Contrinex Industrial Electronics Contrinex Industrial Electronics 3

2

TABLE OF CONTENTS 1. INTRODUCTION ............................................................5

1.1. Contrinex..................................................................................................5

1.2. Safetinex safety systems .........................................................................5

1.3. Active optoelectronic protective devices (AOPD) ................................... 5

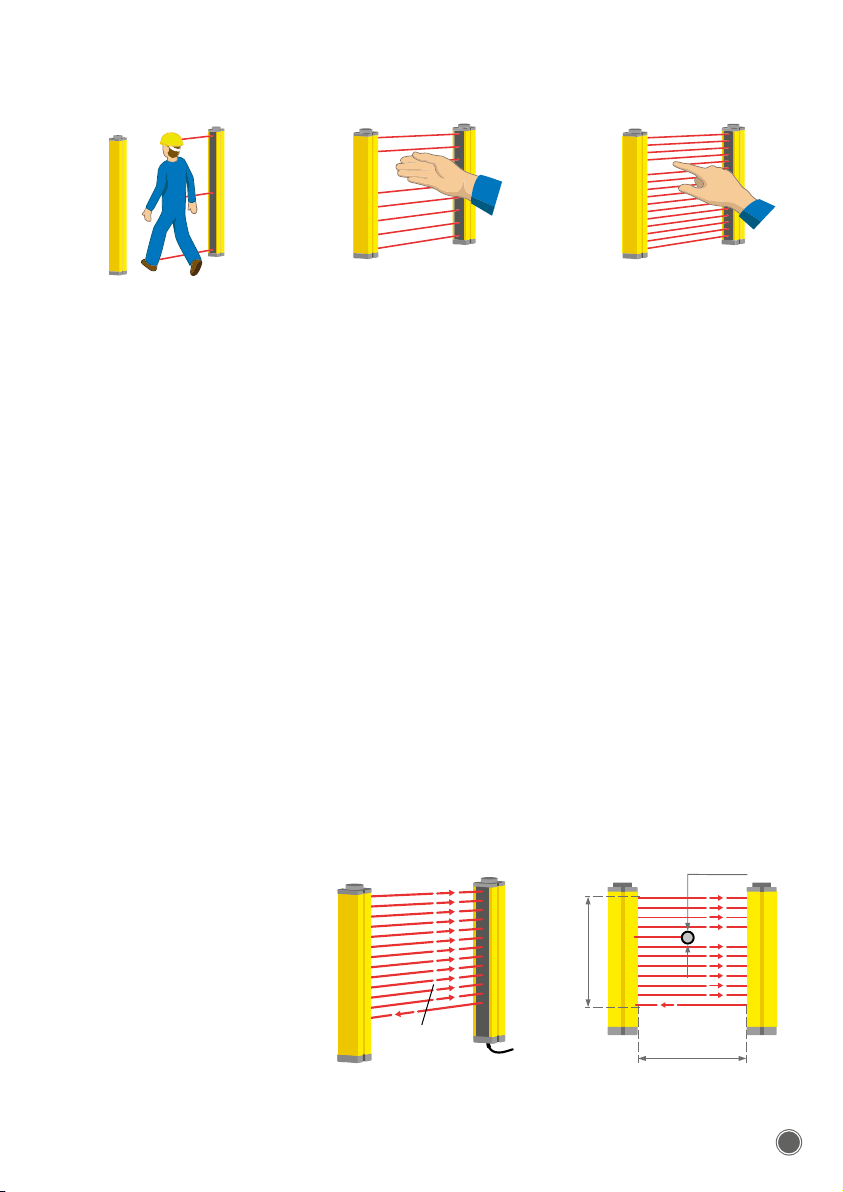

1.3.1. Safeguarding function ........................................................................6

1.3.2. Hazardous area ..................................................................................6

1.3.3. AOPD detection capability .................................................................6

1.4. Advantages of AOPDs.............................................................................7

1.5. Operating principle..................................................................................7

1.6. Certification of Safetinex products........................................................... 8

2. EUROPEAN SAFETY STANDARDS ..............................8

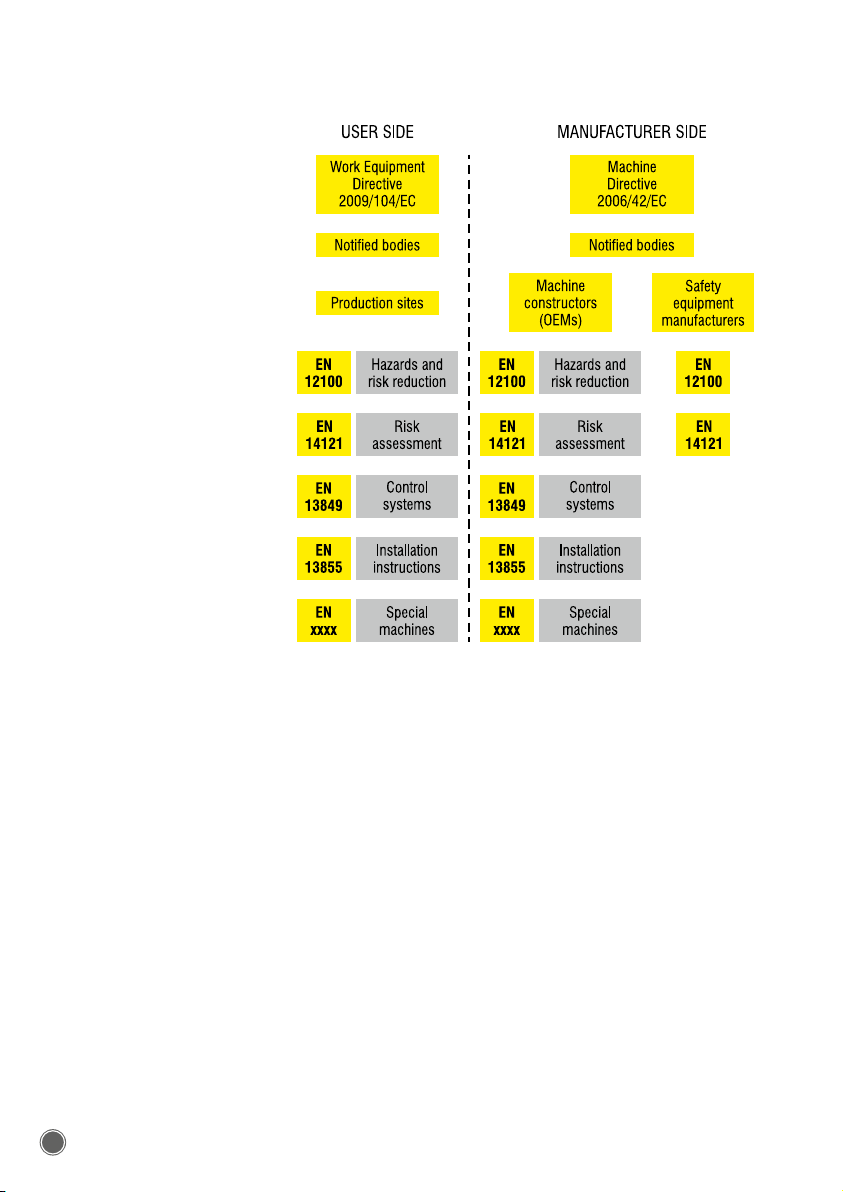

2.1. Types of safety standards applicable in the EU ...................................... 8

2.2. Examples of safety standards..................................................................9

2.3. An approach to European standards ...................................................... 9

2.4. The user side .........................................................................................10

2.5. Machine manufacturer side ...................................................................10

2.6. Notified bodies.......................................................................................11

3. NORTH AMERICAN SAFETY STANDARDS ..............11

3.1. A different approach .............................................................................. 11

3.2. OSHA Regulations and U.S. Consensus Standards .............................12

3.3. North American Standards for safety issues: UL, ANSI and CSA.........13

3.3.1. American standard agencies ........................................................... 13

3.3.2. Canadian standard agencies ...........................................................13

3.4. International standard agencies ............................................................14

4. RISK ASSESSMENT......................................................14

4.1. Definition of hazards and risk reduction strategy .................................. 14

4.2. Risk assessment process ...................................................................... 14

4.3. Methods for determination of risk level.................................................. 17

4.3.1. Determination of risk level in North America ....................................17

4.3.2. Determination of required performance level (PLr)..........................17

4.3.3. Specific standards for safety distance calculation...........................19

5. INSTALLATION ............................................................19

5.1. Installation rules ..................................................................................... 19

5.1.1. Positioning the AOPD .......................................................................19

5.1.2. Minimum safety distance required ...................................................20

5.1.3. Minimum safety distance calculation (EU) ....................................... 21

5.1.4. Minimum safety distance calculation (US & Canada)......................23

6. OTHER COUNTRIES ....................................................24

7. ACRONYMS..................................................................25

8. TECHNICAL DOCUMENTATION ...............................26

8.1. Safetinex YBB for finger protection........................................................26

8.2. Safetinex YBB for hand protection.........................................................26

8.3. Safetinex YCA for access control .......................................................... 26