info@con-formgroup.com.au

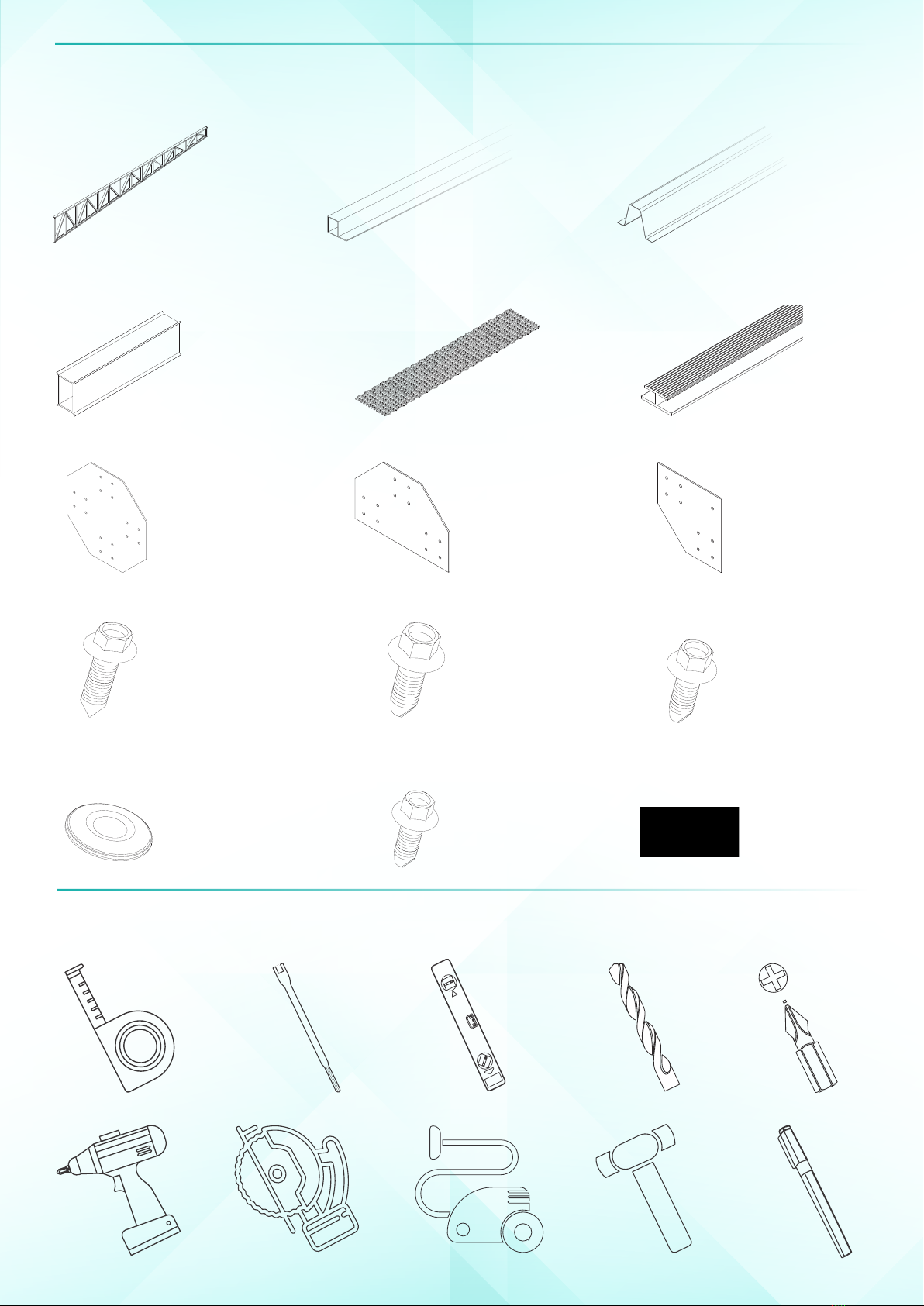

Tools Needed Parts

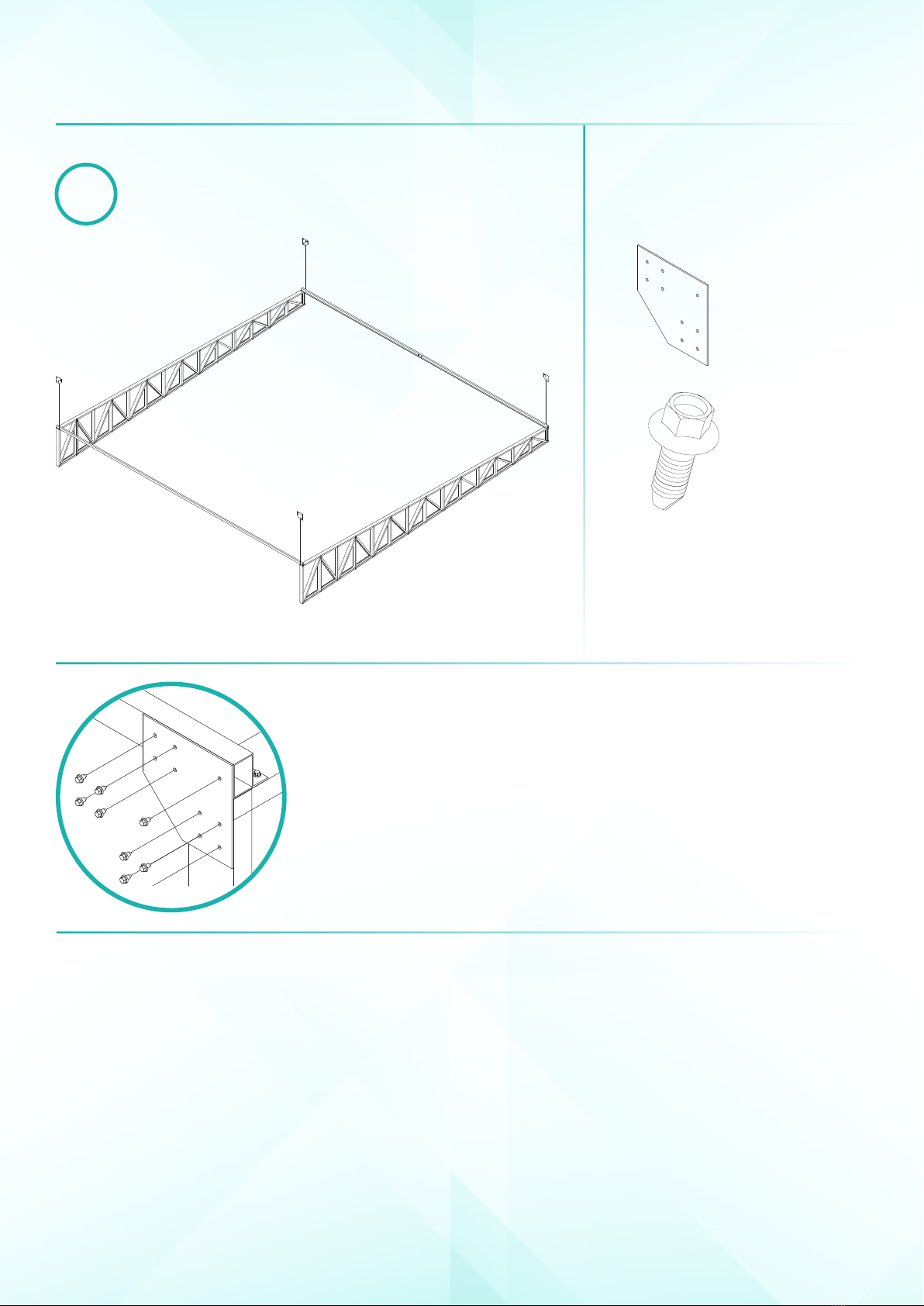

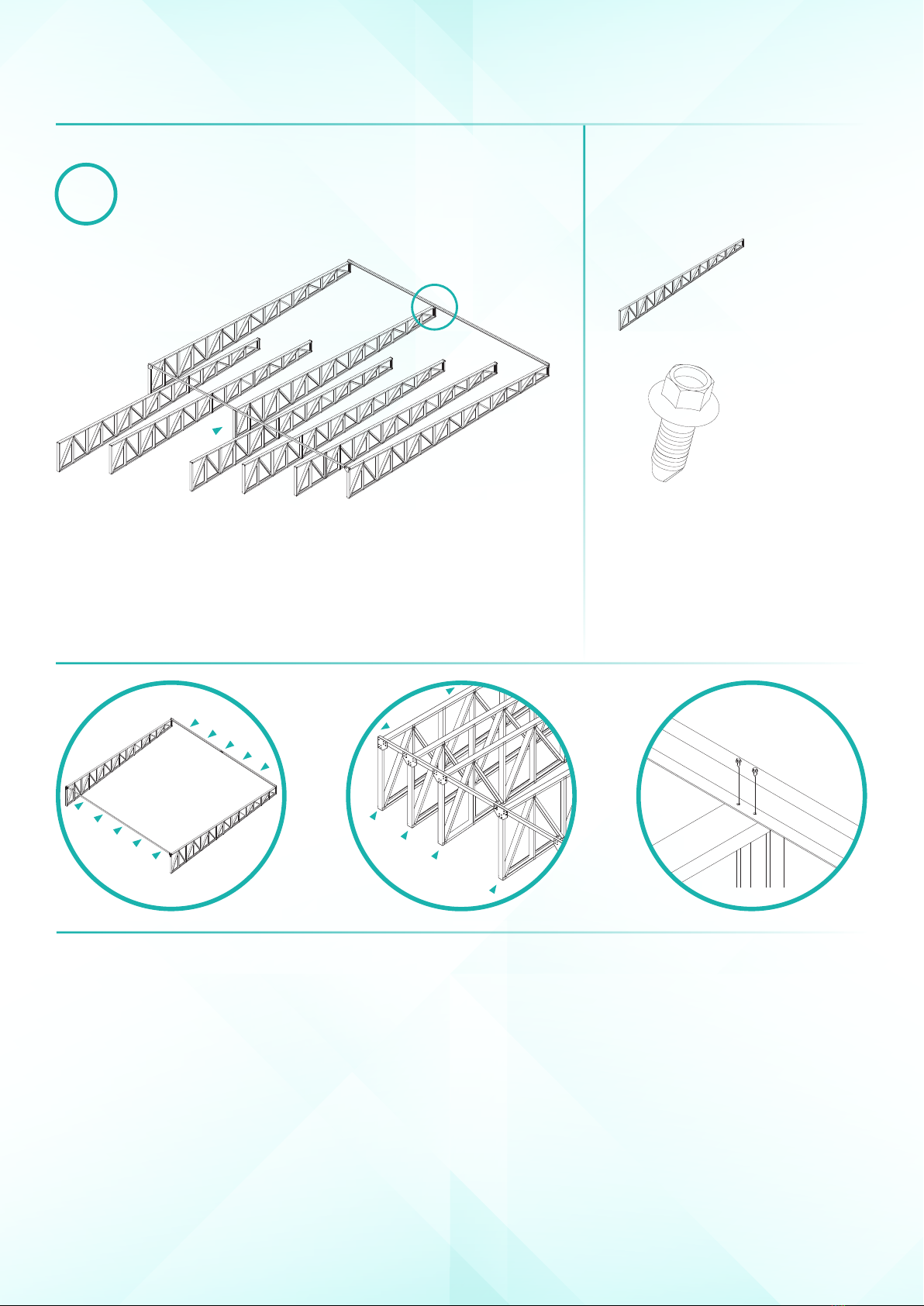

Tape Measure Truss Frames

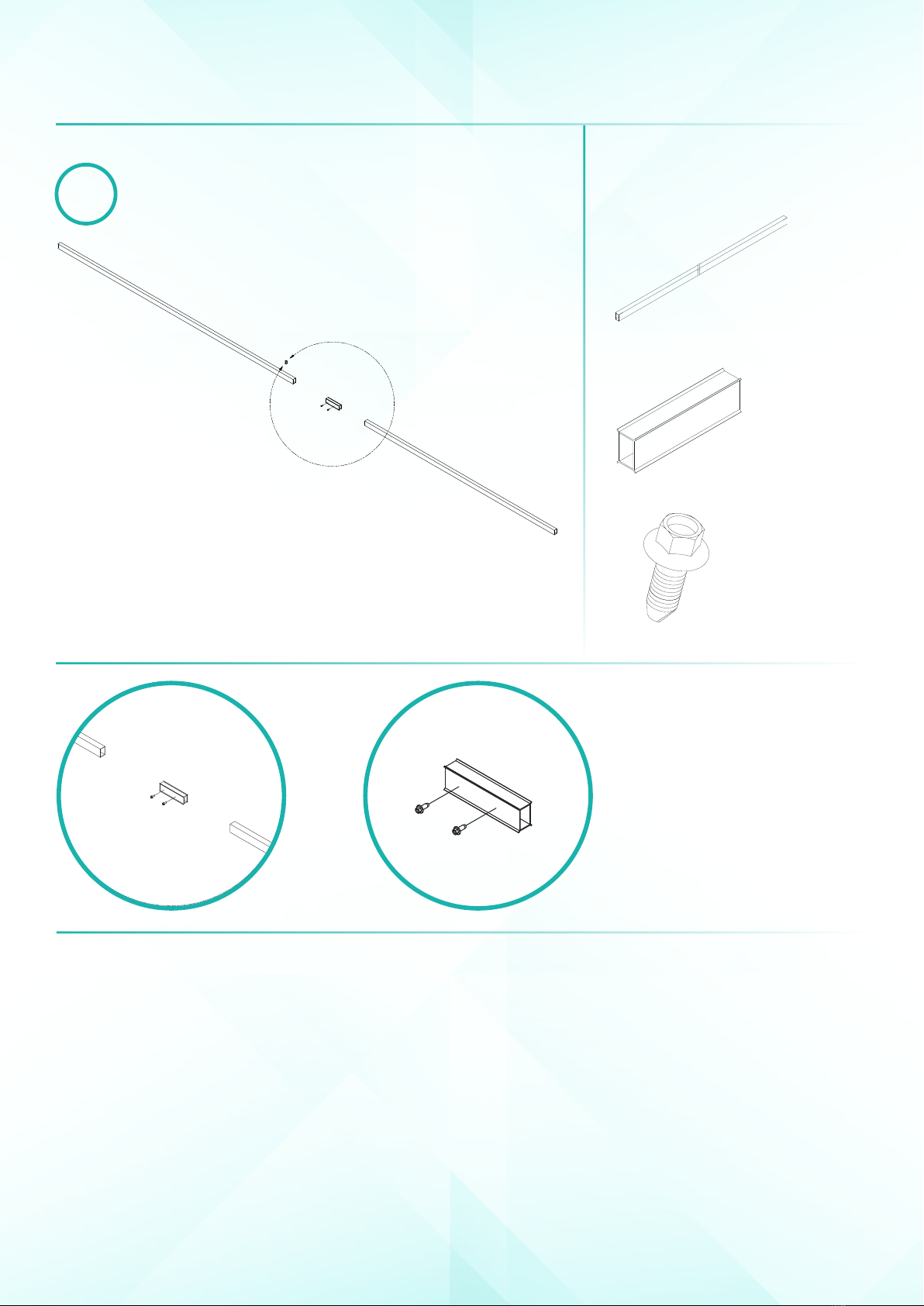

Black Marker RHS Cross Supports

Spirit Level Cross Support Splice

Impact Driver Top Hat Cross Supports

PH2 Phillips Head Bits Top Hat Splice

5/16” Hex Head Driver Bit Full Star Brace

Drill Half Star Brace

High-Speed Drill Bit Kit Quarter Star Brace

Nibbler Drill Attachment C-Channel Horizontal Brace

Circular Saw Diagonal Truss Brace

Mallet Mesh Sheet

18V Wet/Dry Vac Skin Mesh Joiner

Mesh Edge Bar

35mm Self Drilling Tek Screws

35mm Needle Point Screws

20mm Tek Screws

16mm Tek Screws

Hold Down Discs

Certication Plate