5

COMUNELLO ®Copyright 2014 - All right reserved

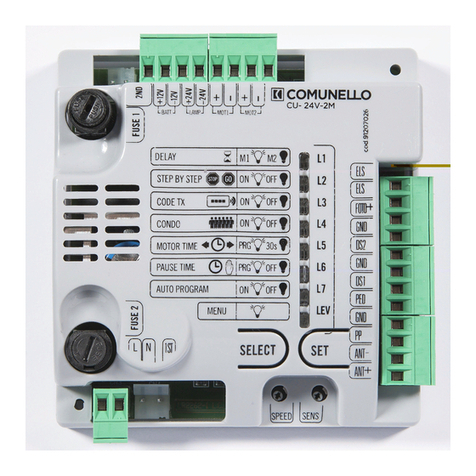

BASIC 24V – (QUAD 24V 2M)

ID Description Cable type Lenght (1m to 20m) Lenght (20m to 50m)

1Main power supply

FG7 CEI 20-22

CEI EN 50267-2-1

2x1,5mm2 2x2,5mm2

6A Motor power supply 2x2,5mm2 2x4,0mm2

2 Flashing light 2x0,5mm2 2x1,0mm2

4A , 5A Photocell TX 2x0,5mm2 2x1,0mm2

4B , 5B Photocell RX 4x0,5mm2 4x1,0mm2

7 Key selector 3x0,5mm2 3x1,0mm2

3 Antenna RG58 max 20m

L N

1 ST

F2

2 ND

ALIMENTAZIONE FOTOCELLULE

PHOTCELL POWER

24V 5W

+

CN3

M

M

MOTORE

MOTOR

n -1 - 24V

MOTORE

MOTOR

n -2 - 24V

CN1

CN5

CN2

ELETTROSERRATURA (*) 3A max

(SOLO CONTATTO M.O.)

ELECTRIC LOCK

FOTOCELLULA 2 - DS2 IN APERTURA (N.C.)

PHOTOCELL 2 - DS2 OPENING (N.C.)

FOTOCELLULA 1 - DS1 IN CHIUSURA (N.C.)

PHOTOCELL 1 - DS1 CLOSING (N.C.)

PULSANTE PEDONALE (N.O.)

PEDESTRIAN PUSH BUTTON (N.O.)

F1

CN4

TRASFORMATORE

TRANSFORMER

230/21.7V - 7.5A

BATTERIA TAMPONE

BACK-UP BATTERY

LAMPEGGIANTE

FLASHING LIGHT

24V 4W

LINEA

POWER SUPPLY

ANTENNA

PULSANTE APRI-CHIUDI (N.O.)

PUSCH BUTTON (N.O.)

FOT+

GND

ELS

ELS

GND

PED

DS1

DS2

GND

PP

ANT-

ANT+

L24

L24

M1+

M1

M2+

M2

+

-

(*) Contatto pulito (M.O.) max 3A per sezionare l’alimentazione esterna dell’elettroserratura