CP-STEP-1-US 01-08

4

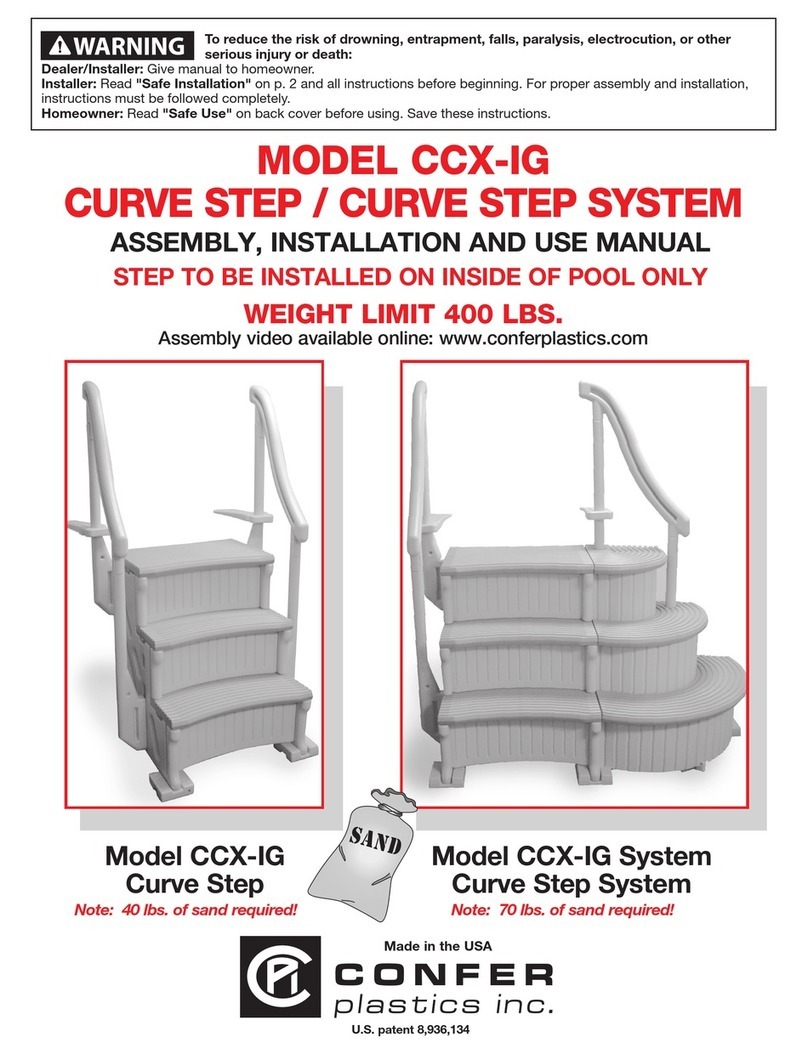

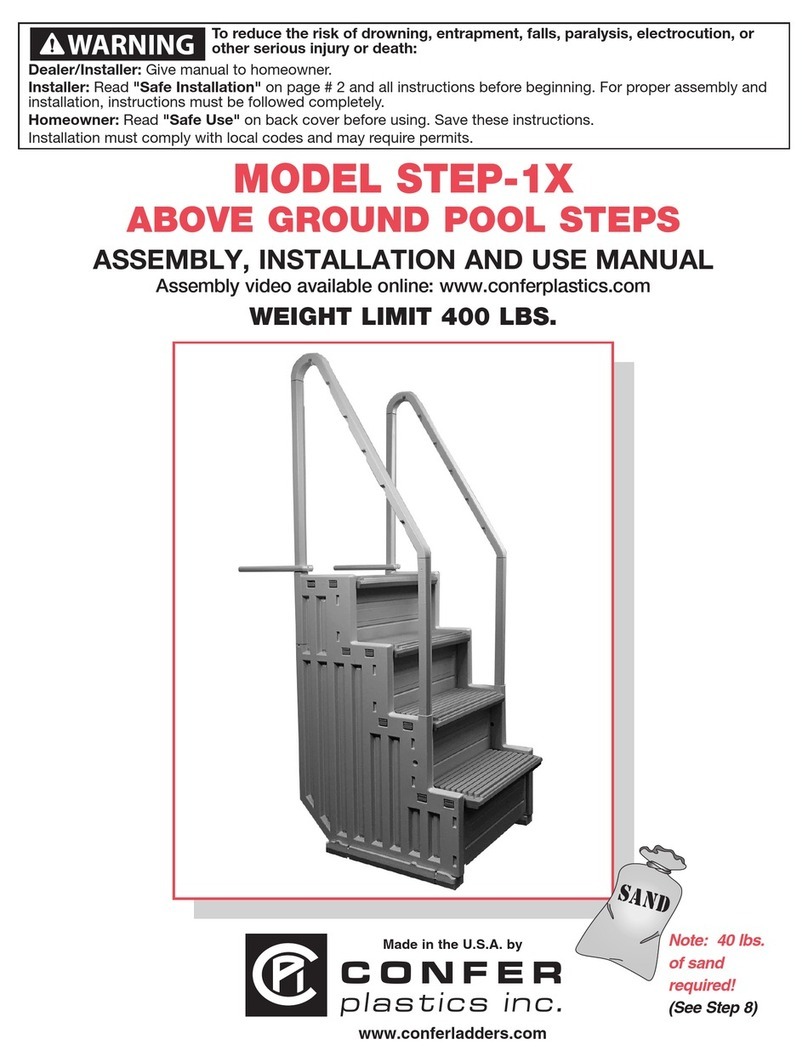

Options available – To make an

up-and-over step system with gate

as shown for your pool purchase

our #Step-Enc Enclosure Kit and

an additional #Step-1.

Contact your dealer or check

online at

www.conferladders.com

Safety Information

1) Always follow the manufacturer’s recommendations for

the safe use of all hand tools and equipment.

2). Do not use the Confer-Step for any purpose other than

that for which it is intended.

3). When lifting awkward or heavy loads, have another

person help you.

4). Maximum weight on steps not to exceed 400 lbs.

5). WARNING: Exceeding the recommended weight

restriction may cause the unit to fail.

6). Consult your local building department before

installation of your pool and equipment.

TO WINTERIZE YOUR POOL

We suggest removing your Confer-Step from the pool for the off-

season months.

If your Confer-Step is attached to a deck: Two people are required

for this operation and it is best to remove the unit while the water is

still warm enough so that one person can get into the pool.

Disconnect the mounting brackets from the deck.The person in the

water can lift the unit up while the person on the deck helps to pull

and guide the unit onto the deck. After the unit is on the deck, and

the water has drained out of the steps, lay the unit on it’s back side

so that most of the water drains from the side panels.

If getting into the water is not an option the unit can be removed by

both people standing on the deck and lifting and tilting the unit to

drain some of the water from the steps. After the unit is light enough

carefully lift it from the pool. Caution: Use care when lifting the unit.

It will weigh at least 130 lbs.

If you have the Confer-Step Enclosure System or Connector

System: disconnect the two units by removing the center

platform/side rail assembly at the top of the steps. Do not stand on

the top step of the outside unit as it may tip. Lift up the unit inside

the pool and tilt it so that water drains out of the steps. Once it is

light enough carefully lift it over the side of the pool, lay the unit on

it’s back side and allow most of the water to drain from the side

panels.

The Confer-Step can be covered, if desired, and stored outdoors.

97 Witmer Road

North Tonawanda, New York 14120-2421

Toll Free U.S. 866-396-2968

716-283-1826/ FAX 716-283-3249

www.conferladders.com

Printed in U.S.A.

MADE IN THE U.S.A. by:

CONFER PLASTICS, INC.

LIMITED, PRO-RATED WARRANTY

Confer Plastics, Inc. warrants their swimming pool ladders to be free from defects in workmanship for one year from

date of purchase. After the first year the cost to replace a part is as follows:

STEP-1

2nd Year - 20%

3rd Year - 40%

4th Year - 60%

5th Year - 80%

Plus shipping/handling

Enclose proof-of-purchase (receipts, etc.) showing date purchased, your name, address, and daytime phone number. You

will be notified of cost to replace part.

This warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.

DO NOT RETURN DEFECTIVE PART TO DEALER

The defective part should be returned, postpaid, to:

Confer Plastics, Inc.

97 Witmer Road

North Tonawanda, N.Y. 14120-2421

of current parts

list price