CONTENTS

Operation

instruction

I.Brief

introduction

...............................................................................................

1

2.Main

specification

..............................................................................................

1

3.Preparation

.......................................................................................................

1

4.Lubrication

........................................................................................................

2

5.Trial

run

............................................................................................................

2

6.Installing

the

needle

..........................................................................................

3

7.Coordination

between

needle,

thread

and

sewing

material.

................................3

8.Adjustment

of

thread

tension

.............................................................................

3

9.Threading

.........................................................................................................

4

10.Adjusting

the

stitch

length

...............................................................................

4

.

I1.Adjusting

the

thread

take-up

of

needle

thread

..................................................

5

12.Adjusting

the

thread

tak-up

of

looper

thread

..................................................

5

13.Adjusting

the

thread

releasing

..........................................................................

5

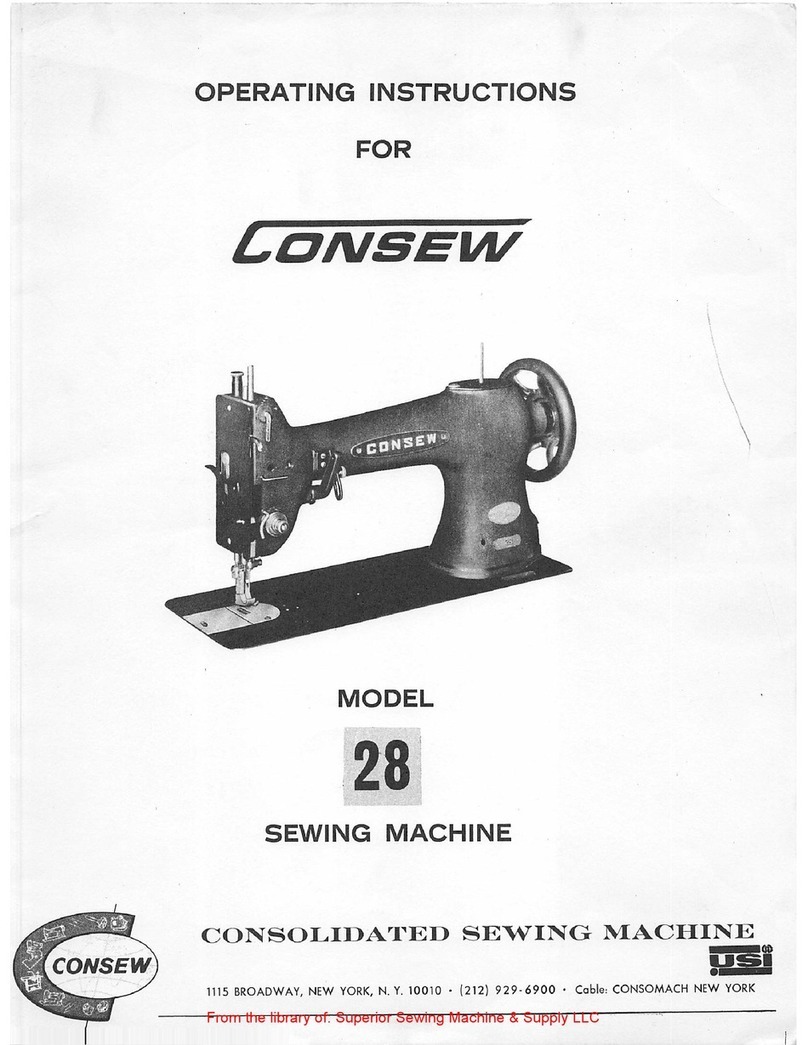

14.Setting

the

needle

safe

bracket

.........................................................................

6

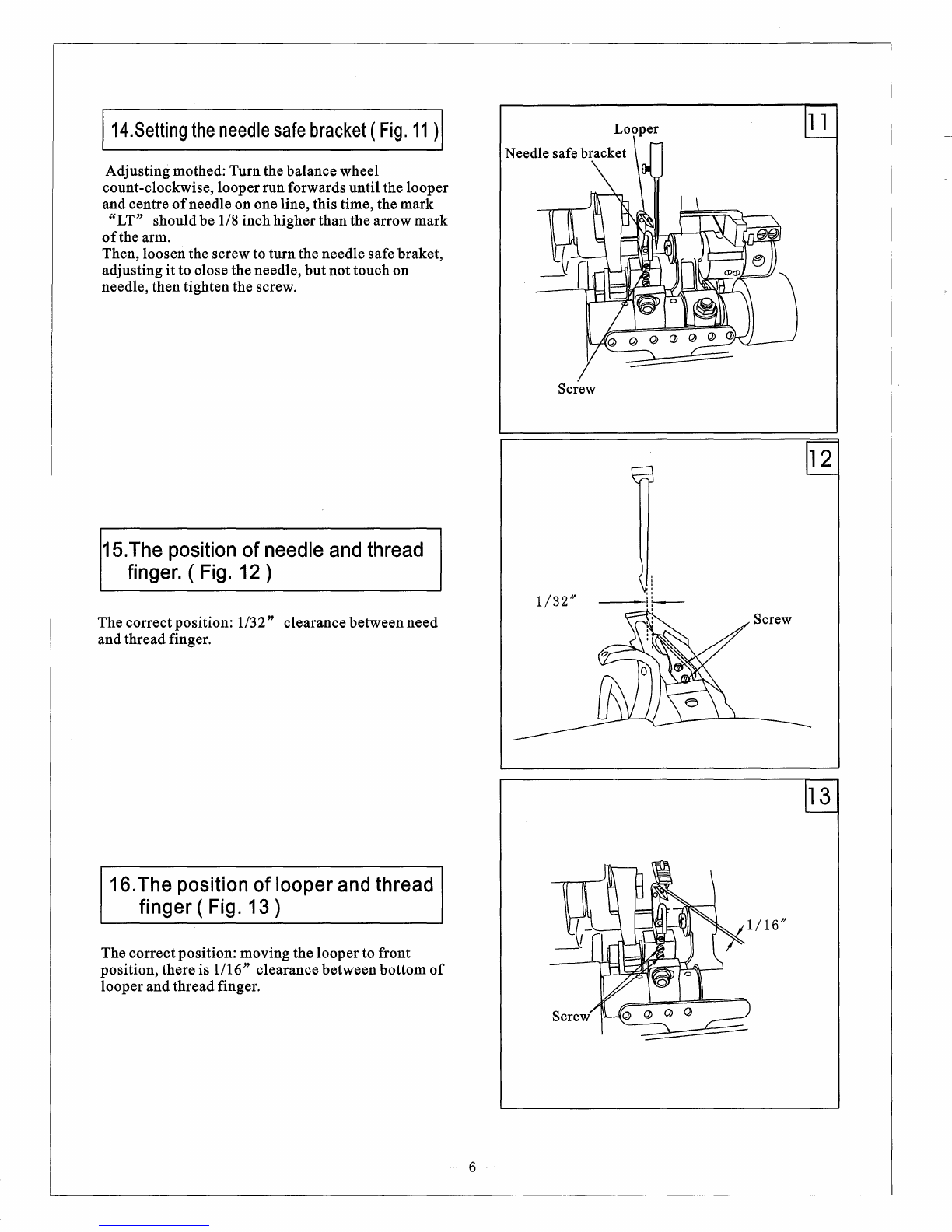

15.The

position

of

needle

and

thread

finger

...........................................................

6

16.The

position

of

looper

and

thread

finger

...........................................................

6

17.Setting

the

position

of

fork

needle

.....................................................................

7

18.Timing

adjusting

for

fork

needle

......................................................................

7

19.Timing

adjusting

of

feed

dog

.............................................................................

8

Parts

Manual

1.Arm

and

bed

............................................................................................9-10

2.Needle

Bar,

Presser

foot

Part

.............................................................11-12

3.Needle

bar

moving,

presser

foot

lifting

bar

.................................... 13-14

4.Lower

shaft

part

..................................................................................15-16

5.Low feed,

looper

Part

.......................................................................... 17-18

6.Fork

needle

swing

shaft

part

..............................................................19-20

7.Preeser

bar,

pressure

cylinder

part

...................................................21-22

8.Threading

..............................................................................................23-24

9.Face

plate

................................................................................................25-26

10.Base

cover

part

....................................................................................27-28

11.

Accessories

..........................................................................................29-30