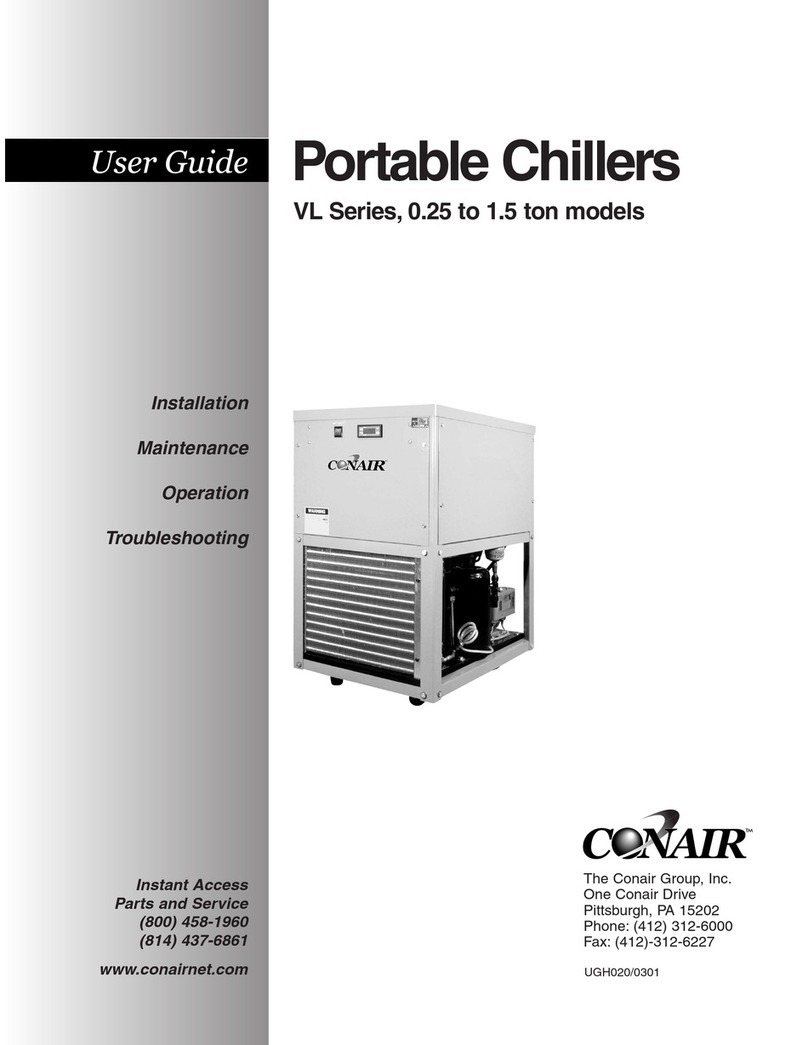

Page: 6 VL Series Portable Chillers, 2 to 40 Tons UGH021/0301

1.1 INTRODUCTION

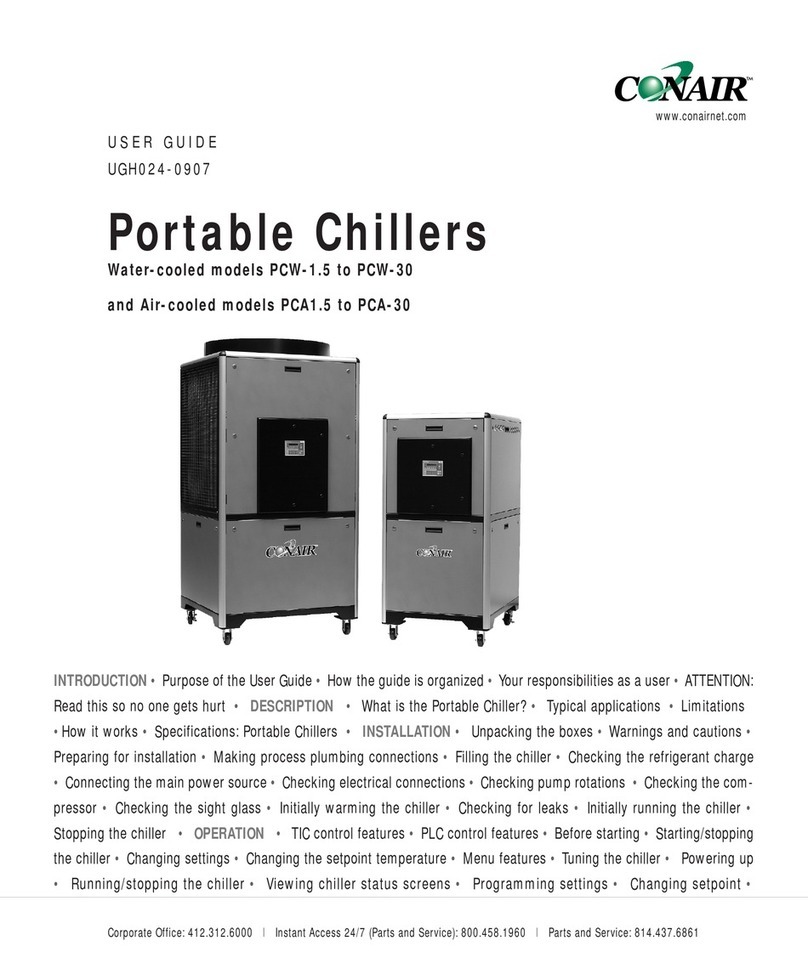

A. This manual covers most ‘VL’ series portable chiller models. Most

‘VL’ series portable chillers are basically identical with exception of

the type of condenser (air cooled or water cooled).

B. All instructions in this manual apply to most ‘VL’ series portable

chiller models regardless of the type of condenser or

instrumentation. Specific instructions relating only to air cooled

condensers, water cooled condenser, or instrumentation are

identified and should be noted by the operator.

C. When calling for assistance from the Conair Service Department, it

is important to know the model and serial number of the particular

unit. The model number encodes critical unit information which is

helpful in any attempt to troubleshoot operating difficulties. The

serial number allows the service team to locate manufacturing and

testing records which can have additional information relating to a

particular unit.

1.2 UNIT LOCATION FOR AIR COOLED MODELS

A. The ‘VL’ air cooled portable chiller is designed for indoor use only.

For most efficient operation, locate the chiller in a clean, dry and

well ventilated environment.

B. The ‘VL’ air cooled portable chiller has an air cooled refrigerant

condenser. For air cooled condensers, a motor driven fan (on

models from 2 to 10 tons) or a centrifugal blower (on models from

15 to 30 tons) generates air flow through the condenser to remove

heat from the refrigerant system. The air cooled condenser on the

‘VL’ portable chiller will discharge a maximum of 15,000 BTU’s per

hour per ton of cooling.

C. The ‘VL’ air cooled portable chiller must have a minimum entering

air temperature of 60°F and a maximum entering air temperature of

95°F for efficient operation.

D. The ‘VL’ air cooled portable chiller must have a minimum of two

feet clearance at the air intake and six feet at the vertical exhaust air

discharge.

1.3 UNIT LOCATION FOR WATER COOLED MODELS

A. The ‘VL’ water cooled portable chiller is designed for indoor use

only. For most efficient operation, locate the chiller in a clean, dry

and well ventilated environment.

1.4 EFFICIENCY

A. Long term efficiency of operation is largely determined by proper

maintenance of the mechanical parts of the unit and the water