CONTENTS

(FE:ATUREs:)

.....................................................................................................................

1

(s'eECIFIC.ATIONS)

......................................................................................................

2

(

t~t:l,LE

QF/$1"/l.NDAao

,GAVGE)

······

...............

···

.....

····

...........................

·········

···

2

(l~s~J;;ALLl~~)

..................................................................................................................

3

1IJ

Installing

the

Machine

Head

..·

..

·..····..·..·

..

·······..··..·....·

..

····..·..·····....·

.................

·

...........

·

..

·...

·........

3

121

Installing

the

Treadle and Chain ......··......·

................

·..·

..........

·....·

................................

·

..

·......·.....

~

~

Installing

the

Motor

Pulley ·········....··.. ·..·..·

..

·..····..····..·..···......·..·

..

·

..

·..·......·........·........···

..

·...·······.. 4

[4]

Belt Tension.adjustment ..·

..

·······

..

·

..

·

..

···········....·

..

··········

..

·..··..···.....·

......................................

·...... 4

151

Installing

the

Pulley Cover ···

..

··

..

·

..

··········....·..·····....·......·..·..·

..........

·

........

·

..

·.....·

...........

·......·....··.. 4

12]

Motor

and

Motor

Pulley ..·..····

..

··....·..··········

..

·..·..····

..

·....··..·

..

··....·

..

··

...................

·........··

..

·..···...... 4

1Z1

Spool

Stand

..··....··....····..····..·

..

····....·····..·····

..

·

..

···..····..·······

..

·

..

··....·..·..·

..

·

.........

···........·...·....·..·... 4

..................................................................

4

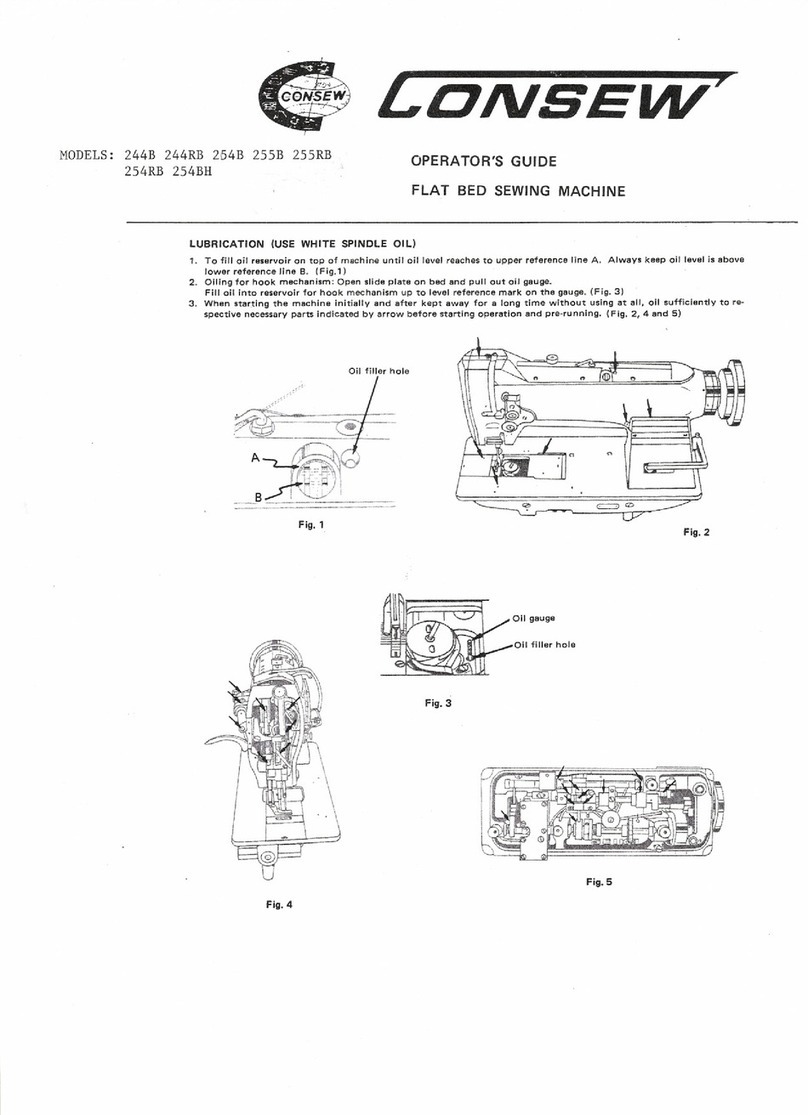

IIl

Lubrication ·....·..·

..

··....·..·······..··

..

···..·······..·..··....··....··

..

······

..

····

·.

·....··

..............

·..·......·..

·.

·...·....·.

·.

4

121

Running In ·

..

···

..

········..···

..

·

..

·..··..·······

......

········

..

·....···

..

··..··..····.....···......·........·

...........

·

..

·.....·

..

·... 5

..........................................................................................

5

IIl

Needles

and

Threads

.....................................................................................................................

5

121

Installing

the

Needles ..·..····

..

·

..

···

..

··....···..···..·..·······

..

·

..

·

..

····

..

·..·

..........................................

··...·... 5

~

Upper

Threading

·

..

·

..

·

..

·..··········....·..·······..·

..

····.. ····.. ·

..

·..····..····

...........................

'

...............

·........

6

[4]

Lower

Threading

........................................................................................................................

6

151

Installing the Lap

per·

....·..·

..

··

..

·......·..·..··....··

..

·..··

..

········

..

·..··

..............

·.....··........·........·.·.·....

·........

7

12]

Sewing ···..·..·..········

..

·....··....·....··..·

..

····..·····

..

·

..

···..·..·

..

·....··..·..··...··..·

..............

·

..................

·....··.. 7

1Z1

Thread

Tension ···

..

·..····

..

·....······..·....·..··......··..·..··..···..····..·..··....·..·

........

·

..........................

···...·..· 7

!§] Presser

Foot

Pressure Adjustment

................................................................................................

8

~

Stitch Length Adjustment ·........··..·..··..·....··

..

····..·..·.. ·..···..··

..

··

.................................................

··.. 8

I!Ql

Puller Feed Adjustment

.................................................................................

8

..............................................................................

10

IIl

Needle and Looper

Timing

Adjustment

..........................................................................................

10

121

Needle

Bar

Height Adjustment ......··...·...·

...........

···

..

·

..

·.....·.....·...·.·

..

·

................................

·

............

10

~

Looper Timing for Avoiding Contact with Needles

...........................................................................

n

[4]

Needle Guard Adjustment

............................................................................................................

11

151

Feed Dog Height Adjustment ....·..··..·..·..·····....·....···..·····

............

·.....·..·.....··

.................

······.. ·..··....

-12

12]

Puller Height Adjustment ..·..···..·........·..··..·..·

..

·..·....··........·..·.....·.. ·..··....·

..

·..

-12

1Z1

Installing

the

Spacer (For the demm specifications)

........................................................................

·--13

!§] Upper

Thread

Take-up

Thread

Guide Adjustment

.......................................................................

----13

~

Thread

Release Lever Adjustment ..·..·····....·

..

········

..

·..·········..···..··

..

·

.................

·..·......······.··....··..·13

I!Ql

Thread

Release

Shaft

Adjustment........·······

....................................................................................

14

[]]

Upper

Thread

Nipper Adjustment ···

.............................................................................................

14

11Z1

Lower

Thread

Take-up Timing Adjustment ·.....·······........······

..

·

..

··

............

··

................

···

..

·..····..·....

-14

fil Puller Device Timing Adjustment

...........................................................

14

( TROUBLESH00TING)································································································I5

From the library of: Superior Sewing Machine & Supply LLC