TABLE OF CONTENTS

I.

GENERAL

DESCRIPTION

Page

1 Special features

...............

,

...........

·

........

·

··

·

...............

.

2 Names of parts ··..·....··

......

···....·....·..··....···......······

..

· 2

3 Sewing speed ·....·

........

·

..

·

......

·.. ·

..

·......·....·......····

..

··.. 2

133

4 Installing

the

machine ....·

............

·............

.. ··

2

5 Bobbin winder spool pin .. ·

......

·

......

··

........

·....·....··...... 3

6 Specifications

..........

··....·....··

........

··....·.. ···· ··

..

···

..

·

..

·· 3

II

HOW

TO

OPERATE

THE

MACHINE

1 Lubrication

..........

,

...............................

·..............·........ 4

2 Oiling

the

rotary hook

..........

·

......

·

........

··.. ··

.........

·.. ·

..

4

3 Needles

.....................................................................

4

4

Threading

the

machine ·.. ·....·....·....·

...........

·

.............

· 5

5 Winding

the

bobbin

thread

...................

·

................

·

..

5

·6 Inserting the bobbin into the bobbin case .. ·....·....·........ 6

7 Fixing

the

zigzag width

of

throw

..

·

..............................

6

8 Embroidering

with

a fixed zigzag width

of

throw

.........

7

9 How to set up

the

embroidering hoop ·.. ·

..

·.. ·

..

·.. ·

........

7

10

How to embroider

......................................................

7

II

The

thread tension

......................................................

8

12

When the thread breaks

........

·

......

·....·

..

·.. ·......·....

·......

8

III

ADJUSTMENT

OF

STITCHING

1

Timing

and adjustment of needle throw

.......................

9

2 Adjusting the correct position of the needle throw

.........

9

3 Matching the rotary hook with the needJe

.....................

IQ

t

GENERAL

DESCRIPTION

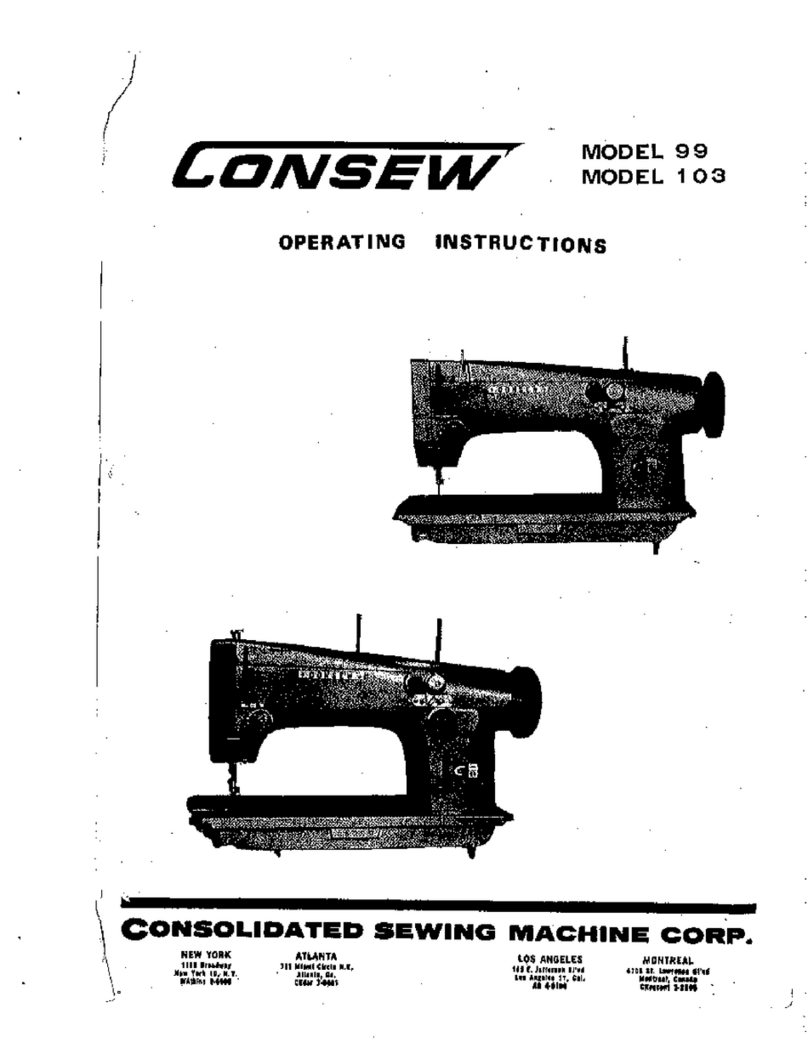

1.

Special features

This

is

a high speed industrial sewing machine for embroidering. With

a speed of I,

700

stitches per minute,

it

can produce a width of throw of

12m/m (15/32'') but

if

the machine

i:;

used

at

IOm/m (25/64") width of

throw, it can embroider at a fast speed

of

2,000 stitches per minute.

This machine can, not only embroider designs on light weight

or

heavy

weight materials, but it can also embroider names and all kinds of marks to

produce attractive and inviting embroidered work.

The

design of this machine

is

of beautiful two-color tone

and

as

the

lubrication

is

of a centralized system, it is

not

necessary to oil the parts

at each instance. Also, as the presser

bar

is

of joint rod system, it

is

not

to push

the

presser

bar

up

or

down when installing an attachment.

-1-

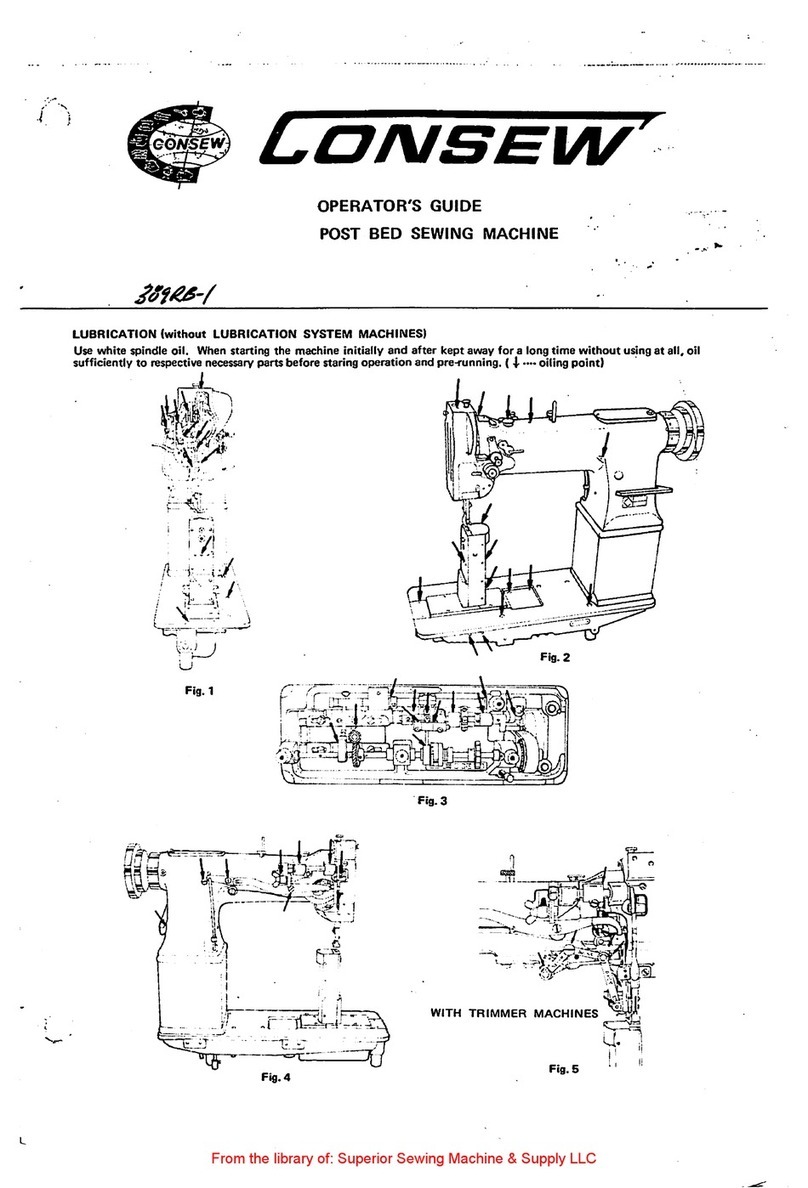

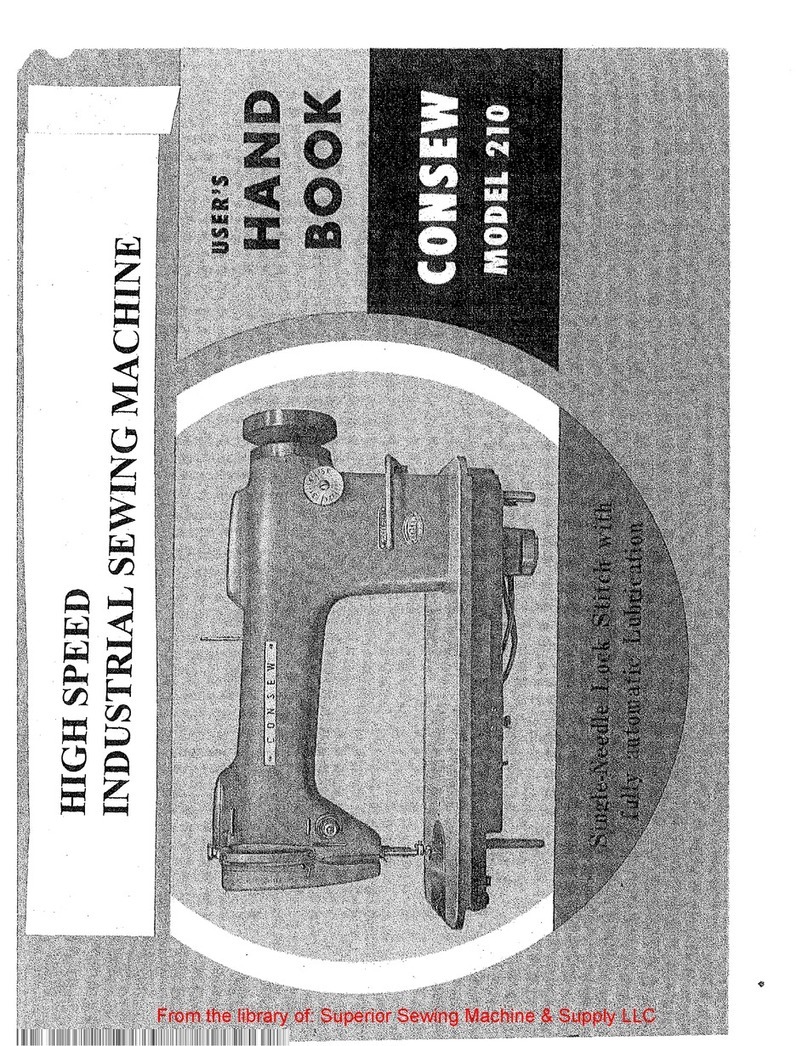

Fig. I Complete View

From the library of: Superior Sewing Machine & Supply LLC