\.

knob

"K''

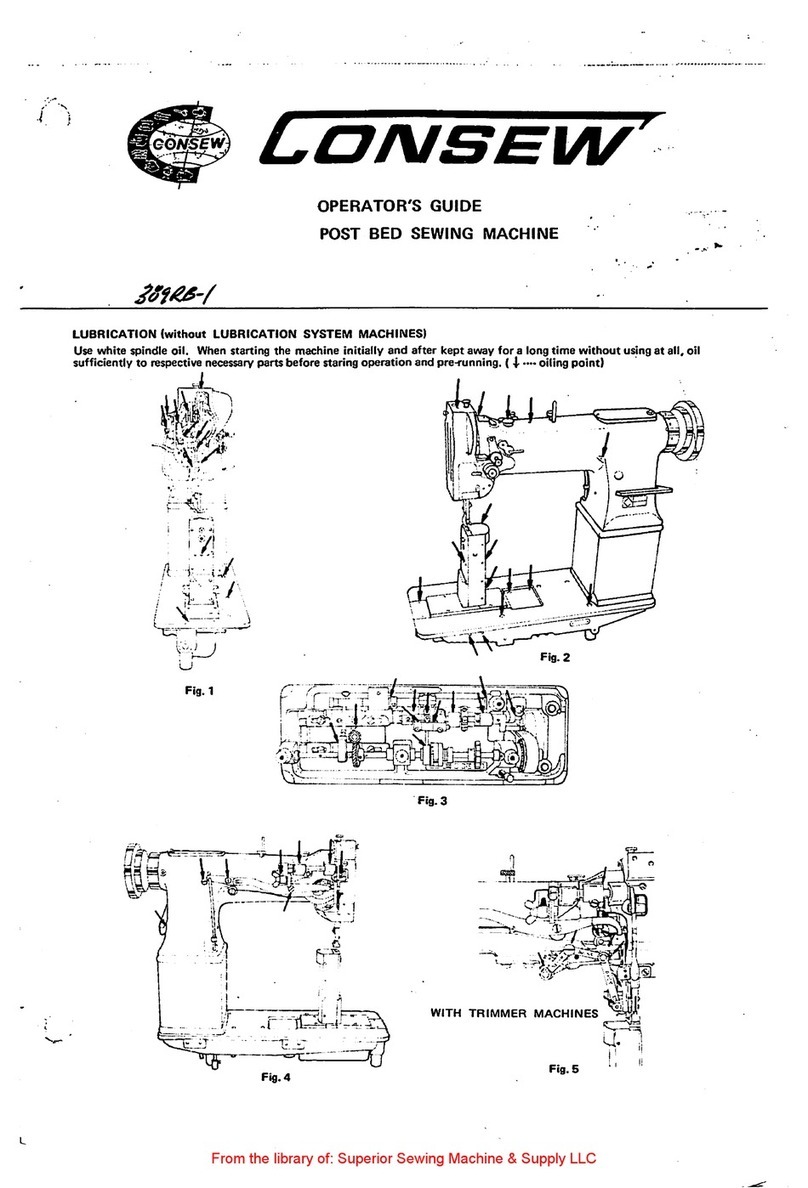

i,Fig.

4)

clockwise

for

~

penetration

and

counterclockwise

for

less penetration.

The

dial

surrounding

the

adjustment

knob

shows

clearly

the

direction of

turning

to

obtain

.the

needed

degree

of

needle

penetration.

If

the

needle

should

fail to

catch

the

fabric,

turn

the

adjustment

knob

gradually -notch by notch- in clockwise

direction

as

stated

above.

On

the

other

,,

hand, if

the

penetration

should

be

too

great,

and

too

much

of

an

impression

'-

should

show

on

the

right

side

of

the

material,

turn

adjustment

knob

to

the

left (counterclockwise) until

the

stitching is as desired.

9.

Removal

of

the

Work

from

the

Machine

Stop

machine

and

turn

handwheel

away

from

operator

until needle ·

completely

out

of

the

material.

Press

the

knee lifter to

the

right

and

pull

the

\vorkpiece

rearward

out

of

the

machine

with a

quick

stroke.

This

will

lock

the

last stitch

and

break

the

thread.

10.

The Skip

Stitch

Device

The

position of

skip stitch device. lever

"L''

at

the

right

side of

the

machine

controls

the

\Vhen

this

lev-

er

points

toward

the

operator,

as

shown

in Fig.

4,

the

needle

catches

the

material

at

each

stitch.

Pushing

lev-

er

"L"

to

the

rear

of

the

machine

so

that

it

points

toward

the

hand-

\\·heel will activate

the

skip-stitch de-

vice

whereby

the

needle will pene-

trate

the

material

at every

other

stitch.

\'-

/

/B

/

_......._

____

_

Fig.

4

L

/

Be

sure

that

lever

"L"

is

pushed

completely

in

either

direction

and

needle

penetration

readjustf!d every time

operation

is

changed

from

skip

to

nonskip

11.

Needle

and

Thread

Recommendations

Standard

type blindstitch

machine

needles

sizes 29-493

through

29-494-1/2

are

the

only

ones

to

be

used

for

Consew

Blindstitch

Machine

Model

222.

For

best results,

use

only

CONSEW

needles.

4

From the library of: Superior Sewing Machine & Supply LLC