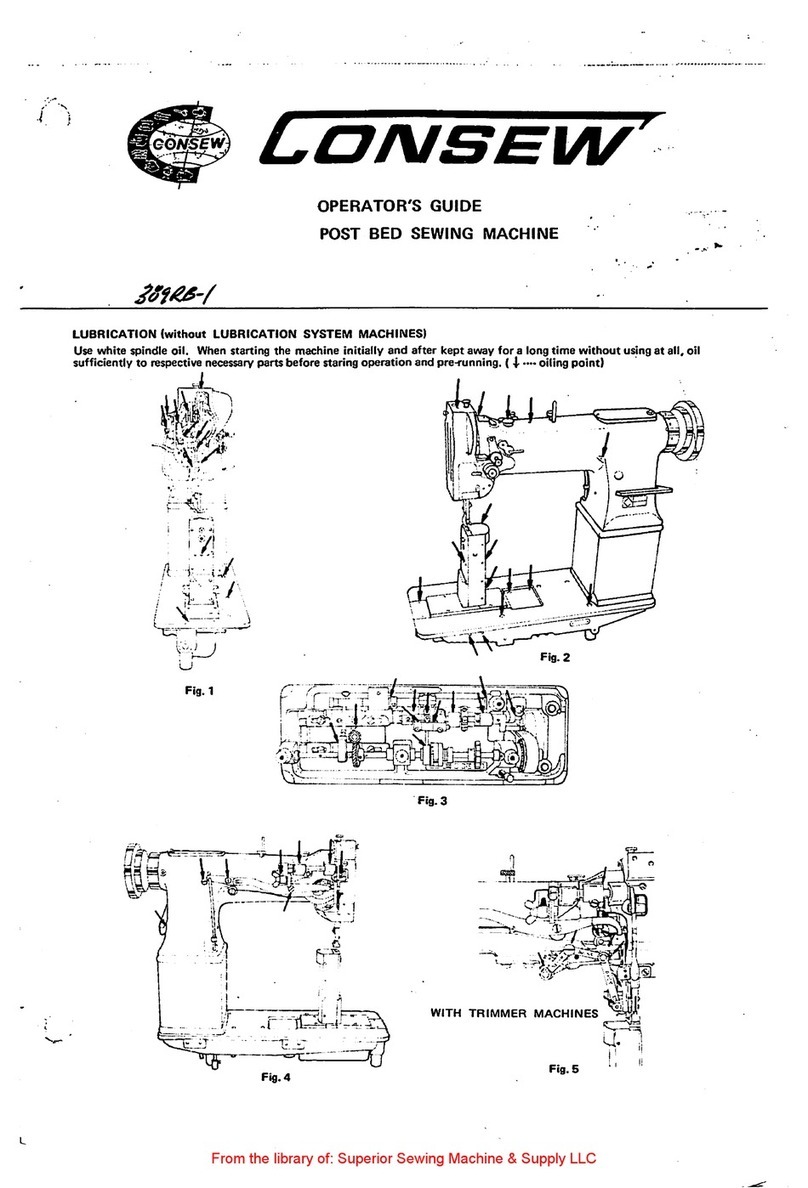

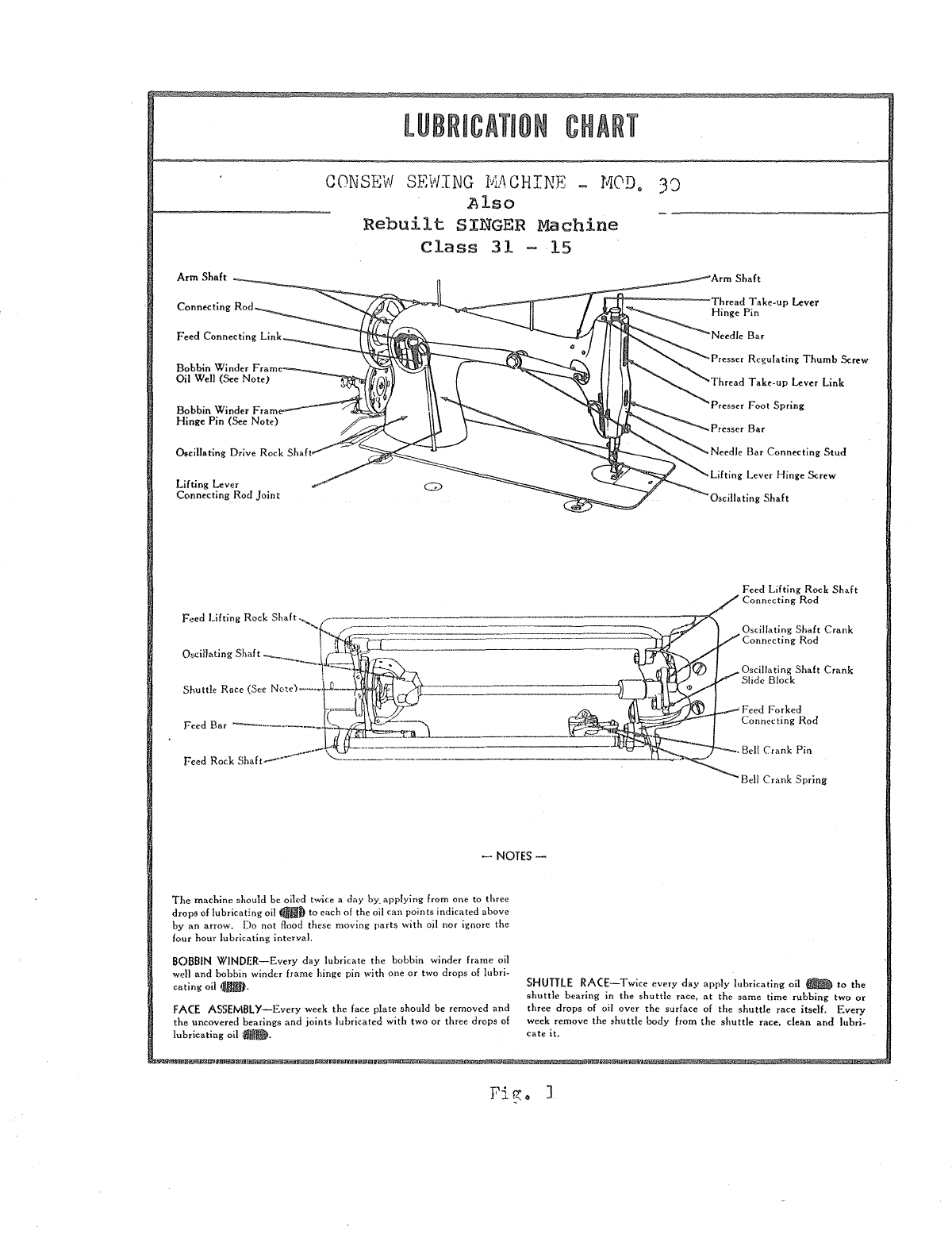

LUBRICATION

CHART

MOD

•

CONSEW

SEWING

MACHINE

.Also

Rebuilt

SINGER

Class

31

Machine

15

Arm

Shaft

Bobbin Winder Frame

Oil Well (See Note)

Bobbin Winder

Frame--

Hinge Pin (See Note)

Oscillating Drive Rock Shaft

Lifting Lever

Connecting Rod

Joint

-·NOTES-

The

machine should be oiled twice a day

by_

applying from one to three

drops

of

lubricating oil OJIto each

of

the oil can points indicated

above

by

an

arrow.

Do

not

flood

these

moving

parts

with ojl nor

ignore

the

four hour lubricating interval.

Needle Bar

Presser Regulating

Thumb

Screw

Thread

Take-up Lever Link

Presser

Foot

Spring

Presser Bar

Needle Bar Connecting

Stud

Lifting Lever Hinge Screw

Oscillating

Shaft

Feed Lifting Rock

Shaft

Connecting

Rod

Oscillating Shaft Crank

Connecting Rod

Oscillating Shaft

Crank

Slide Block

Feed Forked

Connecting

Rod

. Bell Crank Pin

Bell

Crank

Spring

BOBBIN

WINDER-Every

day lubricate the bobbin winder frame oil

well and bobbin winder frame hinge pin with one or two drops of

lubri~

eating oil

!Jill).

FACE ASSEMBLY-Every week the face plate should

be

removed and

the

uncovered bearings and

joints

lubricated

with

two

or three drops

of

lubricating oil fl'llilll).

SHUTTLE

RACE-Twice

every

day

apply lubricating oil fllllilll) to the

shuttle

bearing in the

shuttle

race,

at

the

same

time

rubbing

two

or

three drops

of

oil

over

the

surface

of

the

shuttle

race itself.

Every

week remove the sh\lttle body from the

shuttle

race. clean

and

lubri·

cate

it.

FiR:. J

From the library of: Superior Sewing Machine & Supply LLC