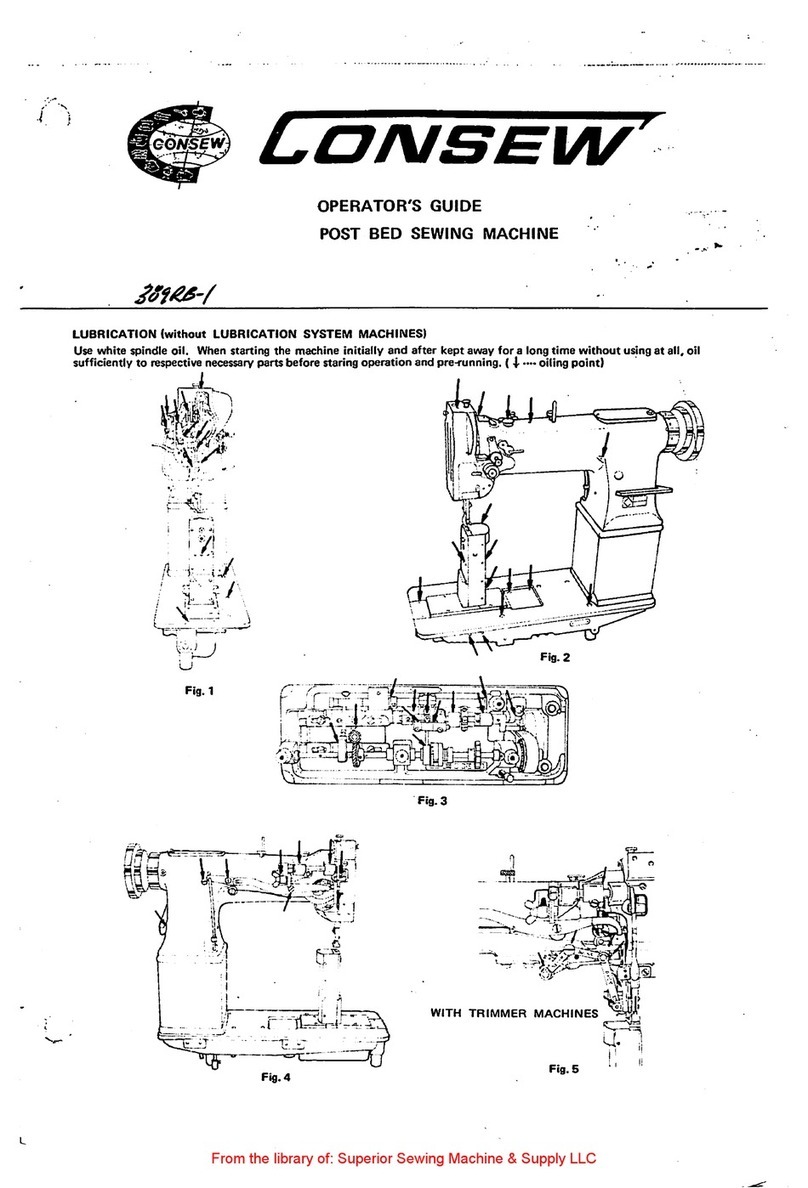

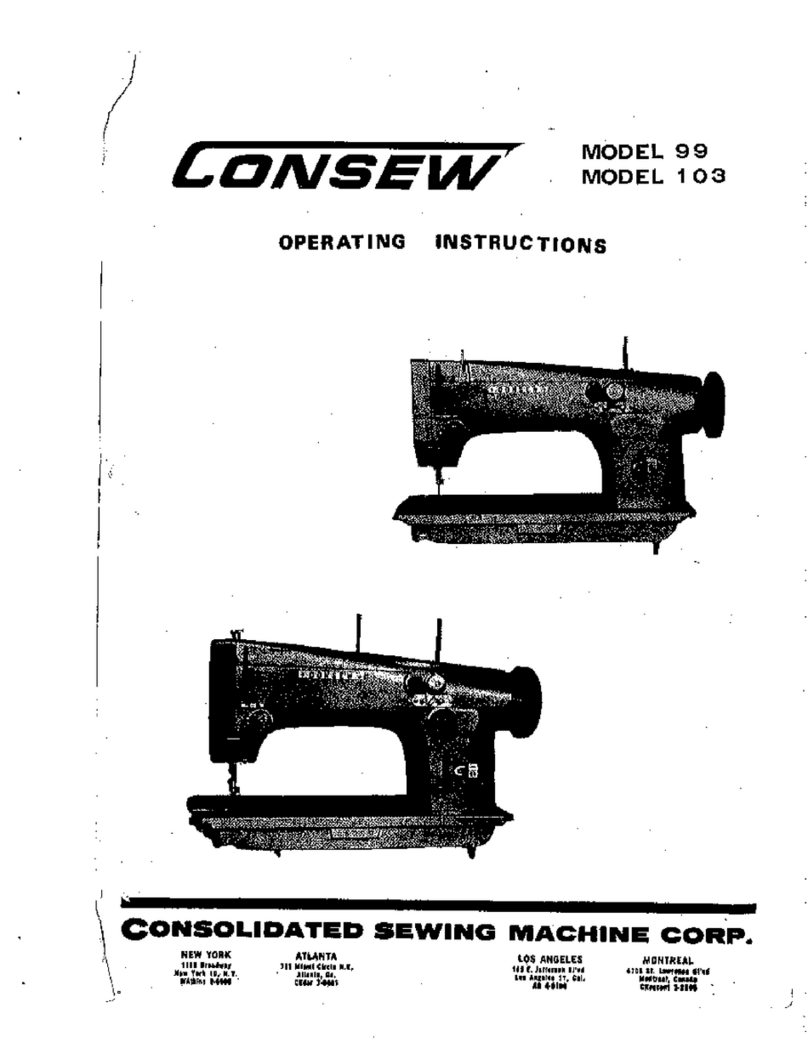

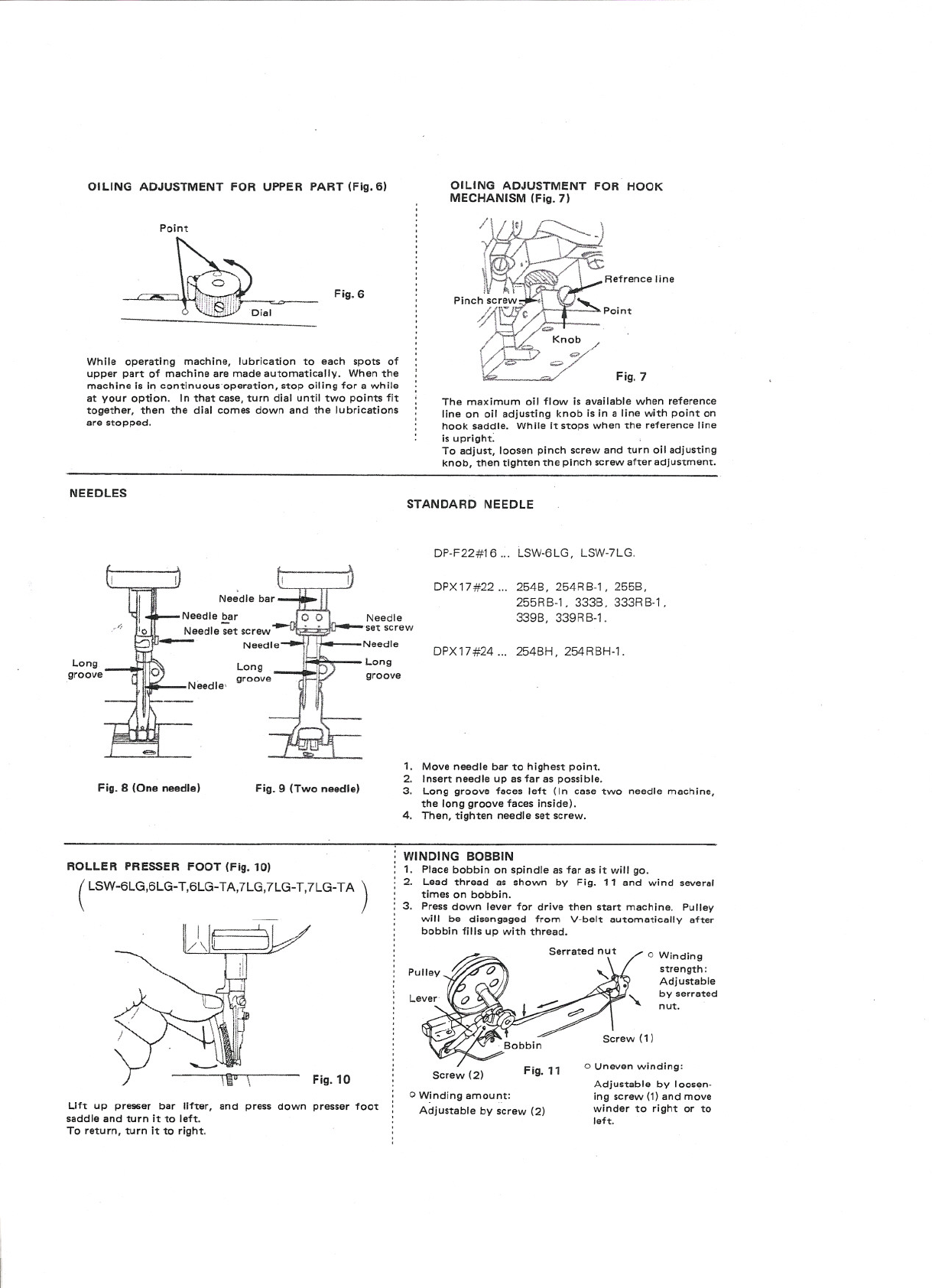

OILING ADJUSTMENT FOR UPPER PART (Fig. 6)

Point

Fig. 6

While operating machine, lubrication to each spots of

upper part of machine are made automatically. When the

machine Is In continuous. operation, stop oiling for a while

at your option. In that case, turn dial until two points fit

together, then the dial comes down and the lubrications

are stopped.

OILING ADJUSTMENT FOR HOOK

MECHANISM (Fig. 7)

Refrence line

Fig. 7

The maximum 011flow is available when reference

line on 011adjusting knob Is In a line with point on

hook saddle. While It stops when the reference line

is upright: .

To adjust, loosen pinch screw and turn 011adjusting

knob, then tighten the pinch screw after adjustment.

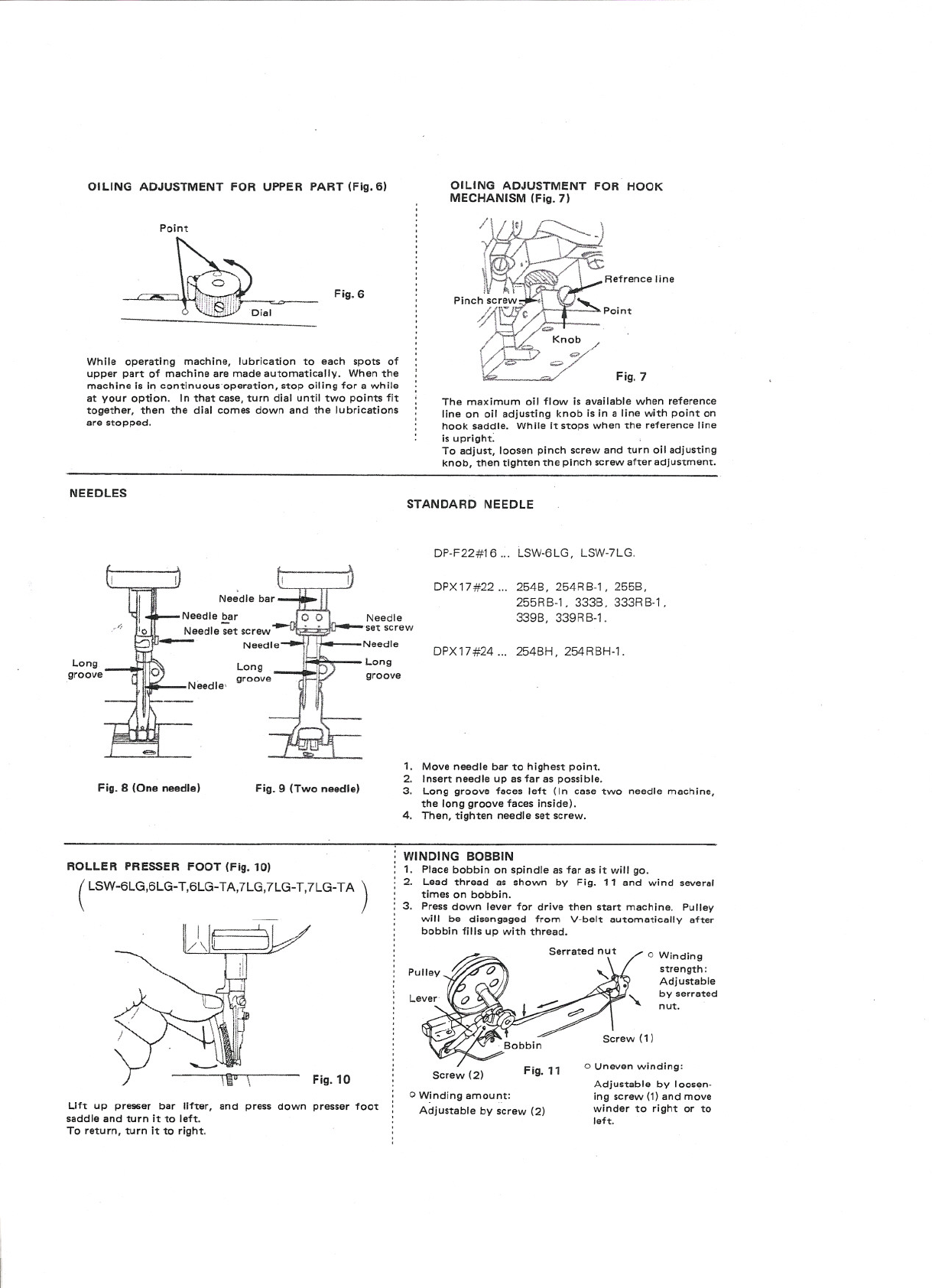

NEEDLES STANDARD NEEDLE

Long

groove

Fig. 8 (One needle) Fig. 9 (Two needle)

Needle

set screw

Needle

Long

groove

DP-F22#16... LSW-6LG, LSW-7LG.

DPX17#22... 254B, 254RB-l, 255B,

255RB-l, 333B, 333RB-l,

339B, 339RB-1.

DPX17#24... 254BH, 254RBH-1.

1. Move needle bar to highest point.

2. Insert needle up as far as possible.

3. Long groove faces left (In case two needle machine,

the long groova faces Inside).

4. Then, tighten needle sat screw.

ROLLER PRESSER FOOT (Fig. 10)

(LSW-6LG,6LG-T.6LG-TA.7LG,7LG-T,7LG-TA )

Fig. 10

Lift up prll96ar bar lifter, and press down presser foot

saddle and turn It to left.

To return, turn It to right.

WINDING BOBBIN

1. Place bobbin on spindle as far as It will go.

2. Laad thraad as shown by Fig. 11 and wind several

times on bobbin.

3. Press down lever for drive then start machine. Pulley

will be dlsangaged from V-belt automatically after

bobbin fills up with thread.

o Winding

strangth:

Adjustable

by serrated

nut.

Screw (2) Fig. 11 o Uneven winding:

Adjustable by loosen-

ing screw (1) and move

winder to right or to

left.

o W!ndlng amount:

Adjustable by scraw (2)