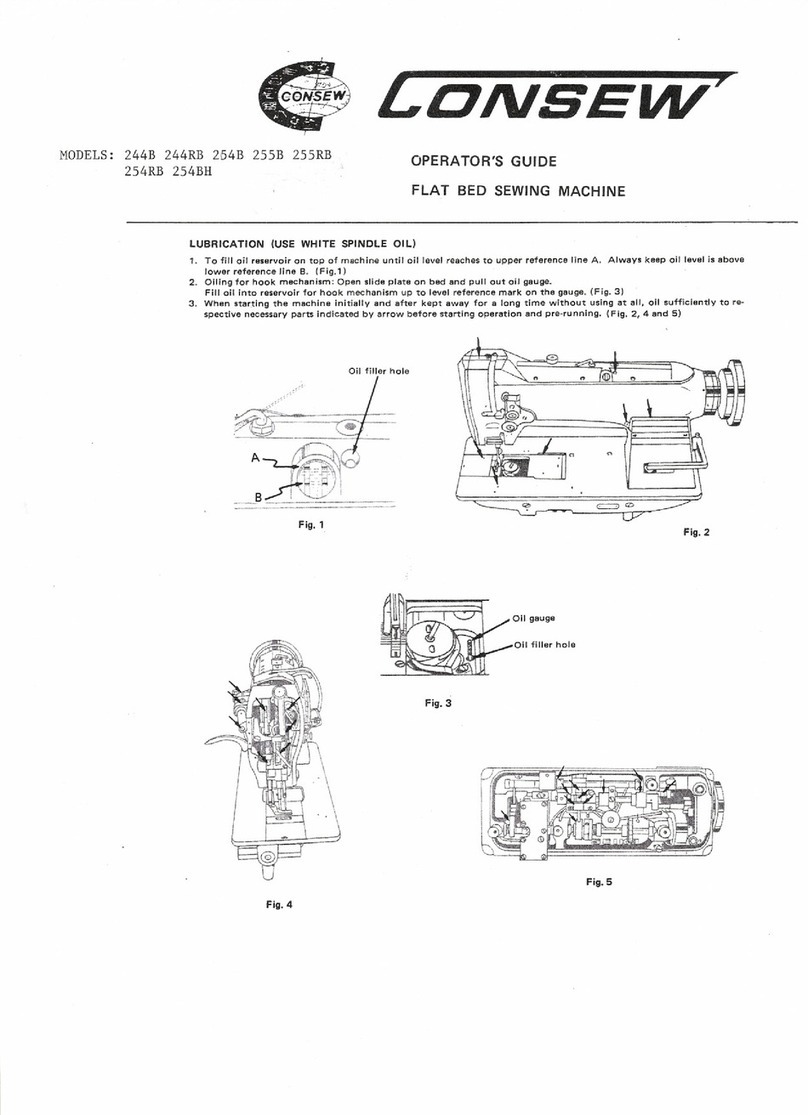

LUBRICATION (with LUBRICATION SYSTEM MACHINES)

Oil

filler

hole

OILING

ADJUSTMENT

FOR

UPPER

PART

(with LUBRICATION SYSTEM MACHINES)

Point

Fig.

6

To

fill oil

reservoir

on

top

of

machine

until

oil

level

reaches

to

upper

reference

line A. Always

keep

oil

level

is

above

lower

reference

line

B.

NEEDLE

1—needle

I

L

Vi.

2—needle

Fig.

7

\

While operating machine, lubrication to each spots of upper

part of machine are made automatically. When

the

machine

is in continuous operation, stop oiling for a while at

your

option.

In that case,

turn

dial until two points fit together,

then

the

dial comes down

and

lubrication is stopped.

Needle

bar

Needle

bar

0^

-Set

screw

Needle

Long

groove

STANDARD

NEEDLE

DP-F22,

#14

.... Lower feed with roller presser

foot

machines

DP X

7,

#18...

Lower

feed

with

flat

presser

foot

machines

DP X

7,

#24

...

Lower

feed

with

large

hook

machines

DP X

17,

#18

... Needle

feed,

walking

foot

(except

single needle,

without

reverse)

machines

Set

screw

Needle

Needle

Long

groove

Long

groove

Fig.

8

Fig.

9

ROLLER

PRESSER

FOOT

Fig.

10

Lift up presser

bar

lifter,

then

press

down

saddle of

presser

foot

and

turn

it

to

left

as far as it will

go.

DPx

17,

#19..

.

With

trimmer

machines

DPx

17,

#22..

.

Needle

feed,

walking

foot,

single

needle,

without

reverse

machines

DPx

17,

#24..

.

Large

hook

machims

(except

lower

feed

machines)

1.

Move

needle

bar

to

highest

points

2.

Insert

needle

up

as

far

as

possible.

3.

Long

groove

faces

left,

(in

case

2-needle,

the

groove

faces

inside.)

4.

Tighten

needle

set

screw.

INSERTING

AND

REMOVING

BOBBIN

Fig.

11 S

Opener

•

Latch

5 •

^Bobbin

• I

*^4-—Slot

Tension

regulating

spring

i'*"'

y I

Bobbin

c^e -

1.

Pull

up

latch

and

remove

bobbin

from

bobbin

case.

2.

To

insert

a full

bobbin,

hold

it

pulling

out

the

end

of

thread

by

5

cm,

and

place

the

bobbin

into

the

bobbin

case,

and

press

down

the

latch.

3.

Lead

the

end

of

thread

pulled

out

through

slot

of

the

bobbin

case,

and

under

tension

spring

through

between,

the

bobbin

case

and

opener.

Close

cap,

but

leave a

space

for

passage

of

the

end

of

thread

pulled

out.

4.