2SQI IO&M B51151-003

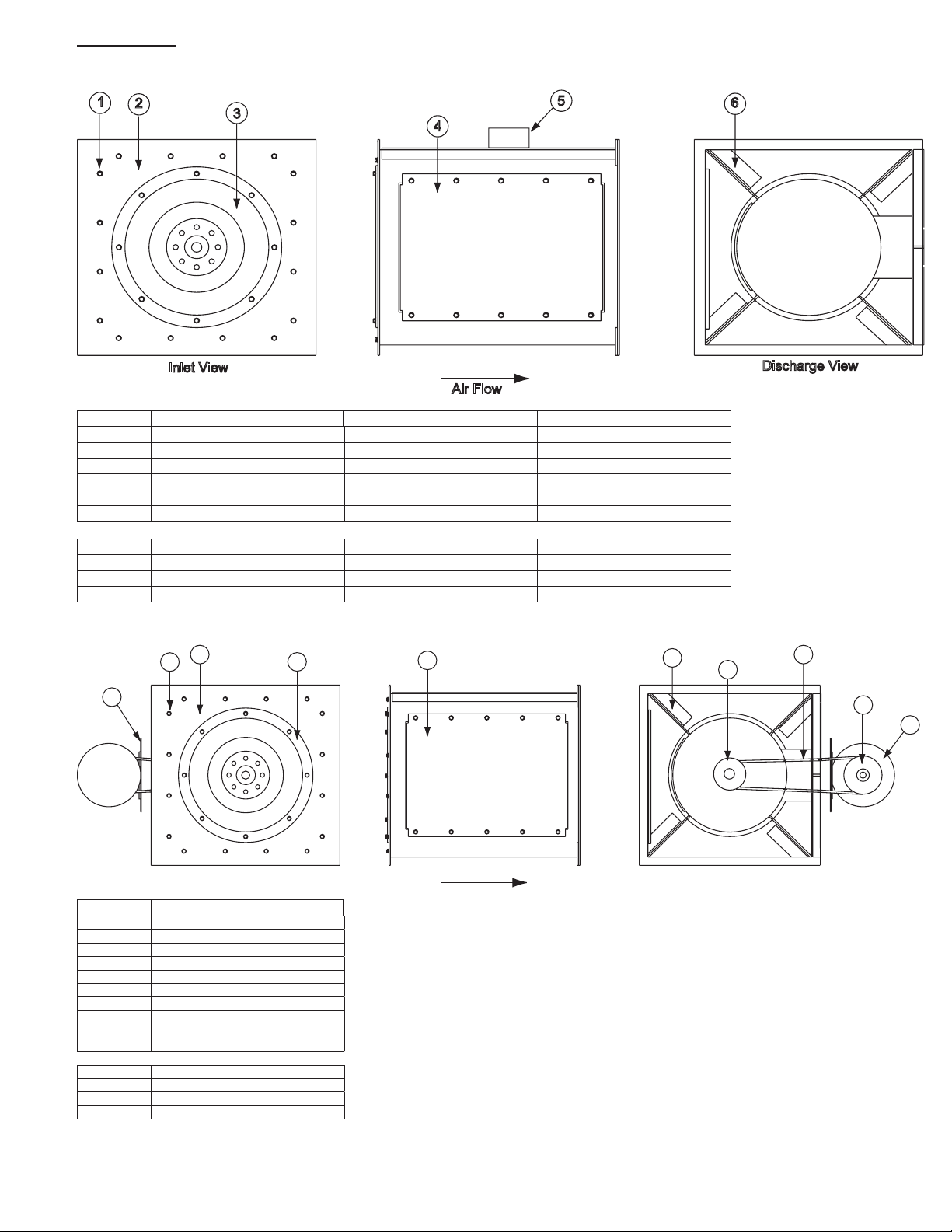

Do not change the pulley pitch diameter to change ten-

sion. This will result in a dierent fan speed.

1. Loosen motor plate adjustment nuts on stud bolts and

move motor plate in order that the belts can easily slip

into the grooves on the pulleys. Never pry, roll, or force

the belts over the rim of the pulley.

2. Adjust the motor plate until proper tension is reached.

For proper tension, a deection of approximately 1/4”

per foot of center distance should be obtained by rm-

ly pressing the belt. Refer to Figure 1.

3. Lock the motor plate adjustment nuts in place.

4. Ensure pulleys are properly aligned. Refer to Figure 2.

Tolerance

Center

Distance

Max.

Gap

Up through

12” 1/16”

12” through

48” 1/8”

Over 48” 1/4”

OFFSET ANGULAR OFFSET/ANGULAR

A

X

Y

ZB

CENTER

DISTANCE

(CD)

GAP GAP

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pulley

setscrew and by moving the motor

pulley on the motor shaft.

Figure 2 indicates where to mea-

sure the allowable gap for the drive

alignment tolerance. All contact

points (indicated by WXYZ) are to

have a gap less than the tolerance

shown in the table. When the pul-

leys are not the same width, the al-

lowable gap must be adjusted by

half of the dierence in width. Fig-

ure 3 illustrates using a carpenter’s

square to adjust the position of the

motor pulley until the belt is parallel to the longer leg of the

square.

Final Installation Steps

1. Ensure that all accessories are installed.

2. Ensure that the blower is secured to ductwork.

3. Inspect wheel-to-inlet clearance. Ensure wheel does not

rub against the inlet.

4. Test the fan to ensure the rotation of the wheel is the same

as indicated by the rotation label.

5. Inspect for correct amperage with an ammeter and correct

voltage with a voltmeter.

NOTICE! Do not allow the fan to run in the wrong

direction. This will overheat the motor and cause

serious damage. For 3-phase motors, if the fan is

running in the wrong direction, check the control

switch. It is possible to interchange two leads at

this location so that the fan is operating in the cor-

rect direction.

Storage

If fan is stored for any length of time, prior to installation,

completely ll bearings with grease or moisture-inhibiting

oil. Refer to pages 4-5. Store the fan in its original crate

and protect from dust, debris, and weather. To maintain

good working condition of a SQI when it’s stored outdoors,

or on a construction site follow the additional steps below.

• Cover the inlet and outlet, and belt tunnel opening to pre-

vent accumulation of dust and moisture in the housing

• Periodically rotate the wheel and operate dampers (if

supplied) to keep a coating of grease on all internal bear-

ing parts

• Periodically inspect the unit to prevent damaging

conditions

Installation

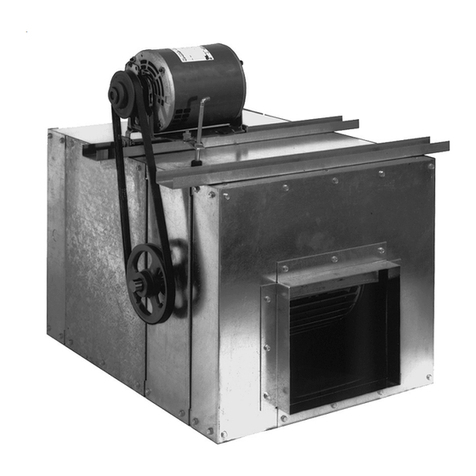

To prevent damage to the fan during shipping, motors

5HP and larger, and extremely heavy motors (cast iron or

severe duty) are shipped loose and must be eld mounted

by bolting the motor on the motor mounting plate in the ex-

isting mounting slots.

Wiring Installation

NOTICE! All wiring should be in accordance with

local ordinances and the National Electrical Code,

NFPA 70. Ensure the power supply (voltage, fre-

quency, and current carrying capacity of wires) is

in accordance with the motor nameplate. Refer to

Wiring Diagrams, page 3-4.

Direct Drive

Wire the electrical box on the blower housing.

Belt Drive

The motor can be wired directly since the motor is exter-

nal to the fan.

Leave enough slack in the wiring to allow for motor move-

ment when adjusting belt tension. Some fractional motors

have to be removed in order to make the connection with

the terminal box at the end of the motor. To remove motor,

remove bolts securing motor base to power assembly. Do

not remove motor mounting bolts.

Motor Plate

Motor Plate

Adjustment Nut

Belt and Pulley Installation

Belt tension is determined by the sound the belts make

when the fan is rst started. Belts will produce a loud

squeal which dissipates after the fan is operating at full

capacity. If the belt tension is too tight or too loose, lost ef-

ciency and possible damage can occur.

Figure 3

Figure 2

Figure 1