5TCN IO&M B51143-003

Inspection

Inspection of the fan should be conducted at the rst 30

minute, 8 hour and 24 hour intervals of satisfactory op-

eration. During the inspections, stop the fan and inspect

as per the Conditions Chart.

30 Minute Interval

Inspect bolts, setscrews and motor mounting bolts. Ad-

just and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten

as necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

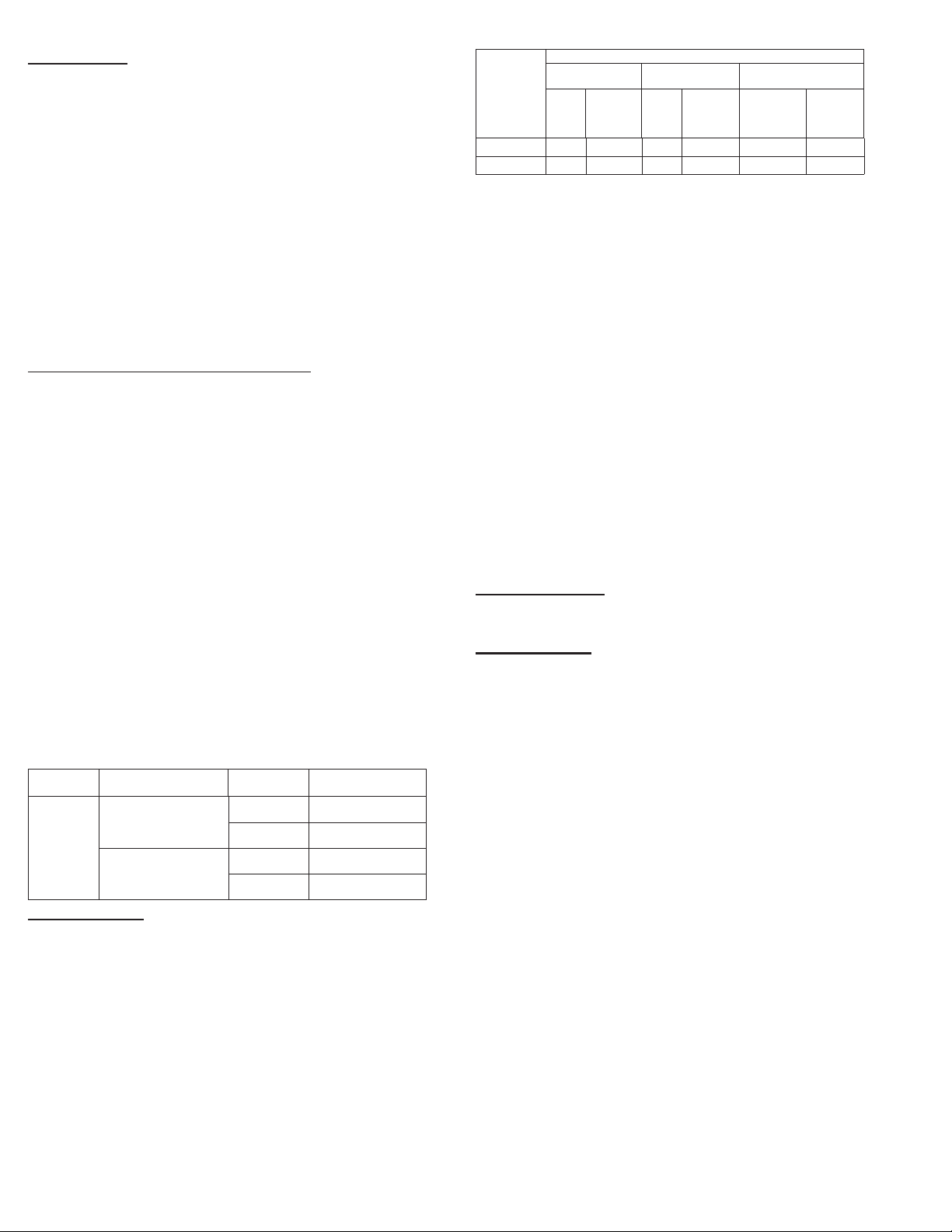

Recommended Torque for Setscrews/Bolts (IN-LB)

Setscrews Hold Down Bolts

Size

Key Hex

Across

Flats

Recommended

Torque Size Recommended

Torque

Min. Max.

#8 5/64” 15 21 3/8”-16 324

#10 3/32” 27 33 1/2”-13 780

1/4 1/8” 70 80 5/8 ”-11 1440

5/16 5/32” 140 160 3/4”-10 2400

3/8 3/16” 250 290 7/8”-9 1920

7/16 7/32” 355 405 1”-8 2700

1/2 1/4” 560 640 1-1/8”-7 4200

5/8 5/16” 1120 1280 1-1/4”-7 6000

3/4 3/8” 1680 1920 - -

7/8 1/2” 4200 4800 - -

19/16” 5600 6400 - -

Maintenance

Establish a schedule for inspecting all parts of the fan.

The frequency of inspection depends on the operating

conditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the rst month of operation. Fans exhausting con-

taminated air (airborne abrasives) should be inspected ev-

ery three months.

Regular inspections are recommended for fans exhaust-

ing non-contaminated air.

It is recommended the following inspections be con-

ducted twice per year:

• Inspect bolts and setscrews for tightness. Tighten as

necessary

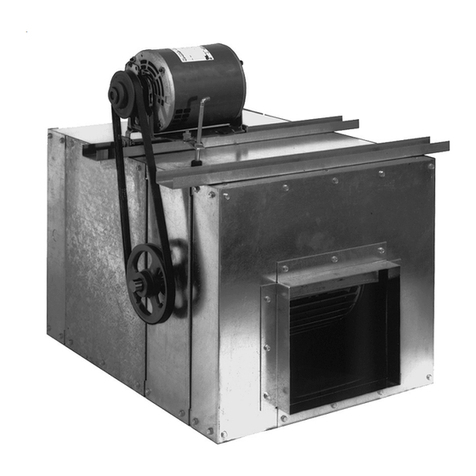

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. Refer to

Belt and Pulley Installation, page 3

• Bearings should be inspected as recommended in the

Lubrication Conditions Chart

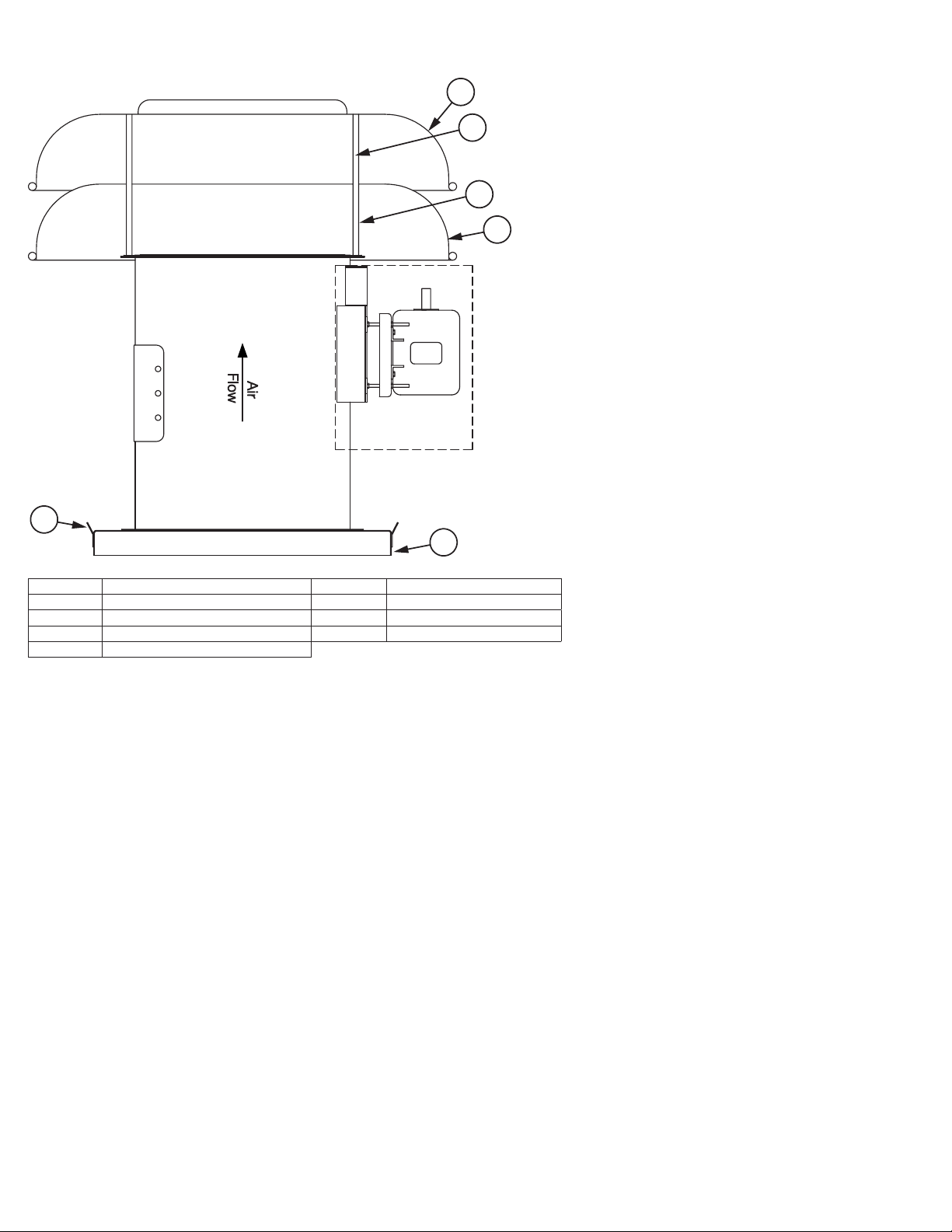

• Inspect variable inlet vanes for freedom of operation and

excessive wear. The vane position should agree with the

position of the control arm. As the variable inlet vanes

close, the entering air should spin in the same direction

as the wheel

• Inspect springs and rubber isolators for deterioration

and replace as needed

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling. Removing dirt from the wheel and

housing prevents imbalance and damage

NOTICE! Follow the wiring diagram in the discon-

nect switch and the wiring diagram provided with

the motor. Correctly label the circuit on the main

power box and always identify a closed switch to

promote safety (i.e., red tape over a closed switch).

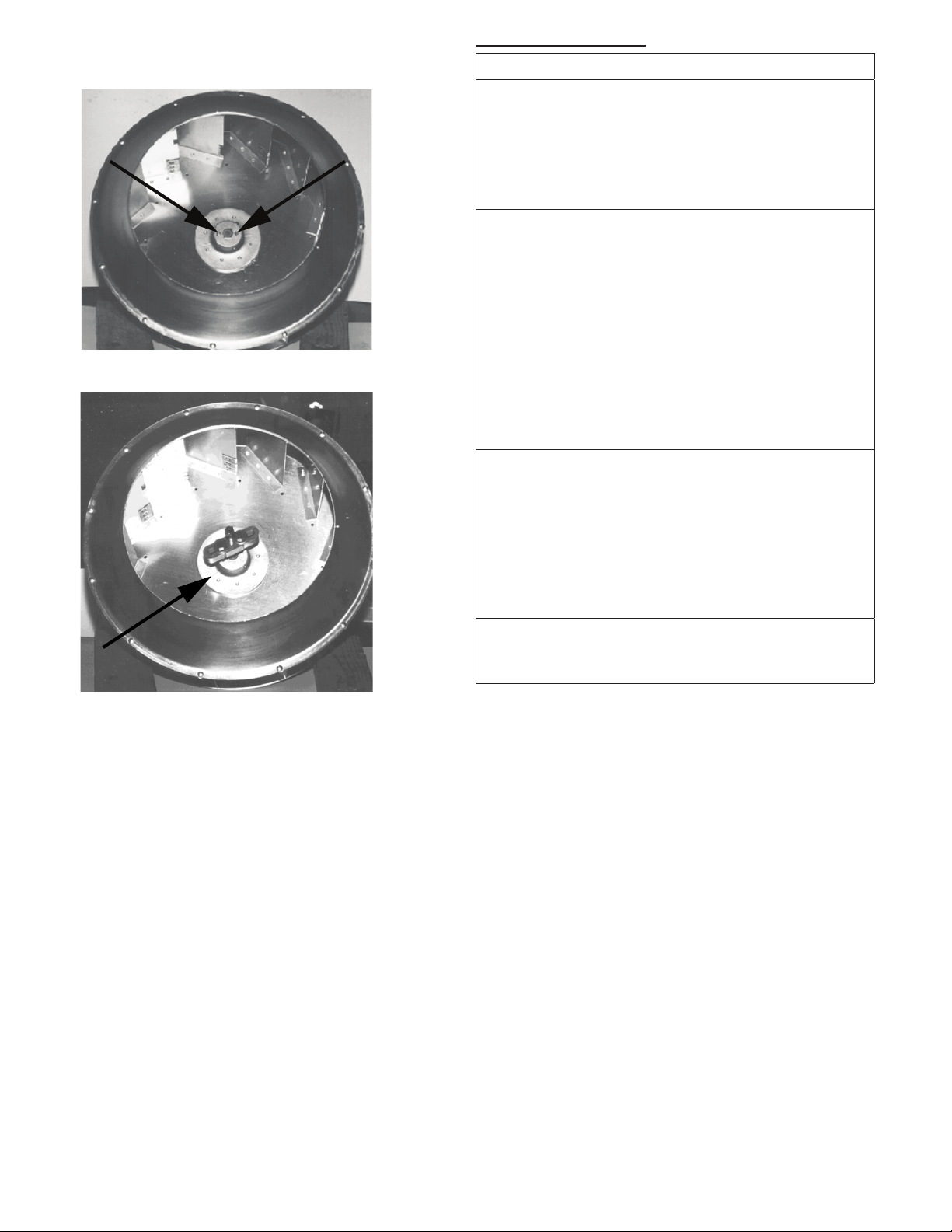

Wheel Rotation

Test the fan to ensure the rotation of

the wheel is the same as indicated by

the arrow marked Rotation.

115 and 230 Single Phase Motors

Fan wheel rotation is set correctly at the factory. Chang-

ing the rotation of this type of motor should only be at-

tempted by a qualied electrician.

208, 230 and 460 3-Phase Motors

These motors are electrically reversible by switching two

of the supply leads. For this reason, the rotation of the fan

cannot be restricted to one direction at the factory. See

Wiring Diagrams, page 4, for specic information on re-

versing wheel direction.

NOTICE! Do not allow the fan to run in the wrong

direction. This will overheat the motor and cause

serious damage. For 3-phase motors, if the fan is

running in the wrong direction, check the control

switch. It is possible to interchange two leads at

this location so that the fan is operating in the cor-

rect direction.

Final Installation Steps

1. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners then tighten accord-

ing to the Recommended Torque chart.

2. Inspect for correct voltage with a voltmeter.

3. Ensure all accessories are installed.

Operation

Pre-Start Checks

1. Lock out all the primary and secondary power sources.

2. Ensure fasteners and setscrews, particularly those

used for mounting the fan, are tightened.

3. Inspect belt tension and pulley alignment.

4. Inspect motor wiring.

5. Ensure belt touches only the pulleys.

6. Ensure fan and ductwork are clean and free of debris.

7. Inspect wheel-to-inlet clearance. The correct wheel-

to-inlet clearance is critical to proper fan performance.

8. Close and secure all access doors.

9. Restore power to fan.

Start-Up

Turn on the fan. In variable speed units, set the fan to its

lowest speed and inspect for the following:

• Direction of rotation

• Excessive vibration

• Unusual noise

• Bearing noise

• Improper belt alignment or tension (listen for squealing)

• Improper motor amperage or voltage

NOTICE! If a problem is discovered, immediately shut

o the fan. Lock out all electrical power and check for

the cause of the trouble. Refer to Troubleshooting.

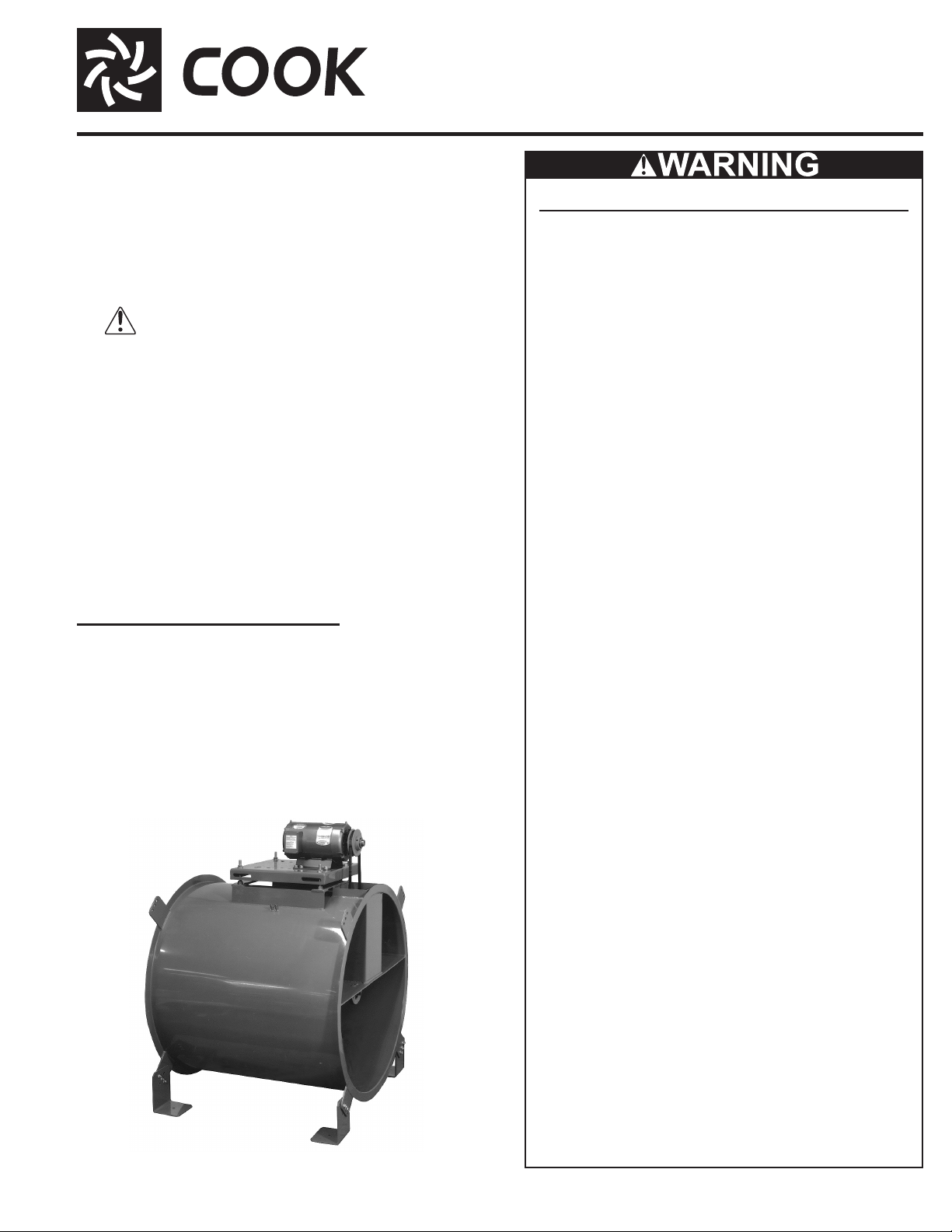

Tubular Centrifugal Inline