P84469 L

Sheet 3 of 4

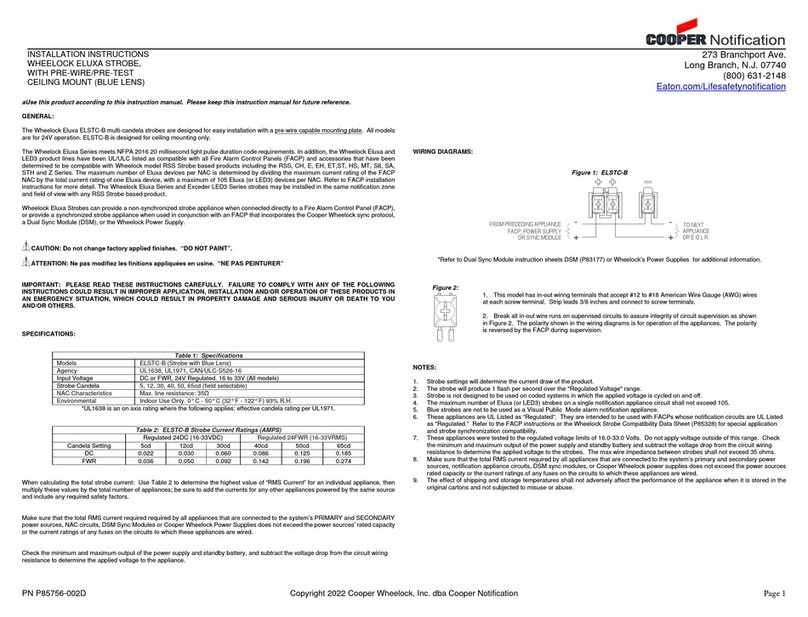

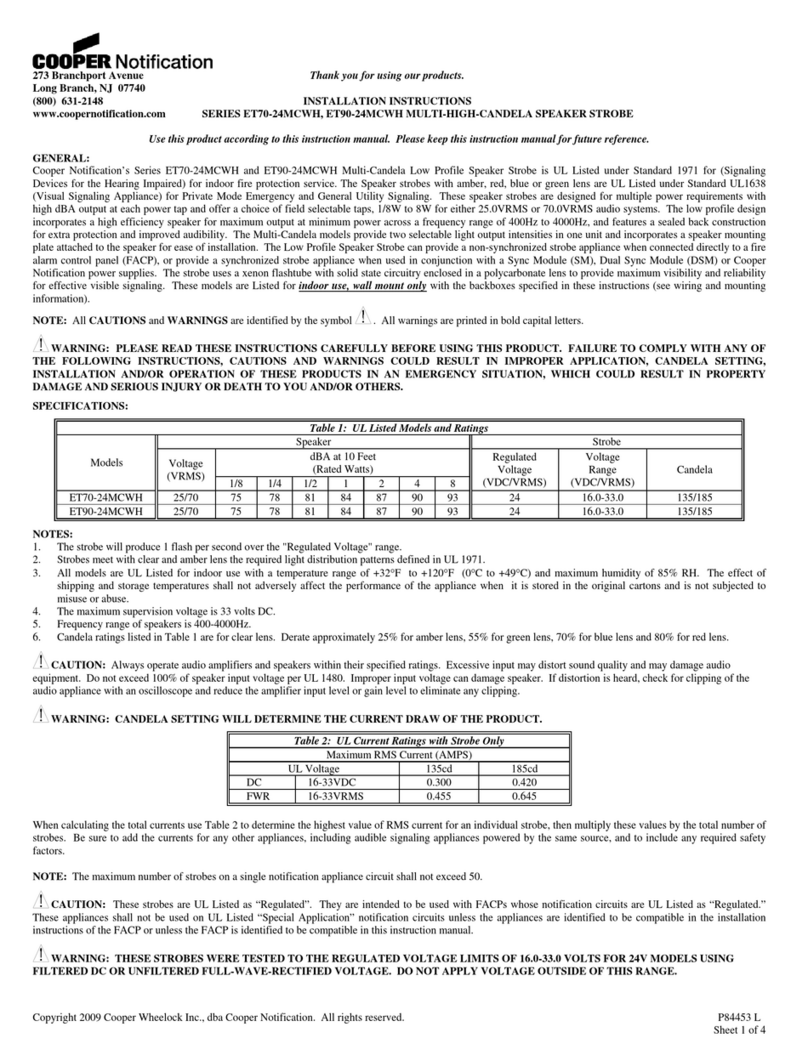

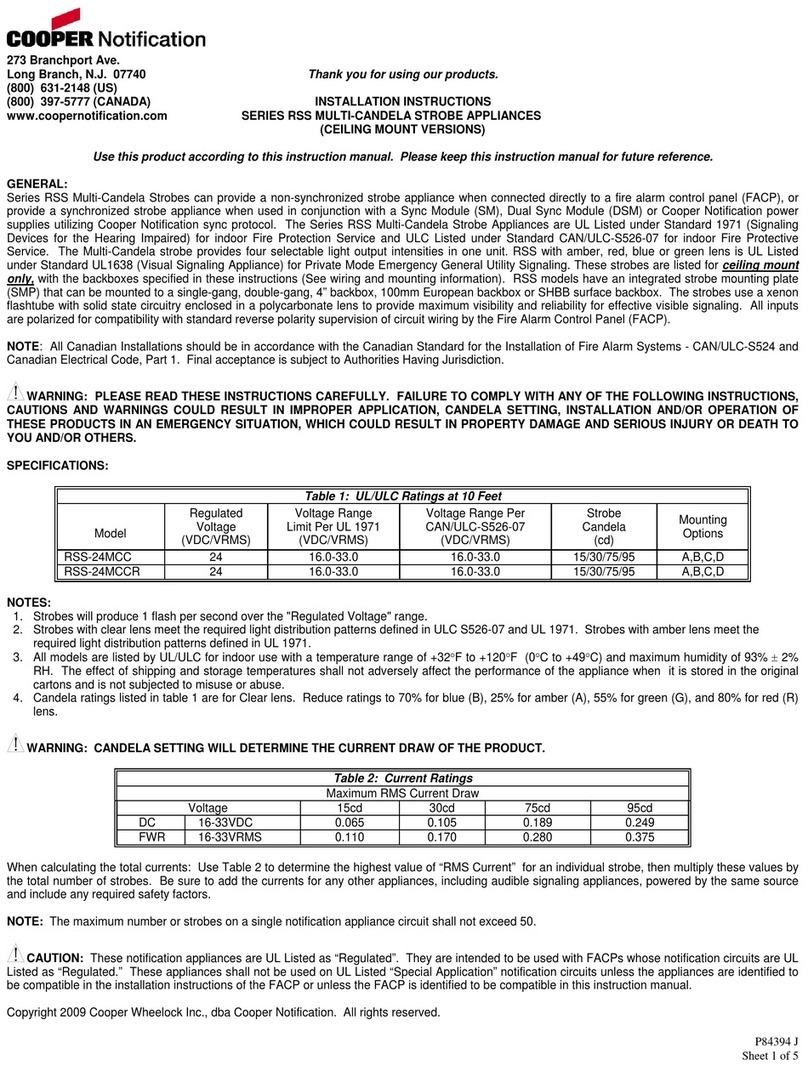

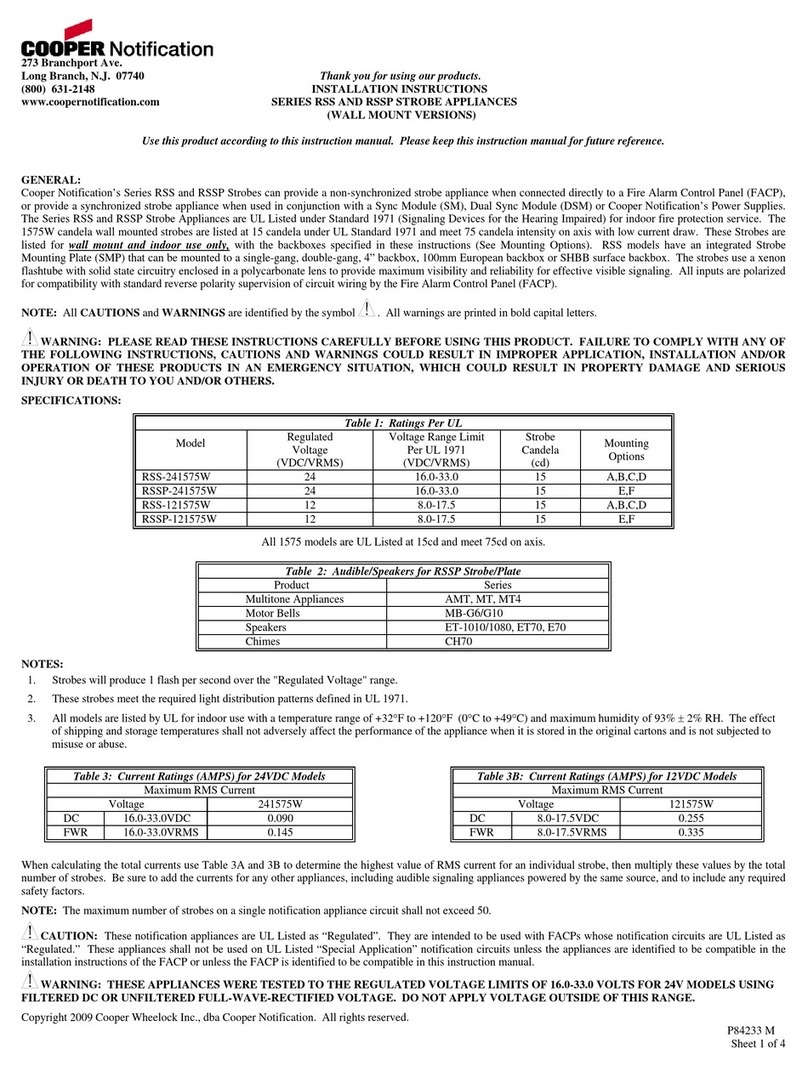

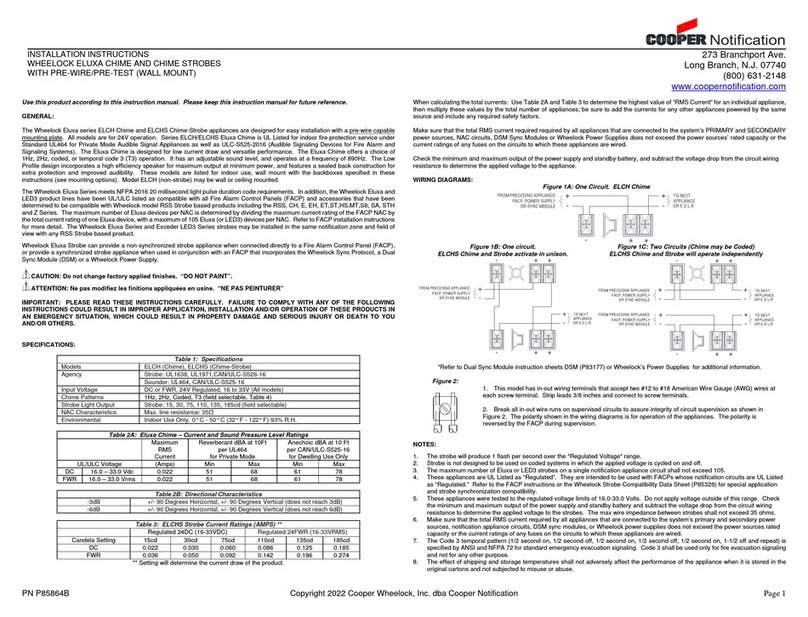

CAUTION: The following figures (A-D) show the maximum number of field wires (conductors) that can enter the backbox used with each mounting option. If these limits

are exceeded, there may be insufficient space in the backbox to accommodate the field wires and stresses from the wires could damage the product. Check that the installed

product will have sufficient clearance and wiring room prior to installing backboxes and conduit, especially if sheathed multiconductor cable or 3/4" conduit fittings are used.

Figure A

FLUSH (4" BOX)

#8-32 SCREWS

4" SQ. X 2-1/8"

DEEPBACKBOX

SCREWCOVERS

8 488

AWG#18 AWG#16 AWG#14 AWG#12

MAXIMUMNUMBEROF CONDUCTORS

Figure B

8 888

AWG #18 AWG#16 AWG#14 AWG#12

MAXIMUM NUMBER OF CONDUCTORS

#6-32 SCREWS

SCREWCOVERS

FLUSH (2-GANG BOX)

2-GANGx 3-1/2"

DEEPBACKBOX

Although the limits shown for each mounting option comply with the

National Electrical Code (NEC), Cooper Wheelock recommends use of

the largest backbox option shown and the use of approved stranded

field wires, whenever possible, to provide additional wiring room for easy

installation and minimum stress on the product from wiring.

MOUNTING PROCEDURES:

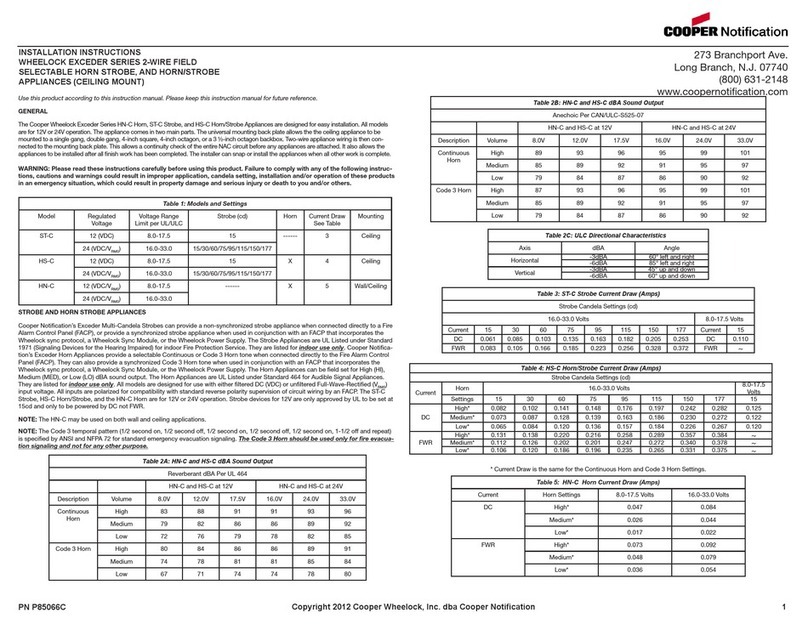

1. This HS4 model can be flush mounted to a 100mm backbox (Figure

A) or double-gang backbox (Figure B). It can also be surface

mounted to a indoor/outdoor backbox (Figures C & D). Mounting

hardware for each mounting option is supplied.

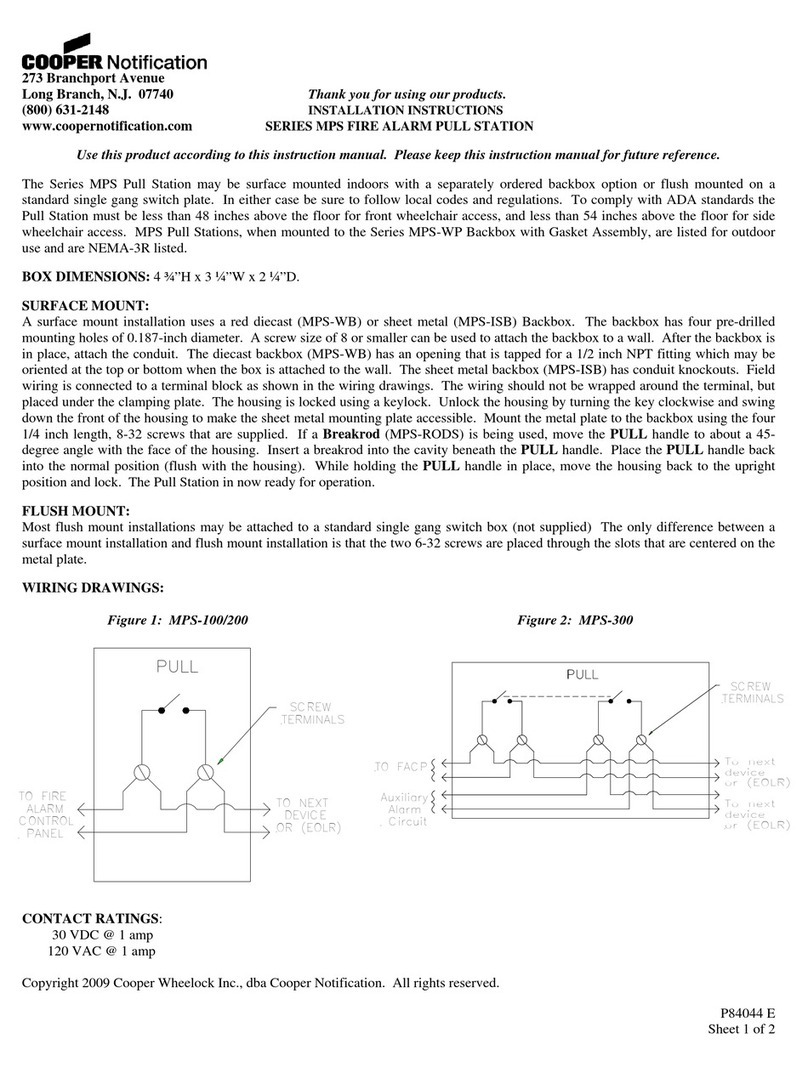

2. Conduit entrances to the backbox should be selected to provide

sufficient wiring clearance for the installed product. Do not pass

additional wires (used for other than the signaling appliance)

through the backbox. Such additional wires could result in

insufficient wiring space for the signaling appliance.

3. When terminating field wires, do not use more lead length than

required. Excess lead length could result in insufficient wiring space

for the appliance.

4. Use care and proper techniques to position the field wires in the

backbox so that they use minimum space and produce minimum

stress on the product. This is especially important for stiff, heavy

gauge wires and wires with thick insulation or sheathing.

5. Connect field wires to the HS4 terminal block (polarity must be

observed). Bend the field wires up 90°at the connection to the

terminal block.

6. Carefully push the field wires into the backbox by hand. Press the

HS4 to the backbox, verifying that it is seated and aligned correctly.

7. Fasten the HS4 to the backbox using the supplied screws.

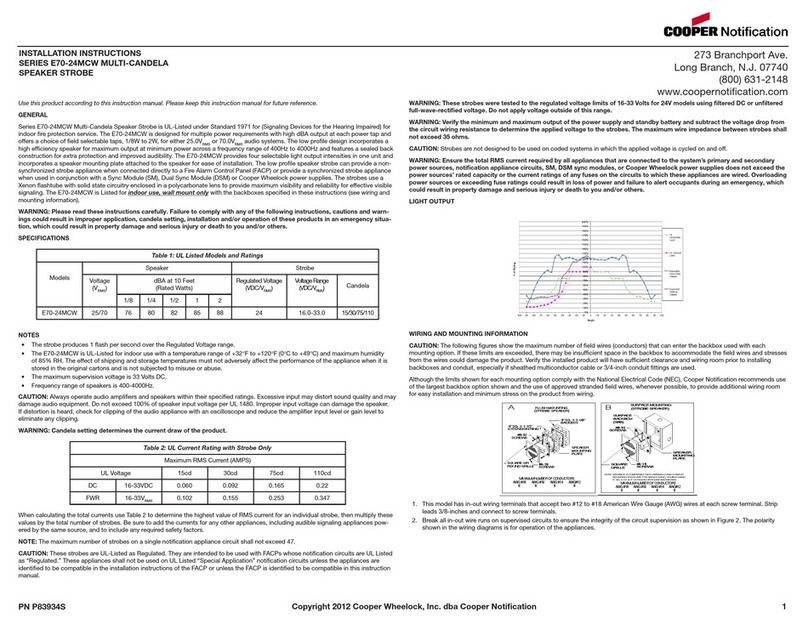

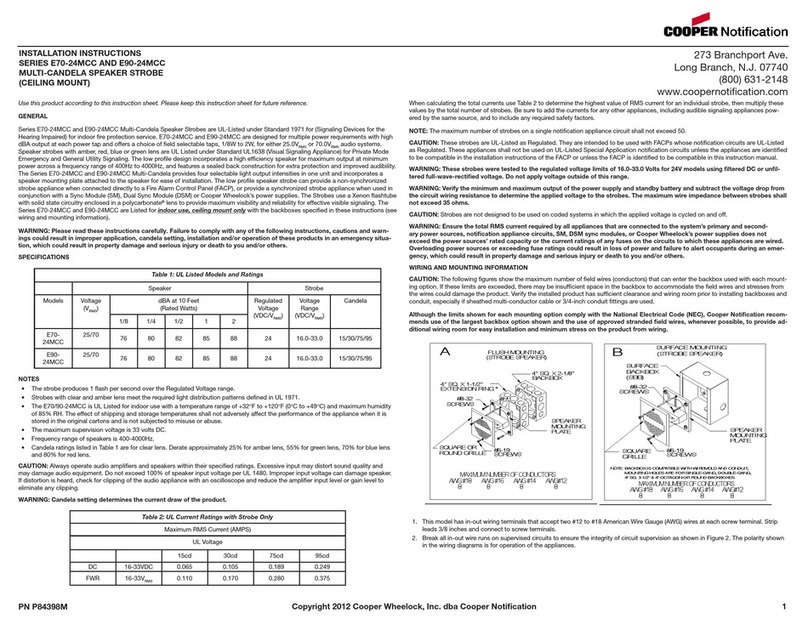

Figure C

8 888

AWG#18 AWG#16 AWG#14 AWG#12

MAXIMUMNUMBEROF CONDUCTORS

WOOD SCREWS

#8-18SCREWS

SCREWCOVERS

SURFACEMOUNTING

BACKBOX

(IOB)

Figure D

8 888

AWG#18 AWG#16 AWG#14 AWG#12

MAXIMUM NUMBER OF CONDUCTORS

#8-18 SCREWS

SCREWCOVERS

CONCEALED CONDUIT MOUNTING

BACKBOX

(IOB)

EXISTING

BOXIN WALL

WARNING: THE HS4 APPLIANCE IS A “FIRE ALARM DEVICE – DO NOT PAINT.”

WARNING: WHEN INSTALLING STROBES IN AN OPEN OFFICE OR OTHER AREAS CONTAINING PARTITIONS OR OTHER VIEWING OBSTRUCTIONS,

SPECIAL ATTENTION SHOULD BE GIVEN TO THE LOCATION OF THE STROBES SO THAT THEIR OPERATING EFFECT CAN BE SEEN BY ALL INTENDED

VIEWERS, WITH THE INTENSITY, NUMBER, AND TYPE OF STROBES BEING SUFFICIENT TO MAKE SURE THAT THE INTENDED VIEWER IS ALERTED BY

PROPER ILLUMINATION, REGARDLESS OF THE VIEWER'S ORIENTATION. FAILURE TO DO SO COULD RESULT IN PROPERTY DAMAGE AND SERIOUS INJURY

OR DEATH TO YOU AND/OR OTHERS.

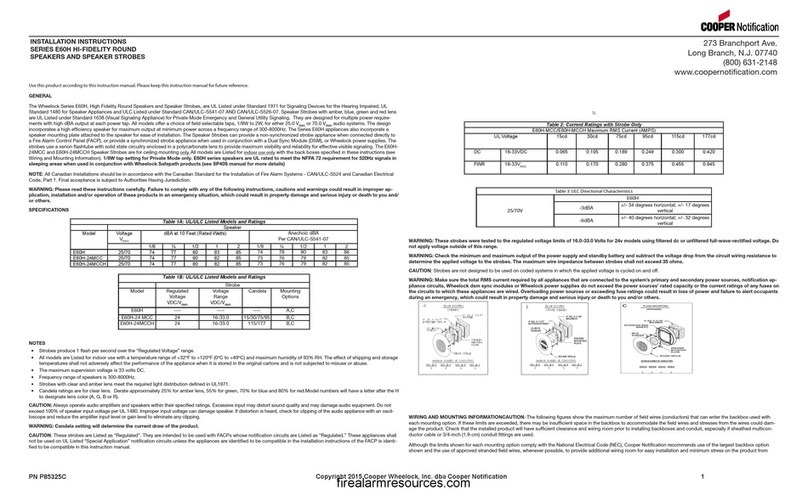

The 135, 177 and 185cd settings are Listed for use in sleeping or non-sleeping areas when installed in accordance with appropriate NFPA Standards and the Authority

Having Jurisdiction.

WARNING: IF 135/185 CANDELA STROBES ARE INSTALLED IN SLEEPING AREAS, THEY SHOULD BE WALL MOUNTED AT LEAST 24" BELOW THE CEILING

AS FOLLOWS: (1) THE ON-AXIS (CENTER OF LENS) LIGHT OUTPUT SHOULD BE DIRECTED AT THE EYELIDS OF THE SLEEPING PERSON, E.G. PILLOW END

OF BED, BED HEAD; (2) NO PART OF THE BED SHALL BE MORE THAN SIXTEEN FEET FROM THE STROBE NOTIFICATION APPLIANCE. INSTALLERS MUST

ADVISE OWNERS AND OPERATORS OF BUILDINGS WITH SLEEPING OCCUPANTS, E.G. HOTELS AND MOTELS, TO WARN GUESTS, RESIDENTS AND

EMPLOYEES TO NOT MOVE THE BED LOCATION TO A POSITION VIOLATING POINTS (1) AND (2) ABOVE OR SERIOUS INJURY AND/OR LOSS OF LIFE MAY

OCCUR DURING A FIRE EMERGENCY.

WARNING: A SMALL POSSIBILITY EXISTS THAT THE USE OF MULTIPLE STROBES WITHIN A PERSON'S FIELD OF VIEW, UNDER CERTAIN

CIRCUMSTANCES, MIGHT INDUCE A PHOTO-SENSITIVE RESPONSE IN PERSONS WITH EPILEPSY. STROBE REFLECTIONS IN A GLASS OR MIRRORED

SURFACE MIGHT ALSO INDUCE SUCH A RESPONSE. TO MINIMIZE THIS POSSIBLE HAZARD, COOPER WHEELOCK STRONGLY RECOMMENDS THAT THE

STROBES INSTALLED SHOULD NOT PRESENT A COMPOSITE FLASH RATE IN THE FIELD OF VIEW WHICH EXCEEDS FIVE Hz AT THE OPERATING VOLTAGE

OF THE STROBES. COOPER WHEELOCK ALSO STRONGLY RECOMMENDS THAT THE INTENSITY AND COMPOSITE FLASH RATE OF INSTALLED STROBES

COMPLY WITH LEVELS ESTABLISHED BY APPLICABLE LAWS, STANDARDS, REGULATIONS, CODES AND GUIDELINES.

NOTE: NFPA 72/ANSI 117.1 conform to ADAAG Equivalent Facilitation Guidelines in using fewer, higher intensity strobes within the same protected area.

CAUTION: Check the installation instructions of the manufacturers of other equipment used in the system for any guidelines or restrictions on wiring and/or locating

Notification Appliance Circuits (NAC) and notification appliances. Some system communication circuits and/or audio circuits, for example, may require special precautions to

assure electrical noise immunity (e.g. audio crosstalk).

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital appliance, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures: 1) Reorient or relocate the receiving antenna, 2) Increase the

separation between the equipment and receiver, 3) Connect the equipment into an outlet on a circuit different from that to which the receiver is connected, and 4) Consult

the dealer or an experienced radio/TV technician for help.