CONTENTS

1.

Application

..................................................................

1

2.

Secure operation

.........................................................

1

3.

Caution before operation

................................................

1

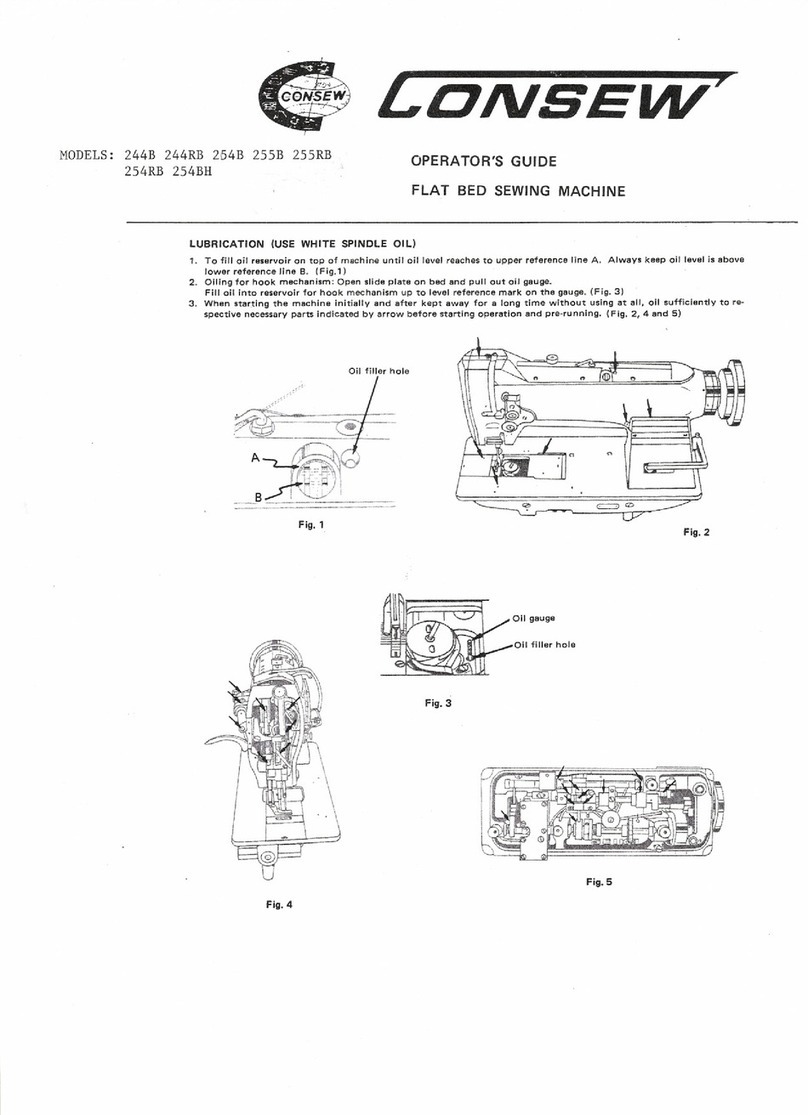

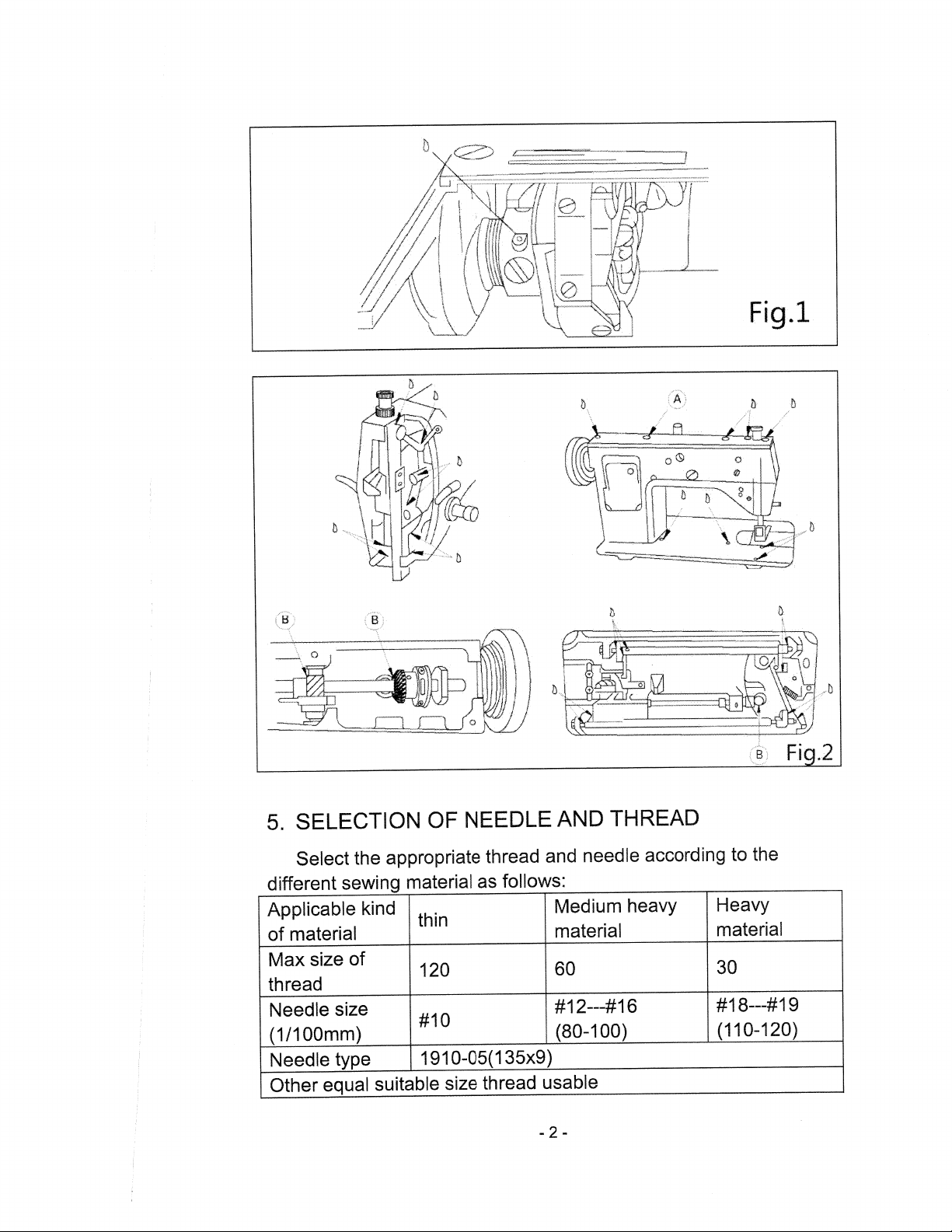

4. Lubrication

..................................................................

1

5.

Selection of needle and thread

.......................................

2

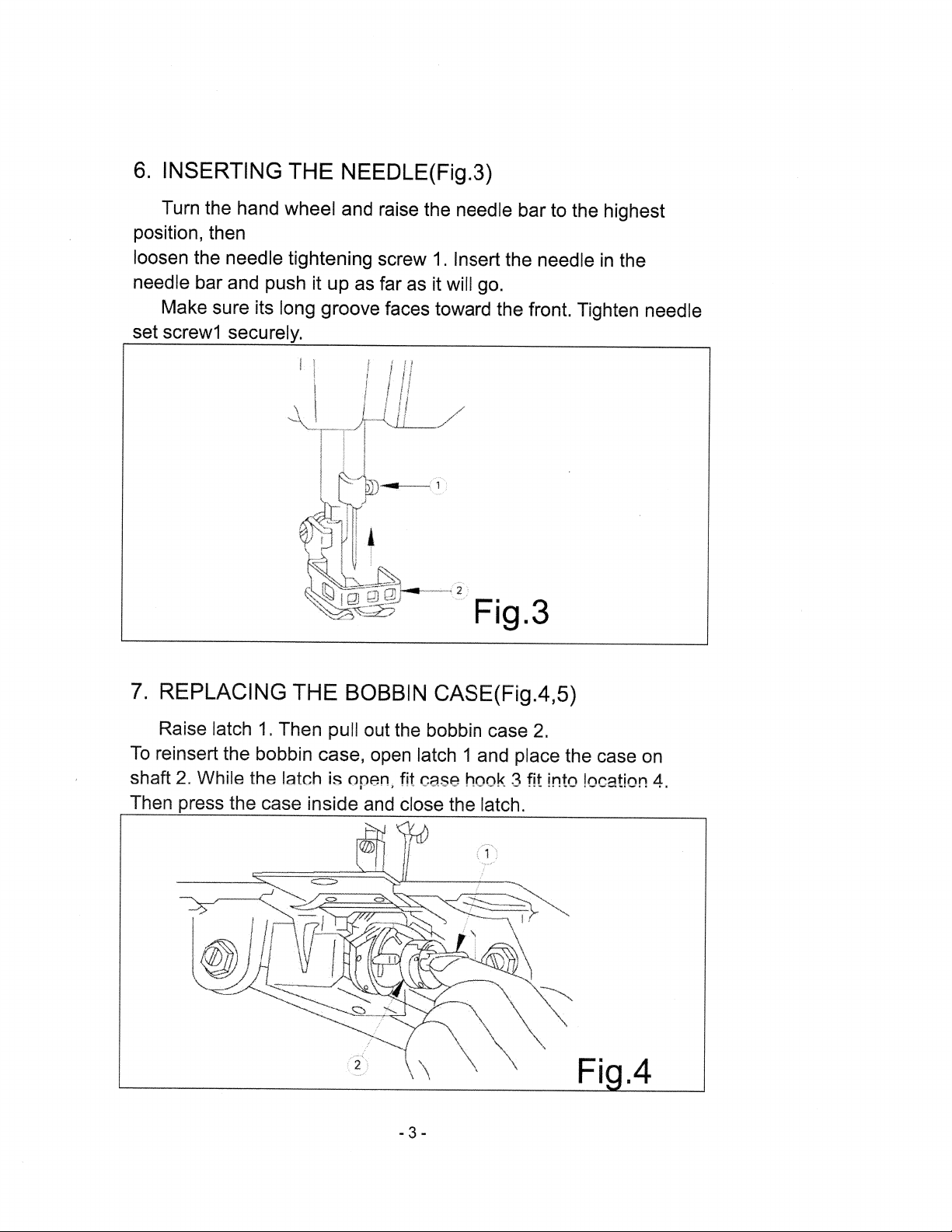

6.

Inserting the needle

......................................................

3

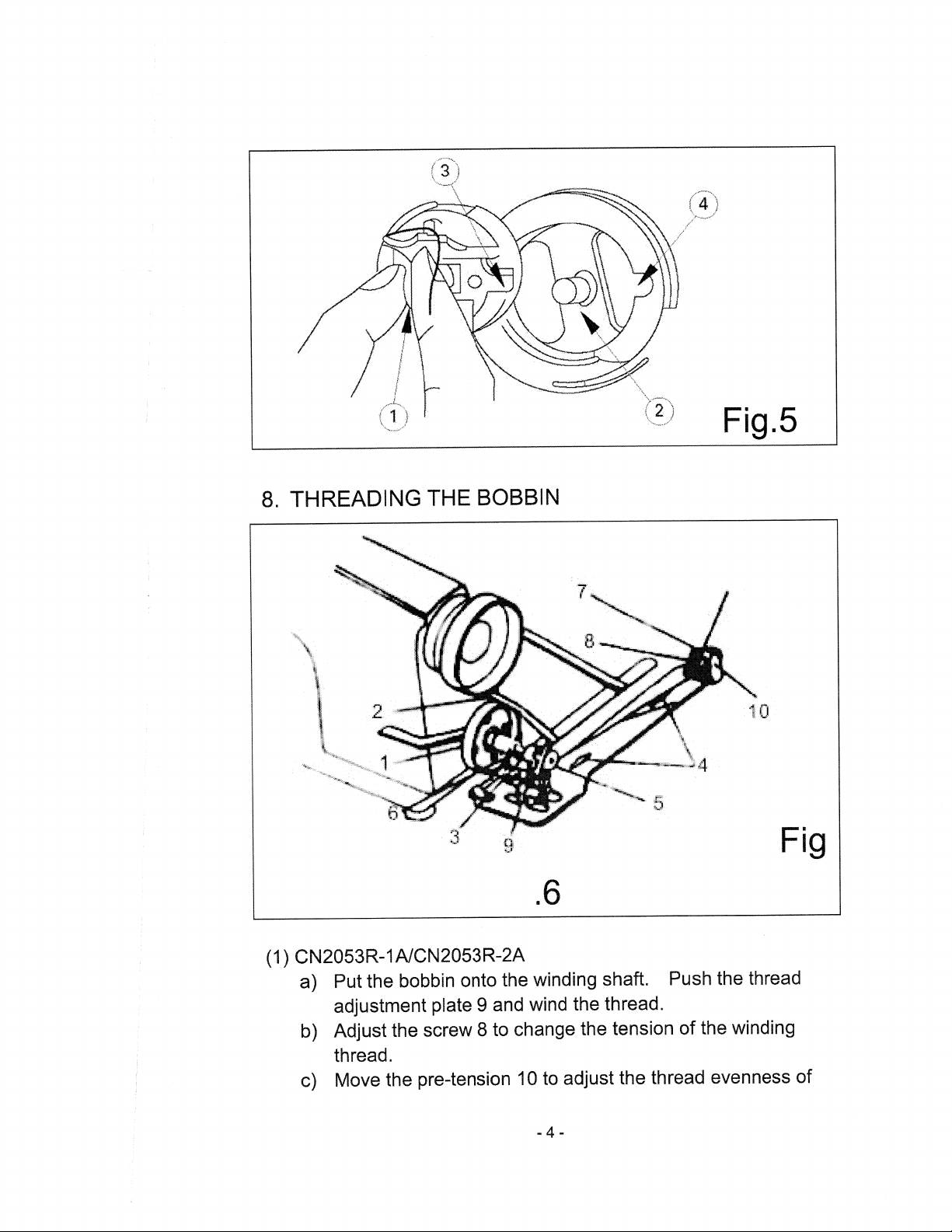

7.

Replacing the bobbin case

.............................................

3

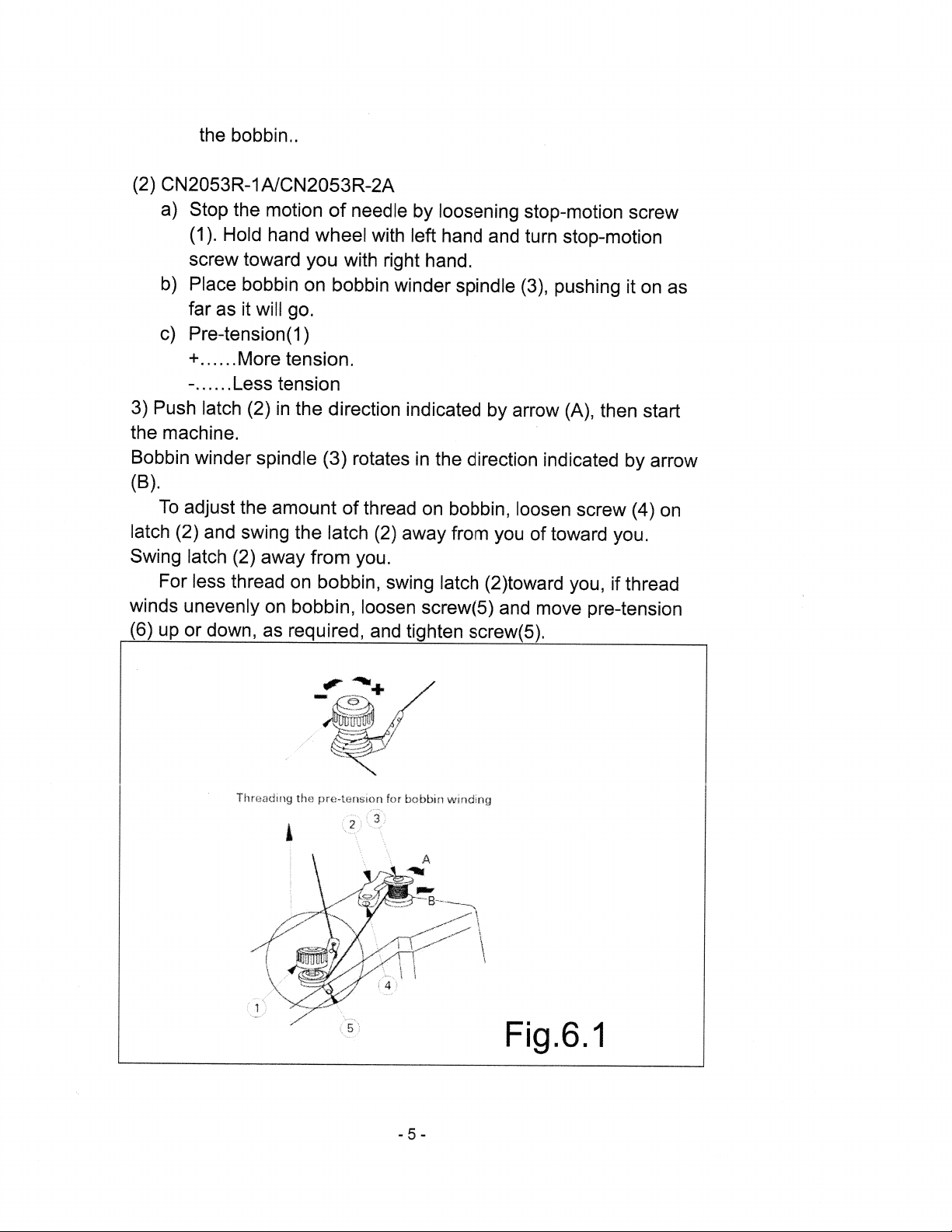

8.

Threading the bobbin

...................................................

4

9.

The installation

of

bobbin ........................................................6

10.Threading the machine...........................................................7

11.

Adjusting stitch length.............................................................?

12.Adjusting presser foot pressure..............................................8

13.Adjusting needle thread tension .............................................8

14. Regulate the length and tension

of

the take-up spring............9

15.Adjusting bobbin thread tension .............................................9

16.Adjusting needle position......................................................10

17.Adjusting the stitch width ......................................................

11

18.Locking unit for linear stitching .............................................

11

19.Assembling the belt cover.....................................................12

20. Mount knee lifter...................................................................13

21. Modes

of

sewing...................................................................14

22. Maintenance

of

the machine ................................................18

23. Main specification .................................................................18

- I -