10

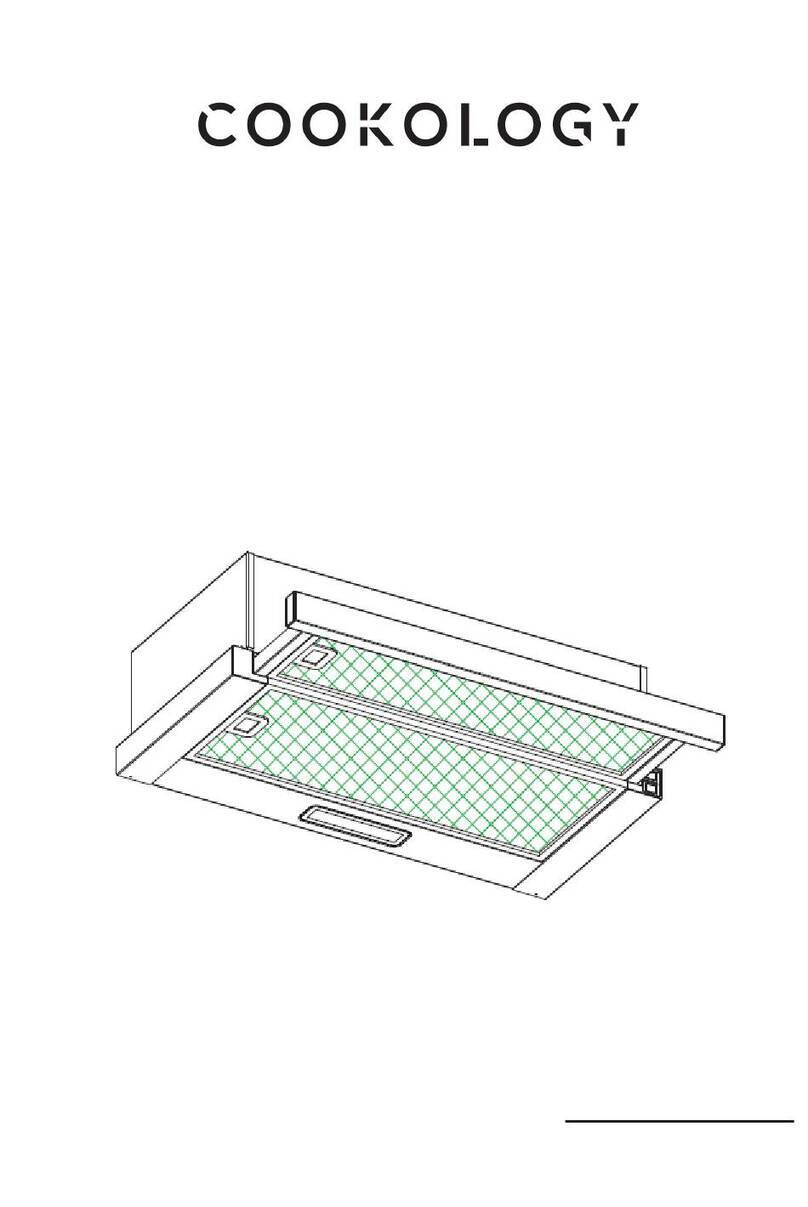

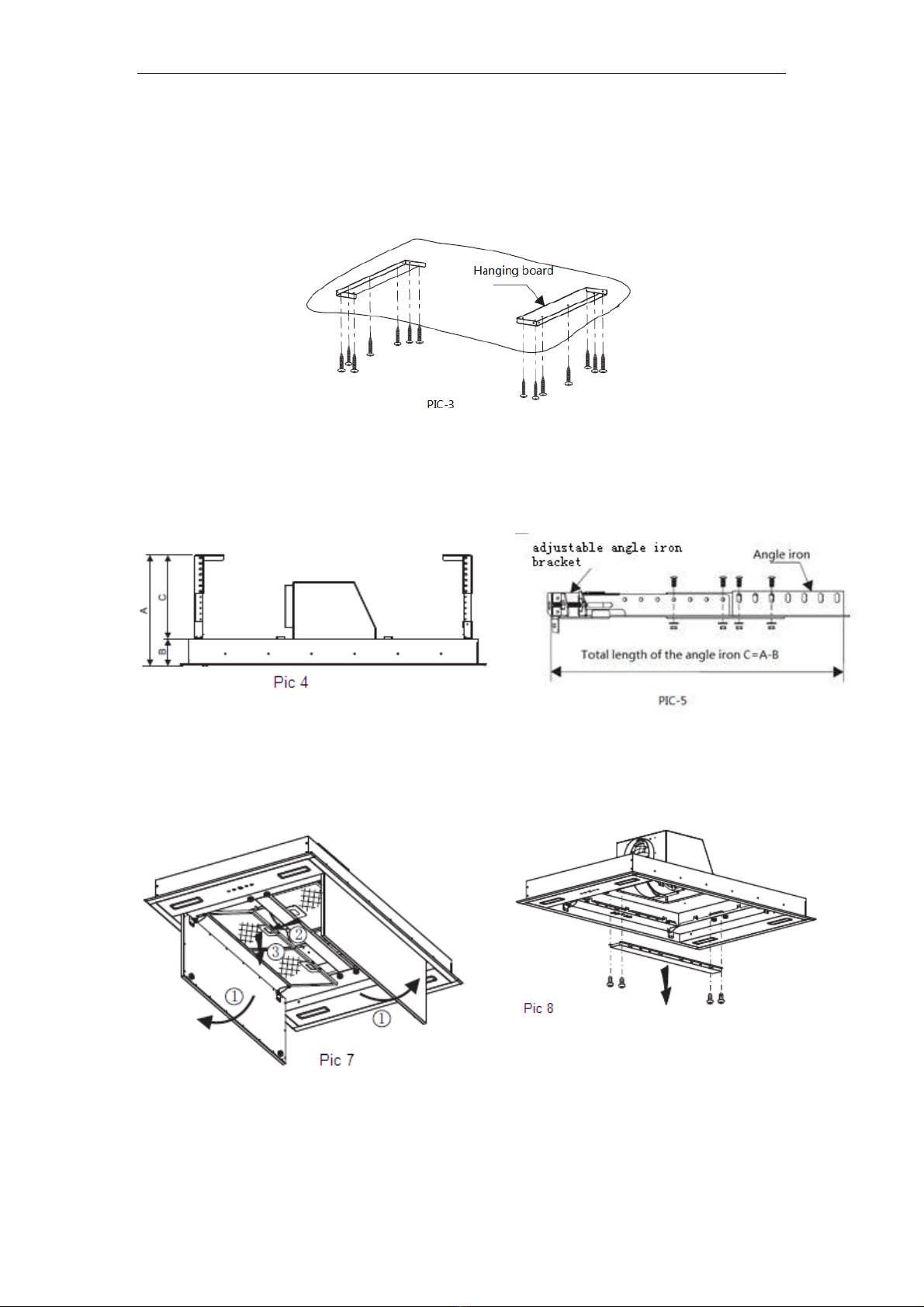

d. Install the panel decorative strip and filter well apply to the reverse

order of a/b steps above. Meanwhile, install the expansion pipe to the

outlet (refer to pic 10).

7. As pic 11 shown, connect the 4 adjustable angle iron bracket with the

housing by 8pcs M4*12mm

machine silk screw, next refer to

pic 12/13, lift up the housing, use

8pcs M4*12mm machine silk screw

and M4 nut with gasket to fix the

housing onto the 2 hanging board,

meanwhile, pull the expansion pipe

outside. (Note: The expansion pipe

must be fixed on the housing

firmly.)

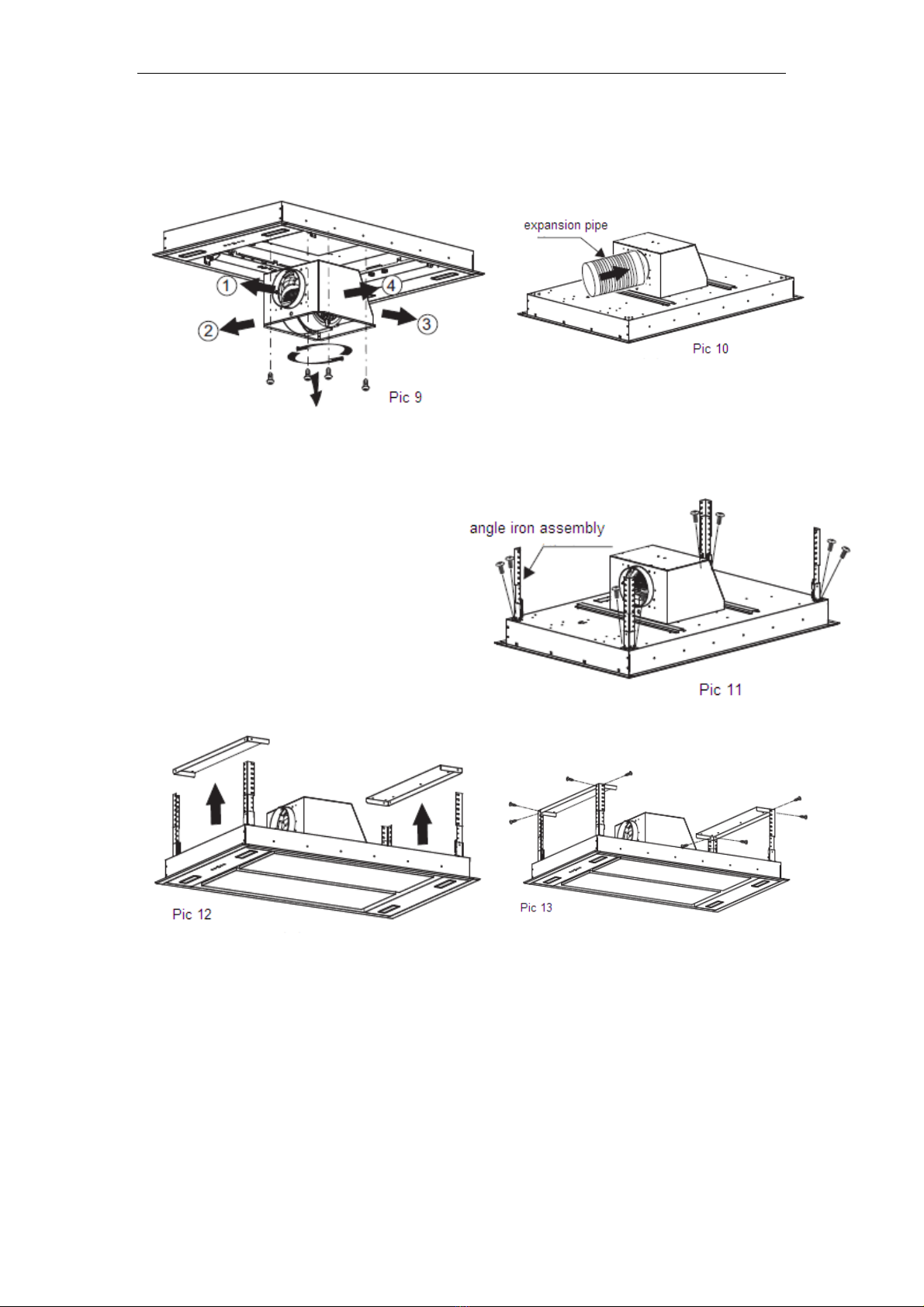

8. After installing the housing to the hanging board, use cross screwdriver

or straight screwdriver to adjust the screw of the angle iron bracket, direct

the housing level position and height till it is suitable. Adjust method:

Adjust rang of the angle iron bracket is 0-25mm, clockwise twist the

screw of the 4 angle iron bracket, slightly move the housing upwards;

meanwhile, anticlockwise twist the screw of the angle iron bracket,

slightly move the housing downwards. Use the cross screwdriver to screw

the safety screw tightly after the level position and height is suitable.

(Refer to pic 14)