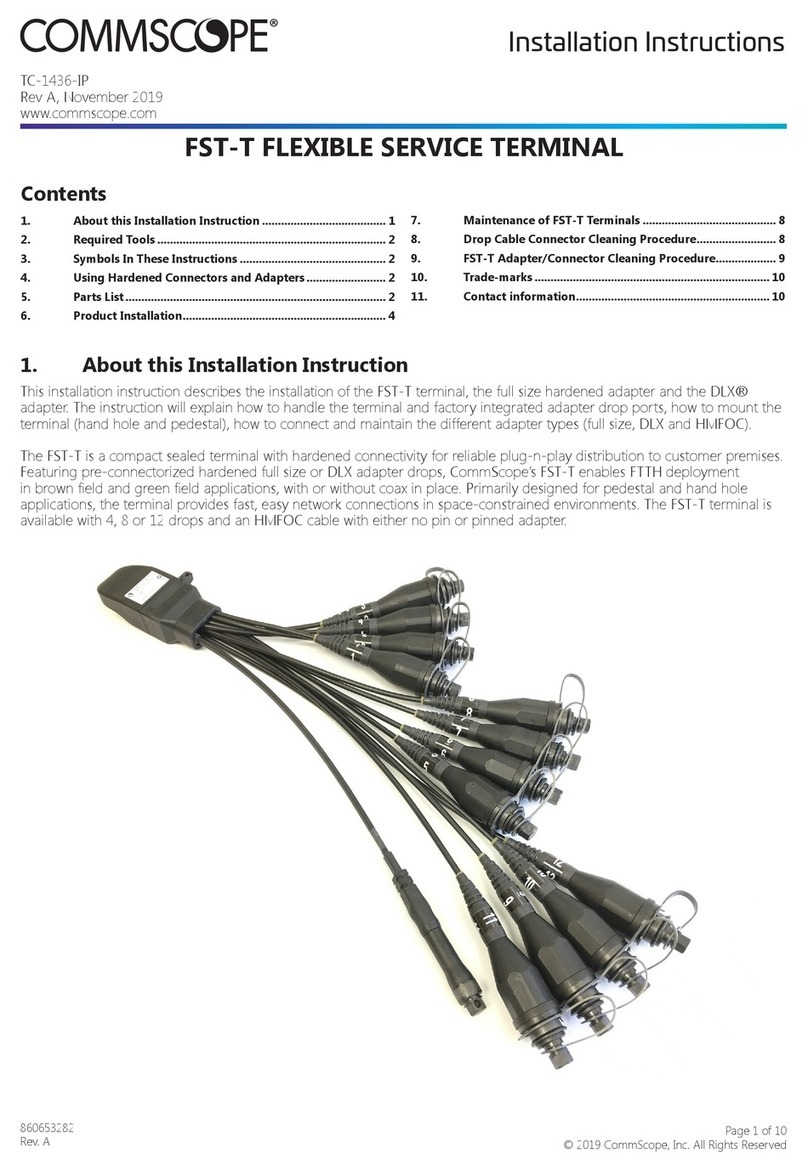

Content

1 General

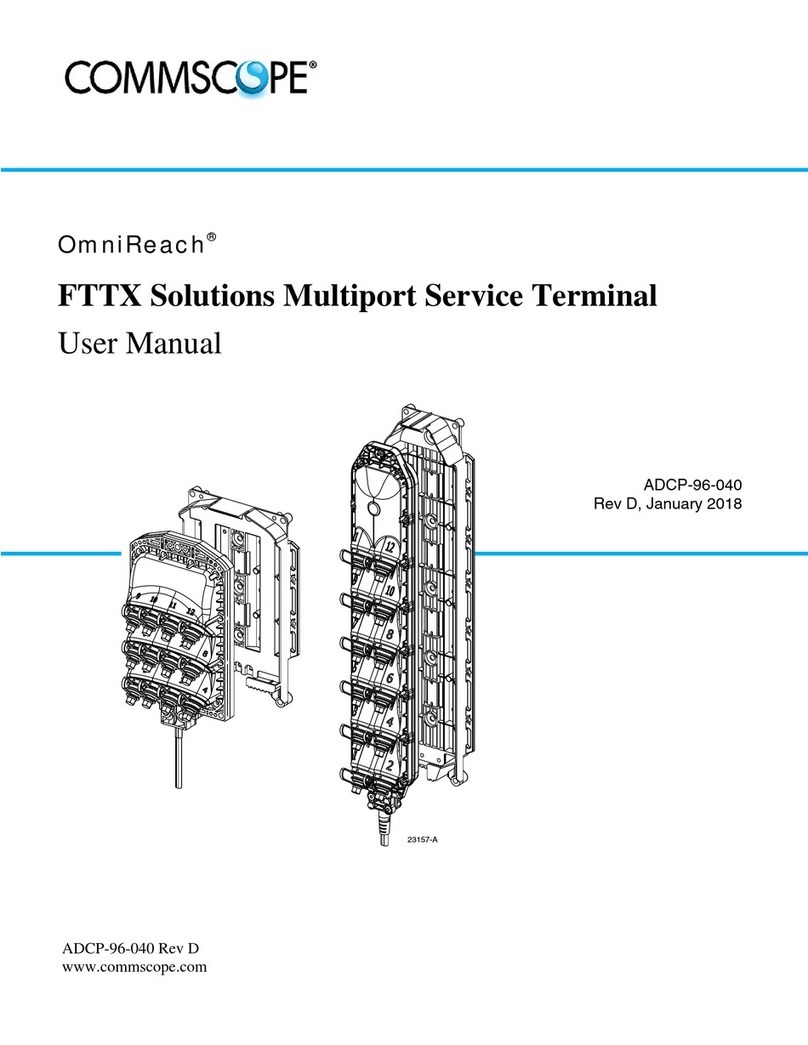

1.1 General product information

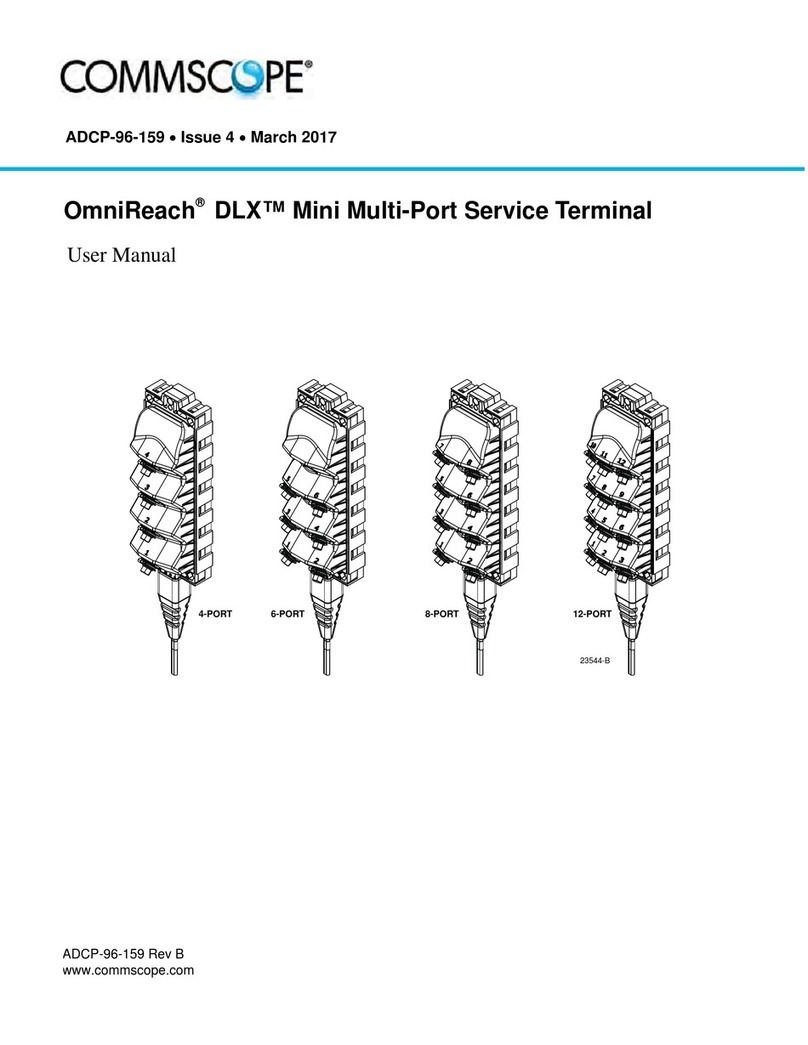

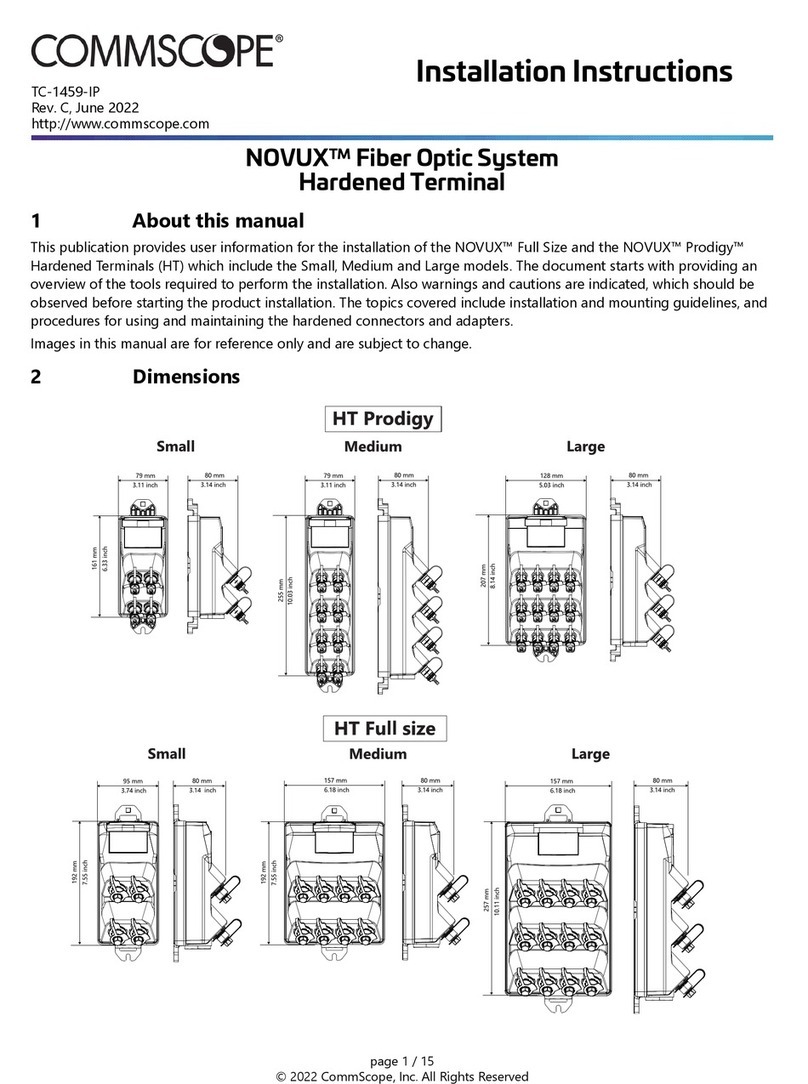

The Mini-OTE 400 is a compact terminal allowing the feeder cable to be field installed in fiber-to-the-x (FTTx) architectures. Featuring pre-

connectorized hardened full-size OptiTap® or mini-size DLX® adapter ports, CommScope’s Mini-OTE 400 terminal enables FTTH deployment in

brown field and green field applications, with or without coax in place. The terminal is designed for a butt splice configuration in pedestal and hand

hole applications. The Mini-OTE 400 terminal is available with 2, 4 or 8 drops.

1.2 Cable types

The Mini-OTE 400 terminal is available with 2, 4 or 8 drops and two entry/exit ports accommodating up to 72F stranded loose tube micro cable

with cable diameter range 4.5 - 6 mm (0.18 ” - 0.24 ” ).

Feeder cable Ø 4.5 - 6 mm (0.18 ” - 0.24 ” )

Fiber types include single fiber 250micron, A2 fiber.

Mini-OTE 400

INSTALLATION INSTRUCTION

Mini-OTE 400

TC-1335-IP

Rev C, March 2017

www.commscope.com

1.3 Symbols in this guide

Note Presents useful information related to Installation Guide contents, the references and data related to the product’s use, etc.

iCaution Describes situations where data loss and incorrect product operation may occur, and provides proper actions to take in these

situations.

!Warning Describes a situation where product damage and user injury may occur, and provides proper actions to take in these situations.

All tools to prepare and clean cables

Socket wrench 1/4” or a flat screw driver to secure the hose clamps

Socket wrench 7/16”

Phillips screw driver

Hexagonal wrench

Pincers

2 Tools required