TFP1484

Page 7 of 16

QTY QTY

1

3

1

1

1

4

2

1

2

1

3

1

5

1

1

1

1

1

1

1

3

1

1

1

1

1

1

2

1

1

1

1

1

1

2

6

4

1

2

2

6

1

5

5

2

5

1

1

2

1

5

1

2

2

6

2

2

5

3

5

2

1

. . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

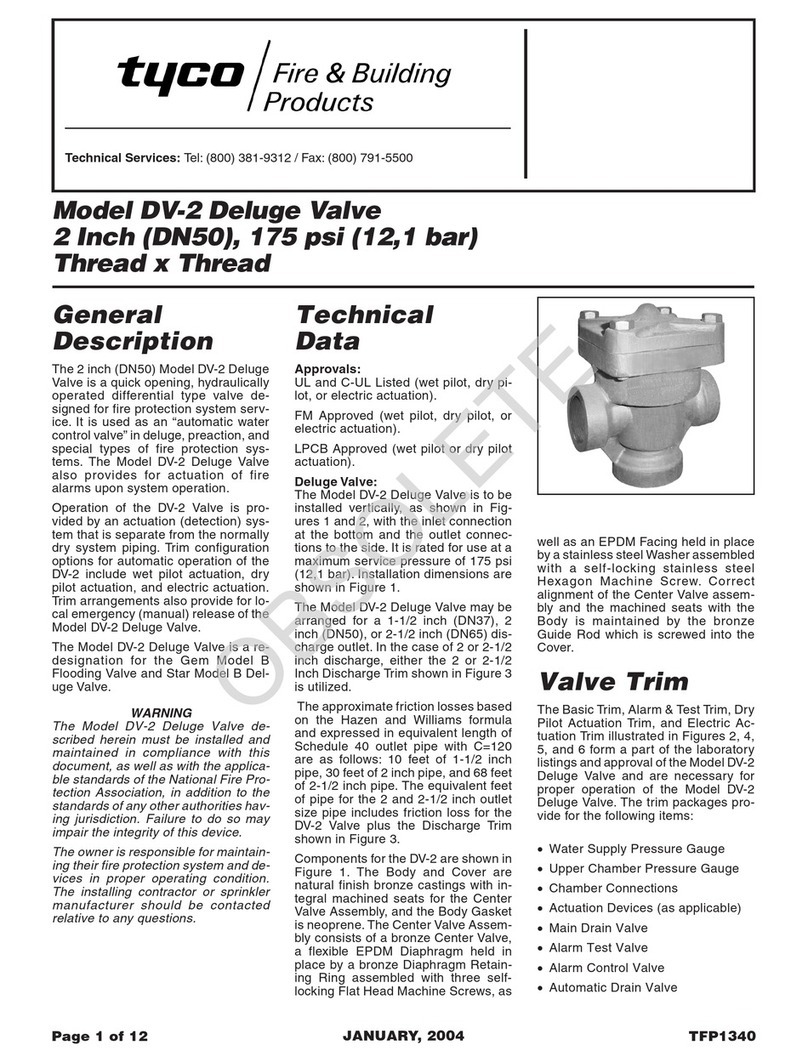

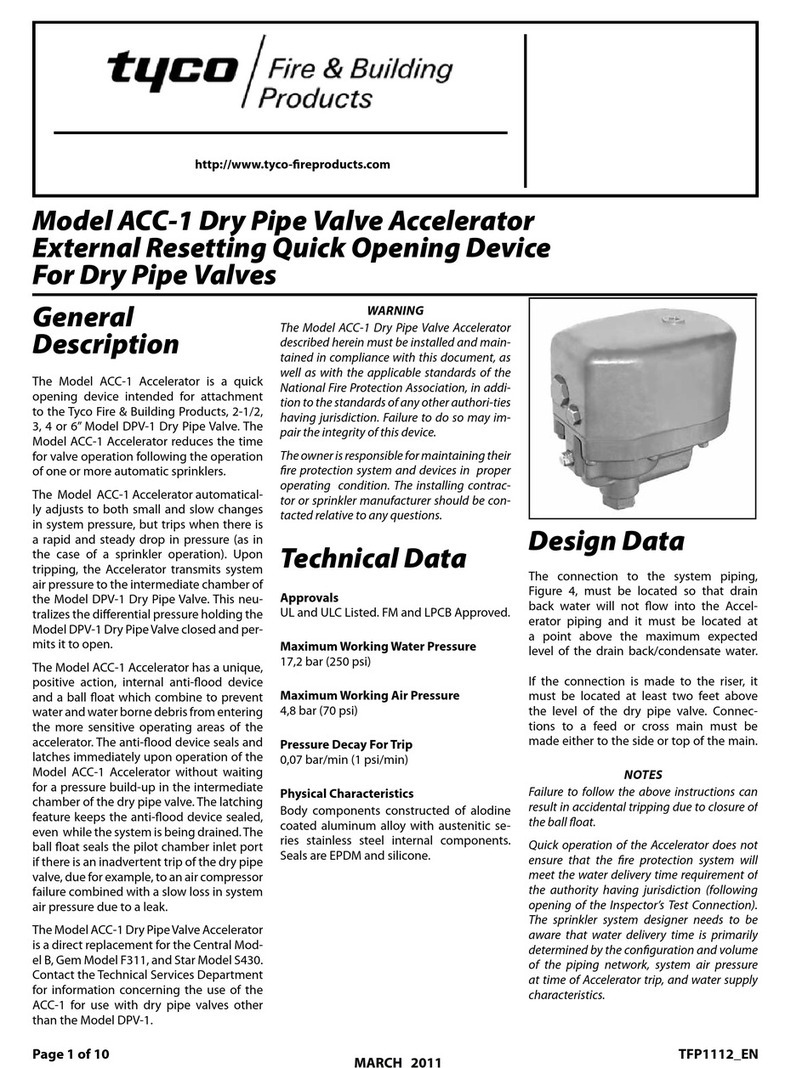

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

NO.

DESCRIPTION DESCRIPTION

Deluge Valve, DV-5, 4" - DN100, ISO Ports;

Rigid Coupling, Figure 577, 4" - DN100; P/N 577ME01141

Riser Check Valve, Model CV-1FR, 4" - DN100;

Reducer, DN20 x DN15; P/N RTEDMN

Pipe Nipple, 1/2" x 160mm; P/N AP160D2

Pipe Nipple, 3/4" x 100mm; P/N AP100E2

Pipe Nipple, 1/2" x 100mm; P/N AP100D2

Pipe Nipple, 1/2" x 250mm; P/N AP250D2

Pipe Nipple, 1/2" x 70mm; P/N AP70D2

Tube, 15 x 1mm, 550 x 400mm; P/N WS00000124

Tube, 15 x 1mm, 370 x 225mm; P/N WS00000096

Pipe, 10 x 12mm, 900mm; P/N WS00000007

Hose, 3 x 6mm, 1.2m; P/N WS00000004

Check Valve, 1/2" NPT; P/N V923221002

Union, DN15 x DN15; P/N UTDMDFN

Tee, DN20 x DN20 x DN20; P/N TTEMEEFN

Tee, DN20 x DN20 x DN20; P/N TTEEEFN

Tee, DN15 x DN15 x DN15; P/N TTDMDFDMN

Tee, DN15 x DN15 x DN15; P/N TTDMDDFN

Tee, DN15 x DN15 x DN15; P/N TTDDMDFN

Tee, DN15; P/N TTDDDFN

Adapter, DN15 x DN15; P/N STDDFN

Reducer, DN20 x DN15; P/N RTFEMN

Reducer, DN20 x DN15; P/N RTEMDFN

Reducer, DN15 x DN8; P/N RTDMBFN

Elbow, DN15 x DN15; P/N ETDMDFN

Elbow, DN15 x DN15; P/N ETDDMN

Elbow, DN15 x DN15; P/N ETDDFN

Adapter, DN20 x DN20; P/N ATEEMN

Compression Fitting, DN15 x 15mm; P/N ATDMCON

Pipe Nipple, 1/2" x 90mm; P/N AP90D2

Pipe Nipple, 2" x 80mm; P/N AP80I2

Pipe Nipple, 3/4" x 80mm; P/N AP80E2

Pipe Nipple, 1/2" x 80mm; P/N AP80D2

Pipe Nipple, 1/2" x 60mm; P/N AP60D2

Pipe Nipple, 1/2" x 50mm; P/N AP50D2

Pipe Nipple, 1/2" x 140mm; P/N AP140D2

Pipe Nipple, 1/2" x 120mm; P/N AP120D2

Plug, 2"; P/N A291I2

Plug, 1/4"; P/N A290B2

Reducing Tee, 2" x 2" x 1/2"; P/N A130RIDI2

Pressure Relief Valve, 1/4"; P/N 923431020

Air Pressure Gauge, 250 PSI; P/N 923431012

Tube Connector, 1/2" x 12mm; P/N 81900211

Restriction, 3mm Orice, 1/2" x 1/2"; P/N 700485

Ball Valve, DN15, Venthole M5; P/N 59304FO

Fail Safe Valve, Model FSV-1; P/N 523431001

Break Station, Model MC-1; P/N 522892001

Solenoid Valve, 24 VDC, 1/2" NPT, 20-250 PSI / 1.4-17.2 bar;

Dry Pilot Actuator, Model B-1; P/N 522801001

Check Valve, Swing Type, 3/4"; P/N 460491005

Check Valve, Swing Type, 1/2"; P/N 460491004D

Elbow, WES 3mm x M5; P/N 406012

Solenoid Valve, 24 VDC, 1/2" NPT, 0.2 - 16 bar;

Drain Valve, Self-Closing, 1/2" NPT; P/N 2162156

Strainer, 1/2" NPT; P/N 20005025

Ball Valve, DN20; P/N 1610000270

Ball Valve, DN15; P/N 1610000210

Angle Valve, 2"; P/N 028300060

Pressure Switch, Model PS40-2; P/N 0263

Pressure Switch, Model PS10-2; P/N 0261

Water Pressure Gauge, 300 PSI; P/N 025500013

P/N 524771923

P/N 595901040

P/N 522871124P

P/N 2191866

36

46

43

45

6

5

2

22 28

26

56

30

10

12

42

6

53

32

10

17

18 58

19

4

48

51

22

56

27 20 22

18

47

28 341 18

12

41

6

341

31

9

20

22

59

24

38

24

37

37

1

27 54

26 13 56

26

12 29

53 17

44

341 58 18

3

20

14

9

50

62

18

6

11

4

23

41

3

20

28

49

62

44

57

7

55

35

15

825

57 25

34

15

10

22

61

58

20

8

7

17

16

62

52

28

10

33

12

10

19

60

22

10 28

58

53

40

17

44

4

17

39

2

26

20

28

12

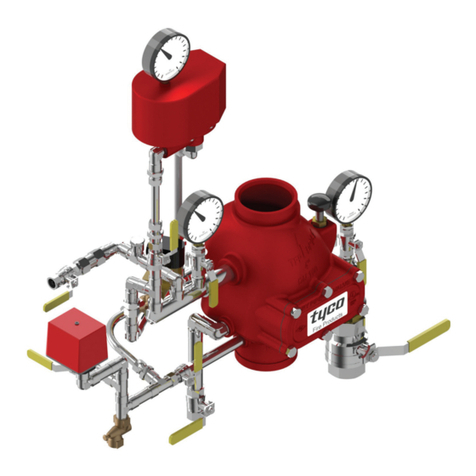

FIGURE 3 (4 OF 6)

DN100 DV-5 PREACTION TYPE A TRIM ASSEMBLY

EXPLODED VIEW