audible scienceaudible science

CAUTION

Refer servicing to

qualified personnel only.

Precautions

On Safety

Should any solid object or

liquid fall into the tonearm,

have it checked by your Factory

Authorized Consultant

On Placement

• Place the unit in a location with

adequate ventilation to prevent

heat buildup and prolong the life

of the unit.

• Do not place the unit near heat

sources, or in a place subject to

direct sunlight, excessive dust or

mechanical shock.

• Do not place anything near

the unit that might create RF

interference.

On Operation

Before connecting to phono

stage components, be sure to

follow component manufacturers

intructions.

On Cleaning

Clean tonearm, and controls with

a soft cloth slightly moistened

with a mild detergent solution. Do

not use any type of abrasive pad,

scouring powder or solvent such

as alcohol or benzine.

If you have any questions or

problems concerning your

Cobra tonearm, please contact

your Continuum Authorized

Installation Consultant

TABLE OF CONTENTS

OUR DESIGN PHILOSOPHY ..................6

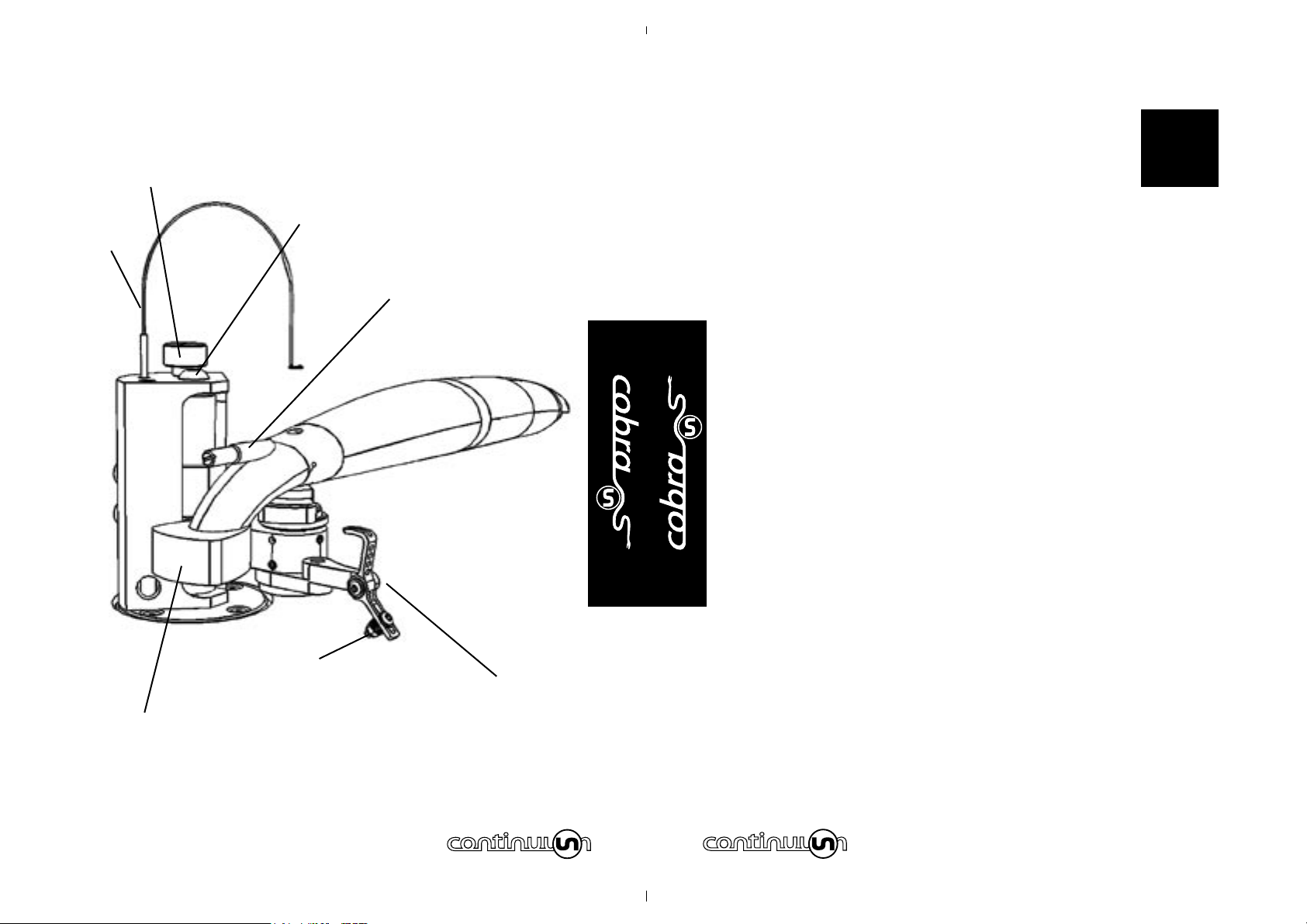

DESIGN FEATURES

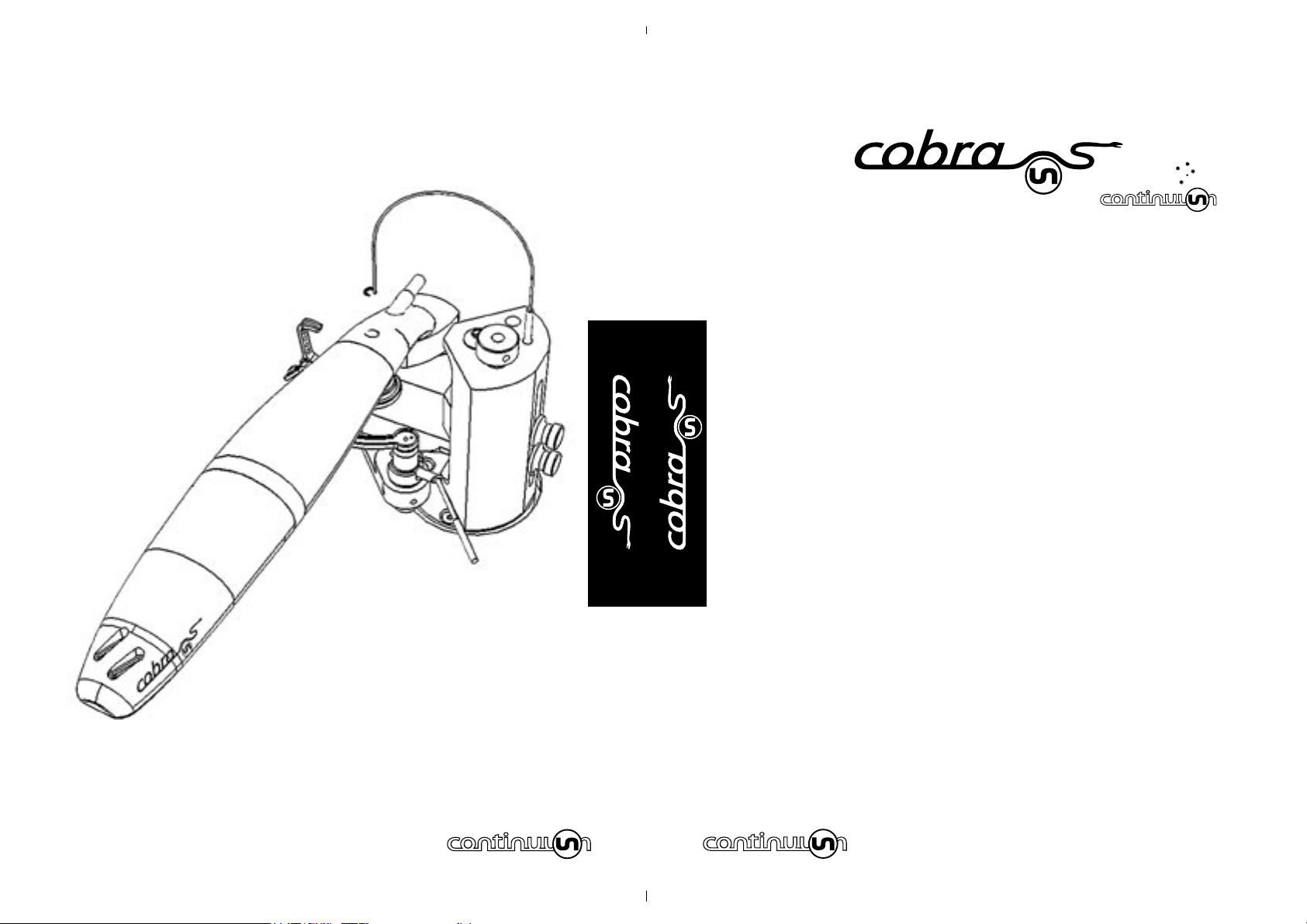

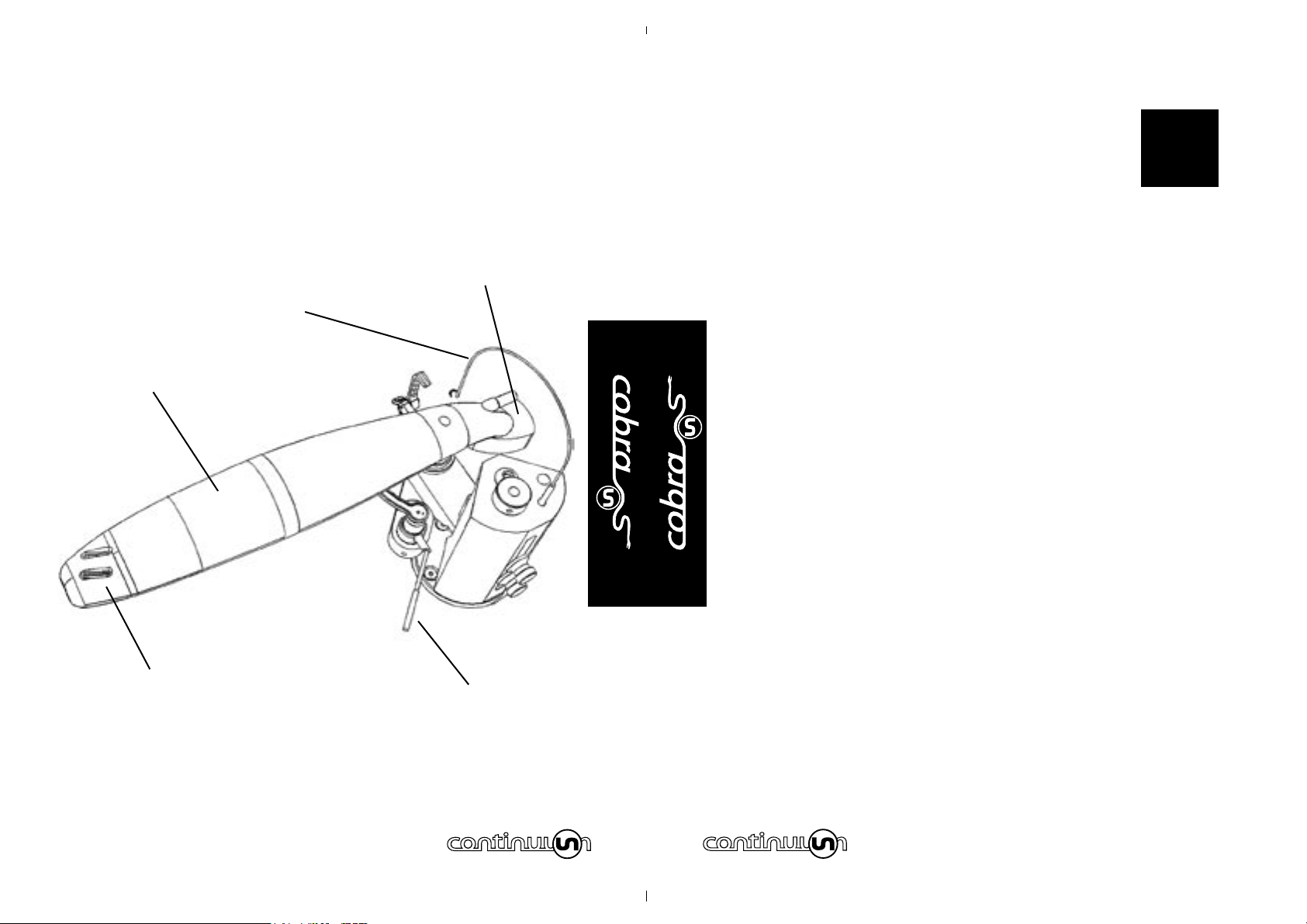

Arm Wand ............................................ 8

Headshell ............................................. 8

Fingerlift .............................................. 10

Arm Lifter ............................................. 10

Counterweight ...................................... 10

Vertical Bearing Motion ........................... 12

Horizontal Bearing Motion ....................... 14

Azimuth Adjustment .............................. 14

Stylus Rake Angle (SRA) or (VTA) ............ 16

Overhang Adjustment ............................ 20

Anti Skate or Bias Adjustment ................. 22

INSTALLATION

Why Set up is Critical ............................. 24

Installation & Set up .............................. 28

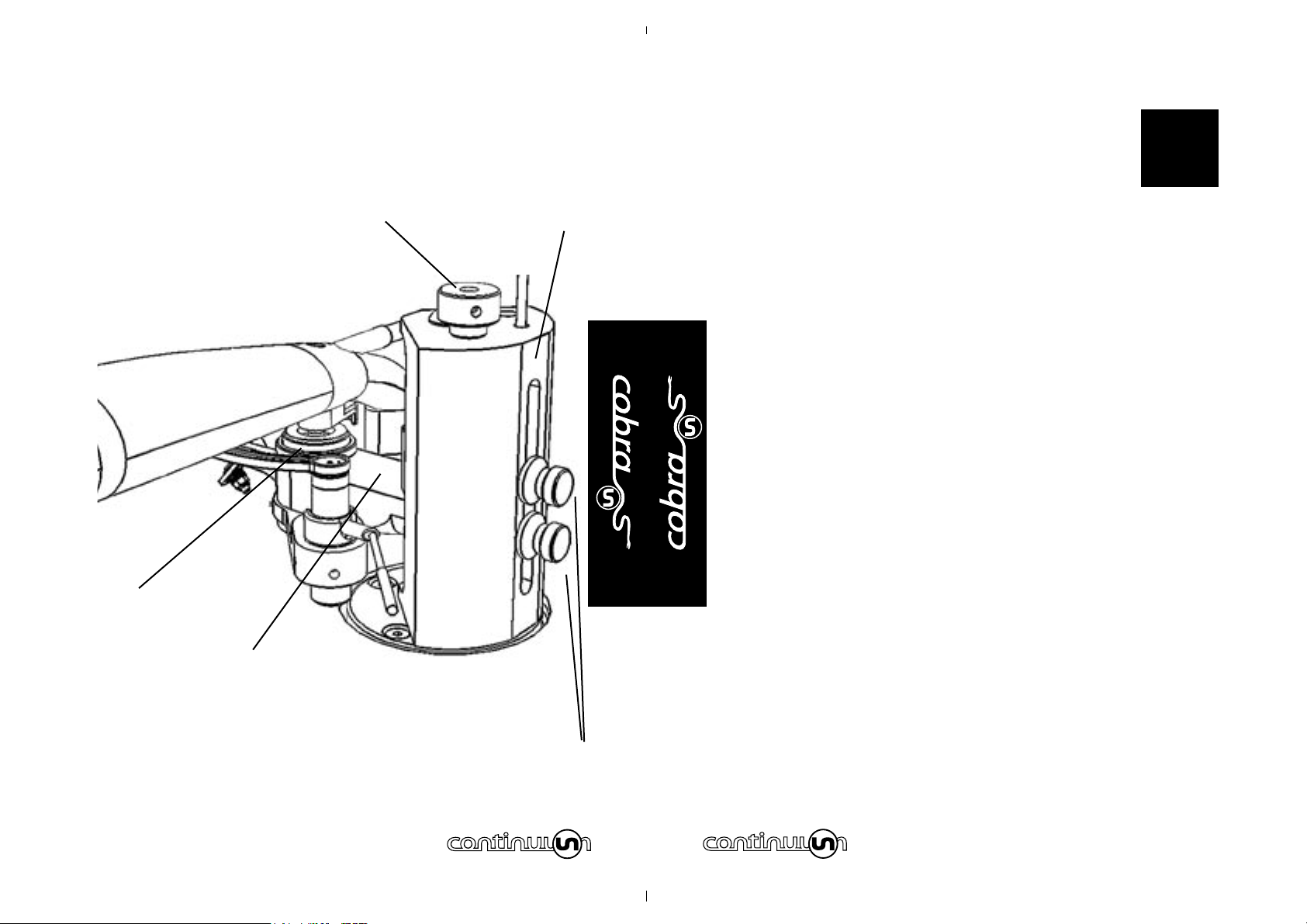

Positioning Central Tower on Turntable ..... 30

Distance of Spindle to Cross Arm Pivot ..... 34

VTA & SRA Set up .................................. 36

Mounting the Cartridge ........................... 38

Mounting & Balancing the Arm ................ 38

Connecting and Adjusting Anti Skate ........ 42

Setting the Azimuth ............................... 48

OWNER CARE & MAINTENANCE

Routine ................................................ 54

Specifications ........................................ 56

THE COBRA’S DESIGN HISTORY ..........

TABLE OF

CONTENTS

page 4