1 Safety Instructions

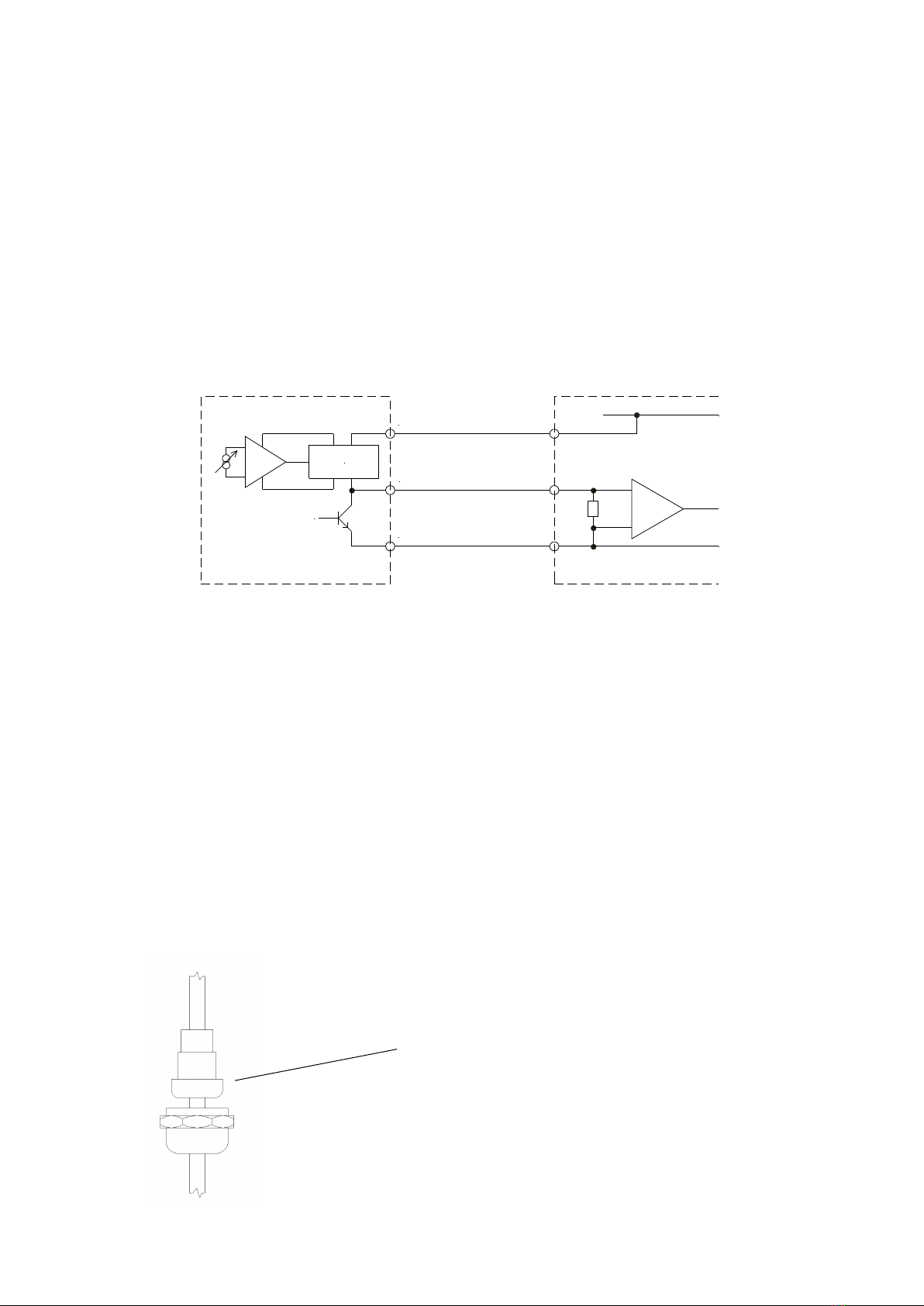

Statox 506 is a transmitter designed as an intrinsically safe device, group 2 category II. It measures the

concentration of toxic gases and oxygen in ambient air. It is safe to be operated in classified areas zone 1

and zone 2.

The gas specific parameters are stored in an F–Ram on board of the sensor. These will be downloaded

into the sensor head electronics automatically as soon as the sensor is plugged in.

Safety advice:

Read and observe this manual carefully. Keep it in a safe place.

This transmitter must be installed and connected observing the regulations for operation in hazardous

areas. It must be performed by authorized and trained personnel only. Respect the regulations for the

operation of safety instrumented systems including standard DIN EN 60079-14.

If operated in a hazardous area, the sensor head power supply must run through an intrinsically safe

repeater or the loop itself must be intrinsically safe, see chapter 3.2 Electrical Connection.

Potential equalization must be in place along the intrinsically safe circuit.

Statox 506 must not be operated in an ambience outside the technical specifications, see chapter 12.

Statox 506 must be operated and serviced by authorized and trained personnel only. Use only original

Compur parts as spares and consumables.

Do not operate uncomplete or damaged sensor heads.

All of the above warnings must be observed. Incorrect installation or connection will void the

explosion proof rating and thus be dangerous to human life and assets.