16 COMUNELLO ®Copyright 2016 - All right reserved

OPERATION WITH TIMER:

The control unit allows a timer to be connected in place of the open – close

pushbutton. E.g.: at 08.00 am the timer closes the contact and the control

unit commands an opening movement; at 06.00 pm the timer opens the

contact and the control unit commands a closing movement. From 08.00

am - 06.00 pm at the end of the opening cycle the control unit disables the

ashing light, automatic closing and the remotes.

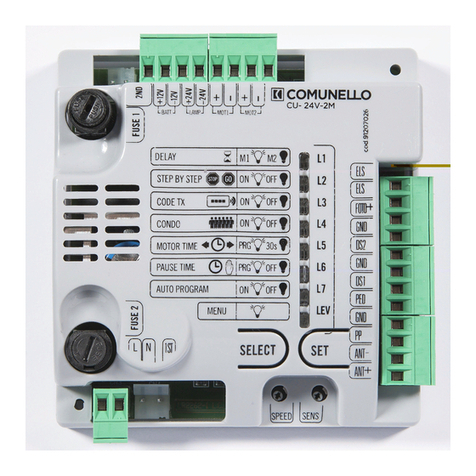

PROGRAMMING:

SELECT key: selects the type of function to store; the selection is indicated

by blinking of the LED.

Press the key repeatedly to go to the required function. The selection

remains active for 10 seconds shown by blinking of the LED; when this

interval elapses, the control unit returns to the original state.

SET key: programs the information in accordance with the function type

preselected with the SEL key.

IMPORTANT: The SET key function can be replaced by the remote if

programmed beforehand (CODE LED on).

Programming enabled only when safety devices are not active.

MAIN MENU

The control unit is factory set to allow the selection of several important

functions.

L1 DIR Left Open Right Open

L2 STEP BY STEP Step-by-Step Automatic

L3 CODE TX Code entered No code

L4 CONDO ON OFF

L5 MOTOR TIME Programmed time 30 sec.

L6 PAUSE TIME With automatic closing Without automatic closing

L7 AUTO PROGRAM ON OFF

LEV MENU ON

1. OPENING DIRECTION (DIR):

In the default conguration the control unit is set with “OPEN TO RIGHT”

logic (seen from the operator side, with operator installed to the right of

the sliding leaf); if the “OPEN TO LEFT” logic must be enabled (seen from

operator side, with operator installed to the left of the sliding leaf), proceed

as follows: use the SELECT key to select the blinking OPEN DIRECTION

LED and then press the SET key: the OPEN DIRECTION LED becomes

steady on and programming will be completed. Repeat the procedure if you

wish to restore the previous conguration.

2. STEP-BY-STEP:

In the default conguration the control unit is set with “Step-by-Step”

operating logic enabled (LED n2 on); if the “Automatic” operating logic is

required (LED n2 on), proceed as follows; use the SELECT key to select

blinking LED n2 and then press the SET key: LED n2 will switch off and

programming will be completed.

If the “Step-by-Step 1” operating logic is required, repeat the operation

above described, by pressing the SEL key twice instead only one (to obtain

the quick blinking of LED .

Repeat the procedure if you wish to restore the previous conguration.

3. TX CODE: (REMOTE CONTROL CODE)

Up to 120 remotes with different codes, either of the xed or the rolling

code type can be saved on the control unit.

Programming:

Programming of the transmission code is performed as follows: use the

SELECT key to select blinking LED L3. Press SET once; the LED will change

its blinking mode (longer 1 0 1 0) to show that the rst level is being saved.

On sending the selected code with the required remote, the CODE LED

will remain steady on to indicate that programming has been completed.

To save the code for pedestrian opening / single leaf proceed as follows:

use the SELECT key to select blinking CODE LED L3. Press SET twice

consecutively; the LED will change its blinking mode (1 1 0 1 1 0) to show

that the pedestrian code is being saved. On sending the selected code

with the required remote, CODE LED L3 will remain steady on to indicate

that programming has been completed.

NOTE: After each programming of a valid code, the control panel

waits for a subsequent code for another 10 sec.

If all 120 codes have been saved, repeating the programming operation will

cause all the programming LEDs to start blinking to signal that no further

codes can be saved.

Deletion.

Use SELECT to go to LED L3; activate blinking of the code to be deleted

(CODE or PEDESTRIAN identied by the respective blinking); press and

hold down SET for > 5 s. After this interval the LED will switch off for 2

seconds and the procedure is completed. If all CODE and PEDESTRIAN

codes are deleted, the LED will remain off.

If only PEDESTRIAN codes remain stored, the LED blinking mode will

change (1 1 1 1 0 1 1 1 1 0)

Rule of the rst saved Remote control:

When programming remotes the following rule is applied: if the rst remote

to be saved is of the rolling code type, the receiver will subsequently

accept only rolling code remotes, thus providing enhanced anti-intrusion

security; if the rst remote to be saved is a xed code type, the receiver will

subsequently accept both xed code remotes and rolling code remotes,

although only the xed part of the latter will be controlled (thus effectively

relinquishing the security of the rolling code system).

IMPORTANT: Whenever a reset is performed the receiver is restored to the

factory settings so the rst remote rule logic will be reset.

4. CONDO:

The Condominium function means that during the opening movement or

during the pause time the control unit will not respond to commands sent

by Pushbuttons or remotes. In contrast, during the closing movement a

command sent by the Pushbuttons or the remotes will reverse the direction

of movement. This operating mode is invaluable when the automation

includes a loop detector. In the default conguration the control unit is set

with the Condominium function disabled; if the Condominium function is

required, proceed as follows: use the SELECT key to select blinking LED L4

and then press the SET key: LED L4 becomes steady on and programming

will be completed. Repeat the procedure if you wish to restore the previous

conguration.

5. MOTOR TIME:

(Programming of the motor run time with max 4 minutes). The control unit

is factory set with a preset motor time of 30 seconds without deceleration.

If motor time must be changed, programming must be carried out with the

gate closed as follows: use the SELECT key to select blinking LED L5 and

then press the SET key momentarily; the operator will start the opening

movement; when the required deceleration starting point is reached

press the SET key again; at the same time the operator will decelerate

and reach the required position; press SET to terminate the opening cycle.

Thereafter LED L5 will start blinking rapidly; now repeat the motor time and

deceleration programming procedure for the closing cycle. If you do not

require the control unit to perform the deceleration, during programming,

when the open-close cycle has been completed press the SET key twice

consecutively rather than just once. During programming, instead of the

SET key on the control unit you can use the button on the remote, providing

the remote has been saved beforehand.

6. PAUSE TIME:

(Automatic closing time programming 4 min. max.) The control unit is

factory set with automatic closing disabled. If you wish to enable automatic

closing proceed as follows: use the SELECT key to select blinking LED L6

and press the SET key momentarily; now wait for a time equivalent to the

required time; press the SET key again momentarily and at the same time

the automatic closing time will be saved and LED L6 will remain steady on. If

you wish to restore the initial condition (no automatic closing) select blinking

LED L6 and then press the SET key twice consecutively in a time period

of 2 seconds. The LED will switch off and the operation will be completed.

During programming, instead of the SET key on the control unit you can use

the button on the remote, providing the remote has been saved beforehand

7. AUTO PROGRAM:

The control unit offers the facility of Automatic Programming (SIMPLIFIED).

First bring the gate leaves to an intermediate position, use the SELECT

key to select blinking LED L7 and then hold down the SET key; the control

unit executes the Auto programming procedure by performing a complete

open-close cycle (keep the SET key pressed until Auto Programming is

completed). During the Auto Programming procedure the Deceleration

cycle is set automatically at approximately 15% of the complete cycle.

During Automatic Programming, instead of the SET key on the control unit

you can use the button on the remote, providing the remote has been

saved beforehand.