INDEX

1,

Brief

introduction···

..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..·..

·1

2,

Main

specification"'"'

..................

···

............

~

........

···

...............

···

..............................

···

......

1

3,

Installation..·..·..·..·..

··

..·

....

··

....

·····

..·..

···

..·..·..

··

..·

....

·..·..

··

..·

....

·..·..·..·..

··

..

····....

··

....

·..·..·..·..

·1

(1). Location

of

the 1nachine

......................................................................................................

1

(2).

Install the

ann

and oil reservoir·

....

·..

····

..·..·..·..·..

··

..

···

..·..

····

..

··

..

·······

..·

....

·..

··

..

···

..

·····

....

··

....

·..

·1

(3).

Install the machine head..·..

·······

..

··

..·

....

·..·..

··

..·

....

··

..·..

····

....

··

..·

..

···

..

·······

..

·······

..·..·..·..

··

....

··

..1

4,

Installing

motor

...............................................................................................................

2

5,

Connecting

the clutch lever to

the

pedal

.................................................................................

2

6,

Installing

the

presser foot lift control

plate

....

:

.........................................................................

2

7,

Installing

the

bobbin

winder·"

............................................

·

.................................................

3

!'L

Installing

the

thread

unwinder

.............................................................................................

3

9,

Preparation

......................................................................................................................

3

0).

Cleaning the machine·

......................................................................................

···

...............

3

(2).

Examination

......................................

·

...........................

·

...

·•·

....................

·

..................

·

.....

3

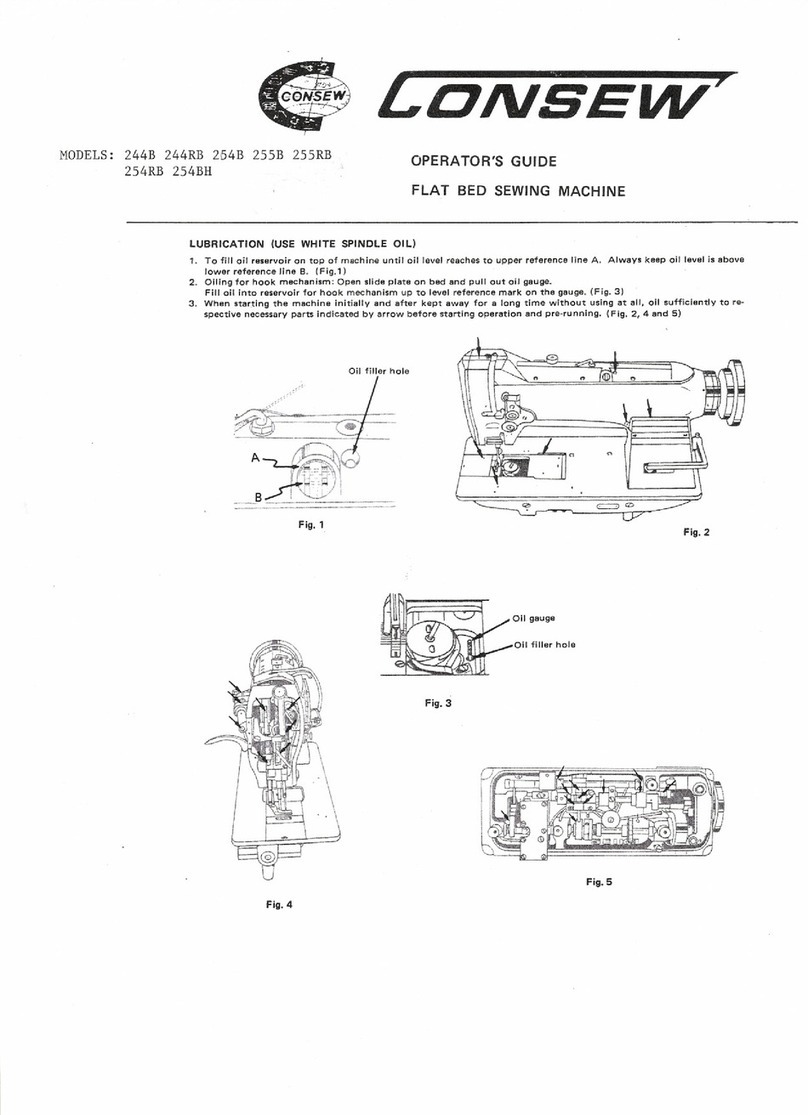

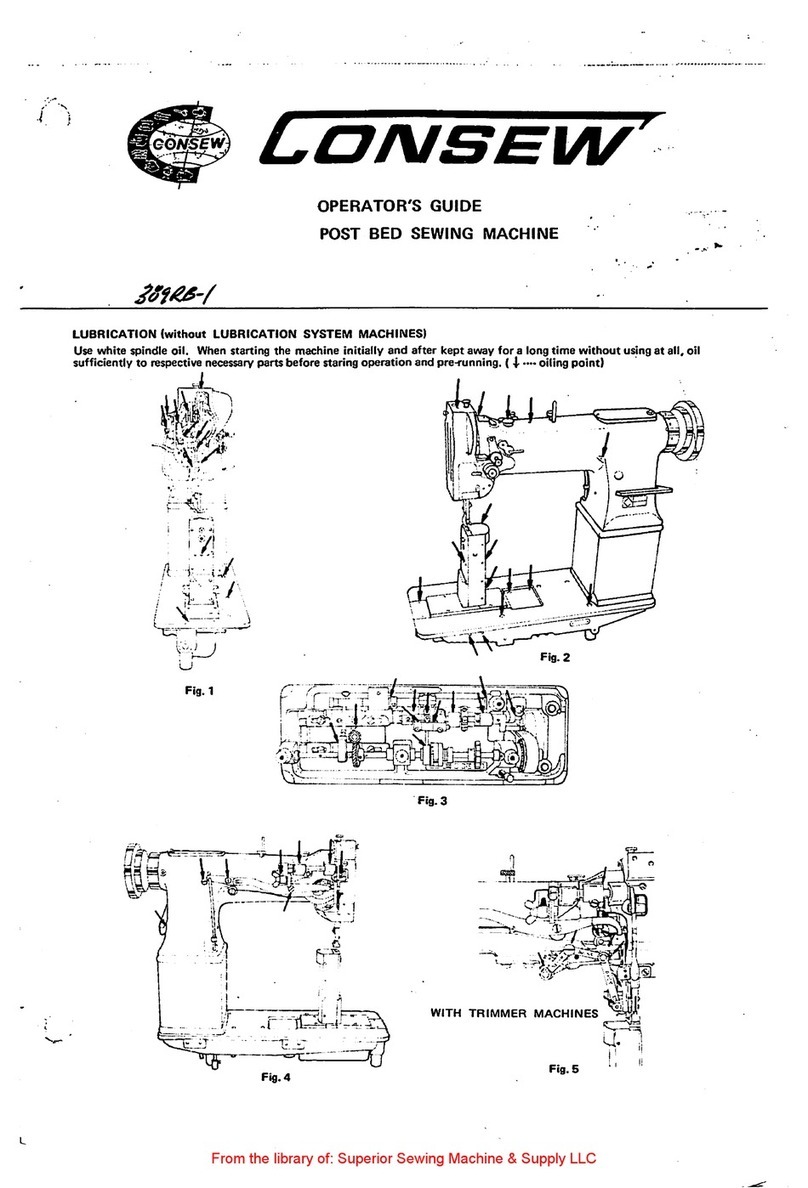

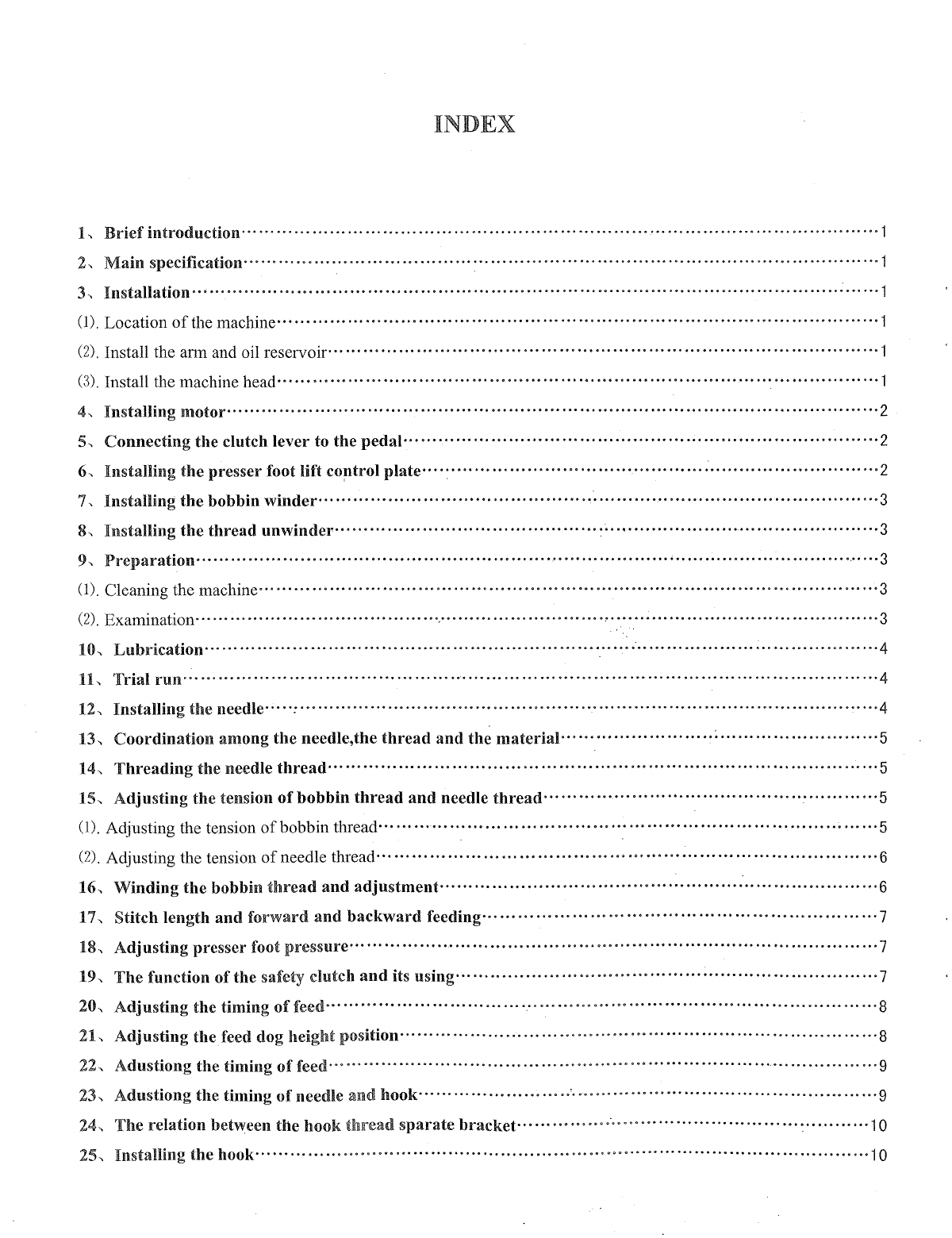

10,

Lubrication

...................................................................

_

.....

.-

.........................................

4

11,

Trial

run

.....................................................................................................................

4

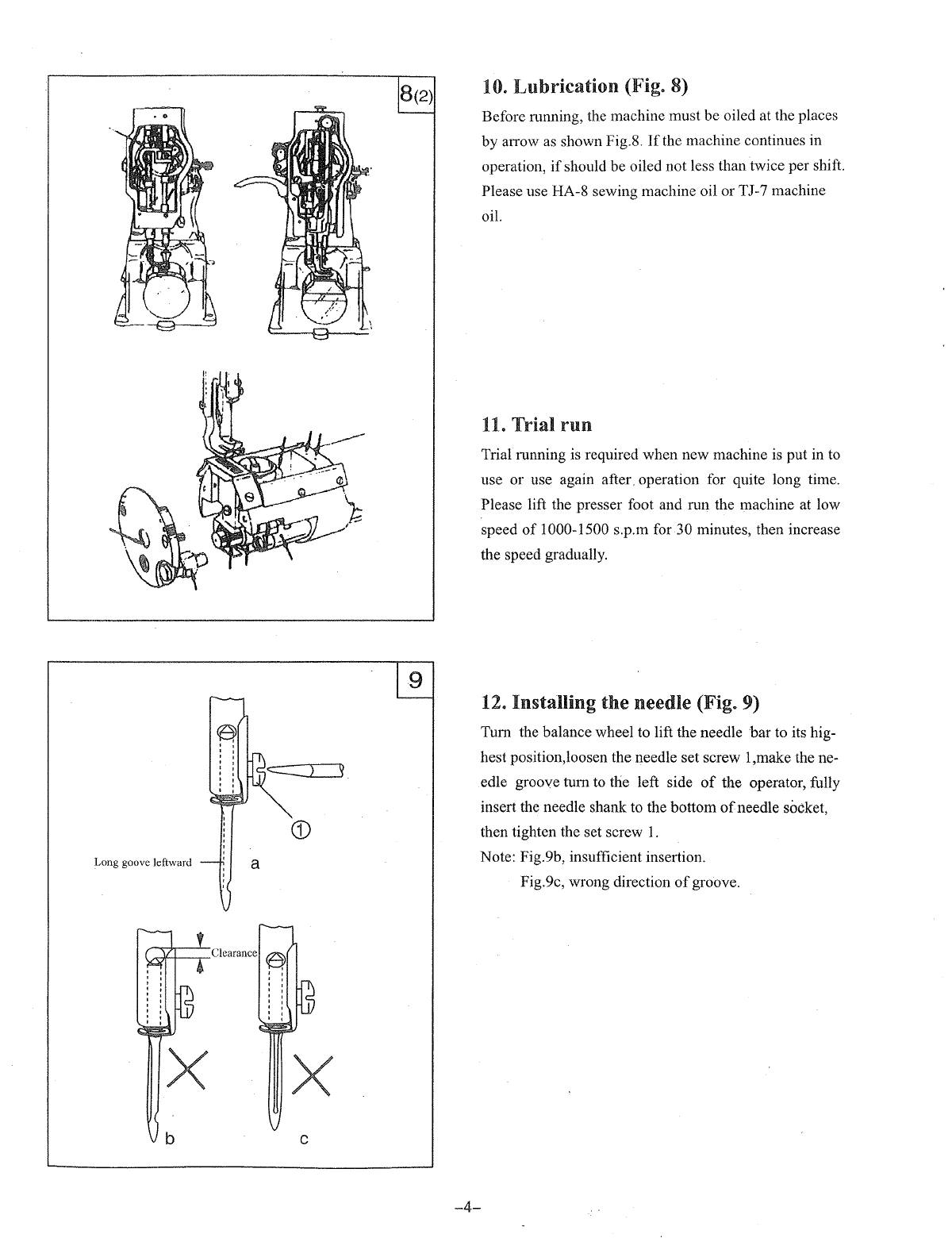

12,

Installing

the

needle·..··:

....................................

·

...................................

·

...........

····

..........

·4

13,

Coordination

among

the

needle,the

thread

and

the

material

..........................

;

...........................

5

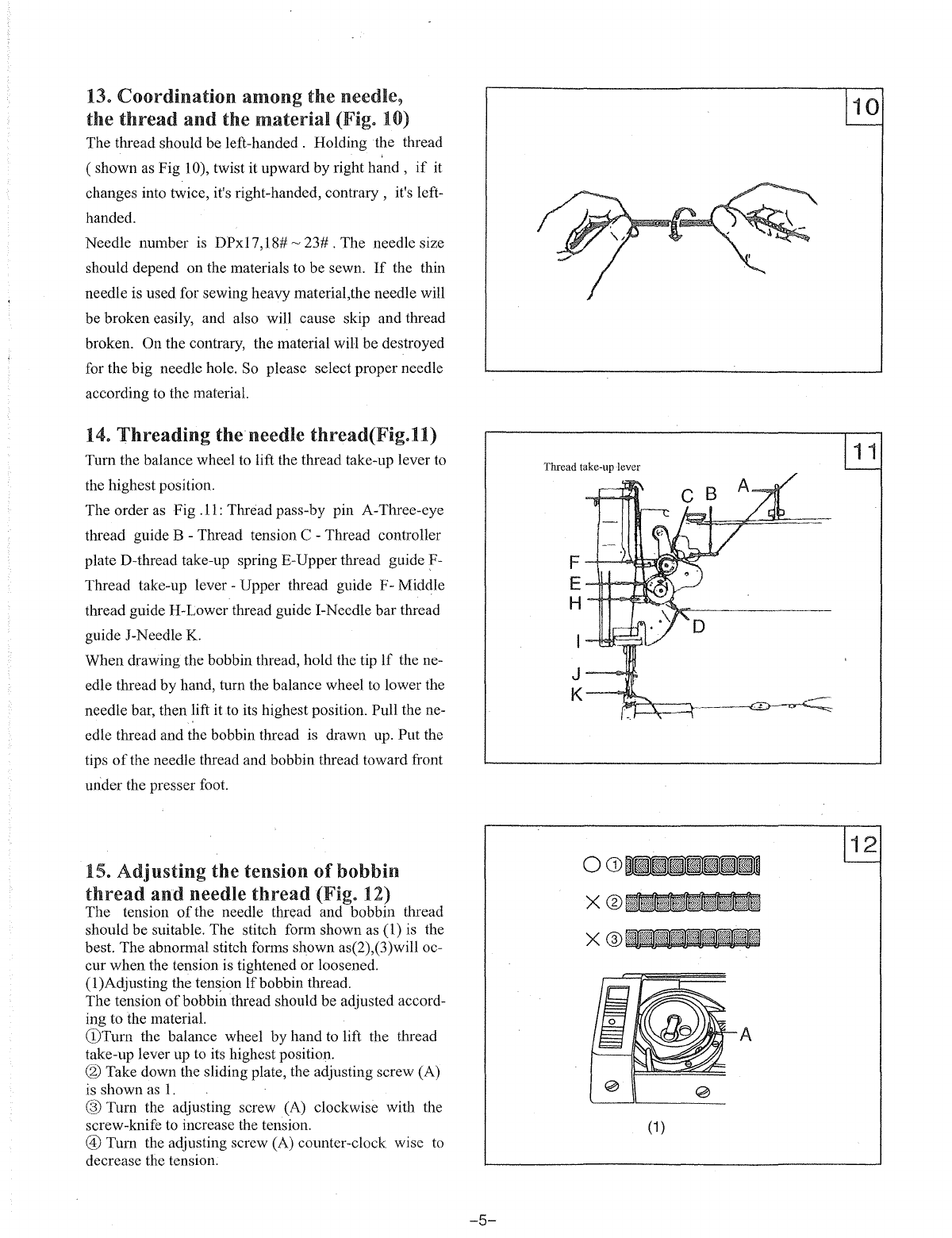

14,

Threading

the needle

thread

.............................................................................................

5

15,

Adjusting

the

tension

of

bobbin

thread

and

needle

thread

..................

·..·

..........

·

.....................

·..5

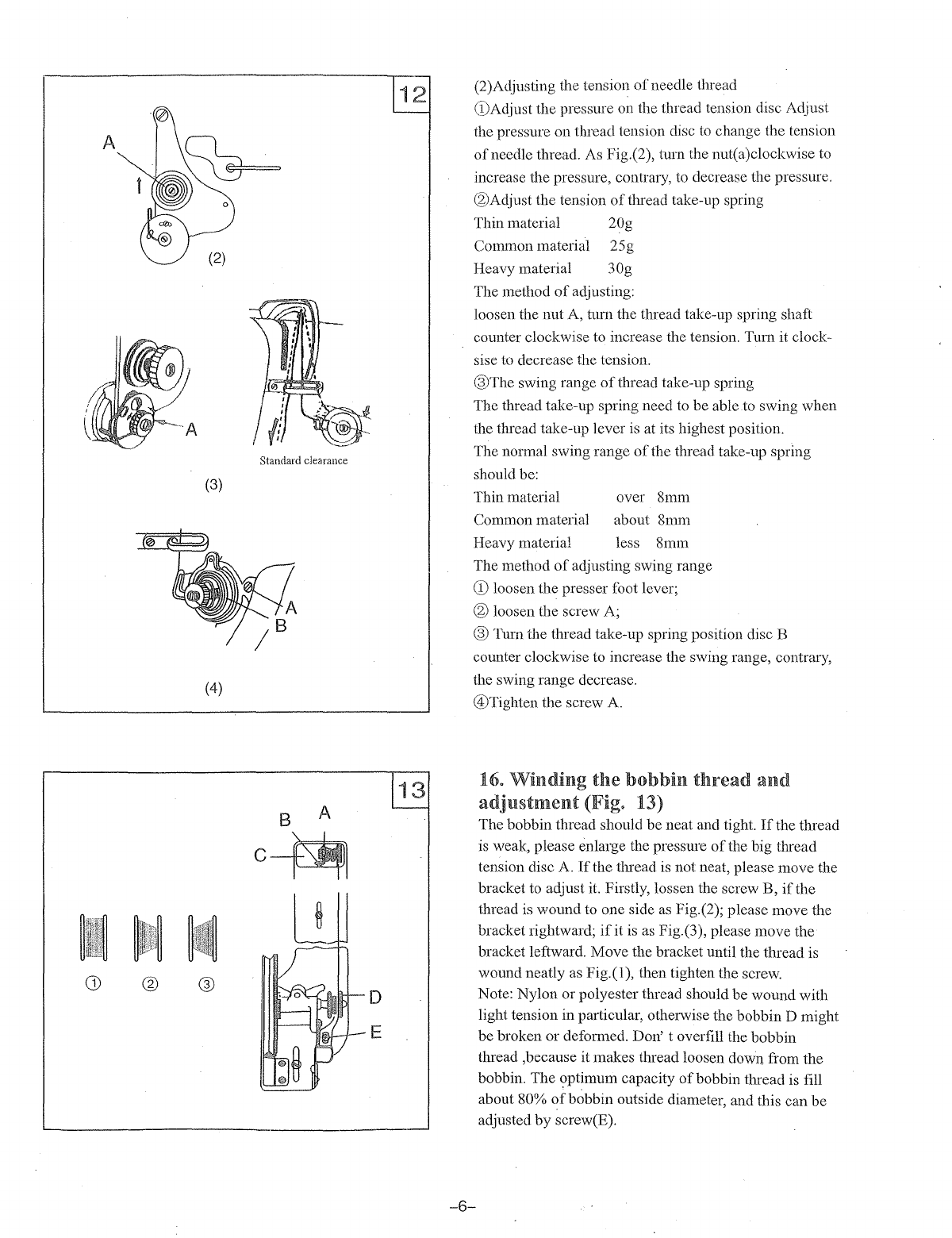

(1). Adjusting the tension

of

bobbin thread·

............................................................................

~

......

5

(2).

Adjusting the tension

of

needle thread·

...................................................................................

6

16,

Winding

the

bobbin

thread

and

adjustment

...........................................................................

6

17,

Stitch

length

and

forward

and

backward

feeding····································

······························7

18,

Adjusting

presser

foot

pressure·"

.......................................................................................

7

19,

The

function

ofthe

safety clutch

and

its using

........................................................................

7

20,

Adjusting

the

timing

offeed

..................................

_

...........................................................

3

21,

Adjusting

the

feed dog height position

.................................................................................

3

22,

Adustiong

the

timing

offeed

..............................................................................................

g

23,

Adustiong

the

timing

of

needle

and

hook"""

....................

·

....................................................

g

24,

The

relation between

the

hook

thread

sparate

bracket

...............

;

................................

~

...........

10

25,

Installing the hook·

....

··

........................................

·

.........................................

·

...............

10

From the library of: Superior Sewing Machine & Supply LLC