3

Content

1. Before Started........................................................................................... 5

1.1 Metrological Legislation...................................................................... 5

1.2 Seal & Serial Number. ........................................................................ 5

1.3 Warm up time ..................................................................................... 5

1.4 In case when in Doubt........................................................................ 5

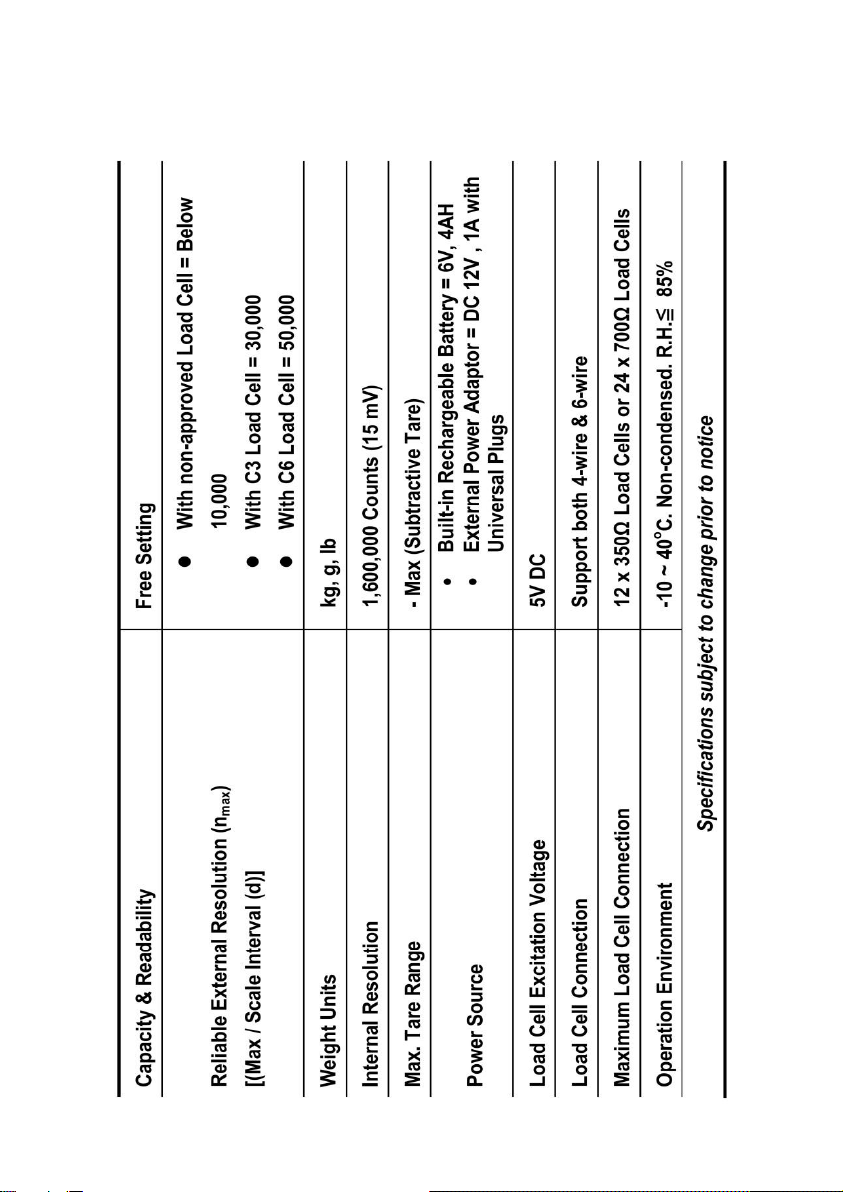

2. Specifications............................................................................................ 6

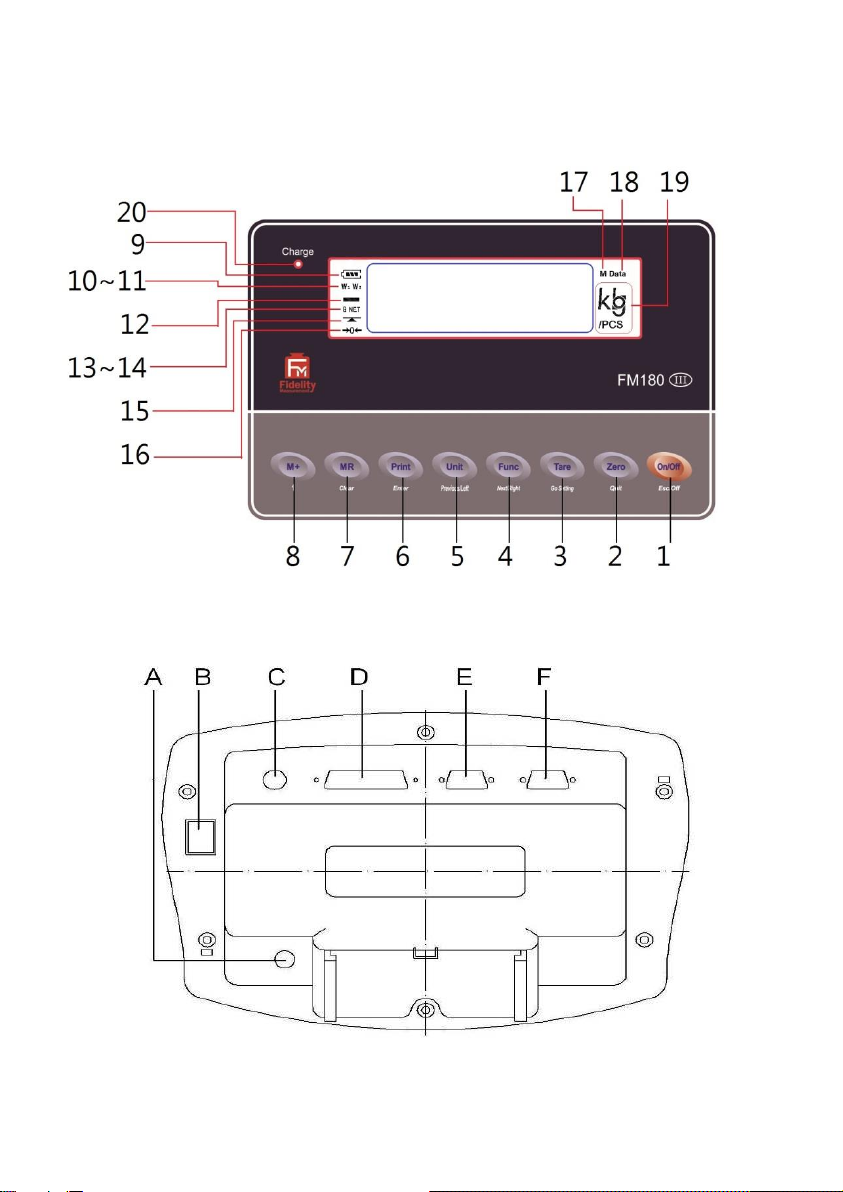

3. Keys, Display & Connections.................................................................... 6

4. Getting Started.........................................................................................11

4.1 Built-In Rechargeable Battery ...........................................................11

4.2 Power Adaptor ...................................................................................11

4.3 Connection with Weighing Platform or Load Cell Junction Box ........11

4.4 Connecting RS232 To Computer...................................................... 12

4.5 Connecting RS232 to Printer (DB25) ............................................... 12

5. Initial Setup ............................................................................................. 13

5.1 Internal Settings................................................................................ 13

5.2 How to Enter & Select Internal Function .......................................... 13

5.3 Key Function During Internal Function Mode................................... 14

5.4 Internal Function Table ..................................................................... 14

6. Instruction for Use................................................................................... 19

6.1 Power On.......................................................................................... 19

6.2 Start Weighing .................................................................................. 19

6.3 About Weigh Unit Conversion .......................................................... 19

6.4 Tare off the Weight of a Container.................................................... 20

6.5 Memory Accumulation Function ....................................................... 22